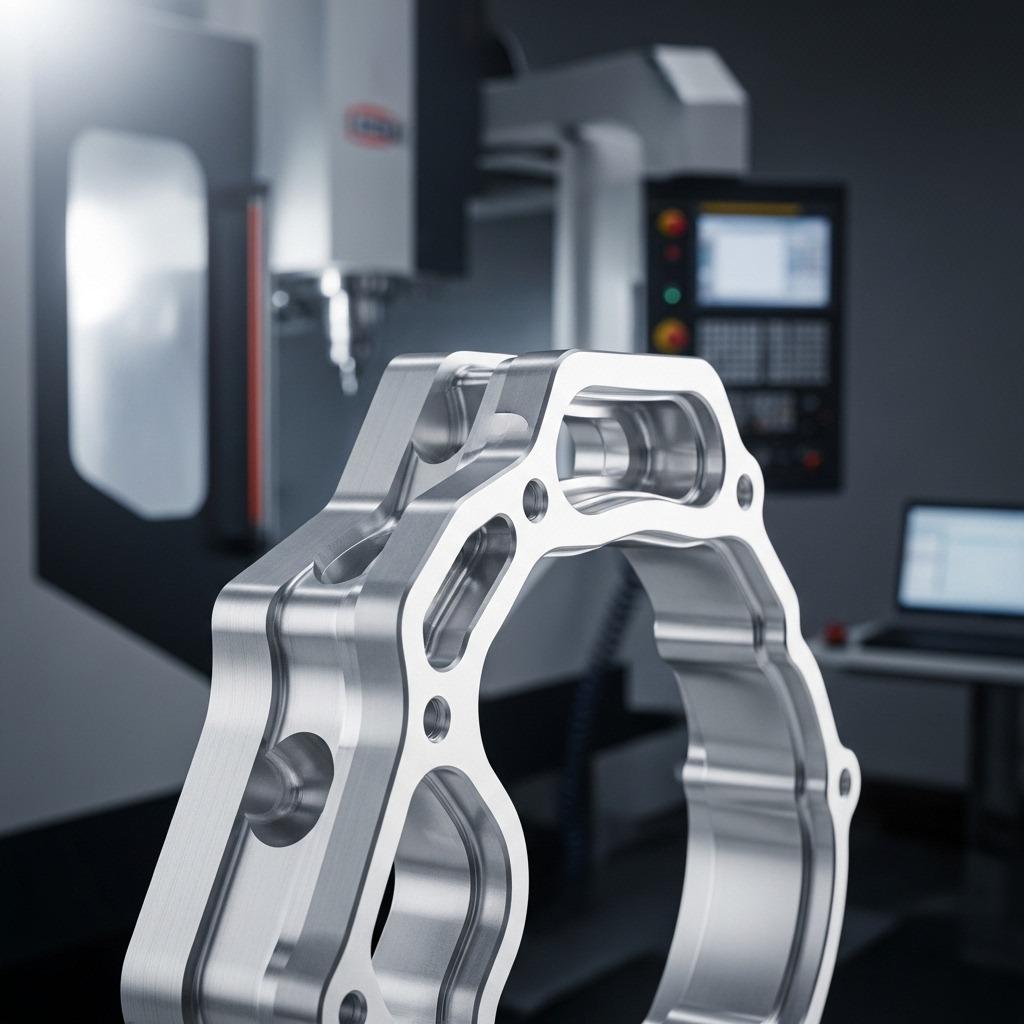

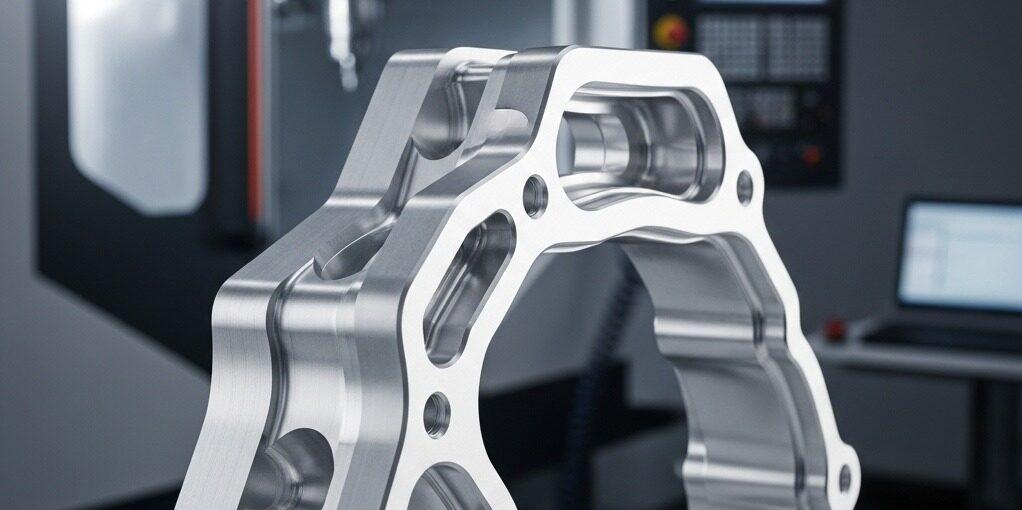

Many businesses face significant challenges with aluminum CNC machined parts developing unsightly white or black discolorations, leading to costly rejections and production delays. These surface defects not only compromise the aesthetic appeal but can also indicate underlying material or process inconsistencies, eroding product reliability and brand reputation. At ly-machining, we leverage our deep technical expertise as a source manufacturer to precisely identify the root causes of these issues, providing robust, tailored solutions to ensure your aluminum components maintain their pristine surface quality.

Aluminum CNC machining surface discoloration, manifesting as white or black spots, typically stems from material impurities, improper cutting fluid management, incorrect machining parameters, or inadequate post-processing. Addressing these issues requires a systematic approach involving material analysis, process optimization, and stringent quality control protocols.

Understanding White Discoloration in Aluminum CNC Machining

White discoloration on machined aluminum surfaces often appears as milky patches, streaks, or a dull, chalky film. This phenomenon significantly degrades aesthetic appeal and can sometimes compromise surface integrity. Identifying the precise cause is crucial for effective remediation.

This issue commonly arises from chemical reactions or physical alterations during the machining and post-processing stages. Our comprehensive analysis focuses on eliminating these detrimental factors to restore optical quality.

