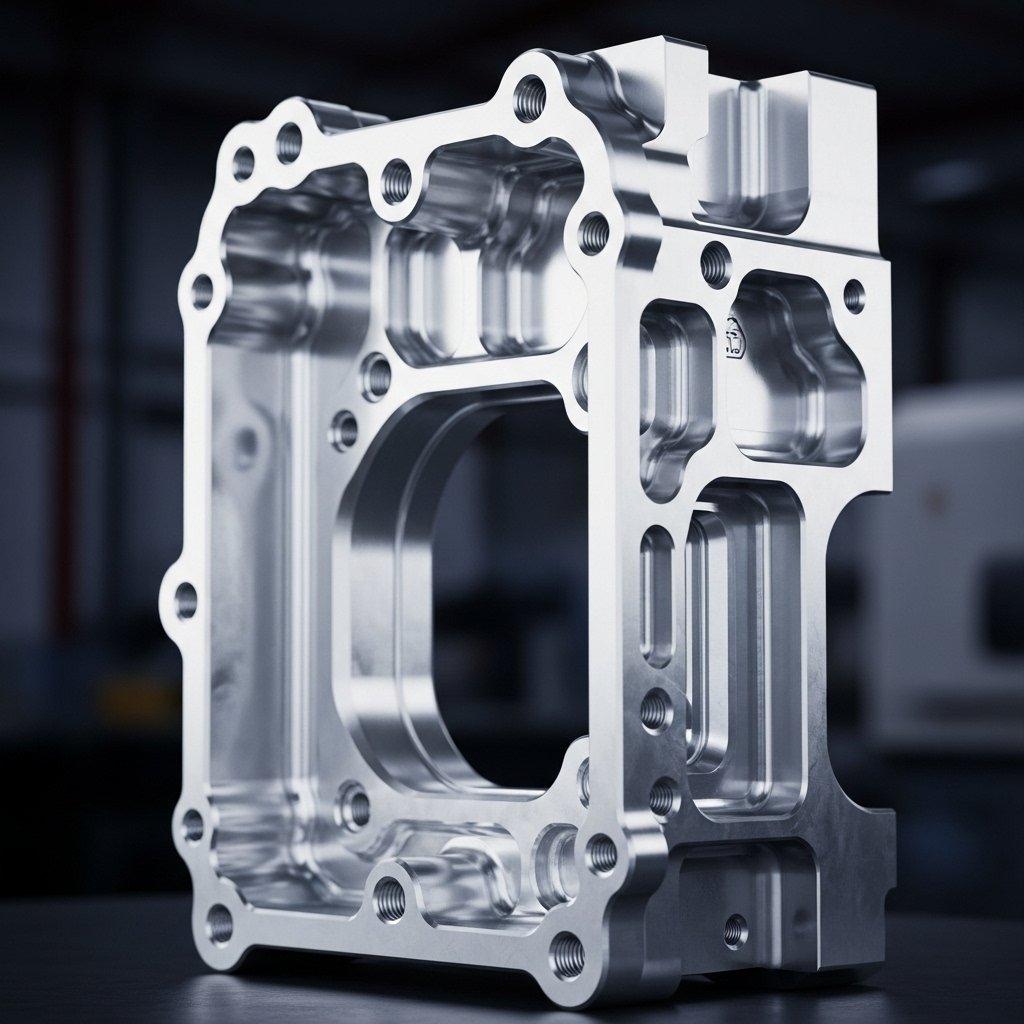

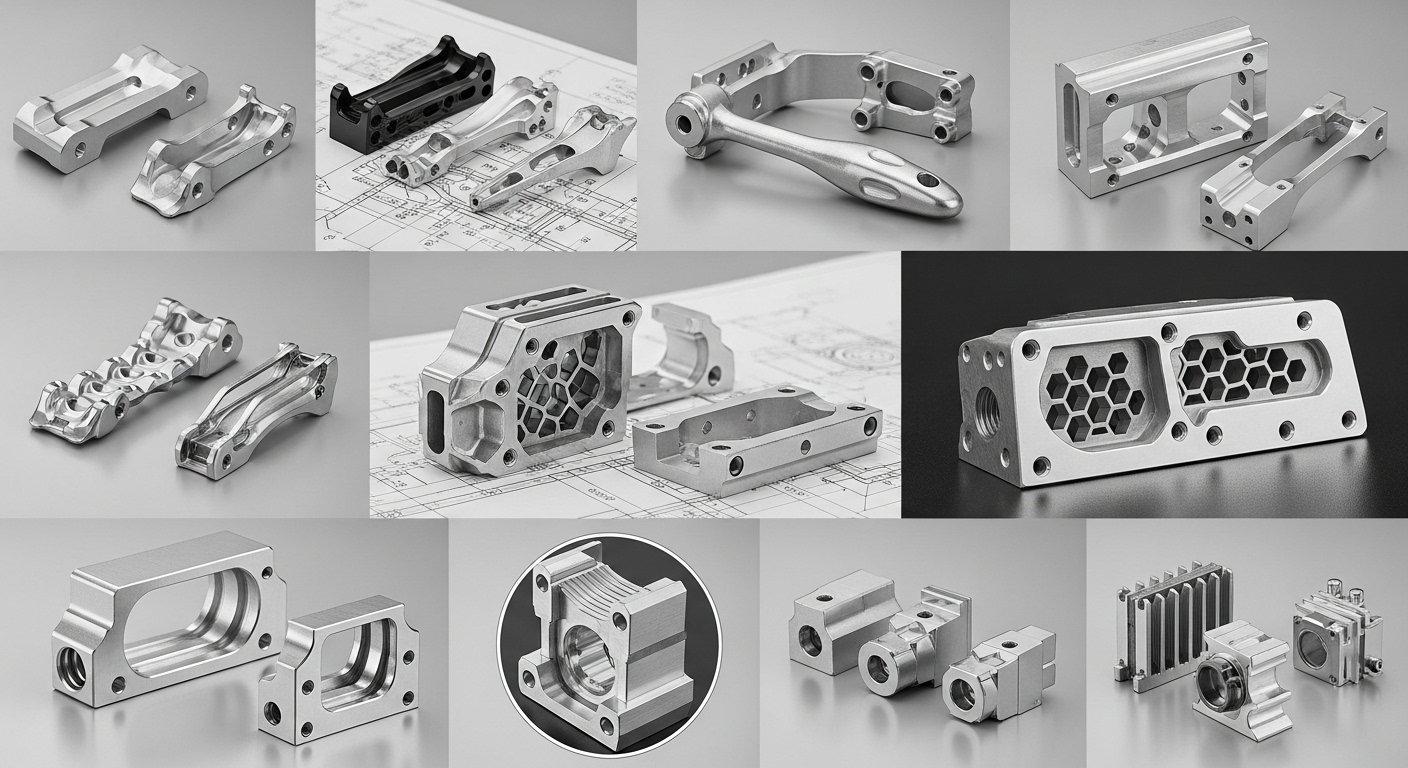

Understanding Quality Standards for Aluminum CNC Machined Parts

Inconsistent quality standards for aluminum CNC machined parts can severely impact project timelines, budgets, and overall reputation. Manufacturers often struggle with rework, scrap, and project delays when components fail to meet precise specifications. Discovering a reliable partner who understands and consistently adheres to stringent quality benchmarks is paramount for project success.

Ensuring uncompromised quality in aluminum CNC machined parts involves rigorous adherence to dimensional tolerances, surface finish specifications, and material integrity protocols. Leading manufacturers employ advanced inspection techniques and process controls to deliver precise, reliable components that meet the most demanding industry benchmarks, safeguarding project success.

Why Aluminum CNC Part Quality Standards Matter

The quality of aluminum CNC machined parts directly influences the performance and longevity of the final product. Subpar components can lead to premature failure, operational inefficiencies, and costly recalls, undermining brand reputation and customer trust. Adherence to strict quality standards mitigates these risks effectively.

