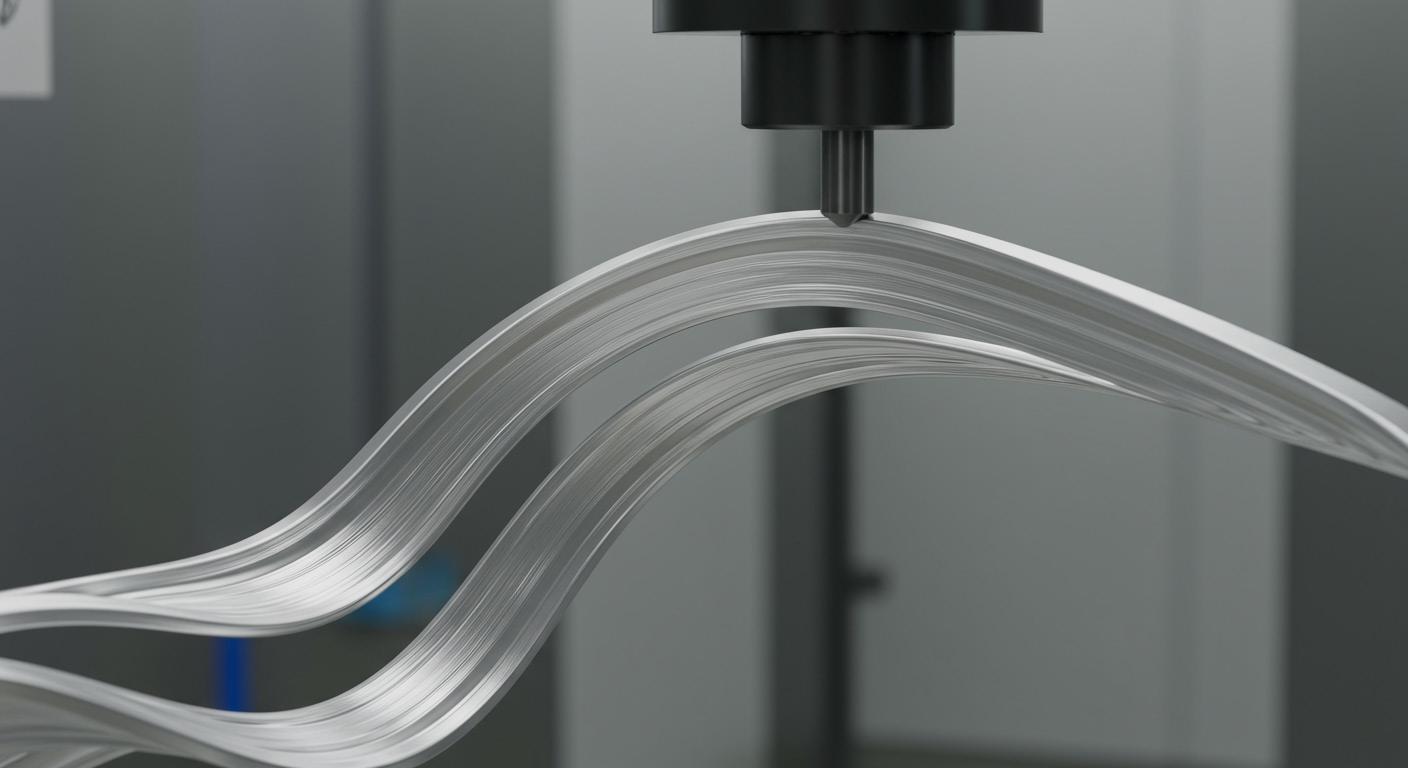

When CNC machining thin-walled aluminum parts, controlling deformation is paramount for quality and precision. Our expertise at ly-machining in Shenzhen focuses on strategic material selection, advanced fixturing techniques, and optimized cutting parameters to mitigate warpage. We employ multi-stage machining, meticulous toolpath planning, and effective post-machining stress relief. Key strategies include using sharp, high-helix tools, maintaining consistent cutting forces, and implementing precise cooling. These integrated approaches ensure the dimensional accuracy and surface integrity of even the most delicate thin-walled aluminum components.

