Selecting a Trustworthy Aluminum CNC Partner

In the high-stakes world of product development, the reliability of your aluminum CNC machining partner isn’t just a preference—it’s the bedrock of your project’s success. But amidst a sea of options, how do you truly differentiate a factory that merely *claims* quality from one that consistently *delivers* it, on budget and on schedule? This guide provides clear criteria to navigate that decision.

Choosing a reliable aluminum CNC machining factory requires scrutinizing technical expertise, robust quality control, transparent pricing, and efficient project management. A true source manufacturer offers direct control, optimized lead times, and expert guidance, ensuring precision components are delivered on time, every time.

Navigating the complexities of CNC manufacturing demands a partner that understands the intricate balance between design intent and production realities. This extends beyond mere capability to encompass a holistic approach to project execution and client collaboration. We aim to empower you with the knowledge to make an informed choice.

Assessing Technical Expertise for Aluminum CNC

The cornerstone of any high-quality aluminum CNC machining operation is the depth of its technical expertise. This encompasses not only the machinery available but also the specialized knowledge required to process aluminum alloys effectively. Precision in aluminum demands specific tooling, speeds, feeds, and cooling strategies.

### Machine capabilities and advanced technology

Modern CNC machining factories leverage advanced multi-axis machines, including 3-axis, 4-axis, and 5-axis systems. These machines offer greater flexibility for complex geometries and allow for single-setup machining, which reduces errors and improves part accuracy. It is crucial to ascertain the factory’s investment in current technology.

Equally important are the auxiliary systems, such as automated tool changers, high-pressure coolant delivery, and in-process probing. These technologies contribute significantly to consistent quality, reduced cycle times, and the ability to hold extremely tight tolerances on aluminum components. Inquire about the factory’s specific equipment list and its maintenance protocols.

### Specialized aluminum machining experience

Aluminum, while versatile, presents unique machining challenges. Its ductility can lead to burring, and its thermal expansion properties require careful consideration during machining. An experienced factory will possess specific knowledge of different aluminum alloys, such as 6061, 7075, or 2024.

This specialized experience dictates the choice of cutting tools, coatings, and machining strategies to achieve optimal surface finish and dimensional stability. Factories that routinely handle diverse aluminum projects demonstrate a deeper understanding of these nuances, minimizing potential production issues. Their expertise ensures that material integrity is maintained throughout the process.

### Design for Manufacturability (DFM) support

Effective DFM support is invaluable for engineers seeking to optimize their designs for cost-effectiveness and manufacturability. A reliable factory acts as a technical partner, offering insights to refine designs before production begins. This collaborative approach can prevent costly rework and accelerate product development cycles.

DFM guidance involves suggesting material alternatives, tolerance adjustments, and feature modifications that simplify machining without compromising part functionality. It bridges the gap between design intent and manufacturing feasibility, ensuring that the final product meets both performance and production requirements efficiently.

| DFM Consideration | Impact on Production | Benefit of Collaboration |

|---|---|---|

| Wall Thickness | Tool deflection, warping | Prevents part distortion |

| Internal Radii | Tool size limitations | Optimizes tool selection |

| Tolerances | Machining time, cost | Balances precision with budget |

| Surface Finish | Post-processing, cost | Aligns aesthetic with function |

| Part Orientation | Setup complexity, accuracy | Reduces setup errors |

Ensuring Robust Quality Control in Aluminum Machining

Quality control is not merely an afterthought; it is an integrated process that spans every stage of aluminum CNC machining. For precision parts, a factory’s commitment to quality is evident in its inspection protocols, equipment, and adherence to industry standards. This safeguards against costly defects and ensures consistent part performance.