Poor quality parts, even those with minor deviations, can cause assembly issues and interoperability problems within complex systems. This necessitates extensive rework or complete replacement, incurring significant financial penalties and project delays for clients.

Impact on Performance and Product Durability

Aluminum’s unique properties, such as its high strength-to-weight ratio and corrosion resistance, are fully leveraged only when parts are manufactured to precise standards. Any deviation can compromise these inherent advantages, affecting the part’s structural integrity and expected lifespan.

Critical applications, such as those in aerospace or medical devices, demand zero defects. Here, component failure due to insufficient quality can have catastrophic consequences, emphasizing the absolute necessity of rigorous quality control throughout the manufacturing process.

Cost Implications of Subpar Quality Parts

The financial repercussions of low-quality aluminum CNC parts extend far beyond the initial manufacturing cost. They include expenses for re-machining, additional inspection, and disposal of scrapped parts. Downtime in assembly lines due to faulty components also adds substantial indirect costs.

Clients face increased operational costs, warranty claims, and potential litigation stemming from product failures caused by unreliable parts. Partnering with a manufacturer prioritizing quality from the outset is a strategic investment that yields long-term savings and reliability.

Key Dimensional Tolerances for Aluminum CNC Machined Parts

Achieving the required dimensional accuracy is fundamental for the functionality and fit of aluminum CNC components. These tolerances define the permissible variations from a part’s nominal dimensions, ensuring components mate correctly and perform as intended.

Precision machining relies on advanced equipment and skilled technicians to maintain these tight tolerances. Consistent calibration and environmental controls within the machining facility are crucial to prevent thermal expansion or contraction from affecting part dimensions.

