Navigating the world of aluminum alloys for CNC machining can be challenging. Are you grappling with which aluminum – 6061 Aluminum or 7075 Aluminum – best suits your project’s needs for strength, machinability, or specific applications? This guide clarifies these distinctions, helping you make an informed decision for your manufacturing in Shenzhen, China.

Understanding Aluminum Alloys for Precision Manufacturing

Choosing the correct aluminum alloy is crucial for the success of any CNC milling or machining project. This decision directly impacts part performance, production cost, and manufacturing efficiency. As a Shenzhen, China manufacturer specializing in precision components, we understand the nuances of these materials.

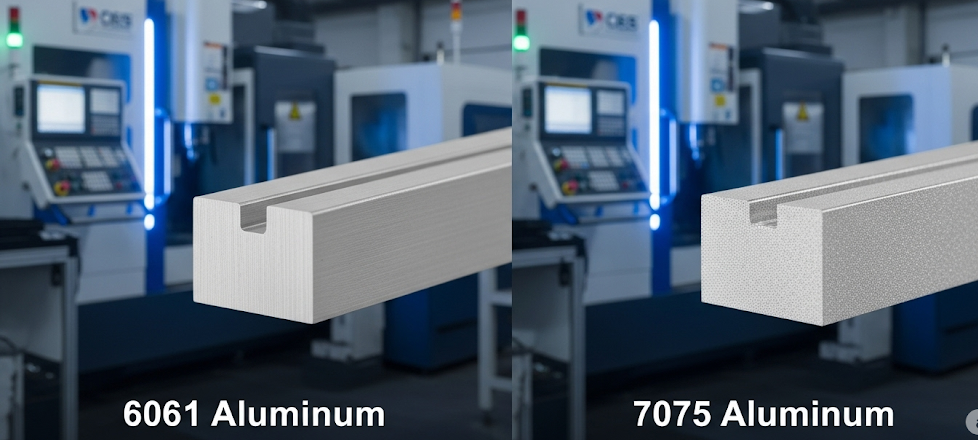

Key Differences: 6061 vs. 7075 Aluminum

Both 6061 Aluminum and 7075 Aluminum are widely used in CNC machining due to their excellent properties. However, they possess distinct characteristics that make them suitable for different applications.

6061 Aluminum: Versatility and Weldability

6061 Aluminum is known for its good strength-to-weight ratio, excellent corrosion resistance, and superior weldability. It’s a highly versatile alloy, making it a common choice for structural components. Its silicon and magnesium content contributes to its desirable properties. Many Shenzhen CNC machining facilities frequently utilize 6061 for a broad range of products.

7075 Aluminum: High Strength for Demanding Applications

Conversely, 7075 Aluminum stands out for its exceptionally high strength, comparable to many steels. This is primarily due to its zinc content, making it a preferred choice for aerospace and other high-stress applications. While stronger, its machinability differs from 6061, and it is less amenable to welding. Local Shenzhen, China factories often turn to 7075 for critical, high-performance parts.

Strength and Hardness Comparison

The primary differentiator between these two alloys often comes down to their mechanical properties, especially strength and hardness.

Tensile Strength and Yield Strength

7075 Aluminum typically offers significantly higher tensile and yield strength than 6061 Aluminum. For instance, 7075-T6 can have a tensile strength of around 572 MPa, whereas 6061-T6 usually ranges around 310 MPa. This superior strength of 7075 makes it ideal for components under high stress or fatigue.

Hardness

7075 Aluminum is also considerably harder than 6061 Aluminum. This increased hardness contributes to its excellent wear resistance, a crucial factor for parts subjected to abrasive conditions. When considering durability for CNC machined parts, 7075 often has the edge.

Machinability Considerations for CNC Projects

Machinability is a vital factor for CNC milling operations, influencing tool life, surface finish, and overall production efficiency.

Machining 6061 Aluminum

6061 Aluminum generally offers good machinability. It produces continuous chips during machining, which can sometimes lead to chip packing if not managed properly. Its softer nature allows for faster material removal rates and extends tool life. Many Shenzhen CNC machining shops find 6061 to be very forgiving during production.

Machining 7075 Aluminum

7075 Aluminum, being harder and stronger, is more challenging to machine. It tends to produce shorter, more brittle chips. While machinable, it often requires lower cutting speeds and feeds, and specific tooling to achieve a good surface finish and maintain tool integrity. Precision CNC machining in Shenzhen using 7075 demands experienced operators and optimized processes.