### Comprehensive inspection processes and equipment

A robust quality control system utilizes a multi-stage inspection approach, from raw material verification to in-process checks and final dimensional validation. Precision measurement tools are critical in this process.

| Inspection Equipment | Purpose in Aluminum Machining |

|---|---|

| CMM (Coordinate Measuring Machine) | High-accuracy 3D dimensional measurement for complex geometries |

| Optical Comparators | Non-contact measurement of profiles and dimensions, especially for small features |

| Profilometers | Surface roughness measurement for critical aesthetic and functional surfaces |

| Height Gauges | Vertical dimensional measurements with high precision |

| Micrometers/Calipers | Fundamental dimensional checks for various features |

### Industry certifications and compliance standards

Certifications such as ISO 9001 demonstrate a factory’s commitment to a recognized quality management system. For specific industries like aerospace or medical, AS9100 or ISO 13485 compliance may be mandatory, indicating adherence to even stricter quality and traceability requirements.

These certifications provide an independent audit of a factory’s processes, ensuring consistent quality outputs and risk mitigation. They offer clients an objective measure of a supplier’s capability to meet stringent industry demands, reducing the need for extensive personal audits.

### Material traceability and detailed documentation

Full material traceability is essential, especially for critical aluminum components. This means documenting the origin of the raw material, its alloy composition, and all subsequent processing steps. Detailed documentation ensures accountability and facilitates root cause analysis in the unlikely event of a defect.

Comprehensive reporting includes inspection reports, material certifications (MTRs), and process control records. This level of transparency provides assurance to clients regarding the integrity and consistency of their aluminum parts throughout the entire manufacturing lifecycle.