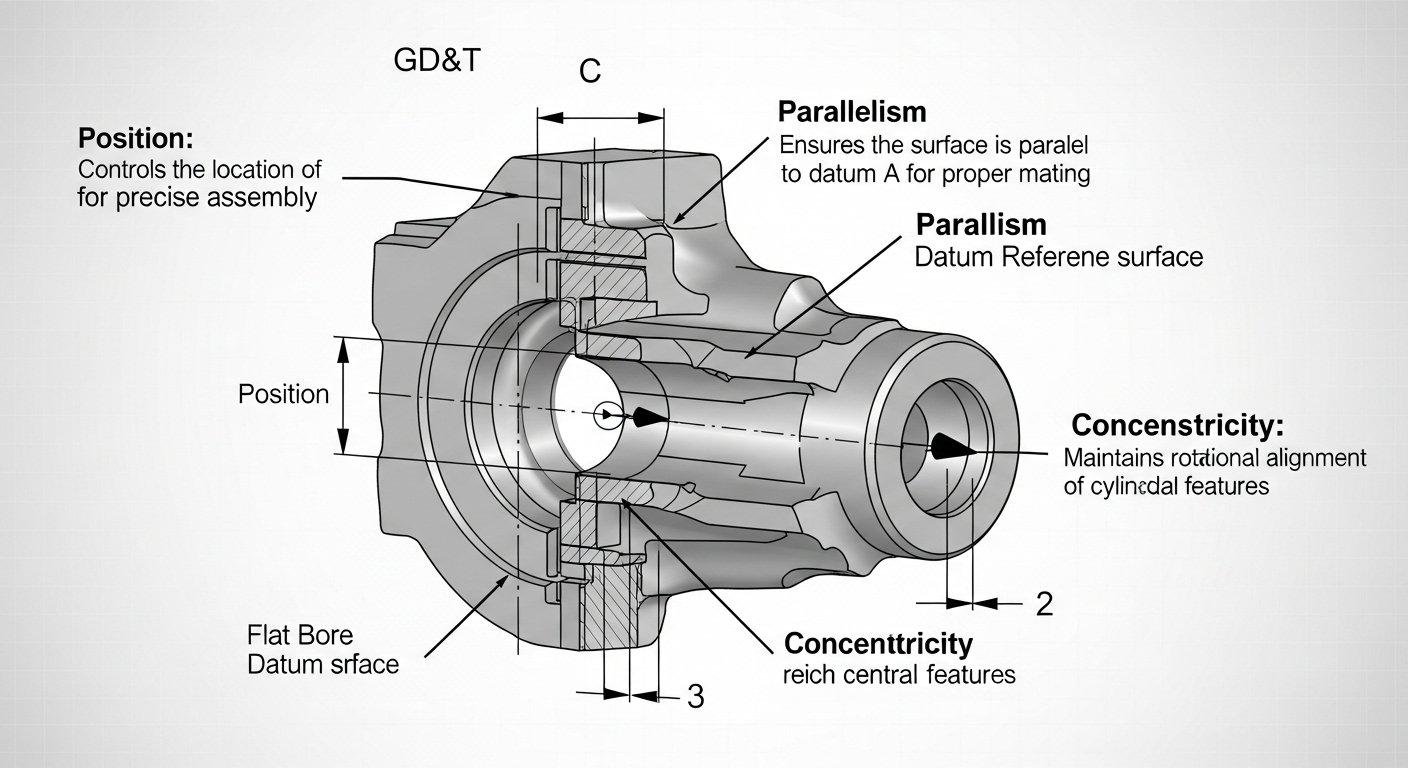

Geometric Dimensioning and Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to define the nominal geometry of a part and its permissible variation. It specifies not just size, but also form, orientation, and location tolerances for critical features.

GD&T is indispensable for aluminum parts used in assemblies where exact fit and interchangeability are paramount. It ensures that components from different production batches will consistently meet functional requirements, regardless of minor manufacturing variations.

Table: Common GD&T Symbols and Their Function

| GD&T Symbol | Characteristic Controlled | Description |

|---|---|---|

| ◎ | Position | Location of a feature from its true theoretical position. |

| ⌖ | Concentricity | How centered features are relative to an axis. |

| // | Parallelism | How parallel a surface or axis is to a datum. |

| ⊥ | Perpendicularity | How perpendicular a surface or axis is to a datum. |

| ⌽ | Flatness | How flat a surface is. |

Achieving Precise Dimensional Accuracy in Aluminum

Aluminum’s relatively soft nature and high thermal expansion coefficient present unique challenges for maintaining tight dimensional tolerances. Careful tool selection, feed rates, and coolant strategies are critical to prevent material distortion and achieve the desired accuracy.

Experienced machinists understand how to compensate for material properties and tool deflection. Furthermore, the use of climate-controlled machining environments minimizes the impact of temperature fluctuations on part dimensions, ensuring consistent precision.

Surface Finish Quality Standards for Aluminum CNC Parts

The surface finish of an aluminum CNC part is vital not only for aesthetics but also for its functional performance, including wear resistance, fatigue life, and sealing capabilities. Specific applications demand different levels of surface smoothness.

Achieving the desired surface finish involves careful control of machining parameters, such as tool geometry, cutting speed, and feed rate. Post-machining treatments also play a significant role in refining the surface.

Ra, Rz, and Specific Surface Roughness Specifications

Surface roughness is quantitatively measured using parameters like Ra (arithmetic average roughness) and Rz (mean peak-to-valley height). Ra provides an overall average, while Rz highlights the extreme variations in the surface profile.

Different applications require distinct surface roughness values. For example, mating surfaces might need a very smooth finish to reduce friction, while parts for painting might require a slightly rougher texture for better adhesion.

Table: Common Surface Finish Specifications

| Parameter | Description | Typical Application |

|---|---|---|

| Ra (µm) | Arithmetic average roughness | General purpose, most common spec. |

| Rz (µm) | Mean peak-to-valley height | Indicates extremes, useful for sealing surfaces. |

| Ry (µm) | Maximum peak-to-valley height | Critical for highly stressed or wear-prone parts. |

| RMS | Root Mean Square roughness | Similar to Ra, used in specific industries. |

Post-Machining Treatment’s Role in Finish Quality

Beyond the machining process, various post-machining treatments can significantly enhance the surface finish of aluminum parts. These include processes like vibratory finishing, shot peening, polishing, and anodizing.