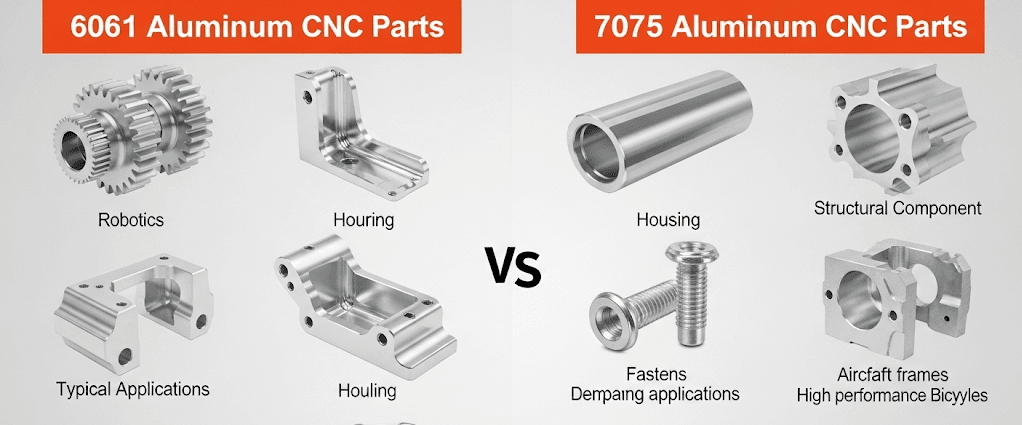

Application Scenarios and Industry Use

The distinct properties of 6061 Aluminum and 7075 Aluminum lead to their use in diverse applications across various industries.

Applications for 6061 Aluminum

Due to its excellent weldability, corrosion resistance, and moderate strength, 6061 Aluminum is commonly found in:

- Structural components (e.g., bicycle frames, railings)

- Automotive parts (e.g., truck frames, wheels)

- Marine applications (e.g., boat hulls, fishing boats)

- Piping and fittings

- General fabrication components

Many local Shenzhen manufacturers leverage 6061 for its versatility in mass production.

Applications for 7075 Aluminum

The high strength of 7075 Aluminum makes it indispensable for demanding applications, including:

- Aerospace components (e.g., aircraft structures, high-stress parts)

- Sporting goods (e.g., rock climbing equipment, bicycle components)

- Military applications

- Molds and tooling requiring high wear resistance

- High-performance automotive parts

For high-stress CNC machined parts manufactured in Shenzhen, China, 7075 is often the material of choice.

Cost and Availability in Shenzhen

The cost and availability of these alloys can also influence material selection for CNC machining projects.

Cost of 6061 Aluminum

6061 Aluminum is generally more affordable and widely available than 7075. Its widespread use contributes to lower production costs for many Shenzhen, China factories.

Cost of 7075 Aluminum

7075 Aluminum is typically more expensive due to its higher alloy content and specialized processing. While the upfront material cost is higher, its superior performance can justify the investment for critical applications. Shenzhen manufacturers often stock both but price 7075 parts accordingly.

Surface Treatment and Finishing Options

Both alloys can undergo various surface treatments, enhancing their properties and appearance.

Anodizing

Both 6061 Aluminum and 7075 Aluminum can be anodized, which improves corrosion resistance and allows for various color finishes. However, the exact color and finish might vary slightly between the two alloys due to their differing compositions.

Other Finishes

Powder coating, painting, and polishing are also viable finishing options for parts machined from either alloy. The choice of finish often depends on the application’s aesthetic and functional requirements. A Shenzhen, China manufacturer can offer a wide range of finishing services.

Choosing the Right Alloy: A Decision Matrix

To simplify your decision, consider the following factors when selecting between 6061 Aluminum and 7075 Aluminum for your CNC machining project:

| Feature | 6061 Aluminum | 7075 Aluminum |

| Strength | Moderate to High | Very High |

| Hardness | Moderate | High |

| Machinability | Excellent, easier to machine | Good, but requires more precise handling |

| Weldability | Excellent | Poor |

| Corrosion Resistance | Good | Good |

| Cost | Lower | Higher |

| Applications | Structural, automotive, general fabrication | Aerospace, high-stress, military, tooling |

| GEO Relevance (Shenzhen, China) | Widely used by Shenzhen CNC machining shops for general components and structures. | Preferred by Shenzhen, China factories for high-performance and critical components requiring maximum strength. |

Frequently Asked Questions

When considering 6061 Aluminum vs. 7075 Aluminum for your CNC machining needs, several common questions arise.

Q1: Is 7075 Aluminum always better than 6061 Aluminum?

A1: Not necessarily. While 7075 Aluminum is stronger, 6061 Aluminum excels in weldability, corrosion resistance, and cost-effectiveness for many general-purpose applications. The “better” alloy depends entirely on the specific requirements of your project, including strength needs, budget, and post-machining processes like welding.

Q2: Can I weld 7075 Aluminum?

A2: 7075 Aluminum is generally considered difficult to weld due to its high zinc content, which can lead to cracking. While some specialized techniques exist, it’s not recommended for welded structures. If your CNC machined part requires welding, 6061 Aluminum is a much more suitable and reliable choice.

Q3: Which aluminum alloy is more suitable for high-wear applications?

A3: For high-wear applications, 7075 Aluminum is typically more suitable due to its superior hardness and strength. These properties contribute to better resistance against abrasion and deformation under stress, making it ideal for components that experience significant friction or impact in a manufacturing environment in Shenzhen, China.