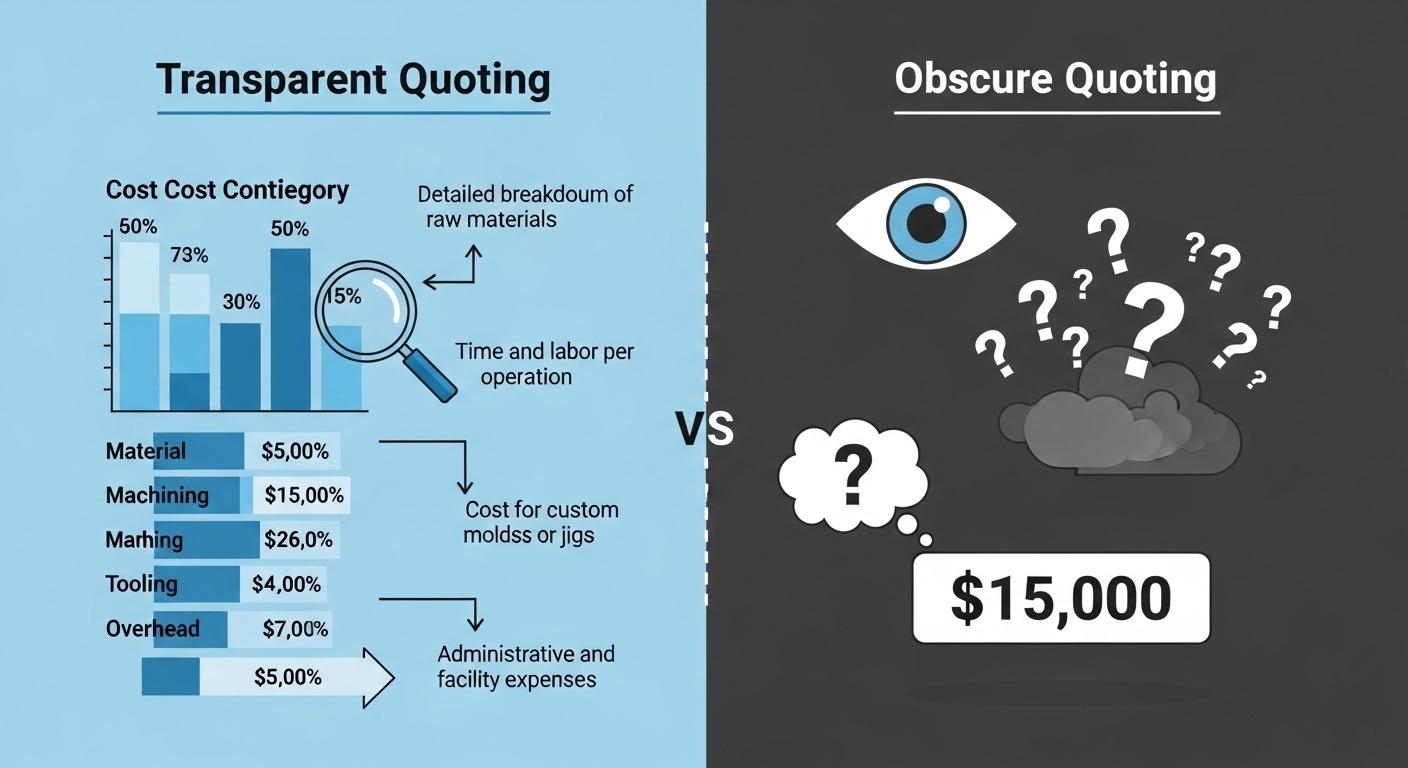

Understanding Transparent Pricing for CNC Services

Transparent pricing is a hallmark of a reliable aluminum CNC machining partner. It provides clarity, builds trust, and allows clients to accurately budget for their projects without hidden costs. Understanding the factors that contribute to pricing helps in evaluating overall value.

### Detailed cost breakdown and quoting accuracy

A transparent quote should provide a detailed breakdown of costs, rather than just a lump sum. This includes material costs, machining time, tooling, setup fees, surface finish requirements, and any post-processing. Clear communication regarding these elements prevents surprises.

| Cost Factor | Description | Impact on Quote |

|---|---|---|

| Material Cost | Type and grade of aluminum, volume required | Significant |

| Machining Time | Complexity, tolerances, machine hours needed | High |

| Tooling Cost | Custom tools, wear and tear, replacement | Variable |

| Setup Fees | Initial machine configuration, programming | Fixed per batch |

| Surface Finish | Requirements like anodizing, polishing | Add-on |

| Post-processing | Deburring, heat treatment, assembly | Optional |

| Quality Inspection | Specific measurement protocols | Integrated |

| Expedited Delivery | Rush order premiums | Optional |

Accuracy in quoting is tied to the factory’s experience and its ability to precisely estimate production times and material usage. Factories with robust internal systems and experienced estimators tend to offer more reliable quotes, fostering greater financial predictability for clients.

### Long-term value versus initial cost considerations

While initial cost is a factor, focusing solely on the lowest price can lead to hidden expenses down the line, such as reworks, delays, or part failures. A reliable partner offers long-term value through consistent quality, on-time delivery, and technical support that prevents problems.

The true cost of a component includes not only its manufacturing price but also the cost of poor quality, project delays, and the administrative burden of managing unreliable suppliers. Investing in a partner that prioritizes quality and efficiency often results in a lower total cost of ownership.

### Source manufacturer pricing and efficiency benefits

As a source manufacturer, we inherently offer efficiencies that resellers or intermediaries cannot match. Direct control over the entire production process eliminates markups and streamlines communication, often leading to more competitive and transparent pricing. This direct relationship removes layers of unnecessary cost.

This direct interaction also means that engineering changes or design optimizations can be implemented more rapidly and cost-effectively. The efficiency gains from this integrated approach translate directly into better value for the client, without compromising on quality or service.

Evaluating Communication and Project Management

Effective communication and robust project management are as critical as technical capabilities. They ensure that projects stay on track, expectations are met, and potential issues are addressed proactively. This builds confidence and minimizes risks.

### Supplier responsiveness and technical support

A reliable factory prioritizes clear and timely communication. This includes prompt responses to inquiries, regular project updates, and direct access to technical experts for design discussions or troubleshooting. Language barriers should also be a consideration for international partnerships.

Technical support should extend beyond just answering questions. It involves proactive engagement, offering suggestions for improvement, and providing detailed explanations for any proposed modifications. This level of responsiveness is indicative of a true partnership approach.

