Addressing Whitening & Discoloration on CNC Aluminum Parts

Are inconsistent surface finishes on your CNC aluminum parts causing costly rejections and production delays? These unsightly defects not only compromise aesthetics but also signal underlying issues that can affect performance and durability. Discover the hidden causes of whitening and oxidation and learn how to achieve flawlessly finished components, every single time, with expert strategies and precise manufacturing.

CNC aluminum parts can whiten or discolor due to material impurities, aggressive machining, improper cleaning, or environmental exposure. Preventing these costly defects involves rigorous material selection, optimized process parameters, advanced post-treatment protocols, and controlled storage, ensuring consistent, high-quality surface finishes for critical applications.

Understanding Aluminum Whitening: Root Causes & Identification

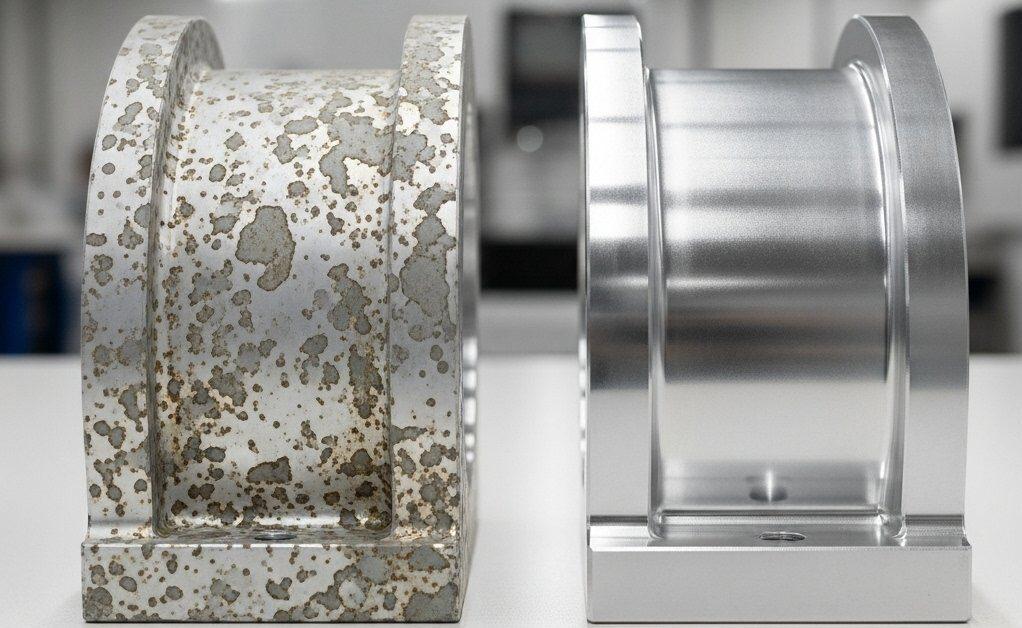

Surface discoloration on CNC machined aluminum components, often appearing as white spots, dull patches, or uneven oxidation, is a critical issue that can compromise both aesthetic appeal and functional integrity. Identifying the precise root cause is the first step toward effective prevention and remediation. These defects are rarely singular in origin, often stemming from a complex interplay of material properties, manufacturing processes, and environmental factors.

Initial Material Quality & Alloy Selection Impact

The journey to a flawless surface begins with the raw material itself. Aluminum alloys are chosen for specific applications, but inherent inconsistencies or improper selection can predispose parts to discoloration. Impurities within the alloy, such as excess iron or copper, can react adversely during machining or post-treatment, leading to uneven surface reactions. Certain alloys, particularly those with higher copper content, are inherently more susceptible to oxidation and corrosion.

Choosing the correct alloy is paramount. For instance, 6061 is common for its versatility, but specific surface finish requirements might necessitate 5052 for better corrosion resistance or 7075 for higher strength with particular attention to its surface treatment.

| Aluminum Alloy | Primary Characteristics | Common Surface Issues |

|---|---|---|

| 6061-T6 | General purpose, good machinability, weldability | Moderate susceptibility to uneven anodizing if improperly cleaned |

| 7075-T6 | High strength, aerospace applications | More prone to galvanic corrosion and pitting due to high zinc/magnesium |

| 5052-H32 | Excellent corrosion resistance, formability | Less prone to whitening, but can show water spotting if not dried properly |

| 2024-T3 | High strength, fatigue resistance | Highly susceptible to corrosion and oxidation due to high copper content |

