Understanding CNC Machining Part Costs

Is the true cost of your CNC machined parts a constant mystery? You’re not alone. Many project managers and engineers grapple with unpredictable expenses and opaque pricing. But what if you could not only understand every factor influencing your CNC part costs but also actively control them, transforming uncertainty into a strategic advantage?

CNC machining part costs are primarily influenced by material choice, design complexity, machining time, and production volume. Understanding these core drivers allows for strategic design optimization and informed supplier selection, leading to reduced overall manufacturing expenses and predictable project budgeting.

Material Selection’s Impact on CNC Costs

The choice of raw material is often the most significant cost driver in CNC machining. Different materials present varying challenges and expenses throughout the manufacturing process. Selecting the optimal material balances performance requirements with economic considerations.

Raw Material Type and Grade

Material types such as aluminum, steel, brass, titanium, and various plastics have inherently different purchase prices. Specialized alloys or certified grades, often required for critical applications, will also command a premium over standard commercial grades due to their specific properties and stringent quality control.

Material Form and Availability

The initial form of the raw material (e.g., bar stock, plate, billet) influences how much material needs to be removed, impacting machining time and waste. Readily available standard sizes can reduce lead times and material costs, while custom-ordered or exotic forms may incur higher expenses and longer acquisition periods.

Material Hardness and Machinability

The hardness and inherent machinability of a material directly affect the machining parameters, tool life, and required machine power. Harder or tougher materials necessitate slower cutting speeds, lighter depths of cut, and more frequent tool changes, all of which increase overall machining time and expendable tooling costs.

To illustrate, consider some common materials and their machinability characteristics:

| Material Type | Machinability Rating (Relative) | Common Applications | Typical Cost Impact (Relative) |

|---|---|---|---|

| Aluminum (6061) | Excellent | Prototyping, aerospace, structural components | Low |

| Brass (C360) | Excellent | Fittings, electrical connectors, decorative parts | Medium |

| Stainless Steel | Fair to Good (depending on grade) | Medical, food processing, marine, high-strength | High |

| Titanium (Ti-6Al-4V) | Poor to Fair | Aerospace, medical implants, high-performance | Very High |

| ABS Plastic | Excellent | Consumer goods, enclosures, functional prototypes | Low |

