Optimizing CNC Aluminum: A Guide to Surface Treatments

Are you facing challenges with the durability, aesthetics, or performance of your CNC machined aluminum parts? Suboptimal surface treatments can compromise structural integrity, lead to premature wear, or fail to meet critical application requirements, costing valuable time and resources. At ly-machining, we offer expert guidance and comprehensive solutions for selecting and applying the ideal surface treatment, ensuring your aluminum components achieve their full potential.

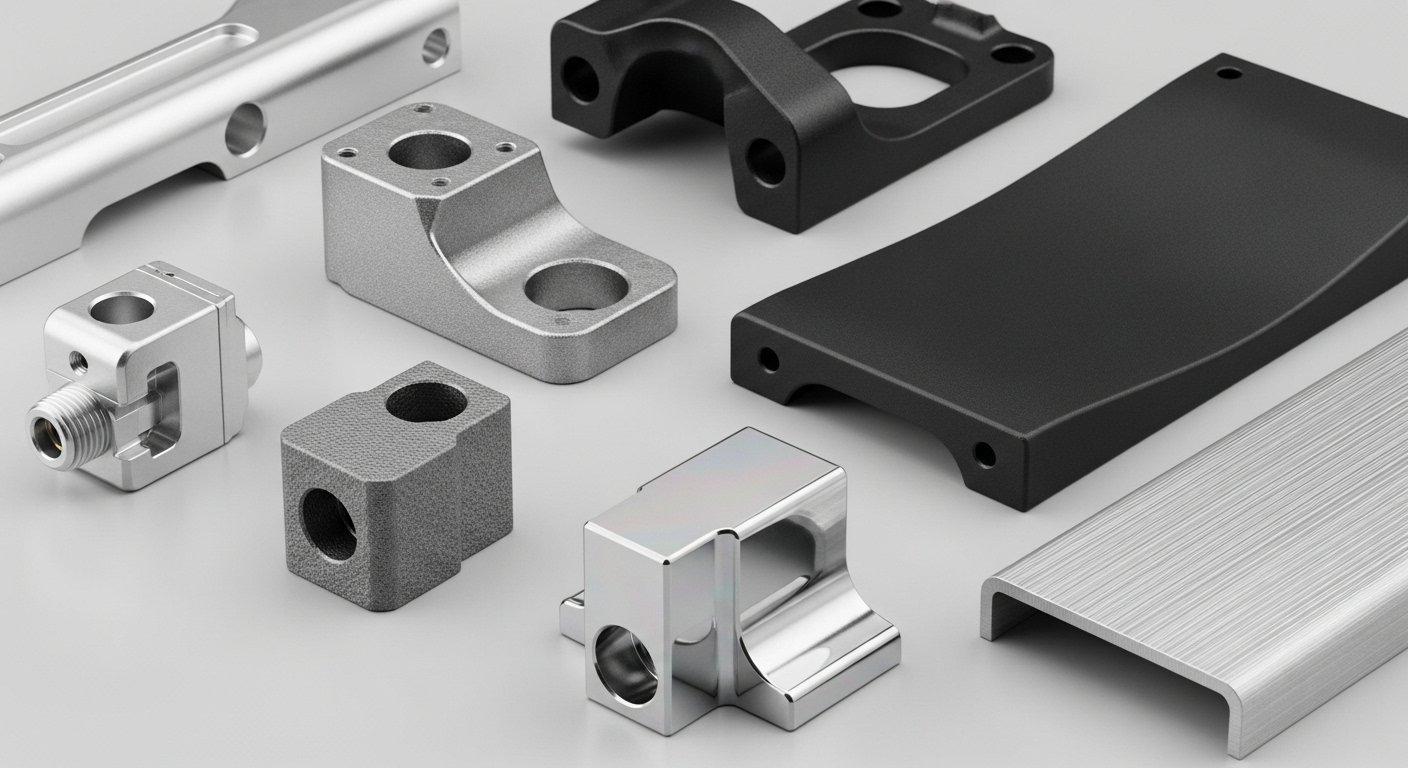

For CNC machined aluminum, selecting the right surface treatment is crucial for enhancing durability, corrosion resistance, and aesthetics. Common methods include anodizing (Type II, Type III), chemical conversion coatings, powder coating, painting, and various mechanical finishes. Each offers distinct advantages tailored to specific functional and visual requirements, optimizing part performance.

