Navigating the world of CNC machining requires an in-depth understanding of materials, especially when aiming for parts that offer both high strength and light weight. Aluminum alloys 6061 and 7075 stand out as two premier choices for performance-driven applications. This article, brought to you by ly-machining, dives deep into the characteristics, advantages, and limitations of each, providing a comprehensive guide to help you make an informed decision for your next project, ensuring optimal performance and cost-effectiveness in your 6061 and 7075 aluminum CNC machining endeavors.

Aluminum Selection for High Strength

Aluminum’s Core Role in Modern Industry

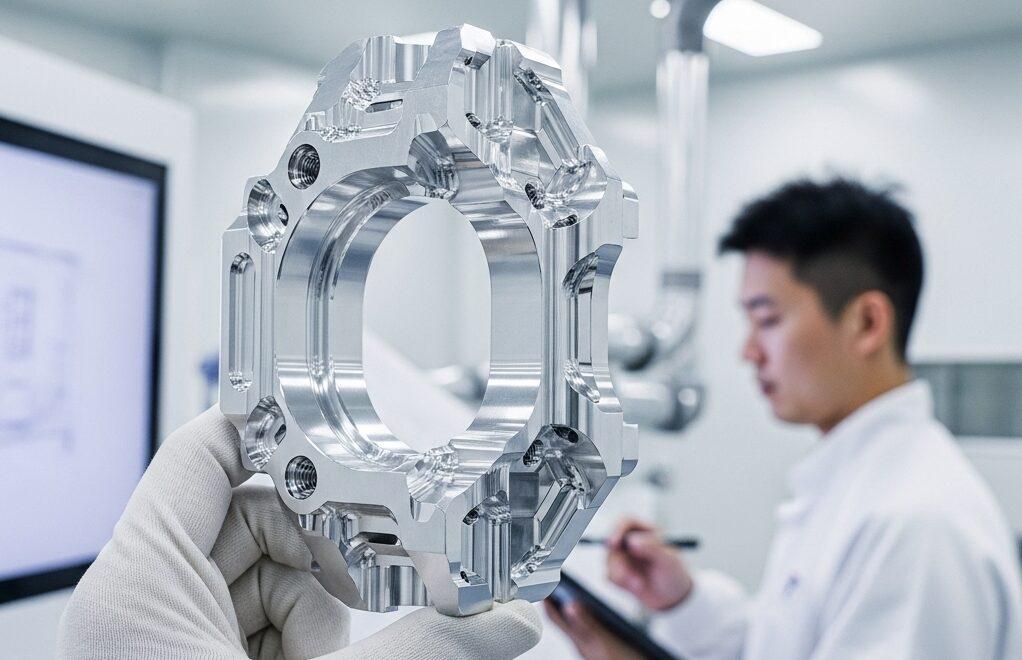

Aluminum alloys have become indispensable in contemporary manufacturing, owing to their exceptional strength-to-weight ratio, corrosion resistance, and versatility. From aerospace to automotive, consumer electronics to architectural structures, the demand for lightweight yet robust components continues to drive innovation in aluminum processing. This pervasive presence highlights the critical need for precise material selection.

6061 & 7075: Top CNC Machining Aluminum Alloys

Among the vast array of aluminum alloys, 6061 and 7075 stand as titans in the realm of CNC machining. Each possesses a unique blend of properties making them suitable for distinct applications. Understanding their specific characteristics is vital for engineers and manufacturers striving for optimal performance in high-precision parts.

6061 Aluminum CNC Machining: Pros and Cons

6061 Processing Perks: Easy Cutting, Cost-Benefit

Aluminum 6061 is renowned for its excellent machinability, making it a preferred choice for many CNC machining applications. Its balanced properties translate into tangible benefits regarding both processing ease and economic viability, offering a compelling case for general-purpose structural components.

6061 Machining Performance & Surface Finish

One of the significant advantages of 6061 aluminum CNC machining is its superior cutting characteristics. It produces well-formed chips that are easy to evacuate, reducing tool wear and improving cycle times. This ease of machining often results in excellent surface finishes, minimizing the need for extensive post-processing.

