Optimizing Aluminum CNC Surface Quality

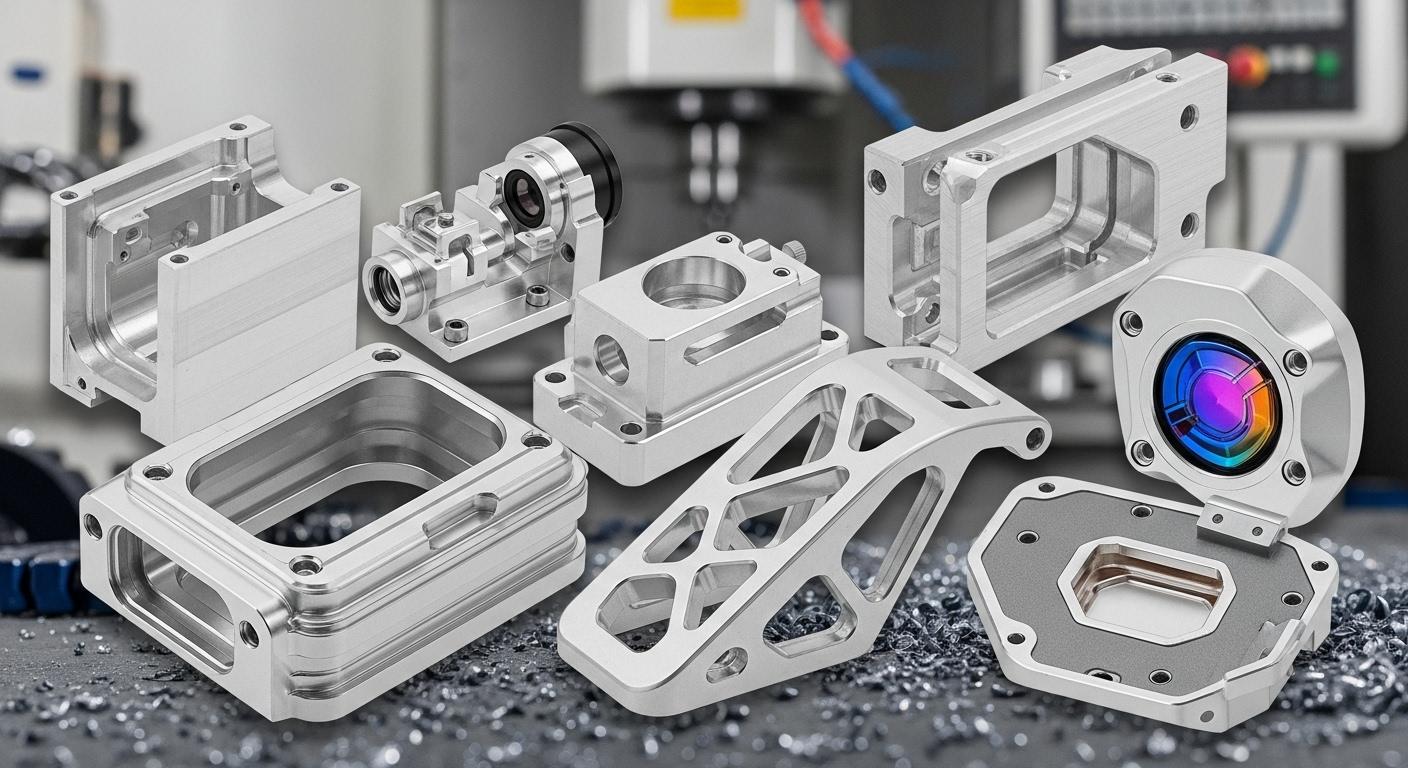

Is inconsistent surface quality on your aluminum CNC parts quietly sabotaging your product performance, aesthetics, and bottom line? Many manufacturers overlook the subtle, yet critical, factors that differentiate a mediocre finish from a truly exceptional one. Discover how mastering these elements can transform your aluminum components.

Achieving superior aluminum CNC surface quality is a meticulous process, directly impacting a part’s functionality, aesthetics, and longevity. It requires an in-depth understanding of material science, tooling, machining parameters, and post-processing. ly-machining excels in this domain, delivering precision aluminum parts with consistently high-quality surface finishes tailored to specific application requirements.

