Optimizing CNC Aluminum: Surface Treatment Guide

The perfect CNC machined aluminum part is only as good as its surface. But with dozens of critical surface treatment options, how do you ensure you’re choosing the one that will prevent costly failures, optimize performance, and elevate your product’s aesthetics? The wrong choice can cut your part’s lifespan in half.

Strategic surface treatment is essential for CNC machined aluminum, enhancing durability, corrosion resistance, and aesthetic appeal. Selecting the correct process — from anodizing to chromate conversion or plating — ensures optimal part functionality, longevity, and cost-effectiveness, preventing premature failure and meeting specific application demands.

Why Strategic Surface Treatment Elevates Aluminum Parts

Aluminum is a versatile material, valued for its strength-to-weight ratio and machinability. However, its natural properties often require enhancement to meet the demanding specifications of various industries. Surface treatments are not merely cosmetic; they are critical engineering steps.

These processes fundamentally alter the part’s outermost layer, imparting properties that raw aluminum lacks. This strategic approach ensures the finished component performs reliably in its intended environment, whether it’s an aerospace bracket or a medical device housing.

Enhanced Durability and Corrosion Resistance for Aluminum CNC Components

Untreated aluminum can be susceptible to wear and environmental degradation, especially in harsh conditions. Surface treatments like anodizing or chromate conversion create a protective barrier. This layer significantly boosts the part’s resistance to corrosion, abrasion, and chemical exposure.

For applications in marine, automotive, or outdoor environments, this enhanced protection is non-negotiable. It safeguards the structural integrity and extends the operational life of critical aluminum CNC components.