Anodizing, for instance, not only provides a protective, corrosion-resistant layer but also offers a durable, aesthetically pleasing finish. This process can further refine the surface texture and improve wear resistance for critical aluminum components.

Material Quality and Integrity of Aluminum CNC Components

The integrity of the raw aluminum material is as critical as the machining process itself. Starting with certified, high-quality aluminum ensures the final part possesses the intended mechanical properties, chemical composition, and structural soundness.

Any internal defects or inconsistencies in the raw material can lead to unpredictable part behavior under stress, compromising safety and performance. Material traceability and rigorous incoming inspection are non-negotiable for high-end applications.

Alloy Selection and Certification for Aluminum Parts

Selecting the correct aluminum alloy is crucial, as each alloy offers a unique balance of strength, machinability, corrosion resistance, and weight. Common alloys like 6061, 7075, and 2024 are chosen based on specific application requirements.

Material certifications, such as a Mill Test Report (MTR), confirm the alloy’s chemical composition and mechanical properties. These certifications provide traceability from the original mill, assuring clients of the material’s authenticity and quality.

Table: Common Aluminum Alloys for CNC Machining

| Alloy Type | Key Properties | Typical Applications |

|---|---|---|

| 6061 | Good strength, weldability, corrosion resistance | General purpose, structural, automotive. |

| 7075 | High strength (aerospace grade), good fatigue resistance | Aerospace, defense, high-stress components. |

| 2024 | High strength-to-weight ratio, good machinability | Aircraft structures, fasteners, military. |

| 5052 | Excellent corrosion resistance (esp. saltwater), formability | Marine, electronics enclosures. |