Machining Process Parameters Contributing to Defects

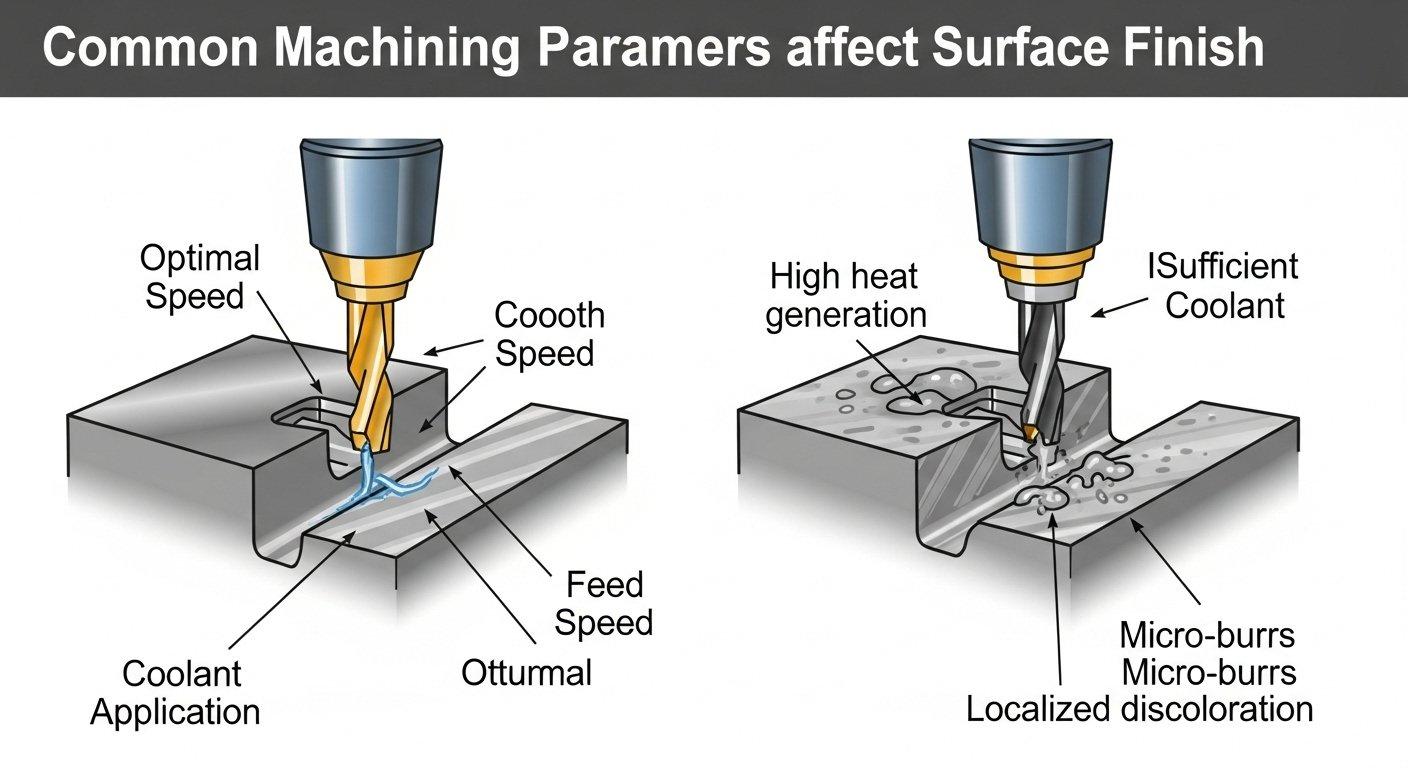

The actual CNC machining process introduces multiple variables that can induce or exacerbate surface issues. Excessive cutting speeds or feeds, coupled with inadequate cooling or lubrication, can lead to localized overheating. This thermal stress can alter the microstructure of the aluminum surface, making it more reactive and susceptible to oxidation. Moreover, using contaminated or incorrect cutting fluids can leave residues that react with the aluminum, initiating discoloration.

Tool wear also plays a significant role. Dull tools generate more heat and can smear the aluminum, creating micro-scratches and rough surfaces where contaminants can lodge, leading to uneven chemical reactions during subsequent processes like anodizing.