Introduction

- Understanding Challenges in CNC Machining Thin-Walled Aluminum Parts

- Advanced Strategies for CNC Machining Thin-Walled Aluminum Parts

- Optimal Fixturing Techniques for Preventing Thin-Walled Part Distortion

- Mastering Cutting Parameters for Minimal Deformation in Thin-Walled Parts

- Post-Machining Deformation Control and Quality Assurance for Thin-Walled Aluminum Parts

- Partnering for Success: ly-machining’s Expertise in Thin-Walled Aluminum CNC Machining in Shenzhen

- Frequently Asked Questions About Thin-Walled Aluminum CNC Machining

At ly-machining in Shenzhen, we understand the critical demands placed on manufacturers today. Delivering high-precision thin-walled aluminum parts that meet stringent quality and lead time requirements is a complex challenge, one that often brings with it the persistent issue of deformation. Our extensive experience has taught us that achieving excellence in thin-walled aluminum CNC machining requires more than just standard practices; it demands a deep understanding of material behavior, process optimization, and meticulous attention to detail at every stage.

This article delves into the core techniques and strategies we employ to tackle these challenges head-on. We aim to provide valuable insights for anyone seeking to master the art of CNC machining thin-walled aluminum parts, ensuring dimensional accuracy and superior surface finish while controlling the pervasive threat of deformation.

Understanding Challenges in CNC Machining Thin-Walled Aluminum Parts

Machining thin-walled aluminum components presents a unique set of obstacles that can significantly impact part quality and production efficiency. These challenges stem primarily from the inherent properties of aluminum combined with the delicate nature of thin-walled geometries. We have learned that a proactive approach, anticipating these issues, is key to successful outcomes in CNC machining thin-walled aluminum parts.

Material Properties and Their Impact on Thin-Walled Aluminum Parts

Aluminum alloys are favored for their excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. However, these very properties also contribute to the machining difficulties associated with thin-walled structures. We find that the low modulus of elasticity in aluminum makes it susceptible to deflection under cutting forces.

Additionally, aluminum’s high thermal expansion coefficient means that temperature fluctuations during CNC machining can induce significant internal stresses and lead to distortion. This is particularly pronounced in thin-walled aluminum parts, where the material simply lacks the bulk to absorb and dissipate heat without changing shape.

| Aluminum Alloy Type | Key Characteristics | Machinability | Deformation Tendency | Typical Applications for Thin-Walled Components |

|---|---|---|---|---|

| 6061-T6 | Good strength, weldability, heat treatable | Good | Moderate | Aerospace components, automotive parts, structural frames |

| 7075-T6 | Very high strength, good fatigue resistance | Fair to Good | Higher | Aircraft structures, high-stress parts |

| 2024-T3 | High strength, good fatigue resistance | Fair | Moderate | Aircraft fuselages, wings, structural components |

| 5052-H32 | Excellent corrosion resistance, formability | Good | Lower | Marine applications, fuel tanks, electronic enclosures |

The Root Causes of Deformation in CNC Machined Thin-Walled Aluminum

Deformation in CNC machined thin-walled aluminum parts is a multifaceted problem, often resulting from a combination of factors. Understanding these root causes allows us to implement targeted solutions.

One primary cause is the clamping force applied during fixturing, which can easily distort a thin part before any cutting even begins. We often observe that improper clamping pressure, or an insufficient number of clamping points, allows the part to flex.

Another significant factor is the residual stress inherent in the raw aluminum material, which can be released unevenly during material removal. Furthermore, the heat generated during the cutting process, combined with inadequate cooling, exacerbates thermal expansion and stress accumulation, leading to warpage.

We also attribute deformation to improper cutting parameters, such as excessive feed rates or depths of cut, which generate high cutting forces and vibrations. These forces can easily push and pull on the delicate thin walls, causing them to bend or buckle.

Advanced Strategies for CNC Machining Thin-Walled Aluminum Parts

To consistently produce high-quality thin-walled aluminum parts without deformation, we rely on a suite of advanced strategies. These techniques are refined through years of practical experience in CNC machining.