Lower 6061 Material Cost & Entry Barrier

Compared to other high-performance aluminum alloys, 6061 generally comes with a lower material cost. This, combined with its favorable machinability, translates into reduced overall production expenses. It also presents a lower entry barrier for shops new to machining aluminum, simplifying setup and operation.

6061 Performance: Medium Strength, Good Welding

Beyond its machinability, 6061 aluminum offers a desirable combination of mechanical properties that suit a broad spectrum of engineering applications. It strikes a balance between strength, workability, and environmental resilience.

Moderate 6061 Tensile & Yield Strength

6061 aluminum provides moderate tensile and yield strengths, making it robust enough for many structural applications without being overly rigid. This makes it ideal for components that require a good balance of strength and ductility, capable of withstanding various stresses in service.

Excellent 6061 Welding & Corrosion Resistance

A standout feature of 6061 is its exceptional weldability, allowing for complex fabrications and repairs. Furthermore, it boasts good resistance to atmospheric corrosion, which can be further enhanced through anodizing, making it suitable for outdoor and marine environments.

6061 Limitations: Lower Strength & Hardness

Despite its many advantages, 6061 aluminum does have limitations, particularly when applications demand extreme performance. Understanding these constraints is crucial for appropriate material selection.

6061 Not for Extreme Strength/Hardness

When a project calls for ultra-high strength or superior hardness, 6061 may fall short. Its mechanical properties, while good, are not in the same league as some specialized alloys, especially those in the 7000 series. This means it might not withstand extreme loads or high-impact stresses.

6061 Under High Fatigue Load Performance

For parts subjected to continuous high-cycle fatigue or intense dynamic loading, 6061 aluminum might not be the optimal choice. Its fatigue strength is good for general use but can be a limiting factor in critical applications where long-term durability under demanding conditions is paramount.

7075 Aluminum CNC Machining: Pros and Cons

7075 Extreme Strength & Hardness Benefits

7075 aluminum alloy stands at the pinnacle of strength among commercially available aluminum alloys. Its impressive mechanical properties make it a go-to material for industries where performance cannot be compromised.

Superior 7075 Tensile & Yield Strength

The defining characteristic of 7075 aluminum is its exceptional tensile and yield strength, often comparable to that of some steels. This high strength is achieved through the addition of zinc as the primary alloying element, making it ideal for highly stressed structural parts in rigorous environments.

Excellent 7075 Hardness & Wear Resistance

7075 also exhibits remarkable hardness and wear resistance. These properties are critical for applications where components are exposed to abrasive forces or require sustained structural integrity under friction. This makes 7075 aluminum CNC machining invaluable for durable parts.

7075 Machining Challenges: Difficulty, Tool Wear

While its strength is undeniable, 7075 aluminum presents more significant challenges during CNC machining than 6061. These difficulties can impact both production efficiency and cost.

Difficult 7075 Machinability & Higher Difficulty

The inherent hardness and strength of 7075 aluminum contribute to its relatively poorer machinability. It can be more challenging to cut, often leading to longer cycle times and requiring more robust machining strategies. The “6061 vs 7075 differences” in machinability are stark.

High Tool Requirements for 7075 CNC Machining

Due to its toughness, 7075 requires specialized tooling—typically harder, more durable cutting tools with optimized geometries. This can lead to increased tool wear, shorter tool life, and consequently, higher tooling costs. Precise control over cutting parameters is essential to achieve desired results.

7075 Cost & Specific Application Insights

The advanced properties of 7075 come with specific cost implications and dictate its application in highly specialized fields. For ly-machining, advising on these factors is paramount.

Higher 7075 Material & Processing Costs

Material for 7075 aluminum is significantly more expensive than 6061. Combined with the higher processing costs due to increased machining difficulty and tool wear, the overall expenditure for 7075 components is substantially greater.

7075 in Aerospace & High-End Applications

Given its high strength and superior performance, 7075 is a staple in critical applications such as aerospace structural components, military equipment, high-performance sporting goods (e.g., bicycle frames, climbing gear), and automotive racing parts. These industries prioritize strength and lightweighting above cost.