Post-Machining Contamination & Improper Cleaning

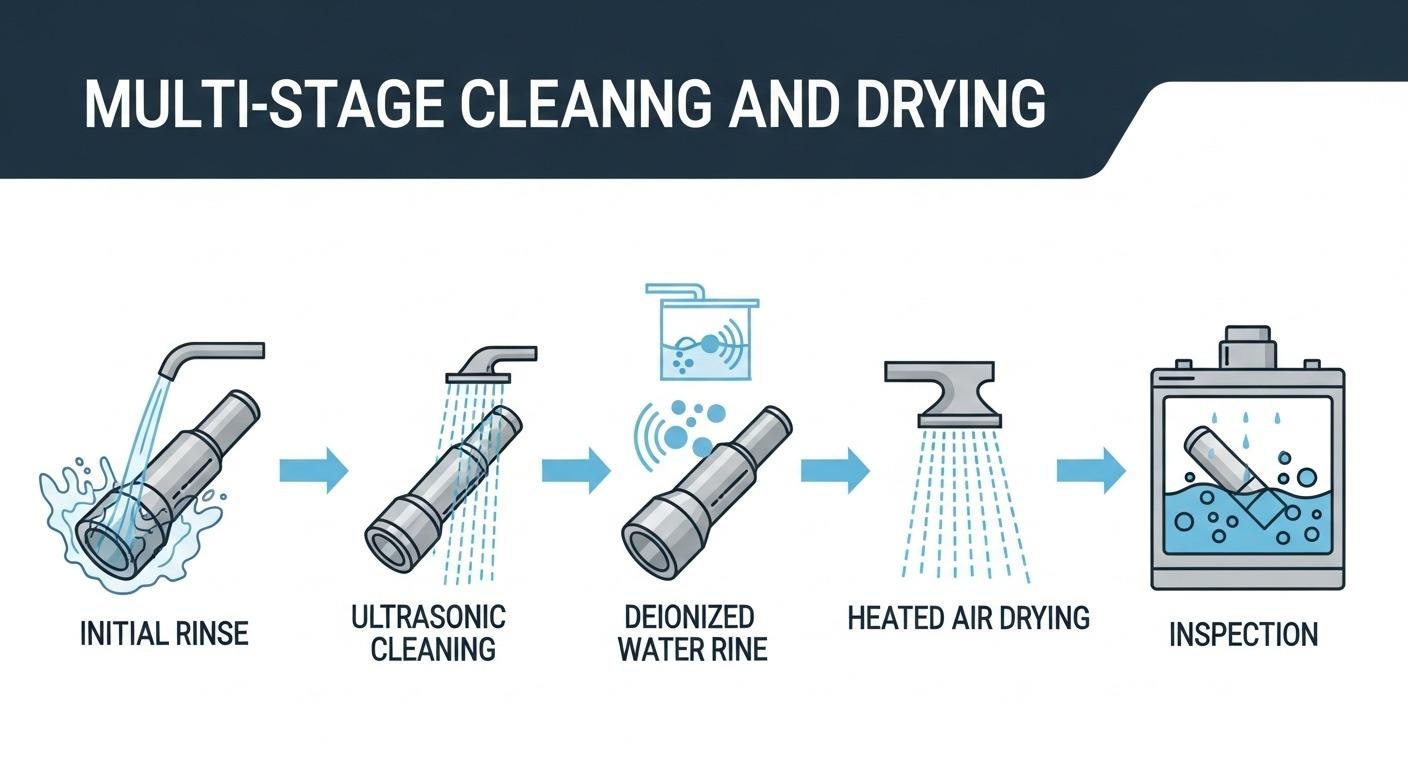

After machining, parts are highly vulnerable to contamination. Residual cutting fluids, metal chips, finger oils, or even airborne particulates can adhere to the surface. If these contaminants are not thoroughly removed through precise cleaning protocols, they can act as catalysts for oxidation or create barriers to uniform surface treatments. For example, residual alkaline cleaning agents that are not completely rinsed off can cause etching and white hazing, especially on anodized surfaces.

The choice of cleaning agents, water quality (deionized water is critical), and drying methods are crucial steps. Improper drying can lead to water spotting, which often appears as white or cloudy stains.

Environmental Factors & Storage Conditions

Even after proper machining and cleaning, parts can develop surface issues due to adverse environmental exposure. High humidity, exposure to corrosive atmospheres (e.g., industrial pollutants, saltwater spray), or direct sunlight can accelerate oxidation and discoloration. Untreated aluminum, particularly, forms a natural oxide layer that can become thick and uneven if exposed to fluctuating conditions.

Improper storage, such as stacking parts without protective interleaving or storing them in damp, unventilated areas, significantly increases the risk of surface damage. Packaging materials themselves, if acidic or reactive, can also contribute to surface degradation over time.