### Reliable delivery timelines and logistics

Adherence to agreed-upon delivery schedules is crucial for product launch success and supply chain stability. A dependable factory will have established processes for production planning, scheduling, and risk mitigation to ensure on-time delivery. Transparent tracking and logistics support are also key.

Before committing, inquire about the factory’s track record for delivery reliability and their internal systems for managing production bottlenecks. A clear understanding of their logistics capabilities, including shipping options and customs clearance support, is also vital for international clients.

### Data security and intellectual property protection

Protecting intellectual property (IP) and ensuring data security are paramount concerns for any client. A reputable CNC machining factory will have stringent protocols in place to safeguard design files, proprietary information, and sensitive project data.

This includes secure IT infrastructure, non-disclosure agreements (NDAs) as standard practice, and controlled access to project-specific information within the facility. Clients should feel confident that their innovative designs are protected throughout the manufacturing partnership.

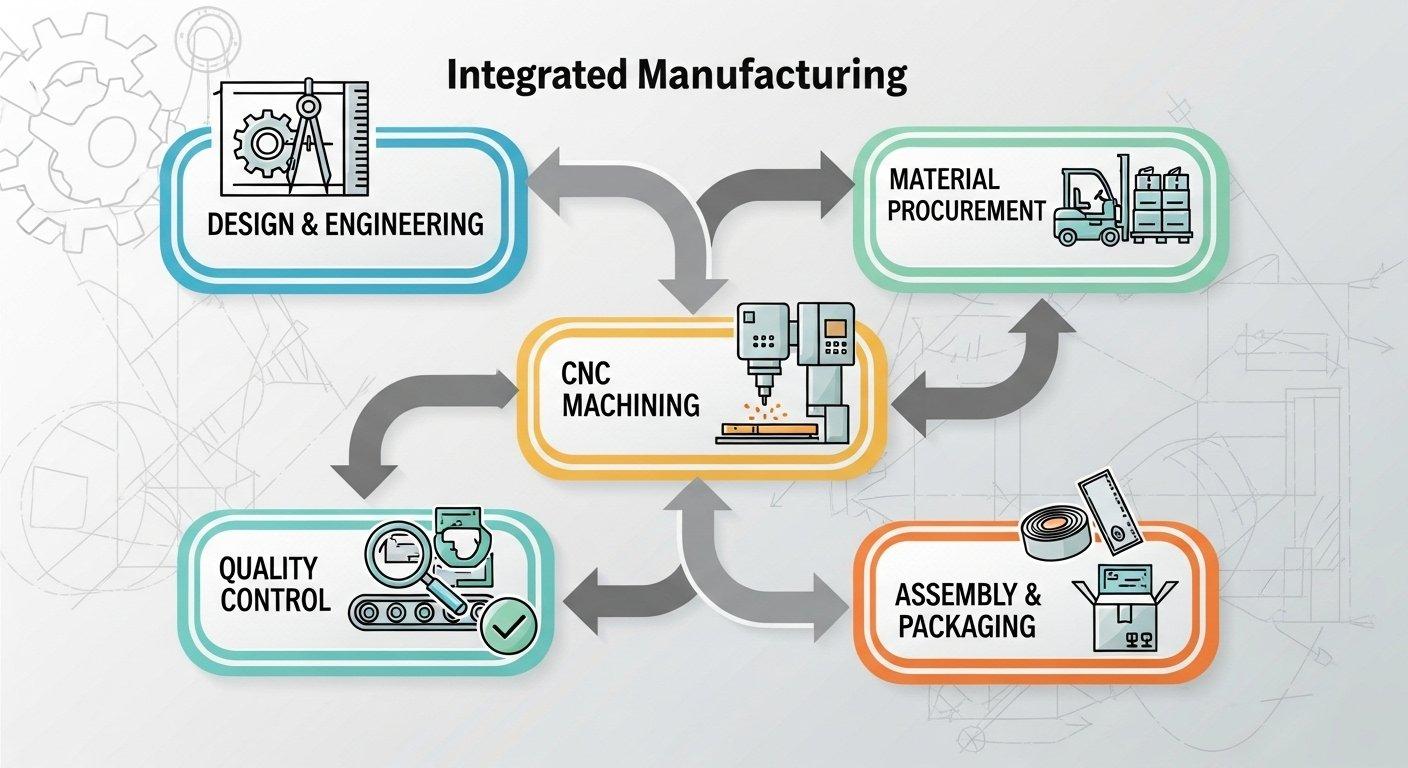

The Strategic Advantage of a Source Manufacturer

Partnering directly with a source manufacturer offers distinct advantages that contribute significantly to project success and overall value. These benefits stem from direct control and an integrated approach to manufacturing.

