Inconsistent part quality, unexpected delays, and soaring rework costs are common challenges that can derail critical aluminum CNC projects. These issues often stem from insufficient quality control, leading to project setbacks, eroded trust, and significant financial burdens. Without a truly reliable manufacturing partner, navigating these complexities becomes a constant source of anxiety.

At ly-machining, we eliminate these risks through an uncompromising, full-process quality control strategy. From the initial sourcing of certified raw materials to the final, rigorous inspection, we guarantee unparalleled precision, reliability, and peace of mind for your most demanding applications.

ly-machining implements a comprehensive, “source-to-finish” quality control strategy for aluminum CNC parts. This system ensures unparalleled precision and reliability by rigorously verifying material properties, maintaining tight dimensional tolerances, and meticulously inspecting every component. Our commitment to quality mitigates project risks and guarantees consistent performance for critical applications.

Why is Aluminum CNC Quality Control So Critical for Your Project?

The demand for high-performance aluminum components across industries such as aerospace, medical, and automotive necessitates exceptional precision. Any deviation from specifications can lead to severe operational failures or assembly incompatibilities. Effective quality control is not merely a preference; it is a fundamental requirement for project success and product integrity.

The Costly Impact of Dimensional Inaccuracies

Dimensional inaccuracies in aluminum CNC parts can have far-reaching consequences. Components that do not meet specified tolerances may not fit correctly during assembly, leading to costly reworks, assembly line stoppages, or even complete batch rejection. These failures directly impact project timelines and budgets.

Achieving Required Surface Finish and Aesthetic Standards

Beyond dimensional accuracy, the surface finish of aluminum parts is often critical for both functionality and aesthetics. A substandard surface finish can compromise performance by affecting friction, wear resistance, or coating adhesion. For consumer electronics or medical devices, a pristine aesthetic is non-negotiable.

Ensuring Material Integrity and Performance Reliability

The mechanical properties of the chosen aluminum alloy are paramount to the part’s performance. Quality control ensures that the material used meets the specified grade and has not been compromised during machining. This verification prevents premature component failure under stress or fatigue, safeguarding the end product’s reliability and lifespan.