Preventing Oxidation & Surface Discoloration in Aluminum Parts

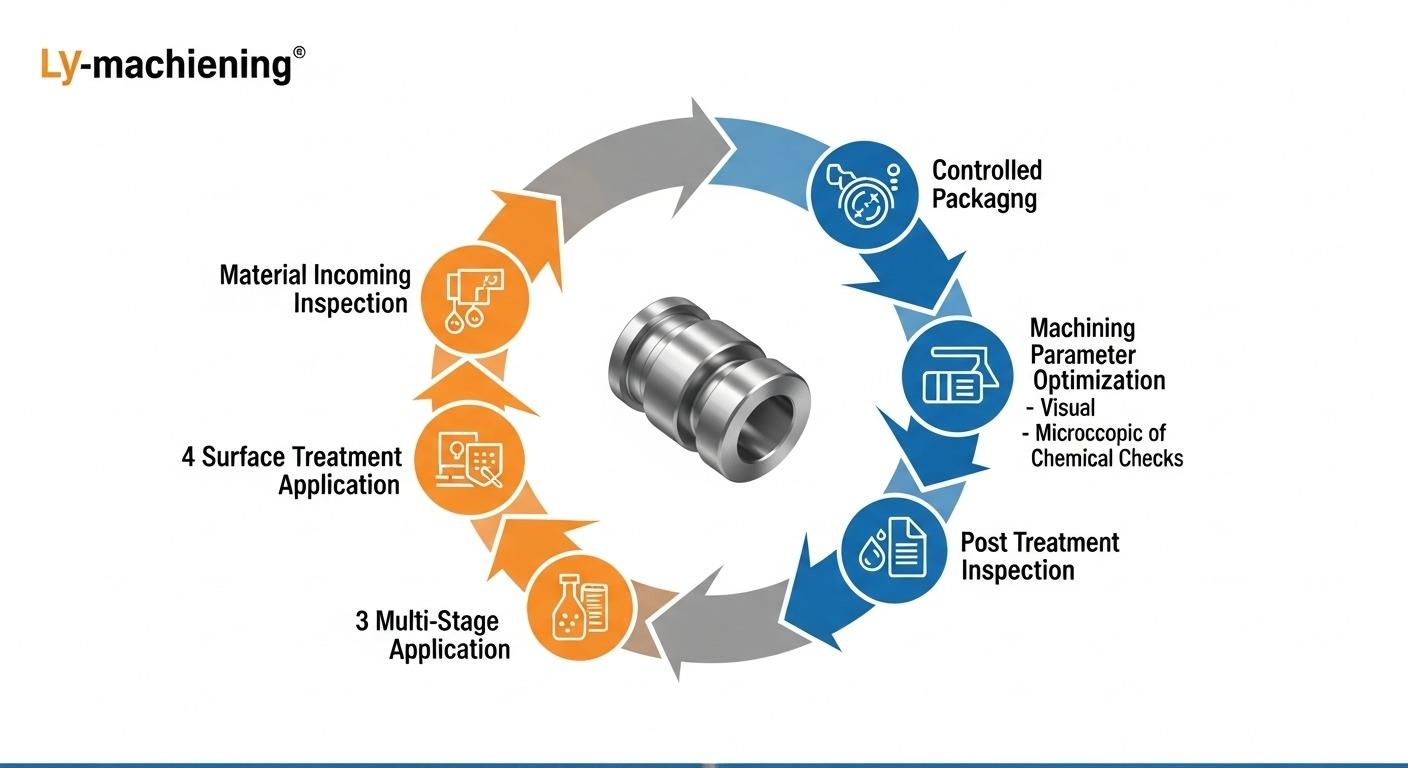

Proactive measures are far more cost-effective than reactive troubleshooting. Implementing stringent controls at every stage of the manufacturing process, from material receipt to final packaging, is essential to consistently deliver parts with impeccable surface finishes, free from oxidation and discoloration. This holistic approach is a hallmark of high-end CNC machining.

Optimizing Material Preparation & Cutting Fluids

At ly-machining, material quality control begins upon arrival. We verify alloy composition and temper to ensure consistency. For machining, we meticulously select cutting fluids based on the specific aluminum alloy and machining operation. Utilizing high-performance, semi-synthetic, or fully synthetic coolants with excellent lubricity and cooling properties minimizes thermal stress and prevents residue buildup. Regular monitoring and maintenance of cutting fluid concentration and pH are critical to prevent bacterial growth and chemical degradation that could lead to surface issues.

