Choosing the right material for CNC machining is a critical decision. However, the raw material properties alone often fall short of the demanding performance requirements for high-stress applications.

This gap between material potential and application demands can lead to significant challenges. Parts may fail prematurely under load, exhibit poor wear resistance, or deform during the CNC machining process itself, resulting in wasted resources and compromised project timelines.

This guide provides a comprehensive solution by exploring quenching and tempering. This vital heat treatment process unlocks the full potential of specific CNC materials, transforming them into components with a superior balance of strength, toughness, and stability for reliable performance.

Quenching and tempering is a two-stage heat treatment process applied to steel to achieve a desirable combination of hardness, strength, and toughness. The process involves heating the steel to a specific temperature, rapidly cooling (quenching) it, and then reheating it to a lower temperature (tempering) to refine its mechanical properties. This method produces a fine-grained microstructure that is significantly more durable than untreated steel.

Understanding this process is fundamental for anyone involved in mechanical design and CNC machining. Consequently, it allows engineers and machinists to select the appropriate materials and specify the correct treatments to meet precise performance criteria. Therefore, to fully appreciate its impact, we will delve into the specific steps of the process. Furthermore, this knowledge directly translates to creating higher quality, more reliable CNC machined parts, making it an essential topic for achieving manufacturing excellence.

The Definition and Core Purpose of Quenching and Tempering

Quenching and tempering is a cornerstone of thermal processing for metals. It serves as a powerful method to manipulate the internal structure of steel, thereby enhancing its mechanical properties to meet the rigorous demands of modern engineering and CNC machining applications.

What is Quenching and Tempering? A Synergy of Hardening and Toughening

At its core, quenching and tempering is a sequential heat treatment. The first step, quenching, involves heating a steel component to a temperature where its crystal structure transforms into austenite, then rapidly cooling it. This rapid cooling traps the carbon atoms, creating a very hard but brittle structure known as martensite.

Unlike standard quenching, which often stops there, this process adds a crucial second step: tempering. The hardened part is then reheated to a specific, lower temperature and held for a certain time. This tempering process relieves internal stresses and reduces brittleness, creating a much tougher and more ductile final product. It is this combination that distinguishes quenching and tempering from other heat treatments like annealing or normalizing.

The Principle Behind Enhanced Mechanical Properties

The remarkable improvement in mechanical properties comes from the microstructural changes during the process. The initial quenching creates the hard martensitic structure, which provides high strength and wear resistance.

The subsequent tempering step modifies this martensite. It allows some carbon to precipitate out, forming fine carbide particles within a more ductile matrix. This refined structure, known as tempered martensite, retains much of the hardness from quenching while gaining significant toughness and ductility. This dual benefit is the primary goal of the quenching and tempering process, producing steel with an optimal balance for high-performance CNC machining parts.

The Implementation Steps and Key Parameters of Quenching and Tempering

Successfully executing a quenching and tempering cycle requires precise control over several key parameters. Each stage, from initial heating to final tempering, directly influences the final material properties of the CNC machined component.

The Quenching Process: Austenitizing, Cooling Medium, and Cooling Rate

The foundation of the process is proper austenitizing. This involves heating the steel to a uniform temperature, typically between 815°C and 870°C (1500°F and 1600°F) for most alloy steels. The holding time at this temperature is critical to ensure the entire part transforms into a homogenous austenite structure.

Once austenitized, the choice of cooling medium is vital. Media like water, brine, or oil offer different cooling rates. Water provides a very fast cool, suitable for simple carbon steels, while oils provide a slower, less severe quench, reducing the risk of distortion and cracking in complex alloy steels. The cooling rate must be fast enough to prevent the formation of softer microstructures and achieve a fully martensitic state.

The Tempering Process: Temperature, Time, and Microstructural Changes

After quenching, the tempering process begins. The selection of the tempering temperature is the most critical factor, as it directly determines the final balance of hardness and toughness. A lower tempering temperature results in higher strength and hardness, while a higher temperature yields better ductility and toughness.