6061 vs 7075 CNC Machining Performance Comparison

Choosing between 6061 and 7075 aluminum for CNC machining hinges on a direct comparison of their critical performance attributes. The 6061 vs 7075 differences are fundamental to material selection.

6061 vs 7075 Mechanical Performance

The most significant distinction between these two alloys lies in their mechanical properties. This table highlights key “6061 vs 7075 differences.”

| Property | 6061-T6 Aluminum | 7075-T6 Aluminum | Key Differences |

|---|---|---|---|

| Tensile Strength | 290 MPa (42,000 psi) | 572 MPa (83,000 psi) | 7075 is significantly stronger, nearly double. |

| Yield Strength | 240 MPa (35,000 psi) | 503 MPa (73,000 psi) | 7075 offers superior resistance to permanent deformation. |

| Hardness (Brinell) | 95 HB | 150 HB | 7075 is much harder, enhancing wear resistance. |

| Density | 2.70 g/cm³ | 2.81 g/cm³ | Very similar, 7075 slightly denser due to alloying elements. |

| Weldability | Excellent (easily welded) | Poor (generally not weldable) | 6061 is preferred for welded assemblies. |

| Corrosion Resistance | Good (can be anodized) | Fair (susceptible to stress corrosion cracking) | 6061 offers better all-around corrosion resistance. |

6061 & 7075 Tensile & Yield Strength Gaps

As seen, 7075-T6 exhibits nearly double the tensile and yield strength of 6061-T6. This makes 7075 the undisputed champion for applications requiring maximum load-bearing capacity and resistance to deformation. The “6061 vs 7075 differences” in strength are paramount.

6061 vs 7075 Hardness & Wear Resistance

Similarly, 7075’s superior hardness (150 HB vs. 95 HB for 6061) translates directly into better wear resistance. This is a critical factor for parts that undergo friction or abrasive contact, extending component lifespan in demanding conditions.

CNC Machining Performance: Cut, Finish, Efficiency

Machinability is another key differentiator between these two aluminum alloys, directly impacting production processes and outcomes for ly-machining’s clients.

| Feature | 6061 Aluminum CNC Machining | 7075 Aluminum CNC Machining | Implications for Machining |

|---|---|---|---|

| Machinability Rating | Excellent (50-70%) | Fair (20-40%) | 6061 is significantly easier to cut. |

| Chip Formation | Continuous, easily broken | Gummy, tougher, stringy | 6061 allows for better chip evacuation. |

| Tool Wear | Low | High | 7075 requires more frequent tool changes, specialized tools. |

| Surface Finish | Excellent, smooth | Good, but can be rougher | 6061 often achieves better finishes post-machining. |

| Cutting Speeds | Higher | Lower | 6061 supports faster production cycles. |

| Coolant Use | Standard | More critical, high-volume | 7075 generates more heat, requiring aggressive cooling. |

6061 vs 7075 Chip Formation & Evacuation

6061 aluminum produces small, easily managed chips, which are critical for efficient material removal and preventing chip re-cutting. Conversely, 7075 often creates stringy, gummy chips that can lead to chip packing, requiring more aggressive chip evacuation strategies during 7075 aluminum CNC machining.

Surface Finish & Dimensional Accuracy: 6061/7075

While both can achieve high precision, 6061 generally yields a smoother surface finish directly from the machine, minimizing the need for secondary polishing. 7075 might require more precise tool paths and potentially additional finishing steps to achieve a comparable surface quality.

Cost-Benefit Analysis: 6061 vs 7075 Total Input

Cost is often a deciding factor, and the “6061 vs 7075 differences” in this area are substantial, influencing overall project budgets.

6061 vs 7075 Total Cost for Various Batches

For high-volume production of general components, 6061’s lower material cost and superior machinability make it significantly more economical. For smaller batches of critical components, the higher cost of 7075 might be justified by its performance benefits. ly-machining works with clients to analyze this balance.