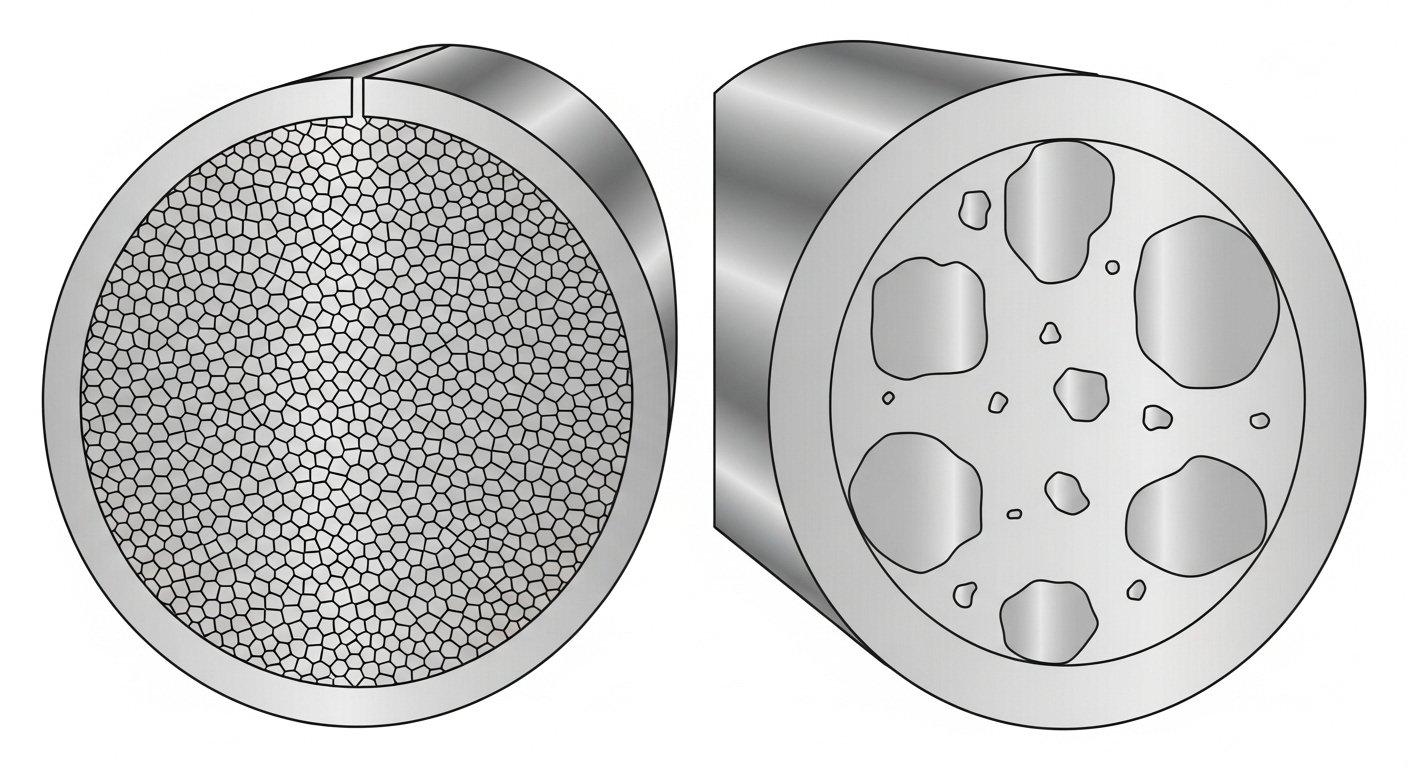

Ensuring Internal Material Homogeneity and Strength

Beyond surface properties, the internal homogeneity of the aluminum material is vital. Processes like ultrasonic testing can detect internal voids, cracks, or inclusions that are not visible externally but could lead to part failure under load.

Proper heat treatment of aluminum alloys further refines their grain structure and enhances mechanical strength and hardness. Controlling these processes ensures that the material consistently meets engineering specifications for strength and durability.