Improved Aesthetics and Functional Performance of Machined Aluminum

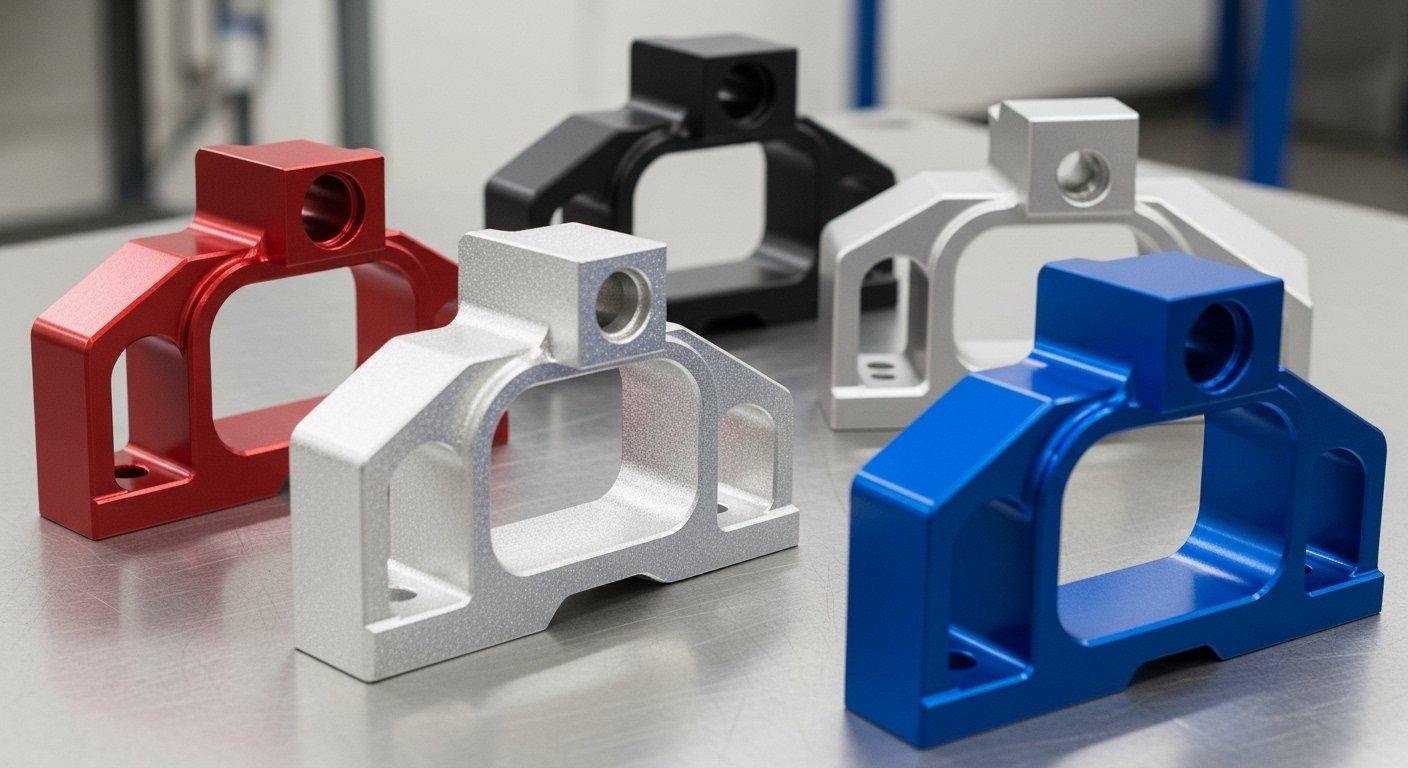

Beyond protection, surface treatments offer a vast range of aesthetic possibilities. Parts can be dyed in various colors during anodizing, or coated for specific textures and sheens. This allows for precise branding and integration into product designs.

Functionally, treatments can improve surface hardness, reduce friction, or alter electrical conductivity. These tailored properties are crucial for optimizing mechanical performance and ensuring the machined aluminum components meet precise operational requirements.

Impact on Product Lifespan and Cost Efficiency in Aluminum Surface Finishing

The upfront investment in proper aluminum surface finishing translates directly into long-term savings. By preventing premature failure, reducing maintenance needs, and extending product lifespan, these treatments mitigate costly replacements and warranty claims.

Furthermore, a well-chosen surface treatment can simplify downstream assembly by providing specific electrical or thermal properties. This optimization of the entire product lifecycle underscores the economic value of expert surface finishing.

Unveiling Key Aluminum Surface Treatment Processes

Understanding the specific characteristics of each surface treatment is vital for making informed decisions. Each process offers unique advantages and is best suited for particular applications, balancing performance, aesthetics, and cost.

Our factory utilizes a comprehensive array of advanced finishing techniques. We ensure that every CNC machined aluminum part receives the optimal treatment for its intended function and environment.