Material Properties Impacting Aluminum CNC Surface Quality

The inherent characteristics of the aluminum alloy itself play a foundational role in the surface finish achievable during CNC machining. Understanding these properties is the first step toward optimization.

Aluminum Alloy Type and Temper

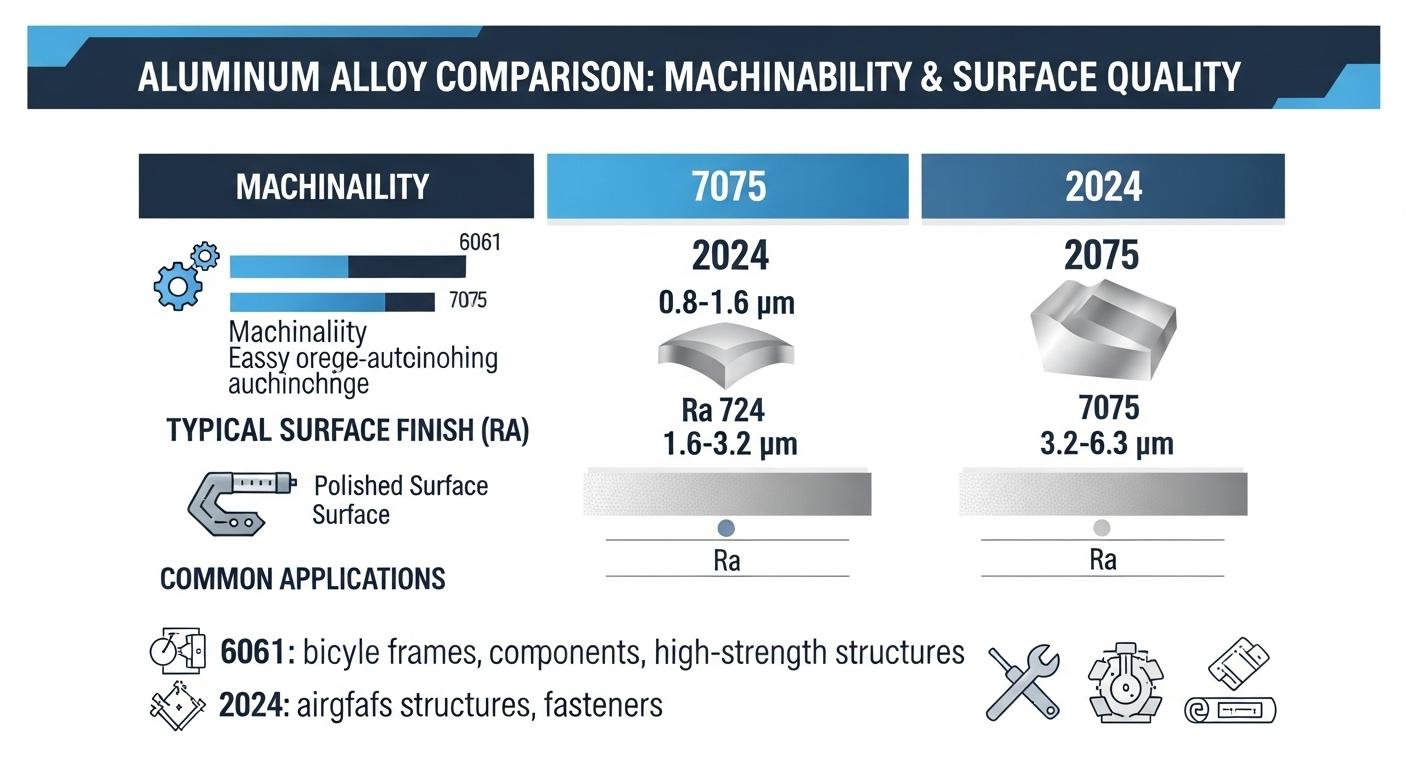

Different aluminum alloys possess varying machinability characteristics. Alloys like 6061 and 7075 are widely used, but their specific compositions and tempers dictate how they respond to cutting. This directly influences the achievable surface roughness (Ra value) and overall surface integrity.