Why Post-Machining Finish Elevates Aluminum Parts

The performance and longevity of CNC aluminum parts extend far beyond their initial machining. The chosen post-machining finish is a critical factor that directly impacts how a component performs in its intended application. It is not merely a cosmetic choice but a strategic engineering decision.

Applying the correct aluminum surface treatment can significantly enhance a component’s functional properties and visual appeal. This step is essential for protecting the base material, improving its operational life, and ensuring it meets precise design specifications.

Enhancing Durability and Corrosion Resistance

Aluminum, while lightweight and strong, can be susceptible to wear, abrasion, and certain corrosive environments. Surface treatments create a protective layer or alter the surface properties, dramatically improving the material’s resilience. This directly translates to longer service life and reduced maintenance.

Corrosion resistance is particularly vital for components exposed to moisture, chemicals, or harsh atmospheric conditions. A well-selected finish acts as a barrier, preventing degradation and maintaining the integrity of the CNC aluminum finish.

Achieving Desired Aesthetics and Functionality

Beyond protection, surface treatments allow for precise control over the visual characteristics of a part. From smooth, high-gloss finishes to uniform matte textures, the aesthetic options are vast. This enables designers to meet specific branding or product integration requirements.

Functionality is also directly impacted. Treatments can improve electrical insulation, enhance heat dissipation, provide a non-stick surface, or even offer a specific coefficient of friction. The right aluminum post-machining finish ensures the part performs optimally in its intended role.

Anodizing Processes for Superior Aluminum Surfaces

Anodizing is an electrochemical passivation process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. It is one of the most popular aluminum surface treatment methods, offering excellent protection and a wide range of aesthetic options.

The process involves submerging the aluminum part into an acid electrolyte bath and passing an electric current through it. This oxidizes the surface, creating a porous film that can be dyed various colors before sealing.

Type II Sulfuric Acid Anodizing (Standard)

Type II sulfuric acid anodizing is the most common anodizing process, producing a coating thickness typically between 0.0001 to 0.001 inches (2.5 to 25 microns). It offers good corrosion and abrasion resistance, making it suitable for a broad array of applications.

This process is highly amenable to dyeing, allowing for a wide spectrum of colors, from vibrant hues to subtle tones. It provides an aesthetically pleasing and functional CNC aluminum finish for many consumer and industrial products.

Type III Hard Coat Anodizing (Enhanced Durability)

Type III hard coat anodizing, also known as hard anodizing, produces a significantly thicker and denser oxide layer, typically ranging from 0.001 to 0.002 inches (25 to 50 microns) or more. This process enhances wear resistance, making the aluminum surface extremely hard.

It is ideal for applications requiring exceptional durability, such as aerospace components, military equipment, and high-wear industrial parts. The resulting finish is typically dark gray to bronze, and while it can be dyed, the color range is more limited due to the thickness.

Chromic Acid Anodizing (Type I, Thin Film)

Type I chromic acid anodizing produces a very thin, dense anodic film, typically 0.00002 to 0.0001 inches (0.5 to 2.5 microns) thick. It offers good corrosion resistance without significantly impacting the fatigue strength of the part.

Due to its thinness, it is often preferred for intricate parts, assemblies with tight tolerances, or components where minimizing electrical resistance is crucial. The finish is typically a non-dyed opaque gray or dull green.