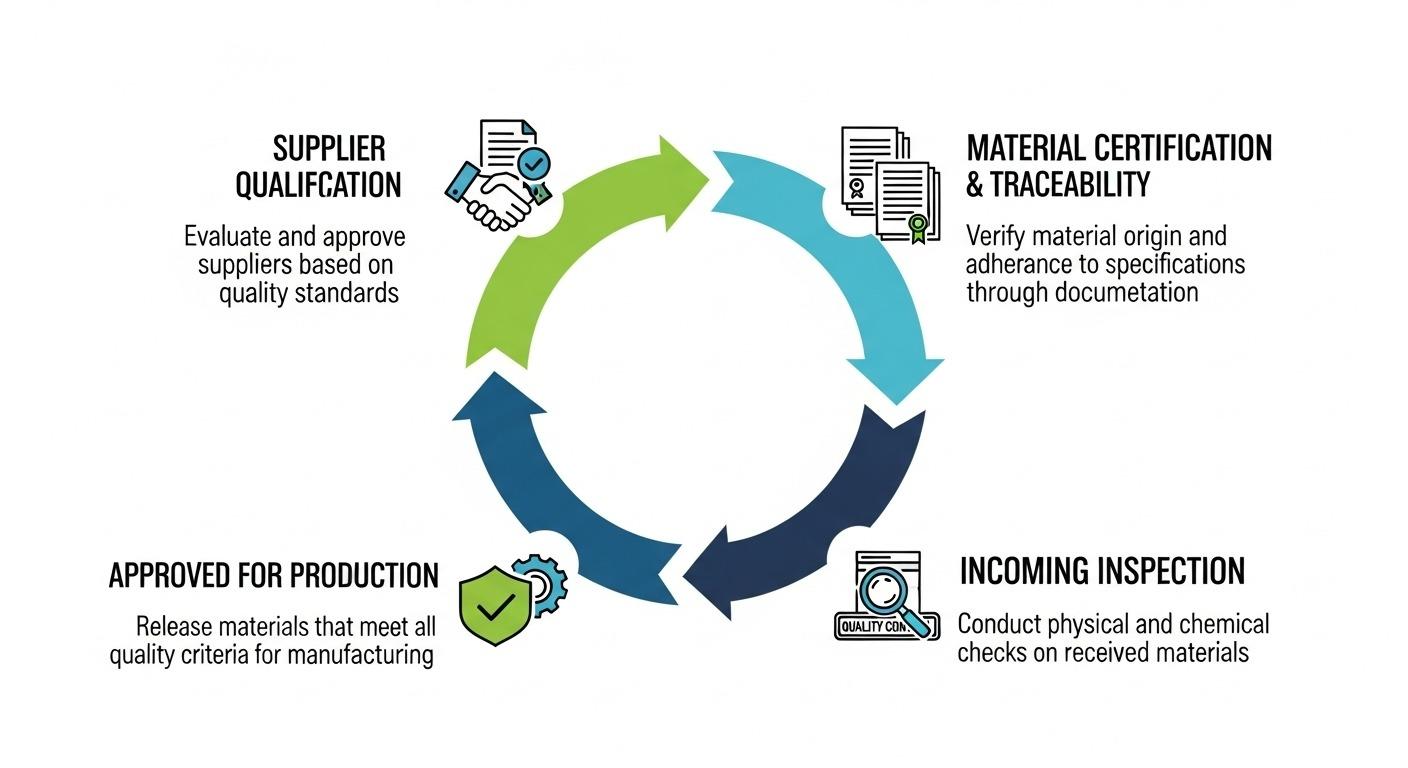

The Foundation: Rigorous Quality Control from Raw Material Sourcing

Quality begins long before machining commences, with the selection and verification of raw materials. Our approach to material sourcing is built on stringent protocols designed to eliminate any variability from the outset. This initial phase sets the standard for the entire manufacturing process.

Strategic Supplier Qualification and Auditing Processes

Our sourcing strategy involves a rigorous qualification process for all material suppliers. We partner only with vendors who demonstrate a consistent track record of quality and adhere to international standards. Regular audits are conducted to ensure ongoing compliance with our demanding specifications for aluminum alloys.

Comprehensive Material Certification and Traceability Systems

Every batch of raw aluminum entering our facility arrives with full material certification. These certifications are meticulously cross-referenced against purchase orders and design specifications to confirm the exact alloy grade, temper, and chemical composition. Our traceability system allows us to track material origin throughout the entire production cycle, providing complete transparency.

Advanced Incoming Raw Material Inspection Protocols

Upon arrival, raw aluminum undergoes a series of strict incoming inspections. This includes visual checks for surface defects, dimensional verification of stock material, and, when necessary, elemental analysis using methods like X-ray fluorescence (XRF) to confirm alloy composition. Only materials passing these stringent checks proceed to the production floor.

Precision Machining Strategies for Optimal Aluminum Part Quality

Achieving high-quality aluminum parts requires a holistic approach to machining, integrating advanced techniques with meticulous process control. Our strategies are designed to ensure dimensional accuracy, superior surface finish, and consistent part-to-part repeatability.