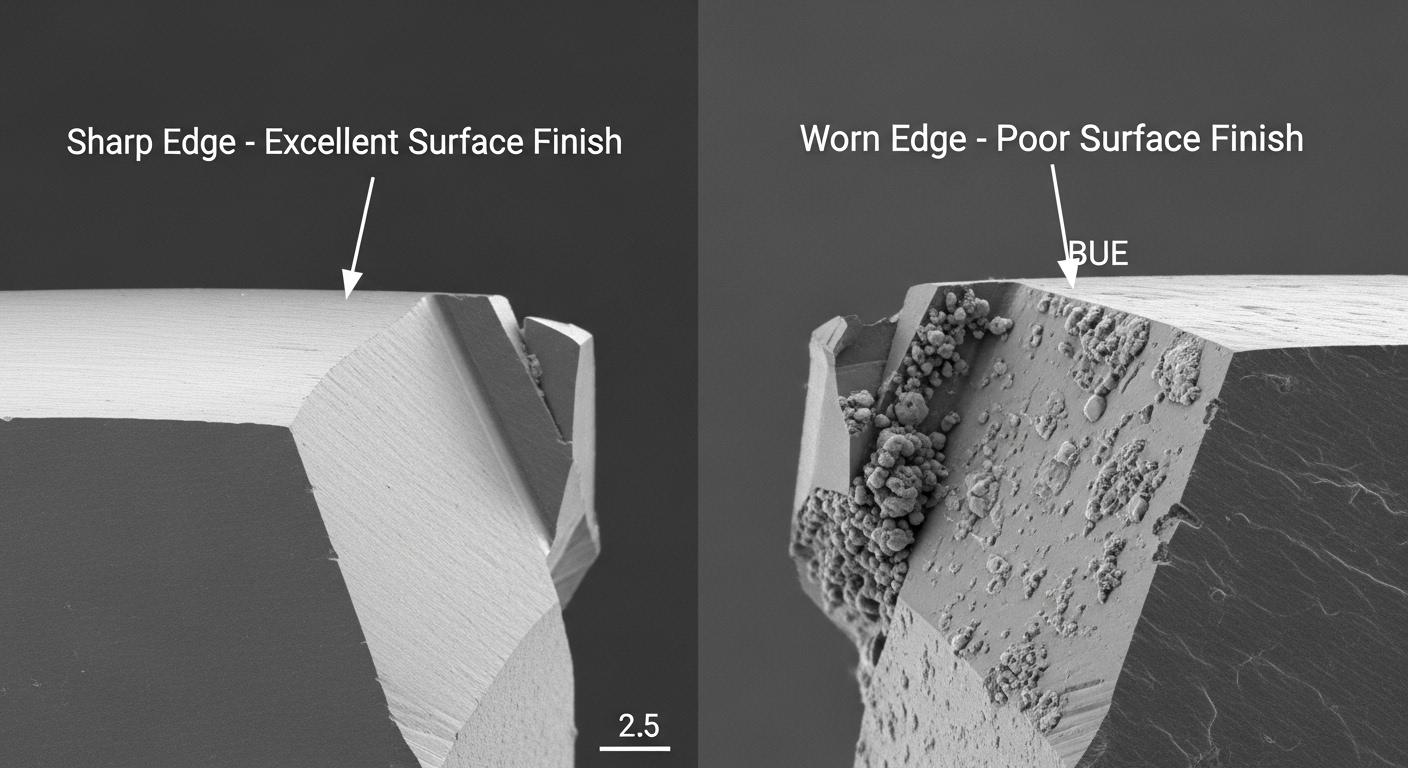

Certain alloys, due to their constituent elements, may be more prone to built-up edge (BUE) or chip welding, which degrades surface finish. Selecting the right alloy for both application and machinability is crucial.

| Aluminum Alloy | Typical Machinability | Achievable Surface Finish (Ra) | Common Applications |

|---|---|---|---|

| 6061-T6 | Good | 0.8 – 1.6 µm | Structural components, frames |

| 7075-T6 | Fair-Good | 1.6 – 3.2 µm | Aerospace, high-stress parts |

| 2024-T3 | Fair | 1.6 – 3.2 µm | Aircraft fittings, fasteners |

| 5052-H32 | Poor-Fair | 3.2 – 6.4 µm | Marine, sheet metal applications |

Material Hardness and Microstructure

The hardness of the aluminum alloy affects chip formation and tool wear. Softer alloys can lead to smearing or gumming, especially with improper tool geometry, resulting in poor finishes. Harder alloys, while less prone to smearing, can accelerate tool wear if not managed correctly.