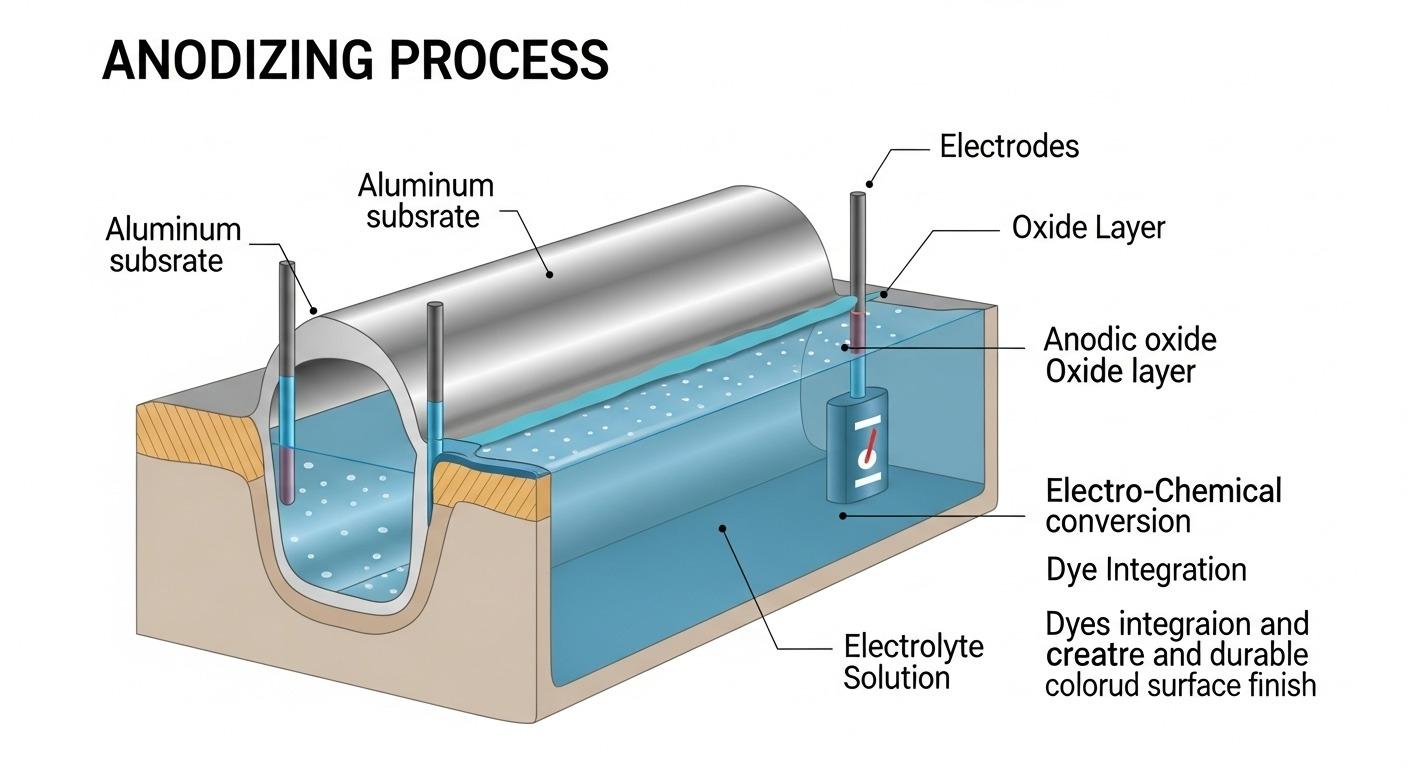

Anodizing: Type II (Sulfuric) and Type III (Hardcoat) for CNC Aluminum

Anodizing is an electrolytic passivation process that increases the thickness of the natural oxide layer on the surface of aluminum parts. This engineered layer offers significantly enhanced corrosion and wear resistance.

The two most common types, Type II (Sulfuric Anodizing) and Type III (Hardcoat Anodizing), cater to different performance requirements. Our expertise ensures precise control over the anodizing parameters for consistent, high-quality results.

| Anodizing Type | Key Characteristics | Typical Thickness | Primary Applications |

|---|---|---|---|

| Type II | Good corrosion and abrasion resistance, accepts dyes | 2.5 – 25 µm | Consumer electronics, architectural, decorative components |

| Type III | Excellent hardness and wear resistance, thick layer | 25 – 150 µm | Aerospace, military, hydraulic cylinders, high-wear parts |

Chromate Conversion Coating (Alodine/Iridite) for Aluminum Protection

Chromate conversion coating, often known by trade names like Alodine or Iridite, produces a thin, gelatinous film on aluminum surfaces. This coating offers excellent corrosion resistance and acts as an ideal primer for paint or other coatings.

It is particularly valued for its ability to maintain electrical conductivity, unlike anodizing. This makes it a preferred choice for electronic enclosures and components requiring grounding.

| Chromate Coating Feature | Description |

|---|---|

| Corrosion Resistance | Provides excellent protection against oxidation and salts. |

| Electrical Conductivity | Maintains low electrical resistance for grounding. |

| Paint Adhesion | Creates a superior base for subsequent painting or coating. |

| Coating Thickness | Very thin, typically less than 1 µm, preserves dimensional accuracy. |

Electroless Nickel Plating for Enhanced Aluminum Durability

Electroless Nickel Plating (ENP) deposits an autocatalytic nickel-phosphorus alloy without external electric current. This process yields an extremely uniform coating, even on complex geometries and internal surfaces.

ENP offers exceptional hardness, wear resistance, and corrosion protection. It is often chosen for parts requiring high lubricity, such as gears and pistons, or for applications where precise tolerances are critical.

Powder Coating and Liquid Painting Options for Aesthetic Aluminum Parts

For comprehensive aesthetic and protective layering, powder coating and liquid painting are excellent choices. Powder coating applies a dry powder that is then cured under heat, forming a hard, durable finish. Liquid painting offers a wider range of colors and specialized finishes.

Both methods provide robust protection against scratches, chips, and UV exposure. They are widely used across consumer goods, automotive, and industrial sectors to achieve specific visual and tactile qualities for aluminum parts.

Mechanical Finishes: Polishing, Brushing, Blasting for Aluminum Aesthetics

Mechanical finishes alter the surface texture of aluminum through abrasive processes. Polishing creates a mirror-like shine, brushing imparts a satin, directional grain, and blasting (e.g., bead blasting, sandblasting) produces a uniform matte or textured appearance.

These processes are often used as standalone finishes or as preparatory steps for further treatments. They are crucial for achieving specific aesthetic requirements and can influence how a part interacts with light or other surfaces.

<div class=”italic text-center text-gray-500 bg-gray-100 border border-d