We will explore key grades, such as 6061, 7075, and 2024, discussing their specific characteristics, advantages, and typical applications. Whether you are involved in aerospace, automotive, or general manufacturing, understanding these alloy grades is crucial for making informed decisions that enhance productivity and product quality.

Additionally, we will examine the factors influencing the choice of alloy, including strength-to-weight ratios, corrosion resistance, and ease of fabrication. By the end, you’ll have a clearer picture of which aluminum alloy grades best suit your machining needs and how they can improve the durability and performance of your components. Join us as we unravel the essential role aluminum alloys play in modern machining and discover how these materials can meet the demands of diverse industries.

What aluminum alloy grades are popular in machining processes? This is a question that comes up often, especially among those in manufacturing and engineering fields where material selection is critical for project success. Let’s break down some of the most commonly used aluminum alloy grades and why they’re favored in machining.

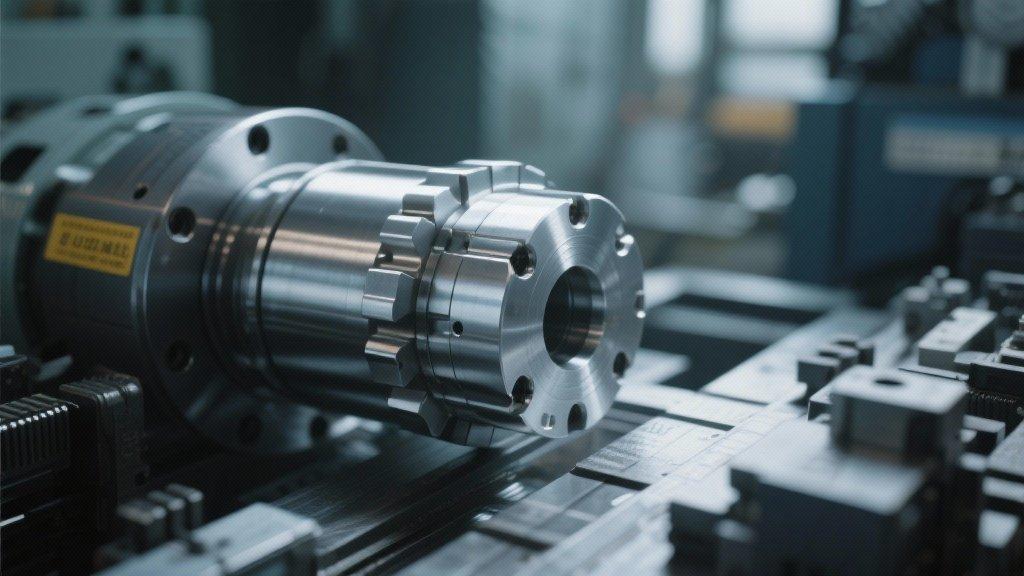

Why Choose Aluminum Alloys for Machining?

Aluminum alloys are prized in machining for several reasons. They provide a fantastic strength-to-weight ratio, making them ideal for applications where both lightweight and strength are paramount. They are also more resistant to corrosion compared to other metals, which adds to their longevity in various environments.

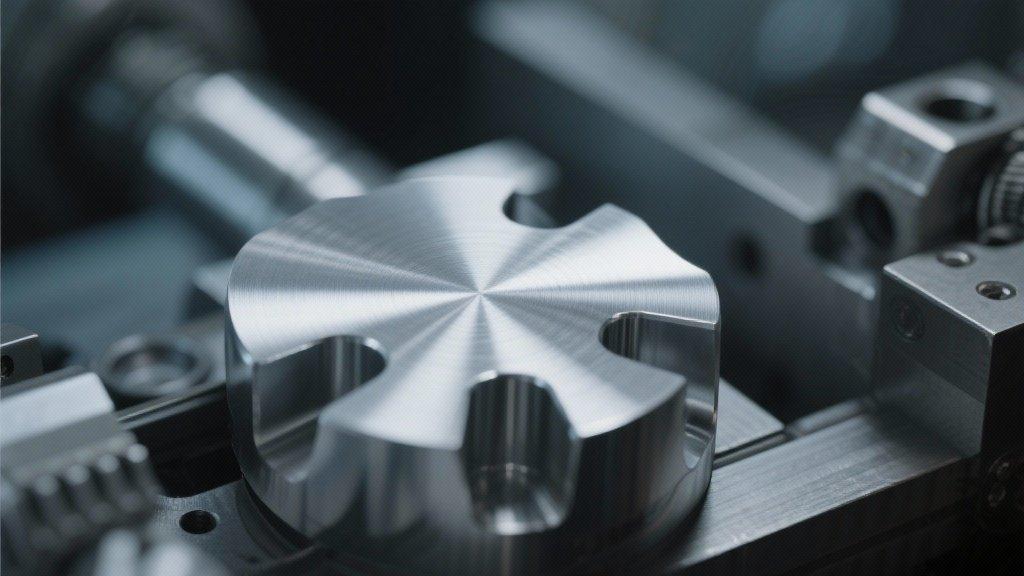

Popular Aluminum Alloys in Machining

Key Considerations When Choosing Aluminum Alloys

When selecting an aluminum alloy for machining processes, several factors come into play:

By analyzing the performance characteristics of each alloy, along with their suitability for specific applications, you can make an informed choice for your machining needs. In summary, the world of aluminum alloys is vast, and understanding the popular grades can enhance your project’s performance and efficiency.

What makes aluminum alloys a popular choice for machining?

Aluminum alloys are lightweight yet strong, which is crucial in applications like aerospace and automotive. They also resist corrosion better than many other metals, enhancing their durability.

Moreover, their excellent machinability means they can be easily shaped and formed, making them a go-to material for many manufacturers.

How do I choose the right aluminum alloy for my project?

Choosing the right aluminum alloy involves considering the specific mechanical properties you need, like strength and corrosion resistance. For example, if you need high strength, alloys like 7075 or 2024 might be ideal.

You should also think about machinability and whether the alloy is easy to work with. Factors like cost and intended use should guide your decision as well, especially if your project spans multiple years.

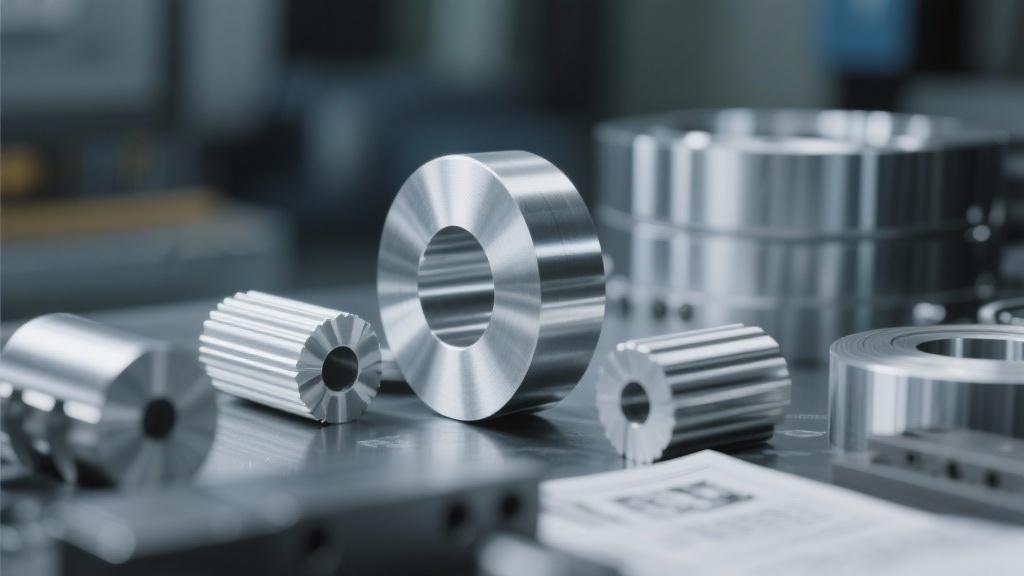

What are the key differences between 6061 and 7075 aluminum alloys?

6061 aluminum is widely regarded for its versatility and ease of machining, making it great for structural applications and general manufacturing. On the other hand, 7075 is known for its exceptional strength, often used in aerospace applications where performance is critical.

While 6061 offers good weldability, 7075 is generally tougher to weld but excels in scenarios where weight-saving is paramount.

How does the corrosion resistance of aluminum alloys impact their use?

Corrosion resistance is a vital factor, especially for outdoor or marine applications. Alloys like 5052 boast excellent corrosion resistance, making them ideal for environments exposed to moisture, while 2024 is less resistant and usually requires protective coatings.

This difference impacts how each alloy is used across different industries, ensuring they meet specific environmental challenges effectively.

Are there specific applications where certain aluminum alloys are preferred?

Yes, specific aluminum alloys are tailored for particular applications. For instance, 6061 is often used in automotive structures, while 7075 finds its place in aerospace components due to its high strength-to-weight ratio.

Meanwhile, 3003 is commonly utilized in household items like cooking utensils, showcasing how the choice of alloy directly influences application success.