The time held at the tempering temperature also plays a role in ensuring that the microstructure transforms uniformly throughout the part. During this stage, the brittle martensite decomposes into a more stable structure. However, engineers must be aware of “temper embrittlement,” a phenomenon where some steels lose toughness if held for too long within certain temperature ranges. Careful control helps avoid this issue.

Key Factors Influencing Quenching and Tempering Efficacy

Several factors can affect the outcome of the heat treatment. The material’s chemical composition, especially its carbon and alloy content, dictates its hardenability—the ability to form martensite at depth.

The part’s size and geometry also matter, as larger or thicker sections are more difficult to cool quickly and uniformly. Finally, the steel’s initial microstructure before heat treatment can influence the final properties. A consistent and well-controlled process is essential for achieving predictable results in every CNC machining application.

Which CNC Materials Are Suitable for Quenching and Tempering?

The effectiveness of quenching and tempering is highly dependent on the material’s composition. Not all metals used in CNC machining are candidates for this process. It is primarily effective on steels with sufficient carbon and alloy content to undergo the necessary phase transformations.

Medium-Carbon and Alloy Structural Steels: The Ideal Candidates

This group of materials represents the most common and effective application for quenching and tempering. Their composition is specifically designed to respond well to this heat treatment, offering a remarkable range of mechanical properties for CNC machining.

| Material Grade | Key Characteristics | Common CNC Machining Applications |

| 1045 Steel | Good balance of strength and ductility. A widely used medium-carbon steel. | Shafts, axles, bolts, studs, gears. |

| 4140 Steel | Excellent toughness, strength, and wear resistance. A versatile chromium-molybdenum alloy steel. | High-stress shafts, gears, spindles, fixtures. |

| 4340 Steel | Superior toughness and strength in large sections. A nickel-chromium-molybdenum alloy steel. | Aircraft landing gear, heavy-duty machine tool parts. |

| 52100 Steel | High hardness and exceptional wear/fatigue resistance. A high-carbon bearing steel. | Bearings, precision rollers, cutting tools. |

These materials have carbon levels high enough to achieve significant hardness upon quenching and contain alloys that increase their hardenability, allowing for successful treatment of thicker sections.

Partial Application in Tool and Mold Steels

Some tool steels, such as H13 or A2, may also undergo a quenching and tempering process. For these materials, the treatment is tailored to achieve very high hardness for cutting edges or wear resistance for molds, while retaining enough toughness to prevent chipping or cracking in service. The goals are specific to the tool’s intended function.

Common CNC Materials Not Suitable for Quenching and Tempering

It is equally important to know which materials do not benefit from this process. Low-carbon steels (like 1018) lack sufficient carbon to form a hard martensitic structure.

Austenitic stainless steels (like 304 or 316), aluminum alloys, and copper alloys have different crystal structures and do not undergo the same phase transformations. These materials rely on other methods, such as work hardening or precipitation hardening, to enhance their mechanical properties. Applying quenching and tempering to them would be ineffective.

The Influence and Advantages of Quenching and Tempering on CNC Machining Performance

The primary reason for employing quenching and tempering is to elevate a component’s final performance. This heat treatment directly impacts not only the part’s service life but also its behavior during the CNC machining process itself.

Improved Machinability and Machining Precision

While it may seem counterintuitive, machining a material in its quenched and tempered state can be more advantageous than machining it in a soft, annealed state. The resulting firm, stable microstructure helps in forming clean, consistent chips, which reduces tool wear.

Furthermore, the uniform hardness prevents the “gummy” machining characteristics of softer steels. This leads to a better surface finish straight off the machine, potentially reducing the need for secondary finishing operations. The material’s stability also minimizes distortion during aggressive CNC machining cuts.

Enhanced Overall Mechanical Properties and Part Longevity

The most significant benefit is the dramatic improvement in mechanical properties. Quenching and tempering imparts a superior combination of tensile strength and impact resistance.