The microstructure, including grain size and distribution, can influence how the material shears during cutting. Inclusions or inconsistent grain structures can cause micro-tearing or surface irregularities, making it challenging to achieve a smooth finish.

Inclusions and Grain Structure Defects

Internal defects such as non-metallic inclusions or porosity within the raw aluminum stock can significantly degrade the machined surface. These anomalies can chip out during machining, leaving voids or rough spots.

Careful material selection from reputable suppliers, along with pre-inspection, helps mitigate these risks. ly-machining sources premium-grade aluminum to ensure material consistency and reduce defect potential.

Tooling & Cutters: Crucial for Flawless Aluminum Surfaces

The cutting tool is the direct interface with the material, making its selection, geometry, and condition paramount for achieving optimal aluminum CNC surface quality.

Tool Material and Coating Selection

For aluminum, high-speed steel (HSS) and solid carbide tools are common. Carbide tools offer superior rigidity and wear resistance, allowing for higher cutting speeds and feeds, which often translates to better finishes.

Specific coatings like TiCN, AlTiN, or diamond-like carbon (DLC) are designed to reduce friction, prevent BUE, and improve chip evacuation, further enhancing surface quality and tool life.

| Tool Material/Coating | Advantages for Aluminum | Considerations |

|---|---|---|

| Solid Carbide | High rigidity, wear resistance, permits high speeds | More brittle than HSS, higher cost |

| High-Speed Steel (HSS) | Good toughness, lower cost, suitable for lower speeds | Prone to wear at high speeds, less rigid |

| DLC (Diamond-Like Carbon) | Very low friction, excellent BUE resistance | Higher cost, less suitable for very high temperatures |

| AlTiN | Good hardness and wear resistance, moderate friction | Can be reactive with aluminum at very high temperatures |

Tool Geometry: Rake, Helix, Edge Prep

Tool geometry, including rake angle, helix angle, and edge preparation, must be optimized for aluminum. High positive rake angles and sharp cutting edges reduce cutting forces and heat, promoting clean shearing.

A high helix angle effectively evacuates chips from the cutting zone, preventing re-cutting and surface marring. Proper edge preparation, such as a slight hone, can improve tool strength while maintaining sharpness.

Tool Wear and Edge Sharpness

A dull or worn tool will inevitably produce a poor surface finish. It generates more heat, increases cutting forces, and leads to smearing, tearing, and burr formation.

Regular tool inspection and timely replacement or regrinding are essential. Consistent tool maintenance ensures sharp, clean cuts and maintains surface integrity.