Optimal Fixturing Techniques for Preventing Thin-Walled Part Distortion

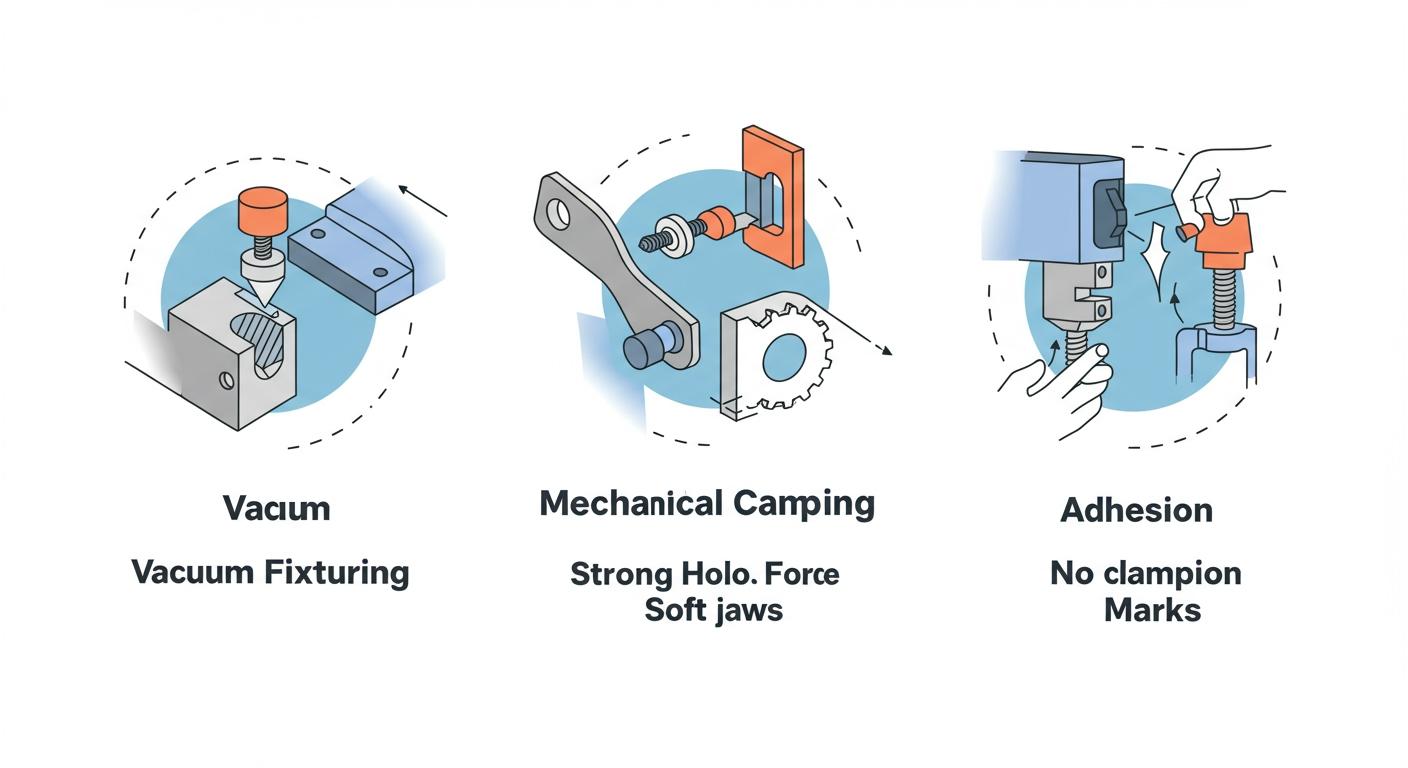

Proper fixturing is the first and arguably most critical step in preventing deformation. Our approach focuses on distributing clamping forces evenly and supporting the part adequately. We often design custom fixtures that conform precisely to the part’s geometry.

Vacuum fixtures are frequently employed for their ability to exert consistent, distributed pressure across the entire surface of the thin-walled part. This minimizes localized stress points that could otherwise lead to distortion.

For more complex geometries, we utilize mechanical fixtures with multiple, carefully positioned clamps and soft jaws. The goal is to provide rigid support against cutting forces without inducing initial stress or bending.

| Fixturing Method | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|

| Vacuum Fixturing | Even pressure distribution, minimal surface marks, quick setup for flat parts | Requires sealed surface, not ideal for complex 3D shapes, limited holding force for aggressive cuts | Flat thin panels, delicate surfaces |

| Mechanical Clamping | Strong holding force, versatile for various shapes, secure against heavy cutting | Potential for localized stress, surface marks, longer setup time, requires careful placement | Irregular shapes, higher cutting forces, robust parts |

| Adhesion Fixturing | No clamping marks, ideal for very delicate or aesthetic parts, uniform support | Slower setup and cleanup, adhesive strength can vary, temperature sensitive | Extremely thin parts, cosmetic surfaces, minimal cutting forces |

Precision Tool Selection and Path Optimization for Thin-Walled Aluminum Machining

The choice of cutting tools and the design of toolpaths are paramount in mitigating forces that cause deformation. We meticulously select tools specifically designed for thin-walled aluminum parts CNC machining.