6061/7075 Post-Processing & Maintenance Costs

6061’s excellent weldability can reduce assembly costs, and its corrosion resistance minimizes maintenance in certain environments. 7075’s susceptibility to stress corrosion cracking may necessitate protective coatings in specific applications, adding to overall maintenance and long-term costs.

Choosing Aluminum for High Strength & Lightweight

Making the right choice between 6061 and 7075 aluminum is a strategic decision that impacts the final product’s performance, cost, and manufacturability. ly-machining guides its clients through this process.

Project Needs: Strength, Weight, Cost, Environment

The first step in material selection is a thorough analysis of the project’s specific requirements. Every parameter, from required strength to service environment, plays a crucial role.

Aluminum Selection for Stressed vs. Non-Stressed

For components that will experience high stresses, extreme loads, or require exceptional stiffness, 7075 is typically the superior choice. For parts that serve mainly structural or aesthetic purposes without extreme load requirements, 6061 aluminum CNC machining often suffices.

Balancing Budget & Production Cycle: 6061/7075

A project’s budget and production timeline are critical. If cost is a primary constraint and moderate strength is acceptable, 6061 offers a compelling economic advantage. If performance is paramount and budget allows, 7075 delivers unmatched strength despite higher costs and longer machining times.

6061 Use Cases: General Parts, Cost-Sensitive

6061 aluminum is the workhorse of the aluminum industry, finding its place in a vast range of applications where its balanced properties shine.

6061 for Auto, Bike Frames, Electronics Shells

Typical applications for 6061 include automotive chassis components, bicycle frames, marine fittings, electronic enclosures, general structural components, and architectural elements. Its ease of fabrication and good corrosion resistance are key benefits here.

6061: Moderate Strength, Machinability, Economy

If your product requires good strength, excellent machinability, and cost-effectiveness, 6061 aluminum CNC machining is likely the best option. It provides reliable performance without the premium price tag or machining complexities of higher-strength alloys.

7075 Use Cases: Aerospace, High-End Sports, Critical Parts

7075 aluminum is reserved for the most demanding applications where its superior strength-to-weight ratio is indispensable.

7075 for Aircraft, Rockets, Premium Bike Parts

Key applications include aircraft structural components (fuselage, wings), rocket components, military armor, high-stress parts in premium bicycles (e.g., cranksets, hubs), and molds for plastic injection or blow molding. These require the absolute highest performance.

7075: Extreme Strength, Rigidity, Lightweight Needs

When a product demands the absolute highest strength, rigidity, and minimal weight—such as in aerospace or competitive sports equipment—7075 aluminum CNC machining is the definitive choice. Its performance justifies its higher cost and machining challenges.

Case Study: Optimal Aluminum CNC Selection

A client approached ly-machining with two distinct projects. The first was a high-performance drone chassis requiring maximum strength-to-weight ratio for flight dynamics and payload capacity. The second was a series of universal jigs and fixtures for their assembly line, needing durability and cost-effectiveness.

For the drone chassis, ly-machining recommended 7075 aluminum CNC machining. Despite the higher material cost and increased processing time, the unparalleled tensile strength and hardness of 7075 ensured the drone frame could withstand intense flight stresses and accidental impacts while remaining incredibly light. This decision directly impacted the drone’s performance metrics and market competitiveness.

For the assembly jigs, 6061 aluminum CNC machining was the clear choice. Its excellent machinability allowed for rapid prototyping and efficient production of complex fixture geometries. The moderate strength of 6061 was more than adequate for resisting daily wear and tear in an industrial setting, and its lower material cost significantly reduced the overall project budget, delivering a robust, economical solution. This case perfectly illustrates the critical “6061 vs 7075 differences” in application.

Conclusion: Best Aluminum, Balancing Cost & Performance

Comprehensive Assessment: Balance Performance, Machinability, Cost

The choice between 6061 and 7075 aluminum for CNC machining is rarely straightforward; it’s a strategic decision balancing mechanical performance, ease of machining, and total cost. 6061 excels where moderate strength, excellent weldability, and cost-effectiveness are priorities, offering a versatile solution for a wide array of general applications.