Impact of Material Selection and Pre-treatment

The inherent properties of the aluminum alloy itself play a critical role in its susceptibility to white discoloration. Certain alloys, especially those with high silicon content or specific tempering states, can react differently to machining environments.

Improper material storage leading to surface oxidation or contamination prior to machining can also contribute. Surface films formed during pre-treatment, if not fully removed, can interact adversely with cutting fluids or cleaning agents.

Table: Aluminum Alloy Susceptibility to White Discoloration

| Alloy Type | Primary Characteristics | Susceptibility Factor |

|---|---|---|

| 6061 | Good strength-to-weight, weldability | Moderate |

| 7075 | High strength, common in aerospace | High (stress corrosion) |

| 5052 | Good corrosion resistance, formability | Low |

| Cast Aluminum Alloys | Porous structure, varied composition | High (surface reactivity) |

Issues with Cutting Fluid Selection and Cooling Methods

Cutting fluids are designed to lubricate, cool, and flush chips. However, incorrect fluid selection or poor maintenance can be a primary cause of white discoloration. Emulsified cutting fluids, if left to degrade or if their concentration is incorrect, can leave residues.

The pH balance of the cutting fluid is also critical; highly alkaline fluids can etch aluminum surfaces. Inadequate cooling can lead to localized overheating, affecting the surface metallurgy and promoting adverse reactions.