High-helix end mills with polished flutes are our preferred choice, as they provide an upward shearing action that reduces cutting forces and improves chip evacuation. A higher number of flutes can also help distribute the cutting load more evenly.

We prioritize sharp tools with appropriate coatings (e.g., AlTiN, ZrN) to reduce friction and heat generation. Dull tools are a primary source of excessive heat and cutting forces, leading directly to deformation.

Toolpath optimization involves employing strategies like climb milling, which directs cutting forces into the fixture rather than away from it, reducing part deflection. We also favor trochoidal milling and constantly varied depths of cut to spread thermal and mechanical loads.

| Tool Characteristic | Impact on Thin-Walled Aluminum Machining | Best Practice |

|---|---|---|

| Helix Angle | Higher angles reduce cutting forces and improve chip lift | Use high-helix (35-45 degrees) for smooth cutting |

| Flute Count | More flutes distribute load, but can increase chip re-cutting if not managed | 2-3 flutes for optimal chip evacuation in aluminum |

| Coating | Reduces friction, wear, and built-up edge | AlTiN or ZrN for improved lubricity and heat resistance |

| Tool Material | High-speed steel vs. Carbide | Solid Carbide for rigidity and wear resistance |

Mastering Cutting Parameters for Minimal Deformation in Thin-Walled Parts

Achieving minimal deformation in thin-walled aluminum parts requires a finely tuned balance of cutting parameters. We systematically adjust spindle speed, feed rate, and depth of cut to manage cutting forces and heat.

We generally opt for higher spindle speeds and lighter depths of cut, coupled with moderate feed rates. This approach generates thinner chips, which carry away heat more efficiently and reduce the overall force exerted on the workpiece.

A consistent chip load is crucial; erratic changes can lead to inconsistent forces and localized heating. We also ensure an ample supply of coolant, not just for heat dissipation but also for lubrication and chip flushing.

Using an air blast alongside coolant can be beneficial to ensure chips are evacuated quickly, preventing re-cutting and heat buildup. This proactive management of heat and forces is fundamental to maintaining part integrity.

| Parameter | Impact on Deformation | Recommended Approach for Thin-Walled Aluminum |

|---|---|---|

| Spindle Speed | Higher speeds reduce cutting forces, but increase heat | High RPM (e.g., 10,000-20,000+ RPM) for effective chip evacuation and lower force |

| Feed Rate | Too high: excessive force; Too low: rubbing, heat buildup | Moderate feed rate to maintain a consistent chip load and avoid chatter |

| Depth of Cut | Deep cuts generate high forces, thin walls deflect | Small radial and axial depths of cut, often using multiple passes |

| Coolant | Dissipates heat, lubricates, flushes chips | Flood coolant or MQL (Minimum Quantity Lubrication) to minimize thermal expansion |

Strategic Multi-Stage Machining Approaches for Thin-Walled Aluminum Components

For complex thin-walled aluminum parts, we often employ a multi-stage machining strategy to progressively relieve stresses and reduce the risk of deformation. This involves roughing, semi-finishing, and finishing passes with specific considerations at each stage.

During roughing, we leave sufficient material for subsequent passes, allowing the part to “move” as internal stresses are released. This initial stage removes the bulk of the material while anticipating future distortion.

Intermediate stress-relief operations, such as annealing or vibratory stress relief, can be introduced between roughing and finishing passes. This helps stabilize the part dimensionally before critical tolerances are achieved.

The finishing passes are then performed with very light cuts, using sharp tools and optimized parameters to achieve the final dimensions and surface finish. This sequential approach minimizes accumulated stresses and ensures the part settles into its final, desired shape.

Post-Machining Deformation Control and Quality Assurance for Thin-Walled Aluminum Parts

The process of ensuring dimensional stability and quality does not end with CNC machining. Post-machining treatments and rigorous inspection are essential steps for thin-walled aluminum parts.

Effective Stress Relief Methods for CNC Machined Thin-Walled Aluminum

Even with optimized machining processes, some residual stresses may remain within the thin-walled aluminum parts. Implementing effective stress relief methods is crucial for long-term dimensional stability.