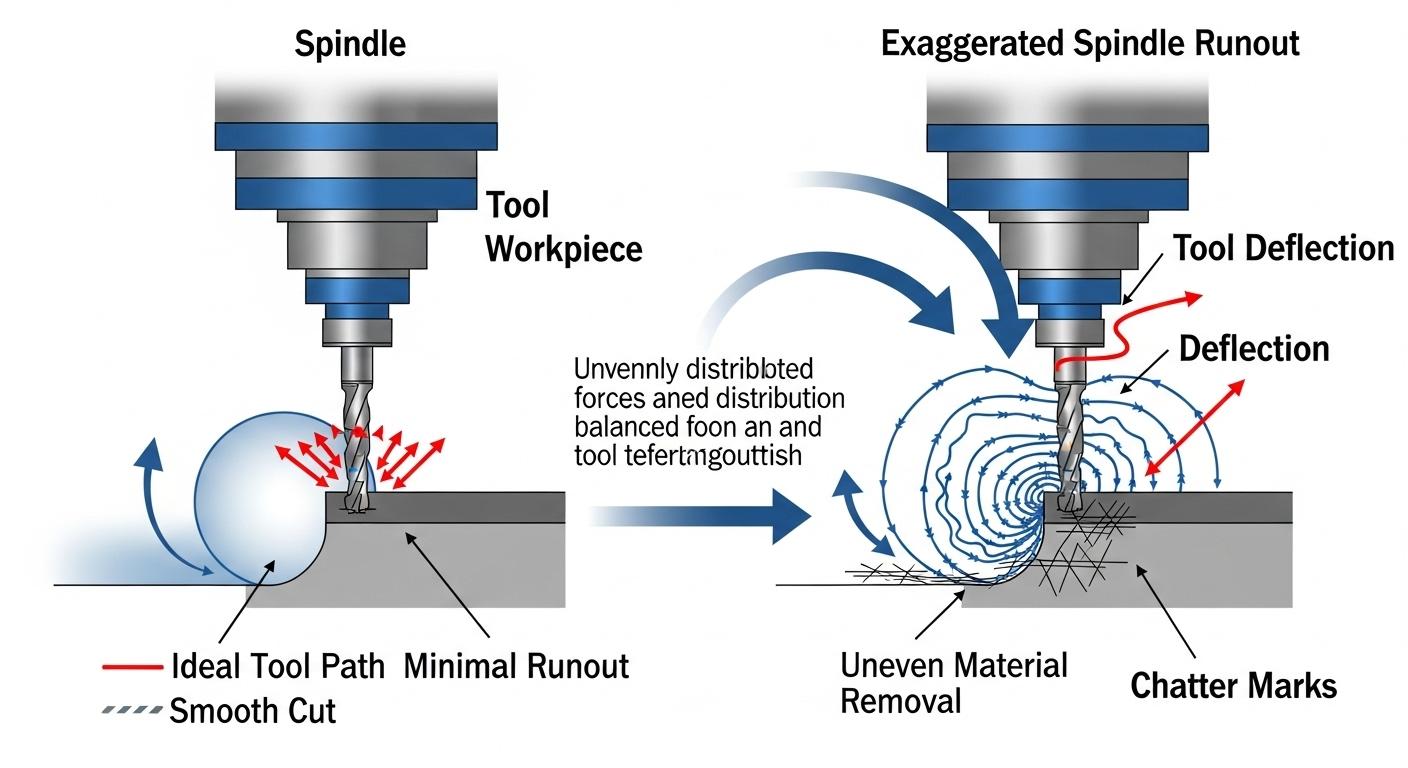

Runout and Tool Holder Rigidity

Tool runout, the eccentricity of a rotating tool, significantly impacts surface quality. Even slight runout causes uneven chip loads and creates chatter marks. Minimizing runout is crucial for achieving fine finishes.

The rigidity of the tool holder and the entire tool clamping system is equally important. A rigid setup reduces vibrations and deflections, allowing the tool to cut precisely and smoothly. High-quality balanced tool holders are indispensable.

CNC Machining Parameters for Optimal Surface Finish

Precise control over machining parameters is fundamental to achieving superior aluminum CNC surface quality. Even the best material and tooling will fail without optimized parameters.

Feed Rate and Spindle Speed Optimization

The interplay between feed rate and spindle speed determines the chip load per tooth, which directly influences surface roughness. An excessively high feed rate can lead to rough finishes, while too low a feed rate can cause rubbing and heat buildup, also degrading the surface.

Optimal spindle speeds, often higher for aluminum, help produce cleaner cuts and finer finishes by shearing material cleanly rather than tearing. Finding the sweet spot for each operation is critical.

| Parameter | Effect on Surface Finish (General) | Optimization Goal |

|---|---|---|

| High Feed Rate | Rougher finish, increased tool pressure | Balanced for material removal and finish |

| Low Feed Rate | Smoother finish, increased rubbing/heat | Avoid rubbing for best results |

| High Spindle Speed | Smoother finish, reduced BUE (for aluminum) | Match to tool material and machine limits |

| Low Spindle Speed | Rougher finish, potential for tearing | Use only for specific tough operations |

Depth of Cut and Radial Engagement

Small, consistent depths of cut and radial engagements (stepover) are generally preferred for finishing passes on aluminum. This reduces cutting forces, minimizes tool deflection, and allows for precise material removal, resulting in a smoother surface.