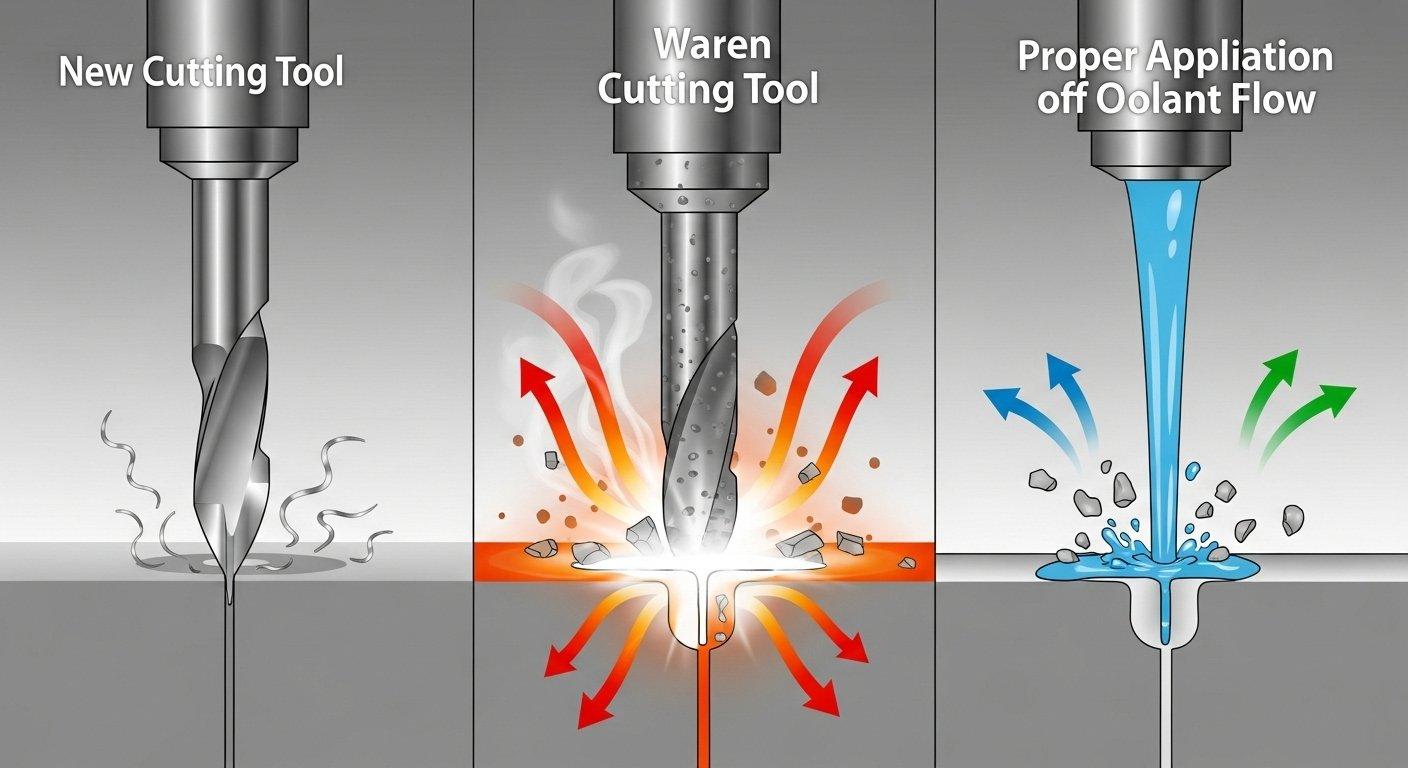

Tool Wear and Incompatible Cutting Parameters

Dull or improperly selected cutting tools generate excessive friction and heat during machining. This thermal stress can alter the aluminum surface, making it more prone to discoloration. Worn tools also produce a poor surface finish, which can appear as a white haze.

Incompatible cutting parameters, such as excessively high speeds or feeds without adequate cooling, exacerbate heat generation. This leads to localized annealing or micro-abrasions that change the surface’s light reflection properties, resulting in a whitish appearance.

Improper Post-processing Leading to White Spots

The post-machining cleaning and drying processes are critical. Using harsh cleaning agents, especially those with strong acids or bases that are incompatible with aluminum, can chemically etch the surface, creating a white, dull finish.

Incomplete rinsing of cleaning solutions or inadequate drying allows chemical residues to evaporate and leave behind white stains. Even exposure to certain atmospheric pollutants during drying can react with residual moisture.

Unraveling Black Discoloration Challenges in Aluminum CNC Machining

Black discoloration presents as dark streaks, spots, or a general darkening of the machined aluminum surface. This defect is typically indicative of oxidation, corrosion, or contamination that has chemically reacted with the aluminum.