Here is a comparison of common anodizing types:

| Anodizing Type | Typical Thickness (microns) | Key Benefits | Common Applications |

|---|---|---|---|

| Type I (Chromic) | 0.5 – 2.5 | High corrosion resistance, minimal thickness | Aerospace, critical assemblies, tight tolerances |

| Type II (Sulfuric) | 2.5 – 25 | Good corrosion/abrasion, wide color options | Consumer electronics, architectural, decorative |

| Type III (Hard Coat) | 25 – 50+ | Excellent wear, superior hardness, high durability | Aerospace, military, hydraulic cylinders, medical |

Chemical Conversion Coatings for Aluminum Protection

Chemical conversion coatings provide a thin, protective layer on aluminum surfaces through a chemical reaction. These coatings are primarily used for corrosion protection, adhesion promotion for subsequent painting, and maintaining electrical conductivity.

They are an excellent option when a lightweight, electrically conductive, or primer-ready finish is required, without the thickness of anodizing or organic coatings.

Chromate Conversion Coating (Alodine/Iridite)

Chromate conversion coating, often referred to by brand names like Alodine or Iridite, creates a gel-like film containing hexavalent or trivalent chromium. This film offers excellent corrosion resistance and serves as an ideal primer for paint and adhesives.

It is applied by dipping, spraying, or brushing and typically results in a gold, brown, or clear finish. These coatings are widely used in aerospace, military, and electronics industries for their reliable performance and conductivity.

Non-Chrome Conversion Coatings (RoHS Compliant Options)

With increasing environmental regulations and the need for RoHS compliance, non-chrome conversion coatings have emerged as a viable alternative. These processes use different chemistries, such as zirconium or titanium, to achieve similar protective properties without hexavalent chromium.

They provide good corrosion resistance and paint adhesion, making them suitable for many applications, particularly in Europe and for products requiring green certifications. Finishes are typically clear or slightly iridescent.

Here is a comparison of chemical conversion coatings:

| Coating Type | Key Benefits | Typical Finish Color | Environmental Compliance |

|---|---|---|---|

| Chromate Conversion | Excellent corrosion, superb paint adhesion, conductive | Clear, gold, brown | Contains Hexavalent Cr |

| Non-Chrome Conversion | Good corrosion, good paint adhesion, conductive | Clear, iridescent | RoHS Compliant, Chromium-free |

Organic Coatings: Paint and Powder Coat for Aluminum

Organic coatings, such as liquid paint and powder coating, provide robust and aesthetically versatile finishes for CNC aluminum parts. These methods involve applying a layer of organic material that cures to form a durable protective and decorative film.

They are chosen for their wide color palette, ability to cover minor surface imperfections, and excellent protective qualities against corrosion, chemicals, and UV radiation.

Powder Coating for Robust, Diverse Finishes

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto the electrically grounded aluminum surface. The parts are then heated in an oven, causing the powder to melt and flow into a uniform, durable, and solid finish.

This method offers exceptional chip resistance, abrasion resistance, and chemical resistance. It also provides a wide range of colors, textures (matte, gloss, textured), and thicknesses, making it popular for automotive, architectural, and appliance parts. The application is environmentally friendly, with minimal VOCs.

Liquid Painting for Precision Aesthetics

Liquid painting involves applying a wet paint solution, typically consisting of pigments, binders, solvents, and additives, to the aluminum surface. It can be applied in very thin layers, allowing for high precision, intricate designs, and specific aesthetic effects like metallic or high-gloss finishes.

This method is often preferred for applications requiring very smooth, high-end aesthetics, fine color matching, or when complex masking patterns are involved. It is common in aerospace, medical, and high-end consumer electronics.

Here is a comparison of organic coatings:

| Coating Type | Application Method | Key Benefits | Durability | Aesthetic Versatility |

|---|---|---|---|---|

| Powder Coating | Electrostatic spray, oven cure | High durability, chip/abrasion resistance, eco-friendly | Excellent | Wide range of colors/textures |

| Liquid Painting | Spray, dip, brush, air dry/bake | Precision aesthetics, fine finishes, custom colors | Good to Excellent | Highly precise, custom effects |

Specialized Plating Solutions for Aluminum Components

While aluminum is generally not plated directly with processes like electroplating due to its active nature, specialized pre-treatment steps enable various plating solutions. These methods impart unique surface properties not achievable with other finishes.