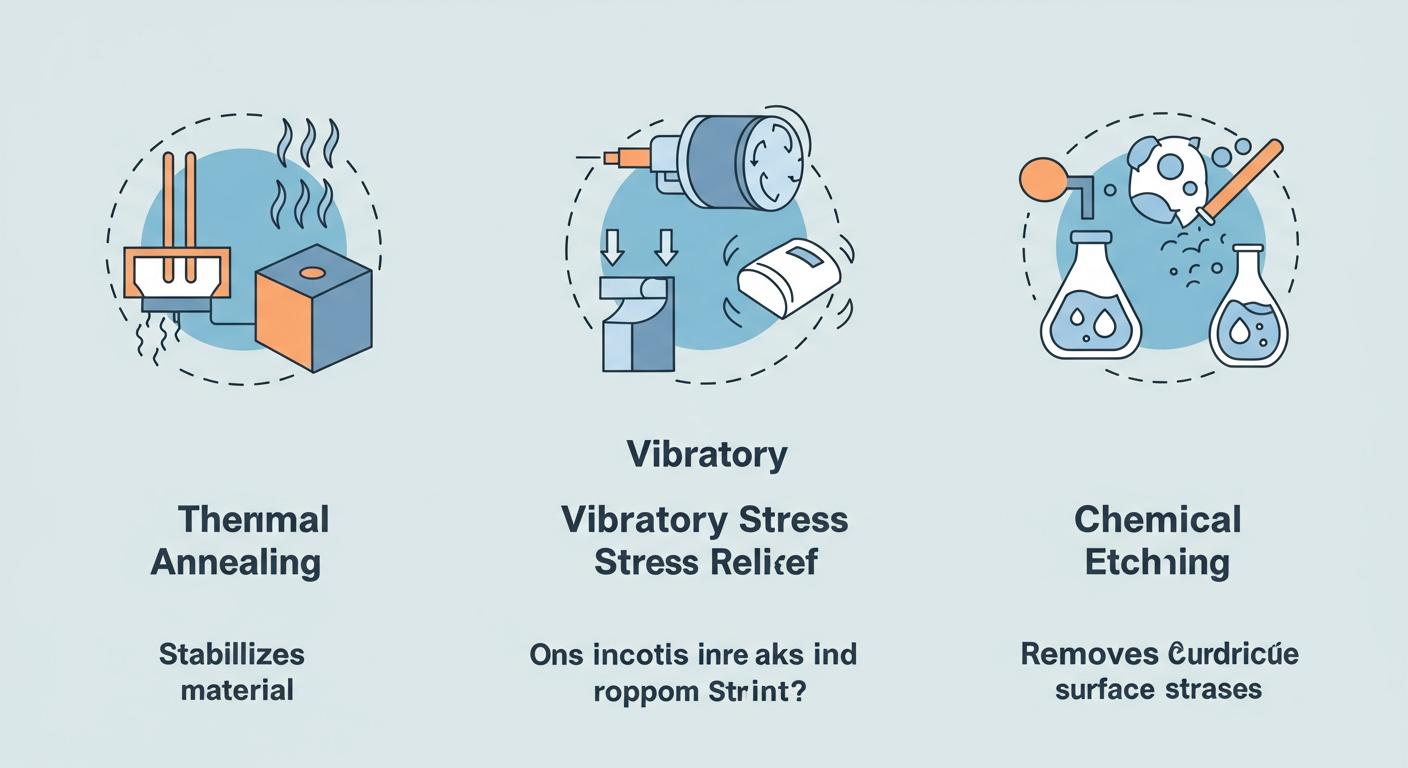

Thermal stress relief, typically through controlled annealing, can be effective. However, it must be performed carefully to avoid altering material properties or inducing new distortions in delicate parts.

Another method we utilize is vibratory stress relief, which applies controlled vibrations to the part, helping to homogenize internal stresses. This can be a gentler alternative for parts sensitive to heat.

Chemical etching can also remove a uniform layer of material, potentially reducing surface stresses and improving fatigue life. The choice of method depends on the specific aluminum alloy, part geometry, and required outcome.

| Stress Relief Method | Principle | Advantages | Disadvantages |

|---|---|---|---|

| Thermal Annealing | Heating to specific temperature and slow cooling | Effective for high stress, stabilizes material | Can alter material properties, potential for new distortion if not controlled |

| Vibratory Stress Relief | Low-frequency vibrations | Non-thermal, no material property change, suitable for large parts | Efficacy can vary, less effective for very high stresses |

| Chemical Etching | Uniform material removal via chemical reaction | Removes surface stresses, improves fatigue life, can reach complex geometries | Requires controlled environment, material loss, waste disposal |

Advanced Measurement and Inspection Protocols for Thin-Walled Aluminum Components

Maintaining the quality and precision of CNC machined thin-walled aluminum parts demands advanced inspection protocols. We employ various methods to ensure parts meet specifications.