Implementing Effective Post-Machining Cleaning Protocols

Our cleaning protocols are multi-stage and precisely controlled. Immediately after machining, parts undergo a preliminary rinse to remove gross contaminants. This is followed by ultrasonic cleaning in specialized, non-corrosive detergents, ensuring deep penetration and removal of microscopic particles and oils. Critical parts may also undergo vapor degreasing. All rinsing is performed with deionized water to prevent mineral spotting. Finally, parts are thoroughly dried using heated air knives or vacuum drying to eliminate any residual moisture.

Selecting Appropriate Surface Treatment Methods

The right surface treatment is crucial for long-term surface integrity and aesthetic quality. We guide clients through selecting the optimal treatment based on their application’s requirements for corrosion resistance, hardness, electrical insulation, and appearance.

| Surface Treatment | Primary Benefit | Common Application | Durability Against Whitening |

|---|---|---|---|

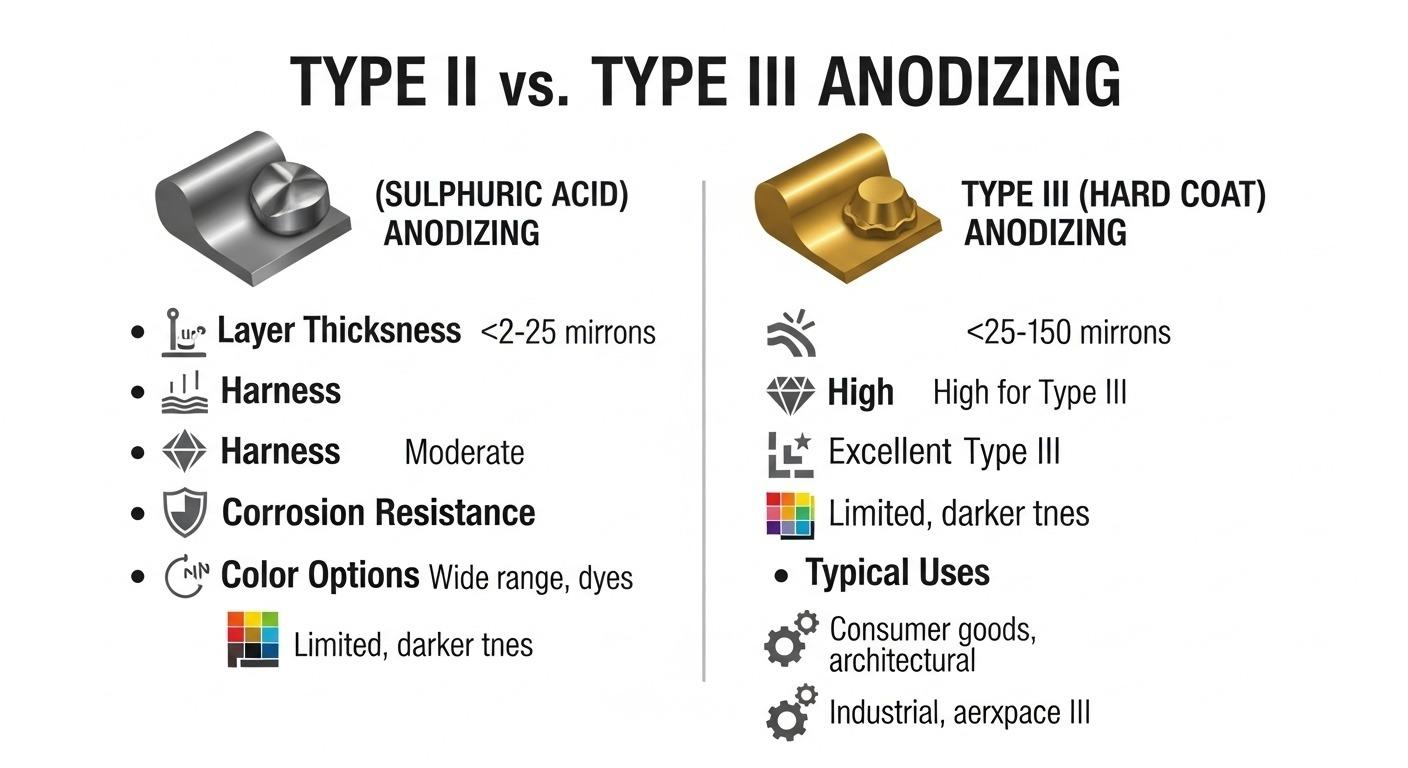

| Anodizing (Type II/III) | Enhanced corrosion/wear resistance, aesthetic color | Consumer electronics, aerospace, automotive | Excellent, if properly sealed |

| Chemical Conversion Coating (Alodine/Chromate) | Corrosion protection, paint adhesion base | Electrical enclosures, military components | Good, but thin and less aesthetic |

| Electropolishing | Improved surface finish, passivity, deburring | Medical devices, food processing | Excellent, highly resistant to environmental factors |

| Powder Coating | Durable, decorative, impact resistant | Architectural parts, outdoor furniture | Very high, forms a protective barrier |

