Selecting the right copper alloy for your CNC machined parts is a critical decision. You need a material that meets specific performance criteria for strength, conductivity, and elasticity.

Choosing incorrectly between C17200 Beryllium Copper and C36000 Brass can lead to component failure, electrical issues, or unnecessary costs. The wrong material choice compromises the integrity and performance of your entire project, causing delays and redesigns.

Ly-machining provides expert CNC machining for both advanced alloys. We help you navigate the distinct properties of C17200 Beryllium Copper and C36000 Brass, ensuring your parts deliver the precise performance required while balancing cost and application demands.

Choosing Your Metal for CNC Machining

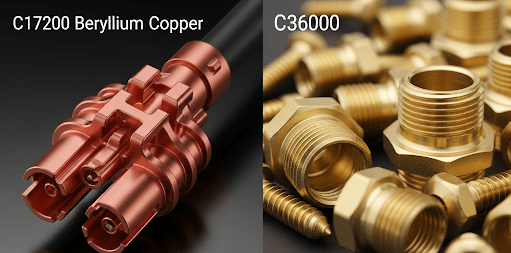

When your project demands high-performance metal components, the choice between C17200 Beryllium Copper and C36000 Brass is a common technical crossroad. C17200 Beryllium Copper provides elite strength and spring-like elasticity, making it essential for demanding electronic and mechanical applications. Conversely, C36000 Brass is renowned for its outstanding machinability and cost-effectiveness, positioning it as a go-to for general hardware and fittings. Understanding their unique profiles is the first step in successful CNC machining.

Therefore, making an informed decision requires a clear comparison of their core attributes—elasticity, strength, and conductivity. Furthermore, these material properties directly influence the CNC milling process, affecting everything from tooling selection to cycle times. Consequently, this guide offers a detailed breakdown to help you select the optimal material for your CNC machining needs, ensuring your components function flawlessly.

Strength & Elasticity: C17200 Beryllium Copper CNC Machining

C17200 Beryllium Copper stands out for its remarkable combination of high strength and elasticity, rivaling many high-strength steel alloys. This makes it an exceptional candidate for parts that must bend and return to their original shape without deformation.

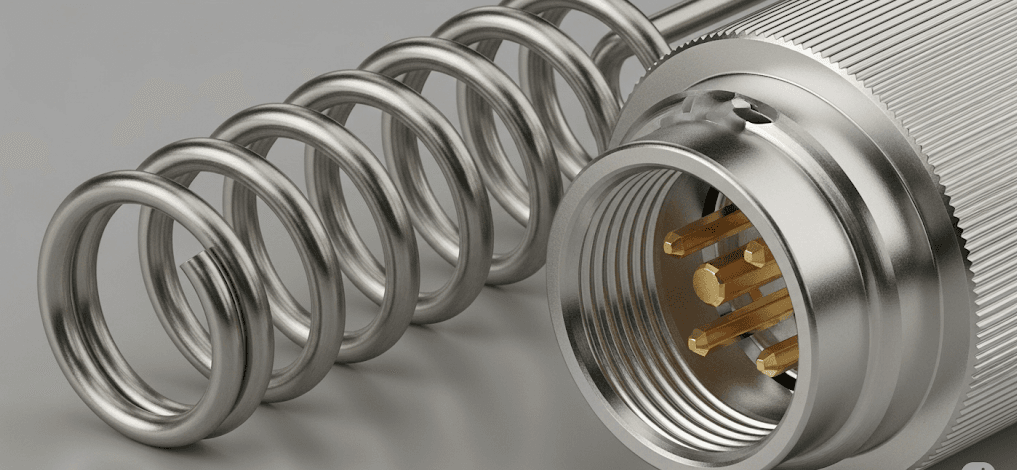

The true potential of this alloy is unlocked through heat treatment after CNC machining. In its solution-annealed state, it is relatively soft and easy to form. After CNC milling, a precipitation hardening process can dramatically increase its hardness and tensile strength, creating powerful, durable parts. This unique quality makes C17200 Beryllium Copper ideal for high-performance springs, connectors, and diaphragm seals.

At ly-machining, our CNC machining process for C17200 Beryllium Copper is carefully controlled to handle the material in both its soft and hardened states, ensuring dimensional accuracy and preserving its superior mechanical properties.

Unmatched Machinability: C36000 Brass CNC Milling

C36000 Brass, often called “Free-Machining Brass,” is the industry benchmark for machinability. Its composition, which includes a small amount of lead, allows it to produce small, broken chips during CNC milling. This characteristic significantly reduces tool wear and allows for very high cutting speeds.

This superb machinability translates directly into lower production costs and faster lead times. For projects requiring high volumes of complex parts, the efficiency of CNC machining C36000 Brass makes it a highly economical choice. It offers good strength and corrosion resistance for many standard applications.

Our facility is fully optimized for C36000 Brass CNC milling. We leverage its properties to produce intricate parts like fasteners, pipe fittings, valve components, and decorative hardware with exceptional speed and precision. Ly-machining delivers consistent quality for all your brass component needs.