Understanding the specific chemical interactions and environmental factors is essential for preventing blackening. Our systematic approach targets these root causes.

Influence of Material Alloy Composition and Impurities

The presence of certain alloying elements and impurities within the aluminum material itself can increase its susceptibility to blackening. For instance, alloys with higher copper or iron content are more prone to oxidation and corrosion under specific conditions.

Inclusions or segregation of these elements on the surface can act as cathodic sites, accelerating electrochemical reactions. Sourcing high-quality, certified material is a foundational step in prevention.

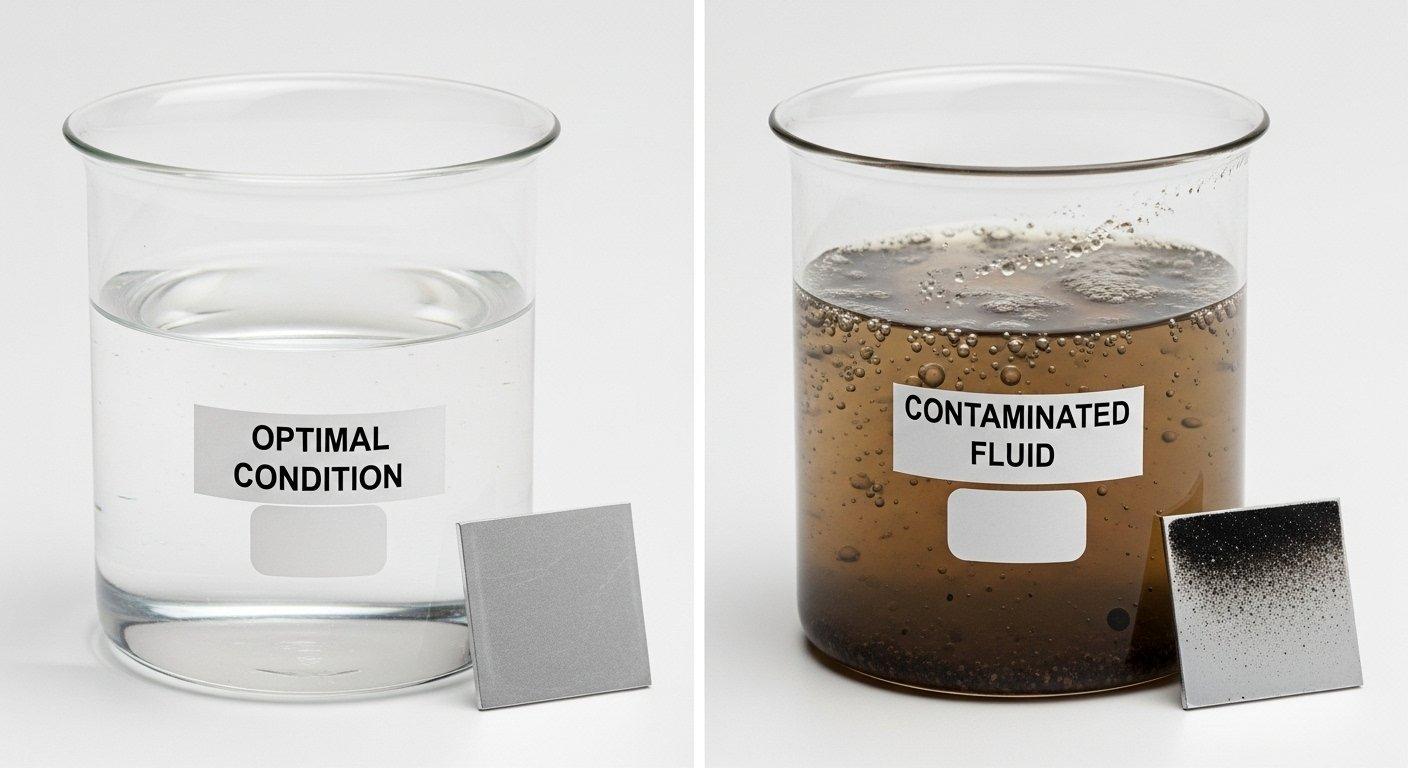

Cutting Fluid Contamination and Oxidative Corrosion

Cutting fluids that are contaminated with tramp oils, foreign particles, or microbial growth can become highly corrosive. These contaminants break down the fluid’s protective properties and introduce agents that react with aluminum.