Conversely, 7075 is the undisputed leader when extreme strength, hardness, and minimal weight are non-negotiable, particularly in critical high-performance industries. Understanding the intricate “6061 vs 7075 differences” is essential for making an informed choice. At ly-machining, we are dedicated to helping clients navigate these complexities to ensure the optimal material selection for every project.

Future Outlook: Aluminum & CNC Machining Evolution

The landscape of aluminum alloys and CNC machining technology is continuously evolving. Advances in material science are leading to even higher-performance alloys, while innovations in machining processes are making complex geometries and difficult materials more accessible and efficient. ly-machining remains at the forefront, embracing these developments to deliver cutting-edge solutions for all high-strength, lightweight aluminum needs.

Related Questions

Q1: What are the primary 6061 vs 7075 differences in material composition?

A1: The primary difference lies in their main alloying elements. 6061 is alloyed primarily with magnesium and silicon, making it a “magnesium-silicon” alloy. 7075 is alloyed primarily with zinc, along with smaller amounts of magnesium and copper, classifying it as a “zinc-magnesium-copper” alloy. This compositional variation is directly responsible for the significant strength differences between the two.

Q2: Can 7075 aluminum be welded for structural applications?

A2: While 7075 aluminum can be welded, it is generally considered to have poor weldability compared to 6061. Welding significantly reduces the strength of 7075 in the heat-affected zone and can lead to cracking. For critical structural applications, mechanical fasteners (bolts, rivets) or adhesives are typically preferred over welding when using 7075.

Q3: How does the surface finish of 6061 aluminum CNC machining compare to 7075?

A3: Generally, 6061 aluminum CNC machining tends to produce a smoother, brighter surface finish more easily due to its better machinability and chip formation. 7075, being harder and more prone to gummy chip formation, might require more precise cutting parameters, specialized tools, and potentially additional post-processing (like polishing or fine grinding) to achieve a comparable surface quality.

Q4: Is 6061 aluminum suitable for anodizing?

A4: Yes, 6061 aluminum is highly suitable for anodizing, especially for decorative and protective applications. It produces a clear, uniform anodized layer that can also be easily dyed in various colors. This enhances its corrosion resistance and surface hardness, making it ideal for aesthetically critical parts.

Q5: What are common heat treatment designations for 6061 and 7075, and what do they mean?

A5: Both 6061 and 7075 are commonly used in the “T6” temper. For 6061-T6, it means the alloy has been solution heat-treated and then artificially aged. For 7075-T6, it’s also solution heat-treated and artificially aged. The -T6 temper generally provides the highest strength for both alloys, achieving their peak mechanical properties through specific thermal processes.

FAQ Section

Q1: What industries frequently use 6061 aluminum CNC machining?

A1: Industries like automotive (chassis, brackets), marine (fittings, boat hulls), general structural engineering, consumer electronics (enclosures), and bicycle manufacturing widely utilize 6061 due to its balance of strength, machinability, and corrosion resistance.

Q2: Why is 7075 aluminum preferred for aerospace components?

A2: 7075 is preferred for aerospace due to its exceptional strength-to-weight ratio, which is critical for reducing aircraft weight and improving fuel efficiency and payload capacity. Its high strength ensures structural integrity under extreme flight conditions.

Q3: Are there any specific considerations for coolant when machining 7075?

A3: Yes, due to its hardness and higher cutting forces, 7075 aluminum CNC machining generates more heat. Therefore, aggressive and high-volume application of a suitable coolant is crucial to manage heat, extend tool life, and ensure chip evacuation.

Q4: Can ly-machining assist in selecting the right aluminum alloy for my project?

A4: Absolutely. At ly-machining, we specialize in guiding clients through the material selection process, analyzing your project’s specific requirements for strength, weight, cost, and environmental factors to recommend the most suitable aluminum alloy (6061, 7075, or others) for optimal results.

Q5: What impact do “6061 vs 7075 differences” have on lead times for CNC machining projects?

A5: The differences can significantly impact lead times. 6061’s superior machinability often results in faster production cycles and shorter lead times. 7075’s increased machining difficulty, higher tool wear, and potentially longer setup times can extend lead times, which must be factored into project planning.