Controlled Storage & Packaging Practices

Post-treatment, parts are handled with utmost care in a controlled environment to prevent re-contamination. We employ specialized packaging materials, such as VCI (Volatile Corrosion Inhibitor) bags or acid-free paper, to protect against moisture and corrosive agents during transit and storage. Each part is often individually wrapped or separated by foam inserts to prevent surface-to-surface contact and abrasion. Our storage facilities maintain stable temperature and humidity levels, further safeguarding the pristine condition of finished components.

Advanced Surface Treatments for Flawless Aluminum Finishes

Achieving superior surface finishes often requires more than just basic machining. Advanced surface treatments enhance aluminum’s inherent properties, providing increased durability, aesthetic appeal, and resistance to environmental degradation. ly-machining offers a comprehensive range of these specialized processes.

Precision Anodizing to Enhance Protection & Aesthetics

Anodizing is an electrolytic passivation process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Precision in anodizing parameters—current density, electrolyte composition, temperature, and duration—is critical to achieving a uniform and robust oxide layer. We specialize in Type II (sulfuric acid anodizing) for aesthetic and protective purposes, and Type III (hard coat anodizing) for extreme wear and corrosion resistance. Proper sealing after anodizing is paramount to prevent staining and maintain its protective qualities.

Chemical Conversion Coatings for Corrosion Resistance

Chemical conversion coatings, such as Alodine or chromate conversion, create a thin, electrically conductive, and corrosion-resistant layer on the aluminum surface. This process is ideal for applications requiring good electrical conductivity, excellent primer adhesion for subsequent painting, or as a standalone corrosion barrier in less demanding environments. It provides a subtle golden to clear finish without significantly altering part dimensions, crucial for tight tolerance components.

Polishing & Mechanical Finishes for Superior Luster

For applications demanding a high aesthetic appeal or ultra-smooth surfaces, mechanical finishing techniques are employed. These include various levels of polishing, brushing, and bead blasting. Precision polishing removes micro-scratches and imperfections, yielding a mirror-like luster. Brushing creates a directional satin finish, while bead blasting provides a matte, uniform texture. Each method requires careful control to achieve consistent results and maintain dimensional accuracy.

Specialized Coatings for Extreme Environments

Beyond conventional treatments, we also provide specialized coatings designed for unique challenges. These include plasma electrolytic oxidation (PEO) for extreme hardness and wear resistance, or fluoropolymer coatings for enhanced non-stick properties and chemical inertness. These advanced solutions are tailored for industries such as aerospace, medical, and defense, where components must perform flawlessly under the most severe conditions. Our technical team works closely with clients to specify the exact coating that meets their performance criteria.

Troubleshooting Existing Whitening or Discoloration Issues

When discoloration occurs, a systematic troubleshooting approach is essential to diagnose the problem accurately and implement effective solutions. Our expertise extends beyond prevention to comprehensive analysis and remediation of existing surface defects. We understand the urgency and cost implications of such issues.