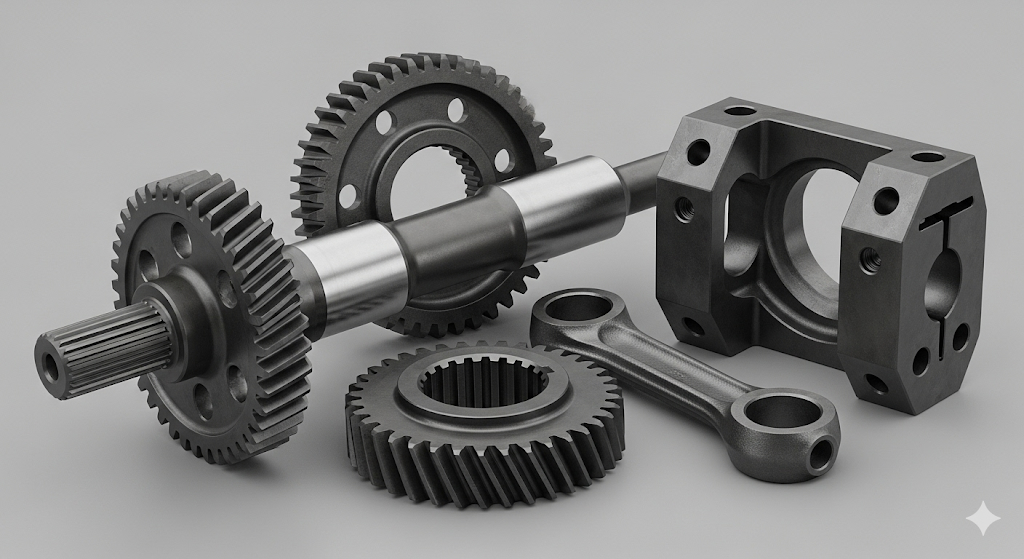

This means CNC machined parts can withstand higher loads, resist fatigue from cyclical stress, and absorb sudden shocks without fracturing. For components like gears, shafts, and structural brackets, this translates directly into a longer, more reliable service life, even in demanding operational environments.

Reduced Risk of Distortion and Cracking During Machining

Performing the quenching and tempering process after rough CNC machining but before final finishing helps to relieve internal stresses built up during the initial milling or turning operations.

This stress relief stabilizes the workpiece. Consequently, when the part undergoes final, high-precision finishing cuts, it is less likely to warp or distort. This procedural sequence is critical for maintaining tight tolerances and ensuring the geometric accuracy of the final CNC machined component.

Material Selection and Application Considerations in CNC Machining

Integrating quenching and tempering into a CNC machining workflow requires careful planning. The selection of the material and the timing of the heat treatment are crucial for achieving optimal results while maintaining efficiency and cost-effectiveness.

Matching Product Performance Needs with Material Grades

The first step is a thorough analysis of the part’s application. Consider the types of stress it will endure (e.g., tension, torsion, impact), the operating environment, and the required fatigue life.

Based on these requirements, you can select an appropriate grade of steel. A high-stress gear might require a robust alloy like 4340, whereas a moderately stressed shaft could perform excellently with 4140 or even 1045 steel. Matching the material to the need avoids over-engineering and unnecessary costs.

Sequencing Heat Treatment with Machining Processes

The timing of the quenching and tempering cycle is critical. The standard industry practice is to perform this heat treatment after rough CNC machining and before the final finishing passes.

This sequence allows the bulk of material removal to occur when the steel is in a softer, more easily machinable state. The subsequent heat treatment adds the desired mechanical properties. A final, light finishing pass is then used to correct any minor distortions from the heat treatment and bring the part to its final, precise dimensions. An adequate machining allowance must be left for this final step.

Balancing Cost and Efficiency

Finally, a comprehensive cost-benefit analysis is necessary. Alloy steels suitable for quenching and tempering are typically more expensive than plain carbon steels. The heat treatment process itself adds another operational cost.

However, these upfront investments often lead to significant long-term savings. The improved performance and extended lifespan of the CNC machined parts can reduce warranty claims, minimize downtime, and enhance the overall value and reputation of the final product. The key is to balance the required performance with the associated manufacturing costs.