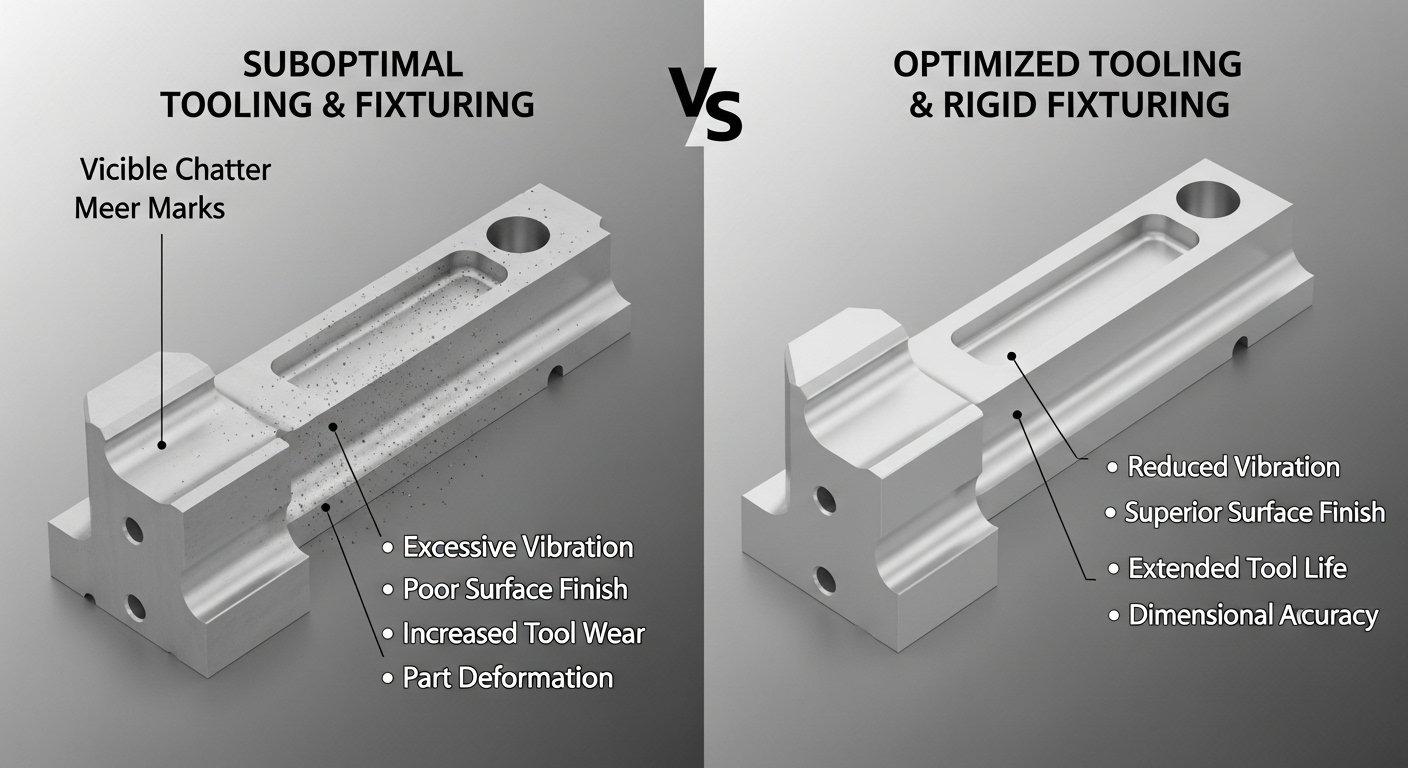

Implementing Advanced Fixturing and Optimized Tooling Selection

Proper fixturing is fundamental to preventing vibration and ensuring workpiece stability during machining, which directly impacts dimensional accuracy and surface quality. We utilize custom-designed, rigid fixtures tailored to each part’s geometry. Our tooling selection is based on the specific aluminum alloy, part complexity, and required surface finish, optimizing cutter geometry and coatings for minimal tool deflection and chatter.

Fine-Tuning Cutting Parameters for Superior Surface Finish

Achieving a superior surface finish on aluminum is a result of carefully controlled cutting parameters. We precisely adjust spindle speed, feed rate, and depth of cut to manage chip formation and minimize heat generation. This prevents material smearing and ensures the desired Ra (roughness average) value is consistently met or exceeded.

Real-time In-Process Monitoring and Adaptive Adjustments

Our CNC machines are equipped with in-process monitoring systems that track critical parameters such as tool wear, temperature, and machine spindle load. Deviations trigger immediate alerts, allowing our skilled machinists to make adaptive adjustments. This proactive approach prevents out-of-spec parts before they are fully machined, reducing scrap and maintaining consistency.

Maintaining Controlled Manufacturing Environments

Environmental factors can subtly influence machining precision. Our manufacturing facility maintains controlled temperature and humidity levels to minimize thermal expansion or contraction of parts and equipment. This stable environment is particularly critical for achieving ultra-tight tolerances on complex aluminum components.