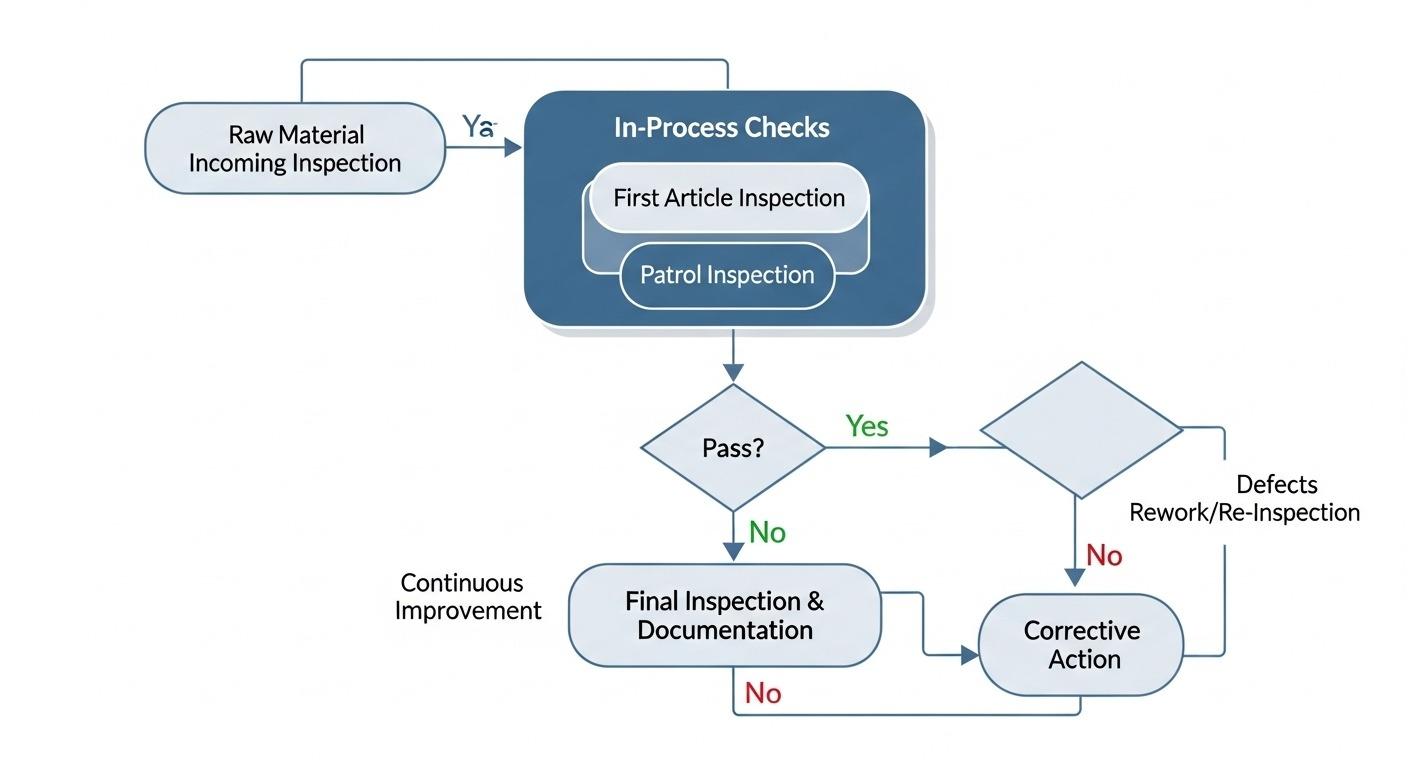

Inspection and Verification of Aluminum CNC Machined Part Quality

Rigorous inspection and verification are the cornerstones of ensuring high-quality aluminum CNC machined parts. These processes go beyond visual checks, employing advanced equipment to precisely measure and validate all critical specifications.

A comprehensive quality control system integrates inspection at multiple stages, from raw material receipt to in-process checks and final component validation. This multi-layered approach prevents defects from propagating and ensures the final product meets design intent.

Advanced Measurement Techniques (CMM, Optical)

Coordinate Measuring Machines (CMMs) offer highly accurate three-dimensional measurements, capable of verifying complex geometries and tight tolerances. They provide precise data on dimensional accuracy, form, and position for critical features.

Optical inspection systems, such as vision systems and optical comparators, provide non-contact measurement and detailed surface analysis. These are particularly effective for delicate parts or features that might be distorted by tactile measurement.

Rigorous Quality Control Protocols and Traceability

Effective quality control protocols include clearly defined inspection plans, standardized work instructions, and regular equipment calibration. Each step in the manufacturing process is documented, ensuring accountability and consistency.

Full traceability of parts, from raw material batch to machining parameters and inspection reports, is crucial for auditing and problem-solving. This system allows for quick identification of the root cause of any deviation, facilitating continuous improvement and defect prevention.

Industry Certifications and Quality Standards for Aluminum Machining

Adherence to industry-specific quality certifications demonstrates a manufacturer’s commitment to excellence and provides clients with an objective assurance of quality. These certifications confirm that a factory operates under established, globally recognized quality management systems.

For critical applications, partnering with certified manufacturers is not just preferred but often mandated. These certifications simplify supplier qualification processes and reduce risk for procurement and engineering teams.

ISO 9001 and AS9100 Relevance to Aluminum Parts

ISO 9001 is a foundational international standard for quality management systems. It signifies that a manufacturer has robust processes in place for consistent product delivery, customer satisfaction, and continuous improvement.

For aerospace and defense industries, AS9100 builds upon ISO 9001, adding specific requirements for quality management in aviation, space, and defense organizations. This ensures the highest level of reliability for aluminum components in critical airborne and space applications.