### Direct control over manufacturing processes

As a source manufacturer, we maintain direct control over every stage of the aluminum CNC machining process, from raw material procurement to final inspection. This end-to-end oversight ensures consistent quality and adherence to specifications without relying on third-party subcontractors.

This direct control allows for tighter process monitoring, immediate problem resolution, and seamless integration of quality checks. It provides a level of certainty and reliability that is often compromised when multiple entities are involved in the production chain.

### Optimized lead times and increased flexibility

Operating as a source manufacturer streamlines the production timeline by eliminating communication delays and logistical complexities associated with intermediaries. This translates into optimized lead times, which are crucial for rapid prototyping and meeting aggressive market demands.

Our direct manufacturing capability also provides greater flexibility to accommodate design changes or urgent production adjustments. Without external dependencies, modifications can be integrated swiftly, ensuring projects remain agile and responsive to evolving requirements.

### Direct access to engineering and technical teams

One of the most significant advantages is direct access to our in-house engineering and technical teams. This facilitates real-time collaboration on design for manufacturability (DFM), material selection, and troubleshooting, fostering a deeper technical partnership.

This direct line of communication ensures that intricate technical details are understood and addressed promptly, minimizing misinterpretations and accelerating the iterative design process. It builds a foundation of technical trust and collaborative problem-solving.

Article Summary:

Choosing a reliable aluminum CNC machining factory requires a meticulous evaluation of technical capabilities, quality control, pricing transparency, and communication efficiency. Partnering with a source manufacturer provides distinct advantages, including direct process control, optimized lead times, and expert technical collaboration, ensuring superior precision and project reliability. This strategic approach mitigates risks and fosters confidence in your supply chain.

Frequently Asked Questions

### What specific questions should I ask about a factory’s aluminum machining capabilities?

When evaluating a factory, inquire about their experience with specific aluminum alloys relevant to your project, such as 6061, 7075, or 2024. Ask about their maximum part size and achievable tolerances, particularly for features critical to your design.

It is also beneficial to understand their approach to surface finish requirements and post-processing capabilities like anodizing or deburring. Additionally, ask for examples of complex aluminum parts they have successfully manufactured, ideally those similar in complexity to your own designs.

### How does a source manufacturer ensure better quality compared to a reseller?

A source manufacturer maintains direct control over every stage of the production process, from material sourcing and machining to quality inspection. This integrated approach minimizes variables and allows for immediate identification and resolution of any issues, ensuring consistent quality.

In contrast, a reseller often outsources production to various third-party factories, leading to less direct oversight, potential inconsistencies in quality, and fragmented communication regarding technical specifications and quality control. The direct line of accountability with a source manufacturer significantly enhances quality assurance.

### What are the key elements of a transparent CNC machining quote?

A truly transparent CNC machining quote will provide a detailed breakdown of all cost components, rather than a single lump sum. This includes the specific type and quantity of raw material, estimated machining time based on part complexity and required tolerances, tooling costs, and any setup fees.

It should also clearly itemize costs for secondary operations such as surface treatments (e.g., anodizing, polishing), deburring, heat treatment, and any required specialized inspection or certification. Clear payment terms, lead times, and shipping logistics should also be explicitly stated, leaving no room for hidden charges.

Ready to elevate your aluminum CNC machining projects with a partner you can truly trust?

Contact our technical experts today for a no-obligation consultation and a transparent, detailed quote tailored to your specific requirements.