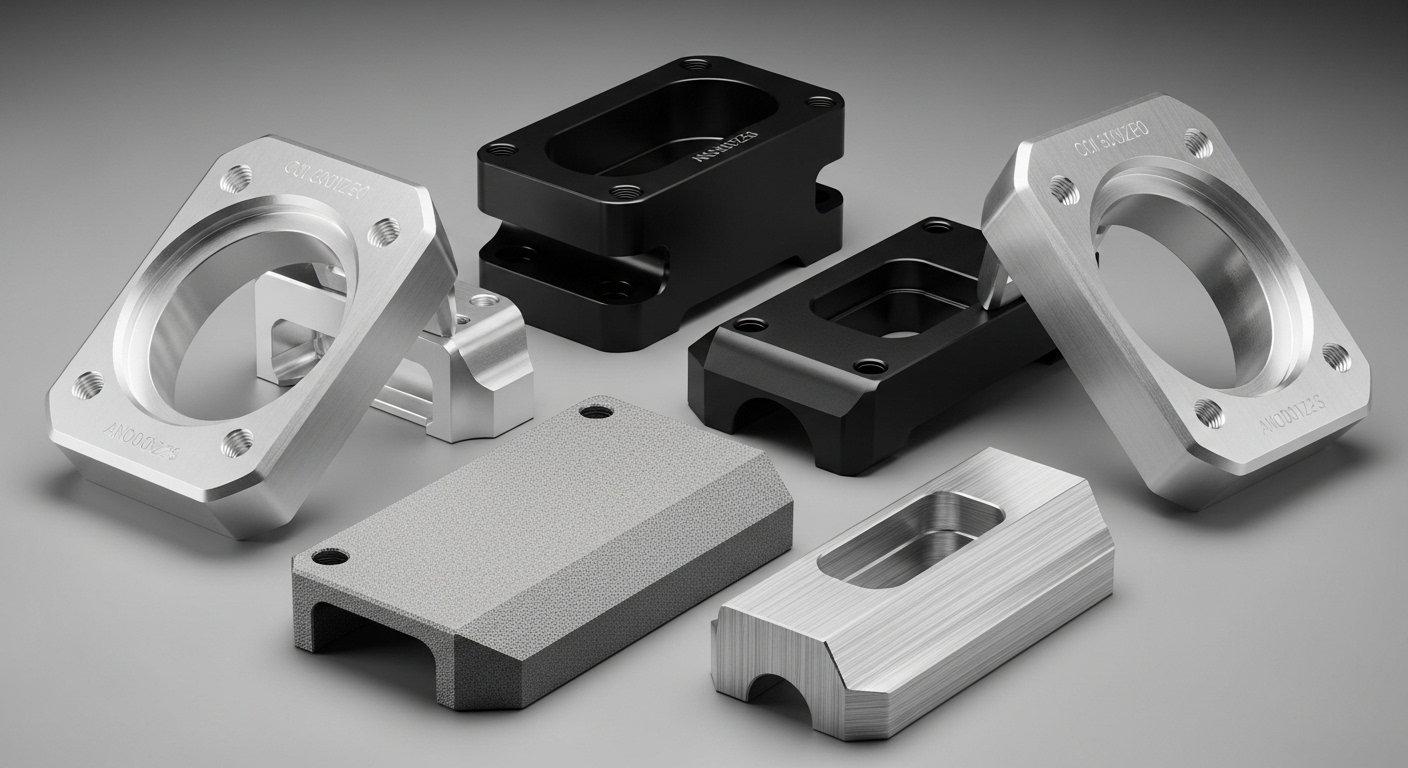

Beyond Machining: Ensuring Flawless Aluminum Finishes and Treatments

The journey to a high-quality aluminum part extends beyond the machining process itself. Post-machining operations, including deburring, surface treatment, and packaging, are equally critical for meeting performance and aesthetic requirements.

Expert Deburring and Surface Preparation Techniques

After machining, parts undergo meticulous deburring to remove any sharp edges or burrs, which can be critical for safety, assembly, and subsequent surface treatments. We employ a combination of manual, vibratory, and automated deburring techniques tailored to the part’s geometry. Thorough cleaning removes all machining oils and contaminants, preparing the surface optimally for further processing.

Quality Control for Anodizing and Other Surface Treatments

For parts requiring anodizing, passivation, or other surface treatments, we work with qualified partners who adhere to our strict quality protocols. We conduct regular audits of their processes and perform incoming inspections on treated parts. This includes verifying coating thickness, color consistency, and adhesion tests to ensure the integrity and longevity of the surface finish.

Adhering to Strict Cleaning and Packaging Standards

The final stage involves rigorous cleaning to remove any residual particles or contaminants, followed by precise packaging. Parts are typically protected with custom inserts, vacuum sealing, or anti-corrosion films to prevent damage, oxidation, or contamination during transit. This ensures parts arrive in the same pristine condition they left our factory.

Advanced Inspection and Verification for Critical Aluminum Components

Our commitment to quality culminates in a multi-stage inspection process that leverages state-of-the-art metrology. This ensures every aluminum part not only meets but often exceeds the most stringent specifications.