Plating can add hardness, lubricity, electrical conductivity, or specific aesthetic qualities, broadening the functional scope of CNC aluminum parts.

Electroless Nickel Plating (ENP) on Aluminum

Electroless nickel plating (ENP) is a chemical reduction process that deposits a uniform layer of nickel-phosphorus alloy without the need for an external power source. This coating provides excellent corrosion resistance, hardness, and wear resistance.

It is particularly valuable for complex geometries, as the autocatalytic nature of the process ensures uniform coating thickness even in recessed areas. ENP is widely used in automotive, aerospace, and medical industries for its protective and functional properties.

Other Niche Plating Methods for Specific Needs

Beyond ENP, other specialized plating methods can be applied to aluminum following proper pre-treatment. These include:

* **Electroless Copper:** For EMI shielding or as a base for subsequent plating.

* **Electroless Gold:** For electrical contacts, providing excellent conductivity and corrosion resistance.

* **Electroless Silver:** For high electrical conductivity and aesthetic appeal.

These niche plating solutions address very specific performance requirements where other finishes may not suffice.

Here is a brief overview of selected plating options for aluminum:

| Plating Type | Key Properties | Typical Thickness (microns) | Common Use Cases |

|---|---|---|---|

| Electroless Nickel (ENP) | Excellent hardness, wear, corrosion resistance, uniform coating | 5 – 75 | Automotive, aerospace, medical, molds |

| Electroless Copper | High electrical conductivity, EMI shielding | 1 – 10 | Electronics, shielding, base for other platings |

| Electroless Gold | Superior electrical conductivity, corrosion resistance | 0.5 – 2 | Electrical contacts, high-reliability connectors |

Mechanical Finishes to Refine Aluminum Surfaces

Mechanical finishes alter the surface texture and appearance of CNC aluminum parts through physical abrasion or deformation. These methods do not add a layer but refine the existing surface, influencing both aesthetics and tactile feel.

They can remove machining marks, achieve specific gloss levels, or create uniform matte textures, providing a foundational finish for subsequent treatments or serving as the final desired appearance.

Polishing and Buffing for High Luster

Polishing and buffing are abrasive processes that smooth the aluminum surface, removing scratches, tool marks, and minor imperfections. Polishing uses coarser abrasives to refine the surface, while buffing uses finer compounds to achieve a high-gloss, mirror-like finish.

These processes are labor-intensive but result in exceptionally bright and reflective surfaces, often desired for decorative or highly visible components. The result is a premium CNC aluminum finish.

Bead Blasting and Sand Blasting for Uniform Matte

Bead blasting (using glass beads) and sand blasting (using sand or other abrasive media) involve propelling abrasive particles at high velocity onto the aluminum surface. This creates a uniform, diffused matte finish, removing glare and providing a consistent texture.

Bead blasting generally produces a smoother, satin-like matte finish, while sand blasting creates a rougher, more aggressive texture. These methods are excellent for aesthetic uniformity, preparing surfaces for painting, or reducing reflectivity.

Brushing and Graining for Textured Effects

Brushing and graining create directional texture lines on the aluminum surface. Brushing uses abrasive belts or brushes to create long, parallel lines, offering a distinct, elegant look. Graining is a similar process but often produces a finer, more subtle texture.

These finishes are popular for architectural elements, consumer electronics, and decorative panels where a specific tactile and visual pattern is desired. They provide a sophisticated aluminum post-machining finish.

Here is a comparison of mechanical finishes:

| Mechanical Finish | Surface Effect | Primary Benefit | Common Applications |

|---|---|---|---|

| Polishing/Buffing | Smooth, reflective, high-gloss | Aesthetic appeal, reduced friction | Decorative, medical, optical |

| Bead Blasting | Uniform satin matte | Reduced glare, paint preparation, aesthetic | Automotive, consumer electronics, industrial |

| Sand Blasting | Uniform rough matte | Aggressive texture, improved grip | Industrial, heavy-duty applications |

| Brushing/Graining | Directional textured lines | Aesthetic appeal, haptic feel | Architectural, consumer goods, panels |

Selecting the Optimal Treatment for Your Aluminum Project

Choosing the correct aluminum surface treatment is a multifaceted decision that requires careful consideration of various factors. At ly-machining, our deep technical expertise ensures you make an informed choice that balances performance, aesthetics, and cost.