Assessment Techniques for Identifying Defect Origins

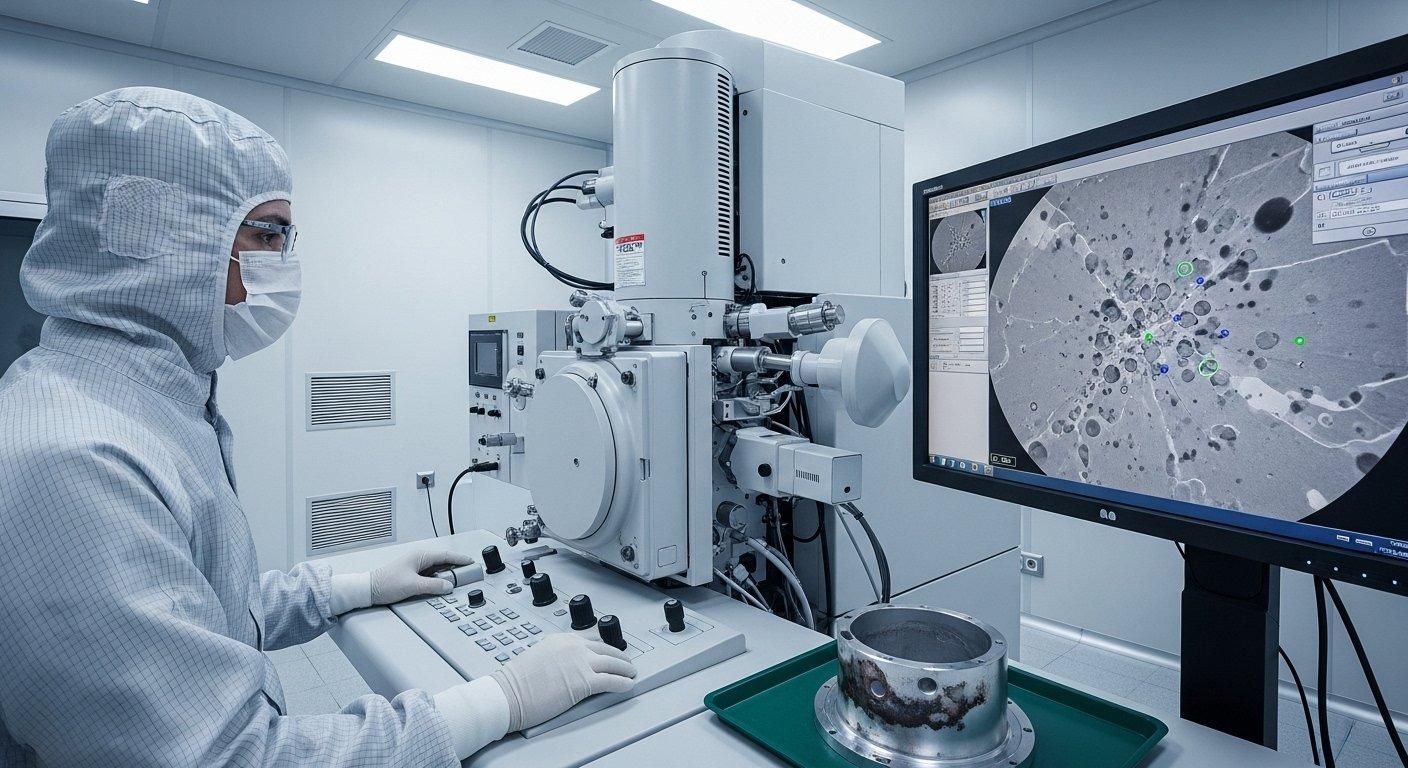

Our diagnostic process employs a range of assessment techniques. Visual inspection under controlled lighting helps categorize the defect type (e.g., hazing, spotting, pitting, uneven color).

Microscopic analysis (SEM with EDX) can identify residual contaminants, analyze oxide layer thickness, or pinpoint material segregation. Chemical analysis of surface residues helps determine the exact nature of pollutants. This comprehensive approach allows us to differentiate between material flaws, process errors, or environmental damage.

Remedial Actions for Minor Surface Imperfections

For minor surface imperfections, remedial actions may be possible. Light polishing or re-brushing can sometimes remove superficial stains or minor scratches. For parts with very localized and slight discoloration, selective chemical cleaning under strict control might be considered. However, any remedial action must be carefully evaluated to ensure it does not compromise dimensional tolerances or the underlying material integrity. Our goal is always to salvage parts without sacrificing quality.

When to Rework or Re-treat Parts

More significant or widespread discoloration often necessitates rework or re-treatment. For anodized parts, this typically involves stripping the existing anodic layer using specialized chemical baths, followed by thorough cleaning and re-anodizing. This process is complex and carries risks, including potential dimensional changes or surface etching if not performed correctly. Our technicians meticulously assess the feasibility of rework, considering the part’s geometry, alloy, and cost-effectiveness versus scrapping and remanufacturing.

Expert Consultation for Complex Discoloration Cases

For highly complex or recurring discoloration challenges, our engineering team provides expert consultation. We delve into historical production data, material certifications, and process logs to uncover subtle interdependencies. We also conduct accelerated aging tests or environmental simulations to replicate conditions and identify root causes.

This deep technical expertise allows us to provide definitive solutions, often involving adjustments to the material specification, machining parameters, or post-treatment chemistries, ensuring long-term prevention.

Partnering for Consistent Quality: Our CNC Aluminum Expertise

Choosing the right manufacturing partner is crucial for ensuring the consistent quality and reliability of your CNC aluminum parts, especially concerning challenging surface finishes. At ly-machining, we are not just a supplier; we are a technical partner committed to delivering flawless components.