Over time, cutting fluids can degrade, losing their pH stability and anticorrosive additives. This allows for electrochemical reactions between the aluminum surface and the fluid, leading to black oxide formation or pitting corrosion.

High-Temperature Machining and Heat Accumulation

Excessive heat generated during the machining process, particularly without effective cooling, can lead to localized oxidation of the aluminum surface. Aluminum readily forms an oxide layer, which can appear dark when formed under high heat.

Poor chip evacuation can also result in chips re-cutting or rubbing against the workpiece, causing localized hot spots. This thermal energy facilitates rapid oxidation, resulting in a dark, discolored appearance.

Inadequate Cleaning or Storage Environment Issues

After machining, if parts are not thoroughly cleaned, residual cutting fluid or metal particles can react with the aluminum. These residues, especially if they contain corrosive elements, will initiate black staining over time.

Improper storage conditions, such as high humidity, exposure to corrosive fumes, or prolonged contact with certain packaging materials, can accelerate surface oxidation. Even fingerprints, if left on the surface, can cause localized blackening.

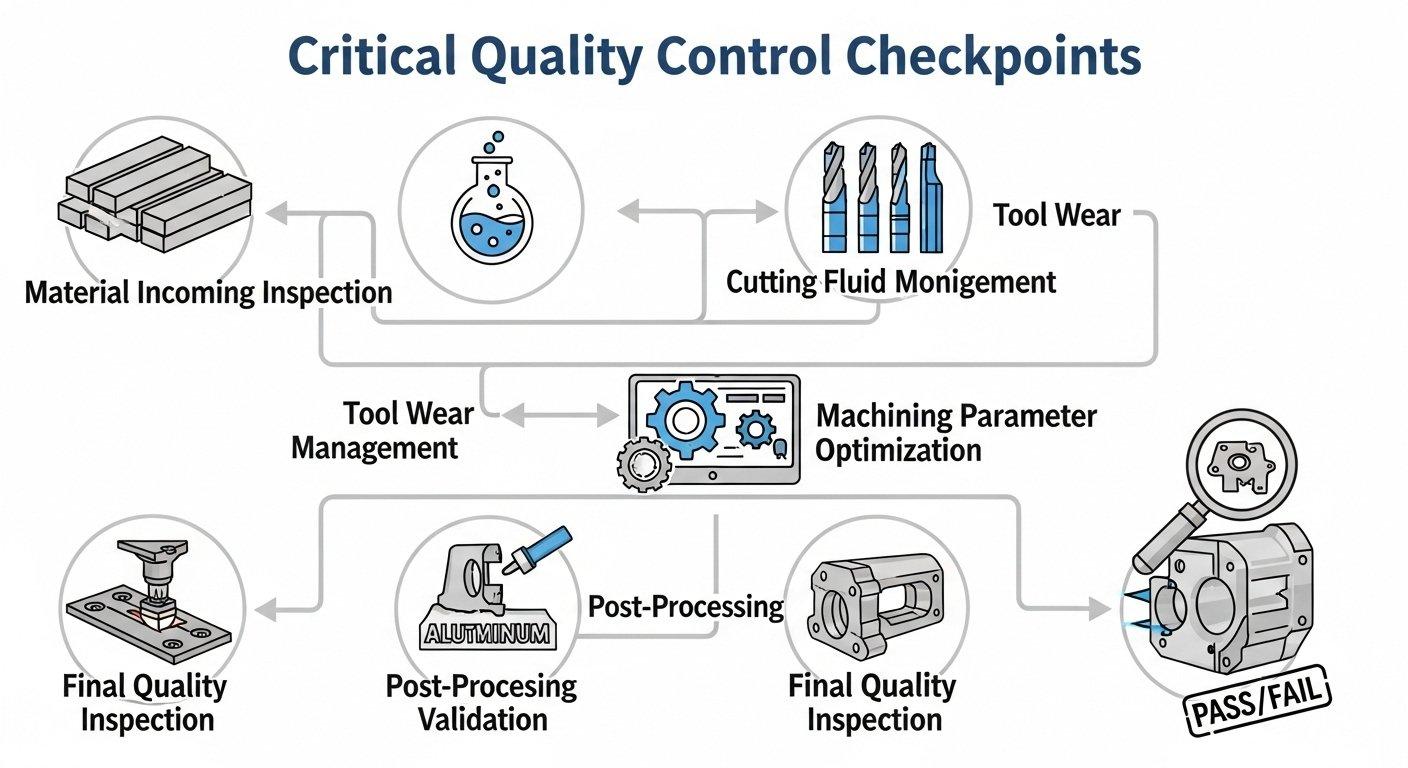

Preventing Aluminum Surface Defects: Critical CNC Machining Quality Control

Effective prevention of both white and black discoloration requires a holistic approach to quality control throughout the entire CNC machining process. From material reception to final packaging, each step must be meticulously managed. Our factory implements stringent protocols to ensure consistent surface quality.

We believe that proactive measures and a deep understanding of process variables are key to achieving flawless aluminum components. This comprehensive quality control framework minimizes defect rates.

Rigorous Material Inspection and Standardization Before Machining

All incoming aluminum materials undergo a strict quality inspection, including chemical composition analysis, hardness testing, and visual surface examination. We verify that materials meet specified standards and are free from pre-existing defects.