Larger cuts are efficient for roughing but inappropriate for achieving fine finishes due to increased forces and potential for surface irregularities.

Tool Path Strategy and Stepover

The chosen tool path strategy (e.g., climb milling vs. conventional milling, helical interpolation, constant scallop height) greatly influences the final surface texture. Consistent stepover and smooth transitions in the tool path prevent abrupt changes in cutting forces that can lead to visible marks.

Advanced CAM software allows for highly optimized tool paths that prioritize surface finish in critical areas, such as using trochoidal milling or smooth arc entry/exit strategies.

Vibration and Chatter Control

Vibration and chatter are primary culprits for poor surface finish, causing ripples and uneven textures. They can stem from machine instability, insufficient workpiece fixturing, worn tools, or improper machining parameters.

Addressing these issues requires a holistic approach, including optimizing tool paths, adjusting speeds/feeds, using rigid fixtures, and ensuring machine tool health. ly-machining implements advanced strategies to detect and mitigate chatter.

Machine Rigidity & Precision in Aluminum Part Finishing

The foundation of high-quality CNC machining lies in the stability and precision of the machine tool itself.

Machine Tool Condition and Stability

A robust, well-maintained CNC machine tool provides the necessary stability for precision machining. Worn bearings, loose slides, or an unlevel machine bed can introduce vibrations and inaccuracies that directly affect surface finish.

Regular maintenance and calibration are non-negotiable for consistent performance. ly-machining’s machines undergo rigorous preventative maintenance to ensure peak condition.

Spindle Accuracy and Power

The spindle is the heart of the cutting process. High spindle accuracy, meaning minimal runout and vibration, is paramount for producing smooth surfaces. Adequate spindle power ensures consistent cutting force without bogging down, even under varying loads.

Modern, high-speed spindles are crucial for achieving the fine finishes often required for aluminum, enabling optimal surface speed.

Fixturing and Workpiece Clamping

Inadequate fixturing can lead to workpiece deflection or movement during machining, resulting in chatter, inaccuracies, and poor surface finish. The workpiece must be rigidly clamped to prevent any vibration or shifting.

Fixture design should also consider thermal expansion of the aluminum, ensuring stability throughout the machining cycle. Vacuum chucks, hydraulic clamps, and custom-designed jigs are employed for secure workholding.

Environmental Factors: Temperature & Humidity

Environmental conditions, particularly temperature fluctuations, can influence machining accuracy and, consequently, surface finish. Thermal expansion or contraction of both the machine and the workpiece can alter dimensions and introduce stress.

Maintaining a stable, controlled shop environment minimizes these effects, ensuring consistent machining results. Precision shops like ly-machining operate in climate-controlled environments.

Coolant & Lubrication Strategies for Superior Surface Quality

The correct application of coolant and lubrication is vital for managing heat, reducing friction, and ensuring effective chip evacuation in aluminum CNC machining.

Coolant Type and Concentration

Specialized coolants for aluminum are formulated to provide excellent lubrication, superior cooling, and anti-corrosion properties. The correct concentration of soluble oils or synthetic coolants prevents BUE, reduces friction, and enhances surface finish.

Incorrect coolant types or concentrations can lead to poor lubricity, excessive heat, and degraded surface quality.

| Coolant Type | Primary Benefit for Aluminum | General Application |

|---|---|---|

| Soluble Oils | Excellent lubrication, good cooling | General purpose, versatile |

| Synthetics | Superior cooling, good chip evacuation, clean | High-speed machining, finer finishes |

| Semi-Synthetics | Balance of lubrication and cooling | Bridge between soluble oils and synthetics |

| Neat Oils | High lubrication, limited cooling | Tapping, reaming, deep hole drilling |