Source Manufacturer Advantage for Quality Control

As a direct source manufacturer based in Shenzhen, China, ly-machining maintains complete control over every stage of production. This vertically integrated approach allows us to implement stringent quality checks from raw material procurement to final inspection and packaging.

We eliminate the variables introduced by multiple subcontractors, providing greater transparency and accountability. Our in-house capabilities ensure that every process, particularly those impacting surface finish, adheres to our exacting standards.

Transparent Pricing & Value-Driven Solutions

We believe in fostering long-term partnerships built on trust and transparency. Our pricing structure is clear, detailed, and competitive, reflecting the true value of high-quality manufacturing and expert technical support.

We focus on providing value-driven solutions that minimize your total cost of ownership by eliminating scrap, reducing rework, and ensuring on-time delivery of defect-free parts. Our goal is to reduce the hidden costs associated with inconsistent quality.

Deep Technical Expertise in Aluminum Surface Finishes

Our core strength lies in our profound technical expertise, particularly in aluminum material science and surface chemistry. Our team of engineers and metallurgists possesses a deep understanding of how different aluminum alloys react to various machining processes and surface treatments. This knowledge enables us to foresee potential issues, design optimal manufacturing workflows, and troubleshoot complex surface challenges proactively. We are dedicated to continuous research and development in finishing technologies.

Case Studies: Preventing & Resolving Surface Issues

A major client was struggling with intermittent surface discoloration on critical aerospace components, leading to significant delays and scrap. Our engineering team conducted a comprehensive analysis, identifying a subtle interplay of material impurities and specific machining parameters.

By modifying the alloy sourcing and optimizing the cutting fluid composition, we completely eliminated the issue, saving them over $100,000 in annual rework and accelerating their product launch by two months. This demonstrates our commitment to deep technical expertise and ability to deliver high-quality parts.

Don’t let surface defects compromise your product’s quality or reputation. Leverage our deep technical expertise and high-quality manufacturing. Contact our CNC aluminum specialists today for a free project consultation and discover a partnership built on precision, reliability, and transparent pricing.

**Article Summary:**

This comprehensive guide on CNC aluminum surface discoloration identifies root causes such as material quality, machining parameters, and environmental factors. It outlines preventative strategies including optimized material preparation, rigorous cleaning, and appropriate surface treatments.

The article also covers advanced troubleshooting, emphasizing expert assessment and remediation. Finally, it highlights ly-machining’s role as a trusted partner, offering deep technical expertise and transparent, quality-driven solutions for flawless aluminum finishes.

Frequently Asked Questions About Aluminum Finishes

Q1: What is the most common cause of white spots or hazing on anodized aluminum parts?

A1: The most common cause of white spots or hazing on anodized aluminum is improper post-anodizing sealing or inadequate rinsing after cleaning and anodizing.

If the anodic layer is not thoroughly sealed, it remains porous and susceptible to absorbing moisture, detergents, or atmospheric contaminants, leading to hydration stains or chemical reactions that appear as white patches. Additionally, residual alkaline cleaning agents or mineral impurities from unpurified rinse water can react with the aluminum surface, causing etching or cloudiness.

Q2: Can different aluminum alloys react differently to the same surface treatment, potentially causing discoloration?

A2: Yes, absolutely. Different aluminum alloys have varying compositions, particularly in alloying elements like copper, zinc, and silicon. These elements can significantly influence how the alloy reacts to surface treatments such as anodizing or chemical conversion coatings. For instance, alloys with high copper content (e.g., 2000 series) are more prone to corrosion and can be challenging to anodize uniformly, often resulting in darker or mottled finishes.

Conversely, 5000 series alloys, known for their corrosion resistance, generally yield more consistent and brighter anodized finishes. Understanding the specific alloy’s reactivity is critical for selecting appropriate treatment parameters to prevent discoloration.

Q3: How does ly-machining ensure consistent surface finish quality across large production batches?

A3: ly-machining ensures consistent surface finish quality through a multi-faceted approach involving stringent process control, advanced equipment, and continuous monitoring.

We implement detailed Standard Operating Procedures (SOPs) for every stage, from material inspection to final packaging, ensuring repeatable results. Our state-of-the-art CNC machinery is regularly calibrated, and cutting fluids are continuously monitored for concentration and purity. For post-treatment, we utilize automated lines with precise control over chemical baths, temperatures, and dwell times.

Furthermore, our dedicated quality control team conducts in-process checks and final inspections, using microscopic analysis and spectroscopy to verify surface integrity and prevent any discoloration issues across large production batches.