Our material storage practices are standardized to prevent contamination or surface degradation. This includes controlled environments and appropriate protective packaging, ensuring material integrity before processing.

Optimizing Cutting Fluid Management and Tooling Selection Strategies

We employ a comprehensive cutting fluid management program, including regular pH checks, concentration monitoring, filtration, and timely replacement. Only high-grade, aluminum-compatible cutting fluids are selected.

Tooling selection is based on the specific aluminum alloy and required surface finish. We use premium, sharp cutting tools with appropriate coatings, and implement strict tool wear monitoring and replacement schedules to prevent heat generation.

Table: Cutting Fluid and Tooling Optimization

| Parameter | Best Practice for Aluminum CNC Machining |

|---|---|

| Cutting Fluid Type | Synthetic or semi-synthetic with low sulfur content, good lubricity |

| pH Level | Maintain within manufacturer’s recommended range (typically 8.5-9.5) |

| Filtration | Continuous filtration to remove chips and contaminants |

| Tool Material | Carbide or PCD (Polycrystalline Diamond) for abrasion resistance |

| Tool Geometry | Sharp cutting edges, high rake angles, polished flutes |

| Tool Coating | TiN or AlTiN for reduced friction and extended tool life |

Precise CNC Machining Parameter Setting and Adjustment

Machining parameters such as spindle speed, feed rate, depth of cut, and coolant pressure are optimized for each specific aluminum alloy and part geometry. We conduct test runs and adjust parameters to minimize heat and achieve the desired surface finish.

Our engineers utilize advanced CAM software simulations to predict and prevent potential thermal issues or stress concentrations during cutting. This meticulous approach prevents surface alteration.

Controlled Post-processing and Storage Environment

Our post-processing protocols ensure thorough cleaning using aluminum-safe detergents and multi-stage rinsing processes. Parts are then rapidly and completely dried in controlled environments to prevent residue formation.

Finished parts are handled with care and stored in clean, climate-controlled environments, protected from humidity, dust, and corrosive agents. Appropriate packaging materials are used to prevent surface contact contamination during transit.