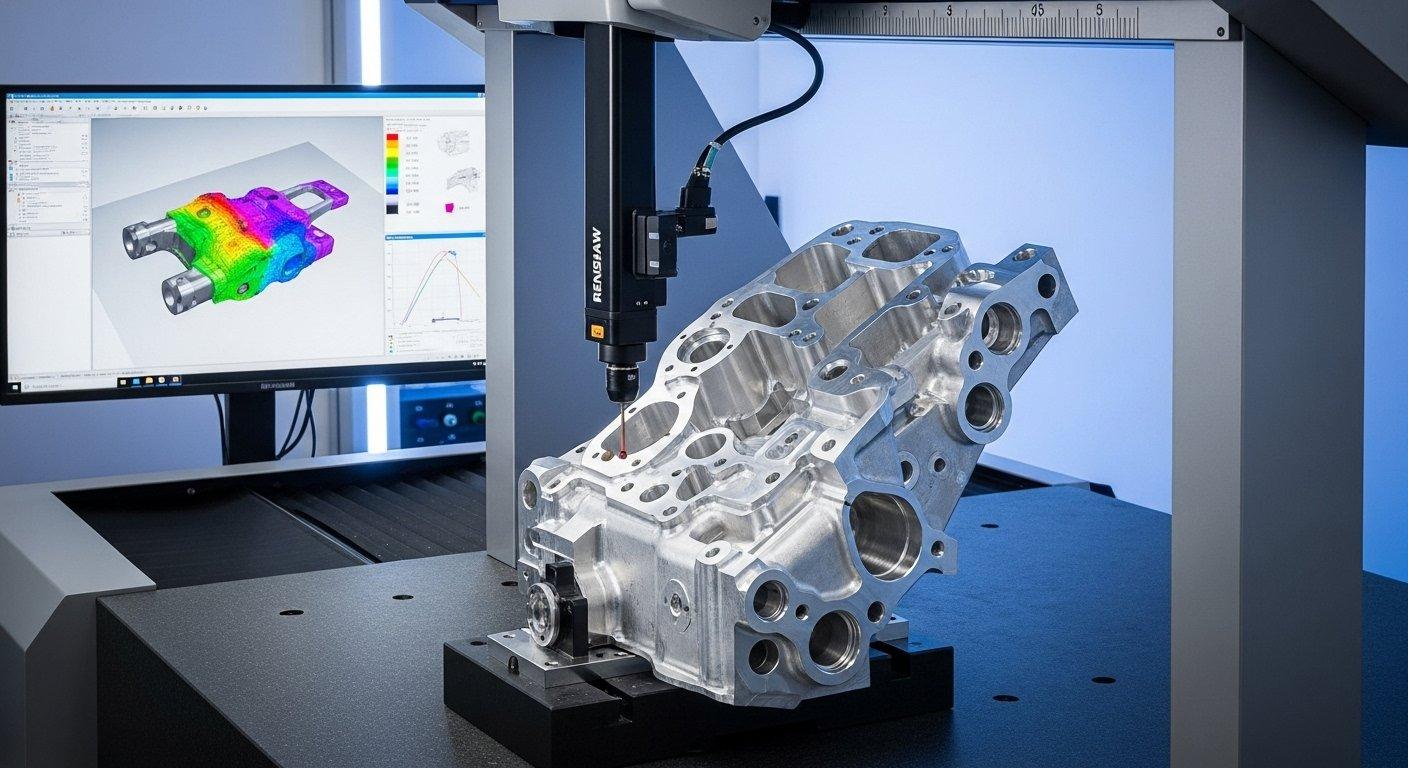

Leveraging CMM and Optical Measurement Systems for Accuracy

We employ advanced Coordinate Measuring Machines (CMMs) capable of sub-micron precision for validating critical dimensions and complex geometries. Optical measurement systems, such as optical comparators and vision systems, are used for fast, non-contact inspection of features, profiles, and surface characteristics. These tools provide comprehensive, traceable measurement data.