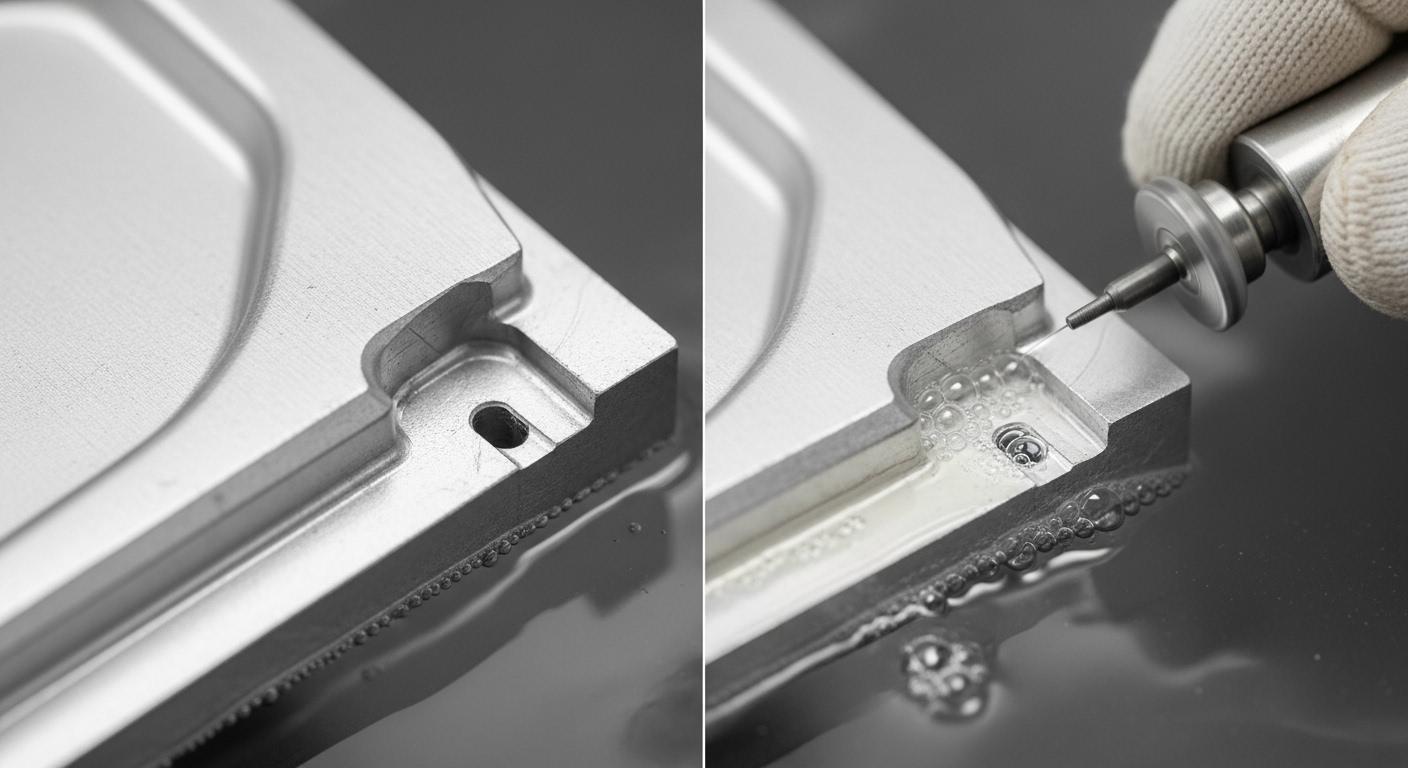

Coolant Delivery Method and Pressure

The method of coolant delivery is as important as the coolant itself. Flood coolant systems are common, but high-pressure through-spindle or through-tool coolant delivery can dramatically improve chip evacuation and cooling right at the cutting edge.

This precision delivery prevents chips from re-cutting and helps achieve much finer, more consistent surface finishes. Mist coolants or minimum quantity lubrication (MQL) are also used for specific applications, balancing cooling with cleanliness.

Chip Evacuation and Management

Effective chip evacuation is paramount. If chips accumulate in the cutting zone, they can be re-cut, rub against the workpiece, or become welded to the tool, all leading to surface damage.

Proper coolant pressure, tool geometry designed for chip breaking, and optimized tool paths are all critical for efficient chip management, directly contributing to superior surface quality.

Post-Processing Techniques Enhancing Aluminum Surface Finish

Even after optimized machining, post-processing steps are often necessary to achieve the desired final aluminum CNC surface quality, especially for highly demanding applications.