Conductivity & Thermal Performance: A Head-to-Head Comparison

Electrical and thermal conductivity are critical factors in many applications, and here the differences between the two alloys are significant. The chosen material must effectively manage heat and electricity for the component to function correctly.

C17200 Beryllium Copper provides good electrical and thermal conductivity, especially when compared to steels. This allows it to be used for electrical connectors and battery contacts that also require high spring force. Its ability to dissipate heat is also valuable in electronic components and injection mold tooling.

C36000 Brass, however, has a slightly higher conductivity rating. While it lacks the strength of beryllium copper, its ability to conduct electricity makes it a solid choice for standard electrical terminals and pins where high strength is not a primary requirement. Our CNC machining processes ensure contact surfaces are clean and optimized for performance.

| Property | C17200 Beryllium Copper (Hardened) | C36000 Brass (Half Hard) | CNC Machining Implication |

| Yield Strength | High (Up to 1205 MPa) | Low (310 MPa) | C17200 is for high-stress applications. |

| Elasticity | Excellent (Spring-like) | Moderate | C17200 is for parts needing flex memory. |

| Electrical Conductivity | ~22-25% IACS | ~26% IACS | C36000 is slightly more conductive. |

| Thermal Conductivity | Good | Good | Both are effective at heat dissipation. |

| Machinability | Fair | Excellent (100 Rating) | C36000 CNC milling is faster and cheaper. |

Application-Specific CNC Machining

Choosing the right alloy ultimately depends on the specific demands of your application. The CNC machining process can be tailored to either material, but the end-use environment dictates the best choice.

We recommend C17200 Beryllium Copper for mission-critical applications where performance cannot be compromised. This includes aerospace components, downhole drilling tools, non-sparking safety tools, and high-cycle electrical connectors. The investment in a premium material is justified by its strength, durability, and reliability. The CNC milling of C17200 Beryllium Copper requires specialized expertise.

For general-purpose applications where cost is a major driver, C36000 Brass is often the ideal solution. Its excellent machinability makes it perfect for producing plumbing hardware, automotive fittings, gears, and decorative items at scale. Ly-machining provides cost-effective CNC machining for these high-volume projects without sacrificing quality.

Quality and Safety in CNC Milling Operations

Handling these alloys requires different approaches to ensure both quality and safety. The CNC milling of C36000 Brass is straightforward, but our quality control still involves rigorous checks for dimensional accuracy and surface finish.

The CNC machining of C17200 Beryllium Copper demands additional protocols. The dust from beryllium-containing alloys can be hazardous if inhaled. At ly-machining, we employ advanced containment systems and air filtration, along with wet machining techniques, to completely mitigate any risk. Our operators are fully trained in safe handling procedures.

This commitment to safety and quality ensures that we can deliver the superior properties of C17200 Beryllium Copper without compromise. You can trust ly-machining to handle your project with the highest standards of professionalism and care, regardless of the material complexity.

Related Questions

Is C17200 Beryllium Copper safe for CNC machining?

Yes, C17200 Beryllium Copper is safe for CNC machining when handled with the proper engineering controls and safety procedures. The primary concern is the inhalation of fine dust generated during processes like grinding or aggressive dry milling. Ly-machining mitigates this risk by using flood coolants during the CNC milling process, which contains particles, and employs robust ventilation and dust collection systems. We adhere to all safety guidelines to protect our team and ensure your parts are produced responsibly.

Why is C36000 Brass considered a ‘free-machining’ alloy?

C36000 Brass earns its “free-machining” title because of its chemical composition. It contains a small percentage of lead (typically 2.5-3.7%), which does not fully dissolve in the alloy’s microstructure. During CNC machining, the soft lead particles act as a lubricant and help the metal chips break into small, manageable pieces. This dramatically reduces friction on the cutting tool, leading to longer tool life, faster possible cutting speeds, and a superior surface finish with minimal effort.

Frequently Asked Questions

1. Which material is better for parts that experience high wear and friction?

C17200 Beryllium Copper is significantly better for high-wear applications. After heat treatment, it becomes extremely hard and durable, providing excellent resistance to wear and abrasion. While C36000 Brass is suitable for many standard bearing applications, C17200 excels in more demanding environments where strength and hardness are critical for longevity.

2. Can C17200 Beryllium Copper be altered after CNC machining?

Absolutely. One of the key advantages of C17200 Beryllium Copper is its ability to be heat-treated after the CNC milling process is complete. We typically machine the parts in a softer, annealed state and then apply an age-hardening treatment. This process optimizes its strength and spring-like properties, a flexibility not available with C36000 Brass.

3. What factors drive the cost difference in the CNC machining of these metals?

Two main factors drive the cost difference. First, the raw material cost of C17200 Beryllium Copper is substantially higher than that of C36000 Brass. Second, C17200 is tougher and more abrasive on cutting tools, meaning the CNC machining process must be slower and requires more robust tooling, increasing the overall cycle time and manufacturing cost per part.