As a source manufacturer, we understand the intricacies of CNC aluminum finish options and their interactions with your specific part design and application. We provide transparent pricing and expert consultation.

Key Factors: Application, Cost, Performance, Appearance

* **Application Environment:** Will the part be exposed to chemicals, moisture, extreme temperatures, or wear? This dictates the required corrosion and abrasion resistance.

* **Performance Requirements:** Are specific properties like electrical conductivity, insulation, hardness, or lubricity crucial?

* **Aesthetics:** What visual appearance is desired – color, gloss level, texture, and uniformity?

* **Budget:** Cost varies significantly between treatments, influenced by complexity, volume, and material.

* **Tolerances:** Some treatments, like hard anodizing, add thickness that must be accounted for in design.

* **Material Alloy:** Different aluminum alloys react differently to certain treatments.

Our Expertise in Custom Surface Finishing Solutions

At ly-machining, we leverage our deep technical expertise and comprehensive manufacturing capabilities to guide you through the selection process. We are not just a supplier; we are your strategic partner in optimizing your CNC aluminum components.

We take pride in delivering high-quality parts that meet the most stringent specifications. For instance, a leading aerospace client approached us with a challenging requirement for a lightweight aluminum component needing extreme corrosion resistance and a specific aesthetic finish. Through our advanced anodizing processes and rigorous quality control, we delivered parts that not only met but exceeded their stringent specifications, ensuring critical flight safety and extending component lifespan. This partnership showcased our ability to tackle complex challenges with precision and high-quality parts manufacturing. We ensure every CNC aluminum finish is perfectly suited to its purpose.

Summary:

Selecting the optimal surface treatment is crucial for CNC aluminum parts, impacting durability, aesthetics, and functionality. This guide explored various methods including anodizing (Type I, II, III), chemical conversion coatings, organic coatings (powder coating, liquid painting), specialized plating, and mechanical finishes (polishing, blasting, brushing). Each method offers unique advantages tailored to specific application requirements, material properties, and design considerations. Partnering with an expert source manufacturer like ly-machining ensures precision, quality, and optimal performance for your aluminum components.

FAQ Section:

Q1: How do I choose between Type II and Type III anodizing for my CNC aluminum parts?

A1: The choice between Type II (standard) and Type III (hard coat) anodizing depends primarily on your application’s requirements for wear resistance and hardness. Type II is suitable for general-purpose applications needing good corrosion resistance and decorative colors, with a coating thickness of 2.5 to 25 microns. Type III is specified for extreme wear resistance, higher hardness, and enhanced durability, with a thicker coating of 25 to 50+ microns, often used for aerospace or military components. Consider the operational environment and the required lifespan of the part.

Q2: What are the main benefits of using chemical conversion coatings on aluminum compared to anodizing?

A2: Chemical conversion coatings, like chromate or non-chrome options, offer distinct advantages over anodizing when a very thin, electrically conductive, or paint-ready finish is needed. They provide excellent corrosion protection without significantly adding thickness, preserving tight tolerances. Unlike anodizing, they retain the aluminum’s electrical conductivity and are often used as a primer for subsequent painting or for EMI shielding. They are generally more cost-effective for these specific applications where a thick, hard layer is not necessary.

Q3: Can ly-machining provide advice on material selection for CNC aluminum parts in conjunction with surface treatments?

A3: Yes, absolutely. As an expert source manufacturer with deep technical expertise, ly-machining provides comprehensive guidance on both material selection and optimal surface treatments. Different aluminum alloys (e.g., 6061, 7075) react uniquely to various treatments, impacting adhesion, color, and final properties. Our engineering team can consult on the best alloy choice for your specific functional requirements, ensuring compatibility with the desired finish to achieve the highest quality parts and performance for your project.