We will also compare aluminum with other common materials like steel and plastics, highlighting how its versatility allows for a broader range of applications. From aerospace to automotive, aluminum’s ability to maintain structural integrity while being lightweight makes it indispensable in modern manufacturing.

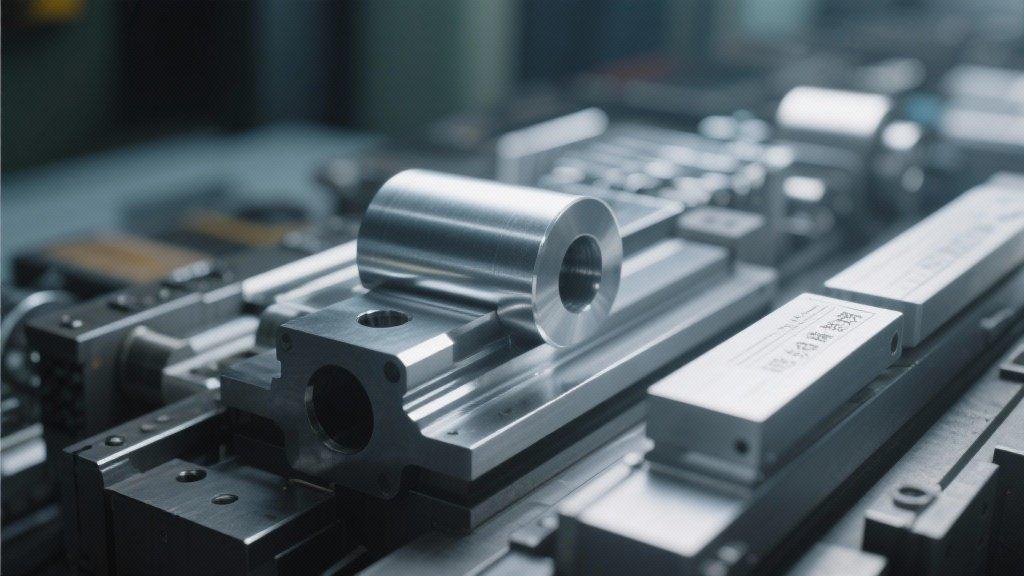

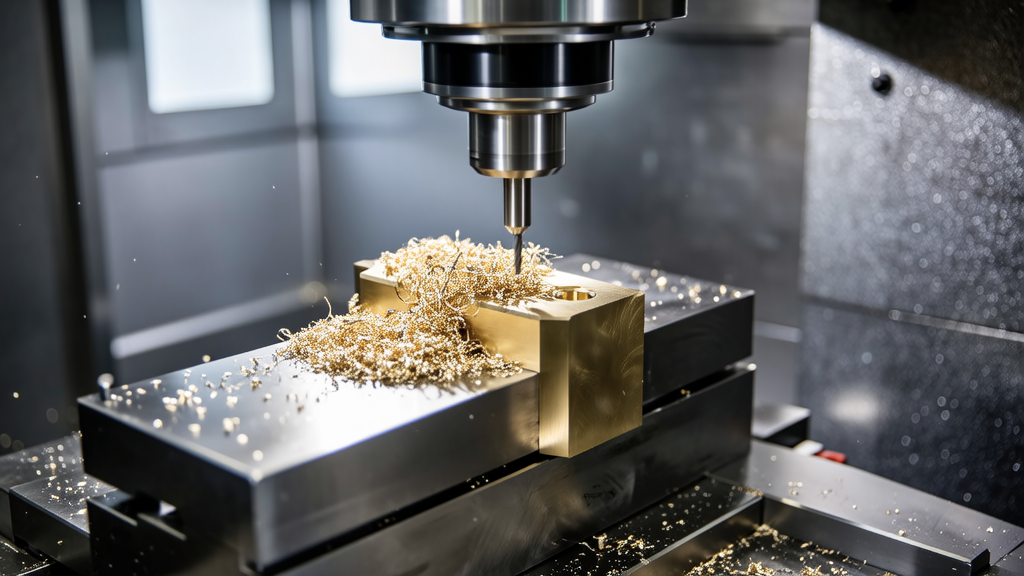

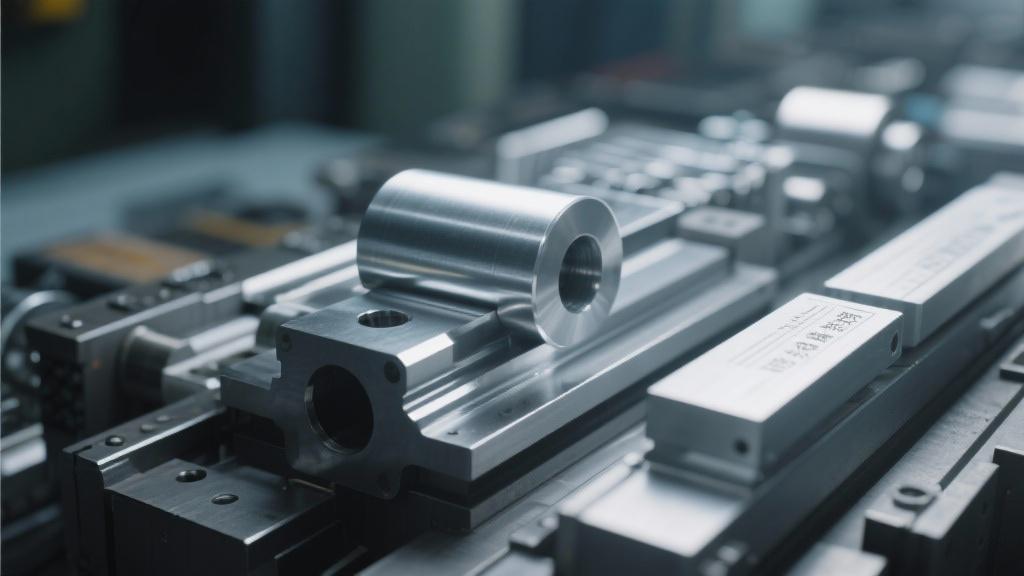

Additionally, this article will address the various machining techniques that work best with aluminum, including CNC machining, milling, and turning, showcasing how each method capitalizes on aluminum’s properties. By understanding the key differences between aluminum and other materials in machining, manufacturers can make informed decisions about material selection, ultimately enhancing productivity and product performance.