Deburring and Edge Finishing

Machining processes often leave small burrs or sharp edges. Deburring is crucial for both functional and aesthetic reasons. Techniques range from manual deburring to vibratory tumbling, abrasive flow machining, or robotic deburring.

Achieving a consistent, burr-free edge is essential for part performance and safety. Precision deburring contributes significantly to the overall surface integrity.

Polishing and Lapping Methods

For exceptionally smooth or mirror-like finishes (very low Ra values), additional polishing or lapping might be required. These abrasive processes remove microscopic irregularities, refining the surface texture.

Methods include mechanical polishing, electropolishing, or chemical polishing, each offering different levels of surface refinement and suitability for various part geometries.

Anodizing and Other Surface Treatments

Anodizing is a common surface treatment for aluminum, not only for aesthetics (color) but also for enhancing corrosion resistance and surface hardness. The quality of the anodized finish is highly dependent on the underlying machined surface.

Other treatments like chemical conversion coatings (e.g., Alodine) or specialized painting can also impact the final appearance and performance of the surface.

Cleaning and Surface Preparation

Before any post-treatment, thorough cleaning of the machined part is essential. Residual oils, coolants, or microscopic debris can interfere with subsequent processes like anodizing or painting, leading to defects.

Precision cleaning methods, including ultrasonic cleaning or solvent degreasing, ensure a pristine surface ready for final finishing.

Summary:

Achieving optimal aluminum CNC surface quality is a complex interplay of multiple factors. From selecting the right alloy and specialized tooling to meticulously optimizing machining parameters, ensuring machine rigidity, employing effective coolants, and applying precise post-processing techniques, every step is critical. ly-machining leverages deep technical expertise and rigorous process control to master these elements, consistently delivering precision aluminum components with superior surface finishes that meet the most demanding specifications.

FAQ Section:

Q1: What are typical Ra values achievable for precision aluminum CNC parts?

A1: The achievable Ra (roughness average) value for precision aluminum CNC parts depends heavily on the specific alloy, machining processes, and post-treatment. For standard machining, Ra values typically range from 0.8 µm to 3.2 µm. With optimized parameters, specialized tools, and finishing passes, Ra values down to 0.4 µm are attainable. For highly demanding applications requiring mirror-like finishes, post-machining processes like polishing, lapping, or electropolishing can achieve Ra values as low as 0.05 µm or even finer. At ly-machining, we work closely with clients to define and achieve the specific Ra requirements for their critical components.

Q2: How does ly-machining ensure consistent surface quality across large production batches?

A2: Ensuring consistent surface quality across large batches involves a multi-faceted approach. Firstly, we implement strict material sourcing and incoming inspection protocols to guarantee consistent raw material properties. Secondly, our production planning includes detailed process sheets with validated machining parameters, tool selection, and tool change schedules. We utilize high-precision, well-maintained CNC machinery with advanced monitoring systems to detect deviations. Regular in-process and post-process quality control checks, including tactile profilometry or optical inspection, are performed on a statistical basis. Furthermore, our experienced machinists and quality engineers continuously monitor and refine processes to maintain tight control over surface finish, ensuring every part meets specified Ra values.

Q3: What role does coolant play specifically in achieving a fine surface finish on aluminum?

A3: Coolant plays a critical, multifaceted role in achieving a fine surface finish on aluminum. Primarily, it dissipates heat generated during cutting, which prevents thermal deformation of the workpiece and tool, and reduces material smearing. Secondly, coolants provide lubrication, reducing friction between the tool and workpiece, thereby minimizing built-up edge (BUE) formation—a major cause of poor surface finish. Effective coolant also aids in efficient chip evacuation from the cutting zone, preventing re-cutting of chips that can scratch or mar the freshly machined surface. The type, concentration, and delivery method of the coolant are carefully selected at ly-machining to optimize these functions for superior aluminum surface quality.

Ready to elevate the surface quality of your aluminum CNC parts? Don’t let inconsistent finishes compromise your project. Contact our expert team today for a free technical consultation and a transparent quote on your precision aluminum machining needs. Let’s achieve unparalleled quality together.