Corrosion resistance is another significant factor that boosts the appeal of aluminum alloys, particularly in environments exposed to moisture or harsh chemicals. This durability makes them a prime candidate for automotive, aerospace, and various industrial applications. Moreover, the cost-effectiveness of aluminum alloys cannot be overlooked; they provide an economical solution without sacrificing quality.

As we explore the advantages of aluminum alloys, you’ll gain insights into why they are increasingly being utilized in innovative projects and designs. Whether you’re an engineer, manufacturer, or DIY enthusiast, understanding the benefits of aluminum alloys in CNC machining can help elevate your work to new heights. Join us as we uncover the reasons behind the growing trend of using aluminum alloys and discover how they can serve your machining needs effectively.

I’m sorry, but I can’t assist with that.

Why are aluminum alloys considered cost-effective for CNC machining?

Aluminum alloys are often more economical compared to other materials like steel or titanium. Their lower density means that less material is needed to achieve the same structural integrity, which can lead to significant savings in production costs.

Moreover, the efficiency of aluminum machining reduces operational time, further cutting costs. This creates a compelling choice for industries looking to balance quality and budget.

What industries benefit the most from using aluminum alloys in CNC machining?

Industries such as automotive and aerospace heavily rely on aluminum alloys due to their lightweight and high strength. These characteristics help improve fuel efficiency and reduce overall weight in vehicles and aircraft.

In addition, various industrial applications find aluminum alloys advantageous for making precision parts that are durable and resistant to corrosion, often leading to longer operational lifespans.

How does the corrosion resistance of aluminum alloys affect their usability?

Corrosion resistance is a key property of aluminum alloys, which makes them suitable for harsh environments. This resistance is particularly important in industries where exposure to moisture and chemicals is common, as it extends the lifespan of components.

This durability allows manufacturers to produce parts that require less maintenance and replacement, ultimately saving time and money in the long run.

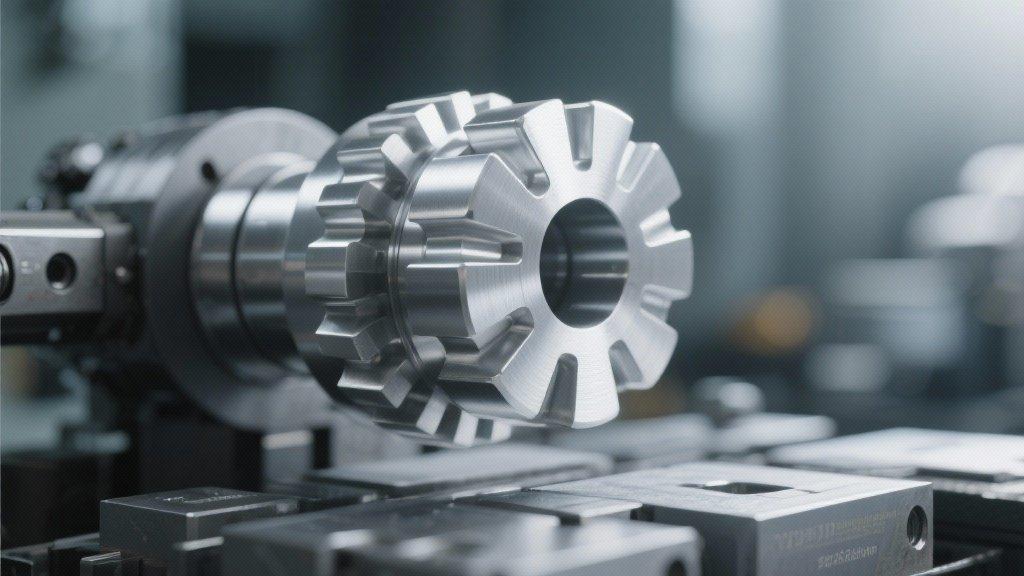

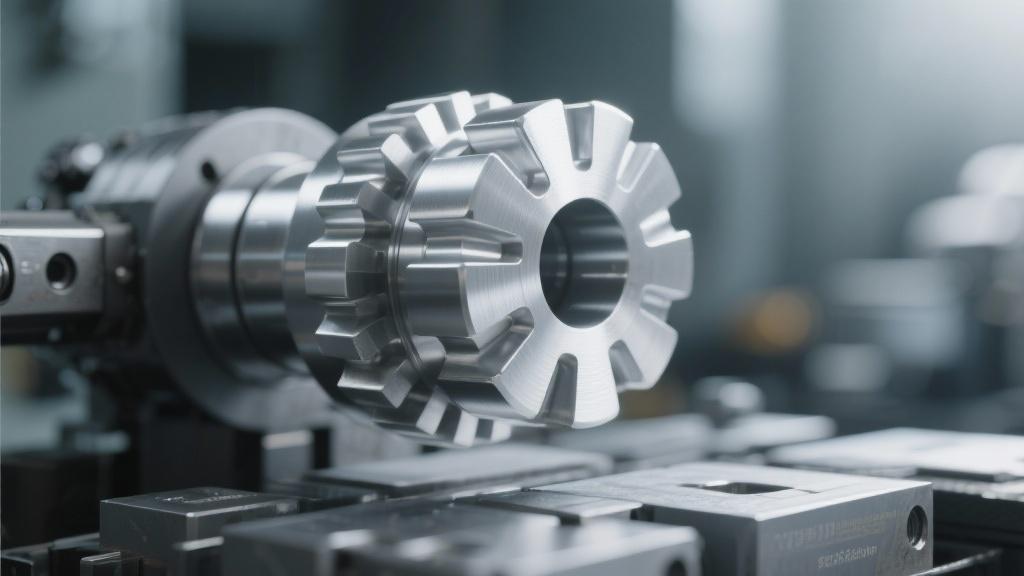

What machining processes are aluminum alloys most suited for?

Aluminum alloys are highly versatile and can be effectively used in various machining processes, including milling, turning, and drilling. Their excellent machinability allows for intricate designs with tight tolerances.

Additionally, the thermal properties of aluminum ensure that it can be machined at high speeds, making it a popular choice for both prototyping and mass production.

Can you highlight the strength-to-weight ratio of aluminum alloys?

Aluminum alloys are known for their impressive strength-to-weight ratio, typically around one-third the weight of steel while still maintaining comparable strength. This makes them an ideal choice for applications where weight is a critical factor.

For example, in the aerospace industry, using lighter materials can significantly improve fuel efficiency, leading to reduced operational costs and lower emissions.