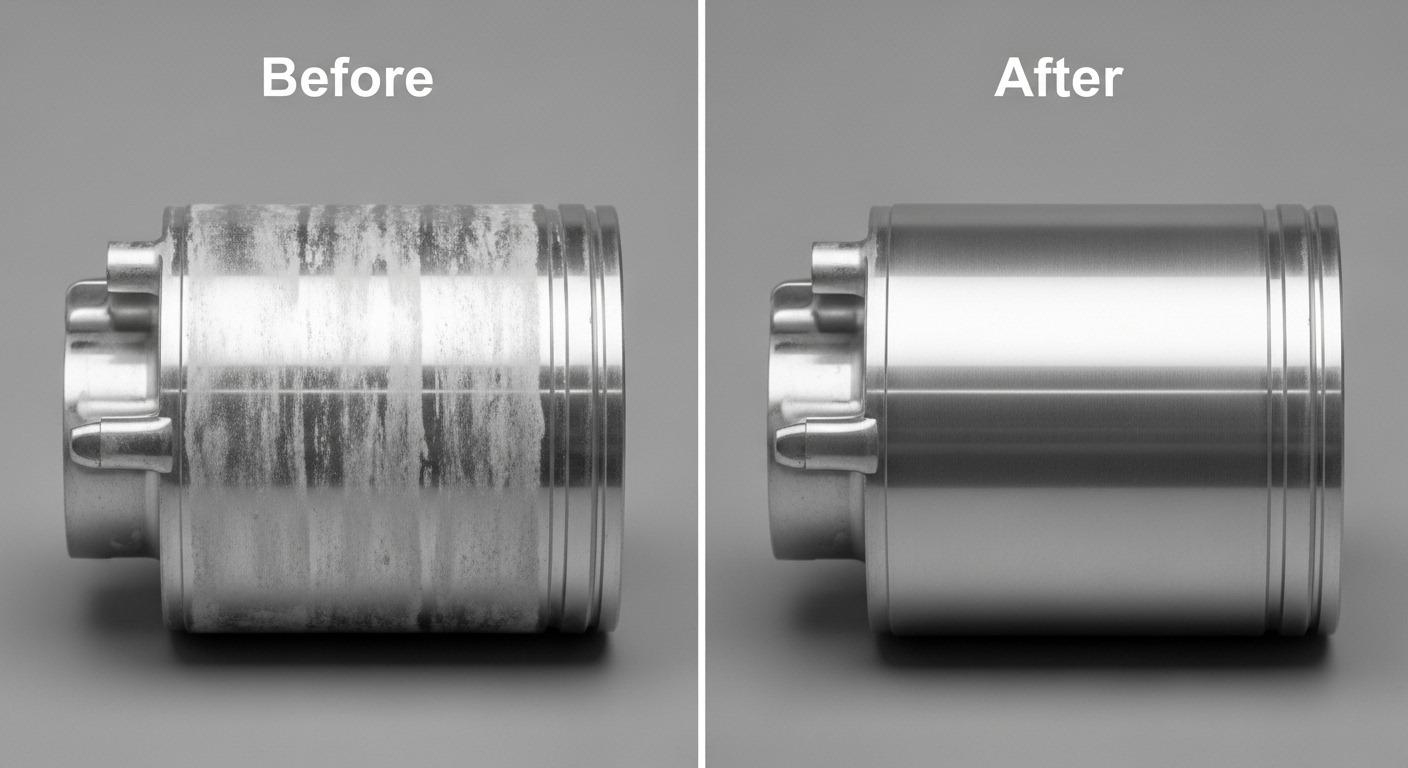

Case Studies: From Discoloration to Flawless Aluminum Quality

Our commitment to problem-solving is demonstrated through our successful interventions. We collaborate closely with clients, applying our technical expertise to transform challenging discoloration issues into consistent, high-quality outcomes. These cases highlight our capabilities.

Our detailed root cause analysis and custom-engineered solutions consistently deliver superior results. We focus on transparency and verifiable improvements in part quality.

White Discoloration Issue Diagnosis and Improvement for a Client

A client producing high-precision optical instrument housings experienced persistent white hazing on their 6061-T6 aluminum parts after machining. Initial attempts to resolve the issue focused on post-cleaning changes, but the problem persisted.

Our team conducted a thorough analysis, revealing that the client’s cutting fluid concentration was excessively high, leading to gummy residues that reacted with an aggressive cleaning agent. We recommended a specific cutting fluid recalibration and a gentler, multi-stage ultrasonic cleaning process. This eliminated the white haze completely.

Black Discoloration Problem Analysis and Resolution in a Project

Another client, manufacturing aerospace components from 7075-T6 aluminum, faced recurring black spots and streaks. This was particularly problematic for anodizing pre-treatment, causing significant scrap rates.