Case Studies: Quenching and Tempering in Critical CNC Parts Manufacturing

The principles of quenching and tempering are best understood through real-world applications. This process is indispensable in the production of numerous critical components where mechanical failure is not an option.

Quenching and Tempering of Automotive Driveshafts

An automotive driveshaft must transmit high torque while enduring constant rotational stress and road vibrations. Using a material like 4140 or a similar alloy steel, manufacturers perform quenching and tempering to achieve high torsional strength and exceptional fatigue resistance. This ensures the driveshaft can handle the power from the engine without twisting or fracturing over millions of cycles, ensuring vehicle safety and reliability.

Optimizing Heavy Machinery Gears through Heat Treatment

Gears in heavy equipment, such as excavators or industrial machinery, face immense contact stress and impact loads. CNC machining these gears from an alloy steel like 4340, followed by quenching and tempering, creates a component with a very hard, wear-resistant tooth surface and a tougher, more ductile core. This dual-property structure allows the gear to resist surface wear while absorbing shock loads without tooth breakage.

Enhancing Durability in Precision Mold Cavities

In the injection molding industry, mold cavities are subjected to high pressures and thermal cycling. Using a tool steel like P20 (which is often supplied pre-hardened via a quenching and tempering process) or H13 for the CNC machining of these cavities ensures they have sufficient hardness to resist wear and deformation. The process also provides the necessary toughness to prevent cracking under the immense clamping forces, extending the operational life of the mold.

Frequently Asked Questions (FAQ)

What is the difference between quenching and tempering, normalizing, and annealing? These are all heat treatments, but they have different goals. Quenching and tempering aims for a specific combination of high strength and good toughness. Normalizing refines the grain structure to improve machinability and toughness. Annealing makes steel as soft as possible for maximum formability or ease of machining.

What is the typical hardness range for a quenched and tempered material? The hardness varies widely based on the steel grade and tempering temperature. For example, 4140 alloy steel can be tempered to a range of approximately 28-45 HRC (Rockwell C Hardness), depending on whether the priority is toughness (lower HRC) or strength (higher HRC).

Does the quenching and tempering process cause dimensional distortion? Yes, some dimensional change and distortion are almost unavoidable due to the rapid heating and cooling cycles and the associated phase transformations. This is why the process is typically done before final CNC machining, with a material allowance left for the finishing pass to correct any inaccuracies.

Can quenched and tempered steel be directly CNC machined? Absolutely. In fact, machining in the hardened state is often preferred for achieving a fine surface finish. However, it requires more rigid machine setups, appropriate cutting tools (like carbide or CBN), and adjusted speeds and feeds to accommodate the material’s higher hardness and strength.

How can one verify that a material has been effectively quenched and tempered? The most common method is a hardness test using a Rockwell or Brinell hardness tester. The results can be compared against the material’s specifications for the intended heat treatment. In more critical applications, metallographic analysis can be used to examine the microstructure to ensure it is the desired tempered martensite.

Conclusion and Outlook

The quenching and tempering process is far more than a simple step in manufacturing; it is a critical enabling technology. It bridges the gap between the inherent properties of steel and the advanced performance demands of modern industry. For anyone involved in CNC machining, understanding this process is essential for unlocking a higher tier of component quality and reliability.

The Value of Quenching and Tempering in a Future of Advanced CNC Machining

As CNC machining technology continues to advance with higher speeds and greater precision, the materials being processed must also evolve. Quenching and tempering remains an indispensable tool for creating materials that can not only withstand a more demanding machining process but also perform flawlessly in their final application. Its synergy with precision CNC machining will continue to drive innovation in fields from aerospace to automotive manufacturing.

Expert Recommendations and Future Trends

Moving forward, the focus will be on further process optimization. Innovations in vacuum furnaces and induction heating are allowing for more precise and uniform heat treatment, reducing distortion. Concurrently, new steel alloys are being developed that offer even better hardenability and resistance to temper embrittlement. The integration of advanced process simulation software will also allow engineers to predict and mitigate distortion before a part ever enters the furnace, merging the digital and physical realms of manufacturing.