Join us as we unravel the important aspects of aluminum machining and discover why this metal continues to be a first-choice material for engineers and manufacturers around the globe. Whether you are a seasoned professional or just entering the field, this insight into aluminum will equip you with the knowledge to leverage its benefits effectively.

Question: What sets aluminum apart from other materials in machining?

Answer: Aluminum’s distinct properties make it a standout choice in machining compared to other materials. Let’s break down some of the key features that really set aluminum apart.

Lightweight Yet Strong

One of aluminum’s most noteworthy characteristics is its lightweight nature. Weighing about one-third the weight of steel, aluminum can deliver significant advantages in industries like aerospace and automotive. Imagine you’re designing an airplane; every gram counts when it comes to fuel efficiency. This means that using aluminum can directly influence performance and operational costs, making it a preferred material.

Excellent Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which makes it highly resistant to corrosion. This means parts made from aluminum can maintain their integrity and appearance over time without requiring extensive coatings or treatments. You could take a look at some consumer electronics; many enclosures and components are made of aluminum not only for aesthetics but also for longevity. With aluminum, you’re often getting an investment that lasts longer than products made from less resistant materials.

Thermal Conductivity and Electrical Conductivity

Aluminum is known for its high thermal conductivity, which is essential in applications where heat dissipation is critical. Think about cooling systems in computers or LED lighting; effective heat management can prolong the lifespan of components. Its electrical conductivity is another essential factor; aluminum is often used in electrical applications, such as electrical wiring and connections, where lightweight and conductivity are both required.

Machinability

When it comes to machining, aluminum is generally easier to work with than materials like steel or titanium. It can be cut and shaped using various machining methods, such as CNC machining, milling, and turning, with relative ease and speed. This means that manufacturers can achieve greater precision and shorter production cycles. I’ve seen shops that specialize in aluminum fabrication reducing turnaround times dramatically thanks to aluminum’s favorable machining characteristics.

Comparison with Other Materials

So, how does aluminum stack up against materials like steel or plastics? While steel is stronger and more durable, it is also heavier and often more challenging to machine. Plastics, on the other hand, may be lightweight and resistant to corrosion, but they often lack the strength and thermal properties of aluminum. In summary, while each material has its advantages, aluminum manages to balance weight, strength, machinability, and durability in a way that quite few can.

Applications

With all these properties, it’s no wonder aluminum finds its place in countless applications—from aerospace and automotive to consumer electronics and structural components. Understanding these unique benefits can help manufacturers and engineers make informed choices about their materials, tailoring their designs to better meet specific project requirements.

So, whether you’re sourcing materials for a new project or simply looking to expand your understanding of manufacturing, keep aluminum on your radar. Its distinct attributes not only simplify the machining process but also provide long-term advantages that are hard to overlook.

In conclusion, aluminum’s lightweight nature, corrosion resistance, thermal and electrical conductivity, machinability, and broad applications create a compelling reason for its preference in numerous machining processes. It’s not just another option; it’s often the optimal choice.

What makes aluminum a lightweight material for machining?

Aluminum is significantly lighter than many other metals, weighing about one-third as much as steel. This lightweight property allows for easier handling and reduced energy consumption in manufacturing processes.

This is particularly advantageous in industries like aerospace and automotive, where minimizing weight can lead to improved fuel efficiency and overall performance.

How does aluminum resist corrosion compared to other materials?

Aluminum naturally develops a protective oxide layer when exposed to air, making it highly resistant to corrosion. This means that aluminum parts can last longer and often require less maintenance compared to materials like steel, which can rust over time.

For instance, in environments where materials are exposed to moisture or chemicals, aluminum retains its structural integrity better than many alternatives.

Can you explain the thermal and electrical conductivity of aluminum?

Aluminum is known for its high thermal conductivity, which allows it to dissipate heat effectively in applications like electronics and LED lighting. This property helps in prolonging the lifespan of sensitive components by managing excess heat.

Additionally, aluminum’s good electrical conductivity makes it a popular choice for electrical applications, such as wiring, where both lightweight and conductivity are essential.

Why is aluminum considered easier to machine than steel?

Aluminum can be machined more easily than steels due to its softer and less dense nature. This means machining processes such as CNC milling and turning are generally faster and require less energy when working with aluminum.

Shops often report shorter production times and lower tool wear when working with aluminum compared to harder metals, making aluminum a cost-effective choice for many projects.

In what applications is aluminum typically used?

Aluminum is ubiquitous in various industries, from aerospace and automotive to consumer electronics and construction. Its lightweight nature, corrosion resistance, and excellent machinability make it a versatile material suitable for countless applications.

For example, you’ll find aluminum in everything from airplane components to bicycle frames, showcasing its adaptability across different manufacturing processes and environments.