Table: Key Certification Benefits for Clients

| Certification | Primary Benefit | Client Assurance |

|---|---|---|

| ISO 9001 | Consistent Quality Management | Reliable processes, repeatable results. |

| AS9100 | Aerospace & Defense Specifics | Highest standards for critical applications. |

| IATF 16949 | Automotive Quality | Strict requirements for automotive parts. |

| ISO 13485 | Medical Devices Quality | Regulatory compliance for medical components. |

Supplier Role in Upholding High Quality Standards

A quality-focused supplier acts as an extension of the client’s engineering team, understanding complex specifications and proactively addressing potential manufacturing challenges. They provide transparent communication and detailed documentation throughout the project lifecycle.

Choosing a supplier that views quality as a partnership is essential. Such a partner invests in advanced technology, ongoing training for personnel, and a culture of continuous improvement, all contributing to superior product quality and client satisfaction.

Choosing a Partner for High-Quality Aluminum CNC Machining

Selecting the right manufacturing partner is a critical decision that directly impacts your project’s success. For high-quality aluminum CNC machining, it is essential to evaluate a factory’s technical capabilities, equipment, and their overall approach to quality assurance.

A reputable source manufacturer offers distinct advantages in quality control, cost-efficiency, and project transparency, providing peace of mind to demanding clients.

Evaluating Technical Expertise and Equipment Capabilities

Assess a potential partner’s engineering team for their deep understanding of material science, machining processes, and industry-specific quality standards. Their ability to provide design-for-manufacturability (DFM) feedback is a strong indicator of expertise.

Inspect their facility for state-of-the-art CNC machinery, advanced inspection equipment, and a clean, organized production environment. Modern equipment, combined with skilled operators, directly translates into higher precision and consistent quality.

The Source Manufacturer Advantage for Quality Assurance

Engaging directly with a source manufacturer, like ly-machining, eliminates intermediaries, fostering direct communication and greater control over the entire production process. This results in enhanced transparency regarding quality control, pricing, and lead times.

Source manufacturers possess end-to-end responsibility, from raw material procurement to final inspection and delivery.

This integrated approach ensures consistent quality, reduces potential for miscommunication, and provides a single point of accountability, ultimately safeguarding your project’s success.

Article Summary

Ensuring high quality in aluminum CNC machined parts is critical for performance, durability, and cost-effectiveness. This article outlined key standards including precise dimensional tolerances (GD&T), specific surface finish requirements (Ra, Rz), and the importance of material integrity and certification.

It highlighted advanced inspection techniques, industry certifications like ISO 9001 and AS9100, and the strategic advantages of partnering with a source manufacturer committed to transparent, rigorous quality control for reliable component delivery.

Call to Action

Elevate your project with uncompromised quality. Contact our expert engineering team today for a transparent, no-obligation quote and a personalized consultation on your aluminum CNC machining quality requirements.

Frequently Asked Questions

What are the most common quality challenges in aluminum CNC machining?

Common quality challenges include maintaining tight dimensional tolerances due to aluminum’s thermal expansion, achieving specific surface finishes without burrs or tool marks, and ensuring internal material homogeneity. Miscommunication of complex GD&T specifications and inadequate inspection protocols can also lead to significant quality issues. Addressing these requires specialized expertise and advanced machinery.

How does material certification impact the quality and reliability of aluminum parts?

Material certification, such as a Mill Test Report (MTR), verifies the exact chemical composition and mechanical properties of the aluminum alloy.

This is crucial because it ensures the raw material meets the required specifications, guaranteeing the final part will possess the intended strength, hardness, and corrosion resistance. It provides essential traceability and prevents issues arising from incorrect or substandard materials.

What should I look for in a CNC machining partner to ensure consistent quality for my aluminum components?

Look for a partner with proven technical expertise in aluminum, demonstrated through relevant industry certifications like ISO 9001 or AS9100. Evaluate their equipment capabilities, specifically for advanced CNC machines and comprehensive inspection tools like CMMs.

Prioritize source manufacturers who offer transparent processes, robust quality control protocols, and full traceability, as this ensures accountability and reliable, high-quality output.