Our investigation traced the issue to two factors: high-sulfur content in their old cutting fluid, promoting galvanic corrosion, and inadequate drying before parts were temporarily stored in a humid environment. We implemented a low-sulfur, biocide-treated cutting fluid and introduced immediate, vacuum-assisted drying followed by climate-controlled storage. This entirely resolved the black discoloration, leading to a zero-defect rate for this specific issue.

Successful Case Summary and Experience Sharing

These cases underscore the importance of a holistic approach to CNC machining. Discoloration is rarely caused by a single factor but rather a combination of material, process, and environmental influences.

Our experience demonstrates that detailed root cause analysis, coupled with precise adjustments across the entire production chain, is essential. We share these insights to educate and empower our clients.

Choosing Expert CNC Machining: Ensuring Aluminum Surface Quality

Selecting a capable CNC machining partner is paramount to avoiding costly aluminum surface defects. At ly-machining, our status as a source factory, combined with deep technical expertise, provides a distinct advantage. We are dedicated to delivering not just parts, but perfect parts.

Our commitment to quality extends beyond basic specifications, focusing on comprehensive material and process control. We ensure your designs are realized with impeccable surface integrity.

Quality Assurance Advantages of a Source Factory

As a source manufacturer, we control every aspect of the production process, from raw material sourcing and inspection to final quality checks. This integrated approach ensures consistent quality and eliminates external variables often found with sub-contracted work.

Our direct control over manufacturing procedures allows for rapid identification and resolution of any potential issues. This vertical integration is a core pillar of our quality assurance.

Precise Technical Expertise and Transparent Quoting Services

Our engineering team possesses profound knowledge in metallurgy, machining dynamics, and surface science specific to aluminum alloys. This expertise allows us to provide proactive design for manufacturability (DFM) feedback and troubleshoot complex challenges.

We offer transparent quoting, detailing material costs, machining operations, and quality control measures. Our clients understand the value delivered through our rigorous processes and high-quality output.

Collaboration Process and Client Service Commitment

We believe in a collaborative partnership, working closely with clients from design conceptualization to final product delivery. Our technical support team is readily available to discuss project specifications and address any concerns.

Our commitment extends to ensuring timely delivery and consistent product performance. We stand behind the quality of every aluminum component we produce, fostering long-term, trust-based relationships.

Article Summary:

White and black discolorations on CNC machined aluminum parts are significant quality issues stemming from material properties, cutting fluid management, machining parameters, and post-processing. White hazing is often linked to chemical residues or thermal stress, while blackening typically indicates oxidation or corrosion. Effective prevention relies on rigorous material inspection, optimized cutting fluid and tooling strategies, precise parameter control, and meticulous post-processing and storage. Choosing a source factory like ly-machining, with deep technical expertise and integrated quality control, ensures the consistent delivery of flawless aluminum components, mitigating risks and enhancing product value.

FAQ Section:

Q1: Can different aluminum alloys have varying susceptibilities to surface discoloration?

A1: Yes, absolutely. Different aluminum alloys possess unique compositions and temper states that influence their reactivity. For instance, alloys with higher copper or silicon content may be more prone to specific types of discoloration due to their electrochemical potential or surface reactivity. It is critical to consider the alloy type when developing machining and post-processing protocols to prevent defects.

Q2: How does ly-machining ensure cutting fluid quality to prevent discoloration?

A2: We implement a multi-faceted cutting fluid management program. This includes using only high-quality, aluminum-compatible fluids, regular monitoring of pH levels and concentration, continuous filtration to remove contaminants and metal fines, and scheduled fluid replacement. Our system is designed to maintain optimal fluid integrity, preventing chemical degradation that could lead to surface reactions and discoloration.

Q3: What role does the storage environment play in preventing post-machining discoloration of aluminum parts?

A3: The storage environment is crucial. After cleaning and drying, aluminum parts are still susceptible to environmental factors. We ensure parts are stored in clean, climate-controlled areas with regulated humidity to prevent moisture-induced oxidation or corrosion. Furthermore, we use appropriate, non-reactive packaging materials to shield parts from atmospheric pollutants, dust, and direct contact that could lead to localized discoloration or contamination.