Coordinate Measuring Machines (CMMs) are indispensable for precisely measuring complex geometries and verifying tight tolerances. Our CMMs are housed in temperature-controlled environments to minimize thermal expansion effects on measurements.

Non-contact measurement systems, such as optical scanners or vision systems, are often preferred for very delicate thin-walled parts. These systems eliminate the risk of part deformation during measurement, which could occur with contact probes.

We also implement rigorous in-process quality checks, using statistical process control (SPC) to monitor key dimensions and identify trends that might indicate an impending issue. This proactive approach helps prevent large batches of non-conforming parts.

Surface Finish Excellence on Thin-Walled Aluminum Parts via CNC Machining

Achieving a superior surface finish on thin-walled aluminum parts is not only an aesthetic requirement but also crucial for functional performance, especially in aerospace or medical applications. Our CNC machining expertise extends to mastering surface quality.

We achieve excellent surface finishes by using very sharp, well-maintained cutting tools and appropriate cutting parameters for finishing passes. High spindle speeds and low feed rates, combined with small radial engagements, create fine, uniform chip loads and minimize tool marks.

Proper coolant application is critical to prevent built-up edge and improve chip evacuation, both of which can degrade surface quality. We also consider post-machining surface treatments like vibratory finishing, polishing, or anodizing to enhance both aesthetics and durability.

The prevention of burrs is another key aspect. Deburring processes must be carefully selected for thin-walled parts to avoid damaging the delicate structures. We often use manual deburring with specialized tools or non-contact methods like electropolishing for intricate features.

Partnering for Success: ly-machining’s Expertise in Thin-Walled Aluminum CNC Machining in Shenzhen