Here is an example of common tolerances for CNC machined aluminum:

| Tolerance Type | Standard Precision | High Precision |

|---|---|---|

| Linear | ±0.1mm | ±0.025mm |

| Diameter | ±0.05mm | ±0.015mm |

| Flatness | 0.05mm (per 100mm) | 0.02mm (per 100mm) |

| Perpendicularity | 0.05mm (per 100mm) | 0.02mm (per 100mm) |

Applying Non-Destructive Testing Methods Where Required

For highly critical aluminum components, non-destructive testing (NDT) methods may be employed. These can include dye penetrant inspection for surface cracks, eddy current testing for subsurface defects, or ultrasonic testing for internal flaws. Such tests ensure the structural integrity of the material without damaging the part.

Comprehensive Final Quality Assurance and Documentation

Before shipment, every part undergoes a final quality assurance check against the engineering drawings and client specifications. A detailed quality report, including measurement data, material certifications, and surface finish validations, is compiled and provided to the client. This comprehensive documentation offers complete traceability and assurance.

Proactive Root Cause Analysis for Any Deviations

In the rare event of a deviation or non-conformance, our quality team initiates a thorough root cause analysis (RCA). Utilizing methodologies like 8D problem-solving, we identify the underlying cause, implement corrective actions, and verify their effectiveness. This commitment to continuous improvement ensures that issues are resolved systematically and prevented from recurring.

Partnering with a Source Manufacturer for Guaranteed Aluminum CNC Quality

Choosing a manufacturing partner with an embedded culture of quality is paramount. As a source manufacturer, ly-machining provides an unparalleled level of control, transparency, and technical expertise from design concept to final delivery.

Our Transparent Pricing Model for High-Value Parts

We believe in full transparency throughout the entire process, including our pricing. Our quotes are detailed and itemized, clearly outlining costs associated with material, machining, finishing, and quality control. This allows procurement managers to understand the value proposition and make informed decisions without hidden fees.

Deep Technical Expertise and Collaborative Engineering Support

Our team comprises experienced R&D engineers and machinists who possess deep knowledge of aluminum alloys and CNC machining best practices. We offer collaborative engineering support, providing Design for Manufacturability (DFM) advice early in the design phase. This proactive engagement helps optimize designs for precision, cost-effectiveness, and manufacturability, reducing potential issues downstream.

Case Studies: Delivering High-Quality, Complex Aluminum Parts

A recent project involved machining a complex aluminum manifold for an aerospace client, requiring AS9100 standards and internal passages with extremely tight tolerances.

Our integrated quality control system, from verifying the specific aerospace-grade aluminum to employing multi-axis machining with in-process probing and 100% CMM inspection, ensured every part met the critical specifications. This meticulous process prevented potential failures during high-pressure flight tests, saving the client significant re-engineering costs and launch delays, reinforcing their trust in our capabilities.

Article Summary

This article detailed ly-machining’s comprehensive, full-process quality control strategy for aluminum CNC parts. It covered the critical importance of quality, stringent raw material sourcing, precision machining strategies, flawless finishing, and advanced inspection methods.

Our commitment to end-to-end quality control ensures unparalleled precision, reliability, and peace of mind for clients, supported by transparent pricing and deep technical expertise.

Frequently Asked Questions About Aluminum CNC Quality

What specific certifications does ly-machining hold to ensure quality?

ly-machining maintains ISO 9001 certification, demonstrating our adherence to internationally recognized quality management system standards. For aerospace and defense projects, we also operate under AS9100 compliance, ensuring the highest level of quality assurance for critical applications.

These certifications are a testament to our robust quality control processes and continuous improvement initiatives, providing verifiable assurance to our clients.

How does ly-machining handle tight tolerance requirements for aluminum parts?

Achieving tight tolerances on aluminum parts involves a multi-faceted approach. We start with stable machine tools and optimized cutting parameters, using precision tooling and custom fixturing to minimize deflection.

In-process probing and real-time monitoring allow for immediate adjustments. Finally, we utilize advanced metrology equipment like CMMs and optical comparators for thorough post-machining verification, ensuring every critical dimension meets the specified requirements, often to within ±0.015mm or finer, depending on geometry and material.

Can ly-machining provide traceability for materials and processes for my project?

Absolutely. We implement a comprehensive traceability system that tracks every aspect of your project. This includes full material certification from our approved suppliers, batch numbers for raw materials, and documented processing steps throughout manufacturing.

All inspection reports, measurement data, and surface treatment certifications are archived and provided, creating a complete audit trail from the initial raw material to the final delivered component. This ensures transparency and accountability for all critical aluminum parts.