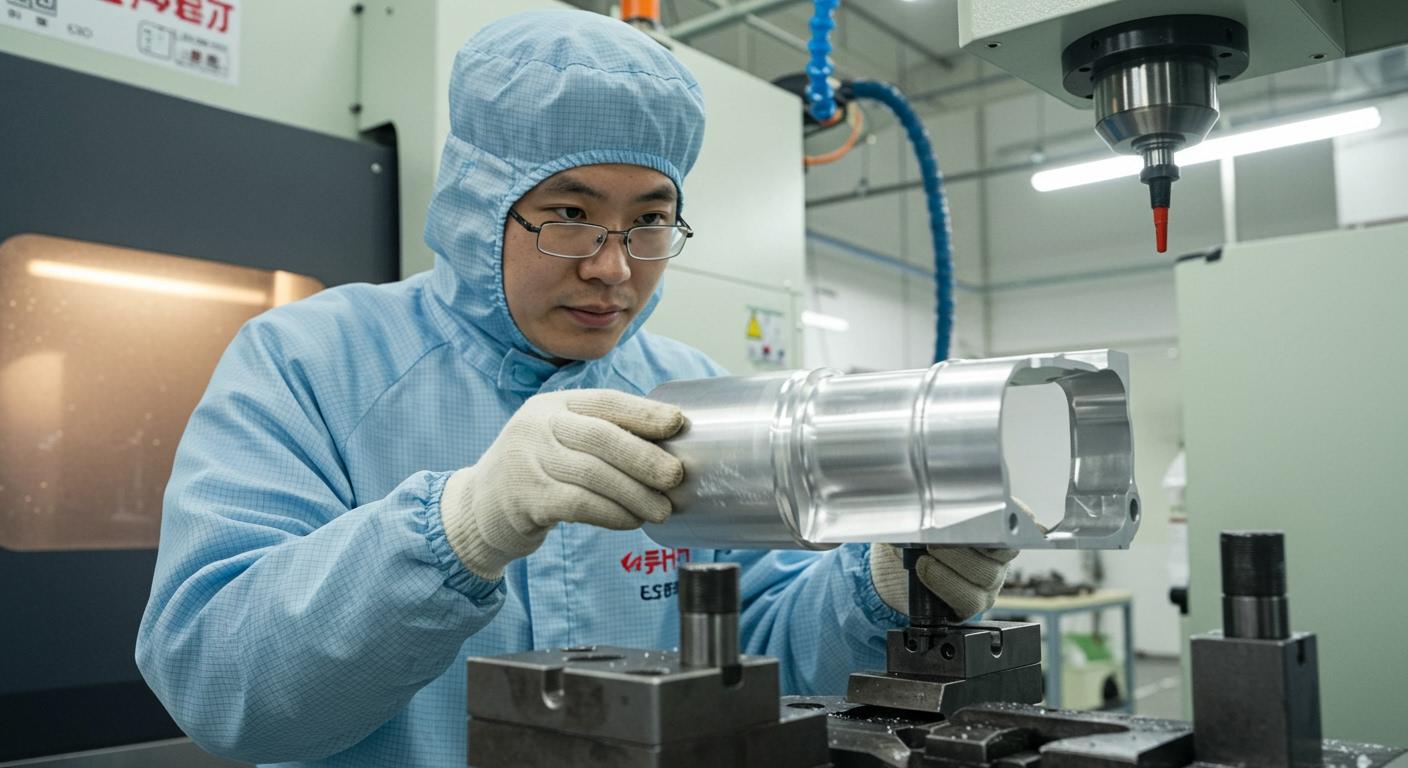

At ly-machining, based in Shenzhen, we pride ourselves on our deep expertise in handling the complexities of thin-walled aluminum parts CNC machining. We understand that our clients require not just parts, but reliable solutions to their manufacturing challenges. Our commitment extends beyond the machine shop floor.

We address common client pain points directly. For delivery times, our robust project management system and optimized production workflows ensure predictable and expedited lead times. We communicate transparently about schedules and proactively address any potential delays.

Quality control is at the core of our operations. From material inspection upon arrival to in-process checks and final dimensional validation using advanced CMM and optical scanning, we maintain stringent quality assurance protocols. Our comprehensive approach to deformation control ensures the integrity of every thin-walled aluminum part.

Regarding surface treatment, we offer a wide range of in-house and outsourced options, including anodizing (clear, colored, hard coat), powder coating, and various polishing techniques. We advise clients on the best finish for their specific application, considering both aesthetic and functional requirements.

Our after-sales support is designed to provide complete peace of mind. We stand by the quality of our work, offering responsive communication and effective solutions should any issues arise post-delivery. Our goal is to build long-term partnerships based on trust and consistent performance in CNC machining thin-walled aluminum parts.

Conclusion

The successful CNC machining of thin-walled aluminum parts demands a specialized, integrated approach that addresses the unique challenges of material properties and delicate geometries. From meticulous fixture design and precise tool selection to optimized cutting parameters and diligent post-machining care, every step is critical in preventing deformation and achieving high-quality results.

At ly-machining in Shenzhen, we leverage our extensive experience and advanced techniques to overcome these hurdles, consistently delivering dimensionally accurate and aesthetically superior thin-walled aluminum components. We are dedicated to providing comprehensive solutions that meet and exceed our clients’ expectations for quality, delivery, and service. Partner with us to bring your most challenging thin-walled aluminum CNC machining projects to fruition with confidence.

Frequently Asked Questions About Thin-Walled Aluminum CNC Machining

1. What are the most common causes of deformation when CNC machining thin-walled aluminum parts?

The most common causes of deformation include improper clamping (too much or uneven force), residual stresses within the raw material, excessive heat generated during cutting due to incorrect parameters or dull tools, and high cutting forces from aggressive feed rates or depths of cut. These factors collectively or individually can cause the delicate thin walls to warp or buckle.

2. How does ly-machining ensure dimensional accuracy for highly complex thin-walled aluminum components?

At ly-machining, we ensure dimensional accuracy through a multi-pronged approach. This includes custom-designed vacuum or mechanical fixtures for even support, strategic multi-stage machining with intermediate stress relief, optimized cutting tools (high-helix, sharp carbide) and parameters (high speed, light cuts), and rigorous post-machining inspection using advanced CMMs and non-contact optical scanners in controlled environments.

3. What post-machining processes does ly-machining offer to enhance the durability and finish of thin-walled aluminum parts?

We offer several post-machining processes to enhance durability and finish. These include various surface treatments like anodizing (clear, colored, hard coat) for corrosion resistance and aesthetic appeal, chemical etching for stress relief and improved fatigue life, and polishing or vibratory finishing for superior surface smoothness. We also provide precise deburring to ensure clean edges without damaging the delicate thin walls.