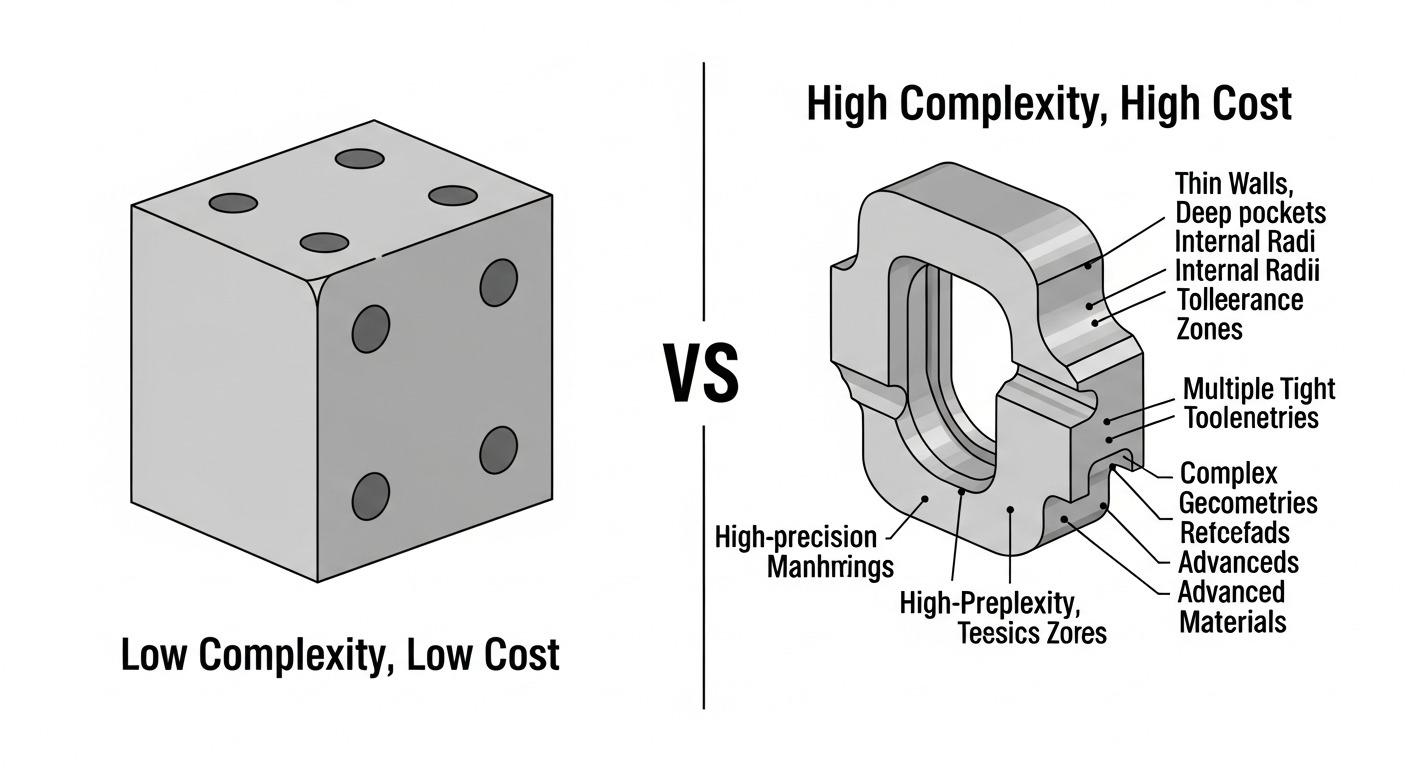

Part Design Complexity and CNC Cost

The geometric complexity of a part is a major driver of custom CNC part pricing. Intricate features demand more specialized machining strategies, longer processing times, and often, more advanced equipment. Simplifying a design can lead to significant cost reductions.

Geometric Features and Tolerances

Parts with numerous features, complex contours, deep pockets, or thin walls require more programming, more tool paths, and potentially more machine setups. Tight tolerances, especially on multiple dimensions, demand slower machining speeds, more precise tooling, and increased inspection frequency, thereby extending machining time and increasing quality control costs.

Consider the cost implications of various tolerance levels:

| Tolerance Level (e.g., IT grades) | Description | Machining Impact | Cost Impact (Relative) |

|---|---|---|---|

| Standard (e.g., +/- 0.005 inches) | Typical for general applications | Standard machining speeds, less frequent measurement | Low |

| Precision (e.g., +/- 0.001 inches) | Requires careful machining, good surface finish | Slower speeds, more advanced tooling, increased inspection | Medium |

| High-Precision (e.g., +/- 0.0002 inches) | Critical for mating parts, specific functionality | Highly specialized tooling, temperature control, multiple inspection stages | High |

Surface Finish Requirements

The specified surface finish (e.g., as-machined, polished, bead blasted) directly impacts the time spent in the finishing stages. Achieving a very smooth surface (e.g., Ra 0.8 µm or better) often requires additional machining passes with fine tools, or secondary operations like grinding, lapping, or polishing, each adding to the overall cost.

Thin Walls and Intricate Details

Parts with extremely thin walls or very intricate details are prone to vibration and deformation during machining. This necessitates slower machining feeds and speeds, specialized fixtures, and often, multiple machining operations to ensure structural integrity and dimensional accuracy, significantly increasing machining time and potentially tool wear.

Machining Process Choices Affecting CNC Cost

The methods chosen for manufacturing a part play a crucial role in determining its final cost. This encompasses everything from the initial machine setup to specialized operations and post-processing. Strategic choices here can significantly reduce CNC machining costs.

Setup Time and Programming Complexity

Each time a new part is introduced or a design changes, setup time is incurred. This includes fixture preparation, tool loading, and programming the CNC machine. Complex geometries require more intricate programming, leading to longer initial setup times. For low-volume runs, setup time can be a substantial portion of the per-part cost.

Machining Time and Tool Wear

The actual time the machine spends cutting the material is a direct cost driver. Factors like material hardness, part geometry, surface finish requirements, and cutting parameters all dictate machining duration. Tool wear is also a consideration; aggressive machining strategies can shorten tool life, necessitating more frequent and costly tool replacements.

Specialized Tooling Needs

Standard tools are cost-effective, but certain part features may require specialized or custom cutting tools. These tools often have higher upfront costs and may have longer lead times, impacting both budget and production schedules. Utilizing standard tool geometries where possible can help reduce custom CNC part pricing.

Post-Processing Operations

Beyond the primary machining, many parts require secondary operations. These can include deburring, heat treatment, anodizing, plating, painting, or assembly. Each additional step adds labor, material, and time costs. Integrating post-processing efficiently into the workflow is crucial for CNC cost optimization.

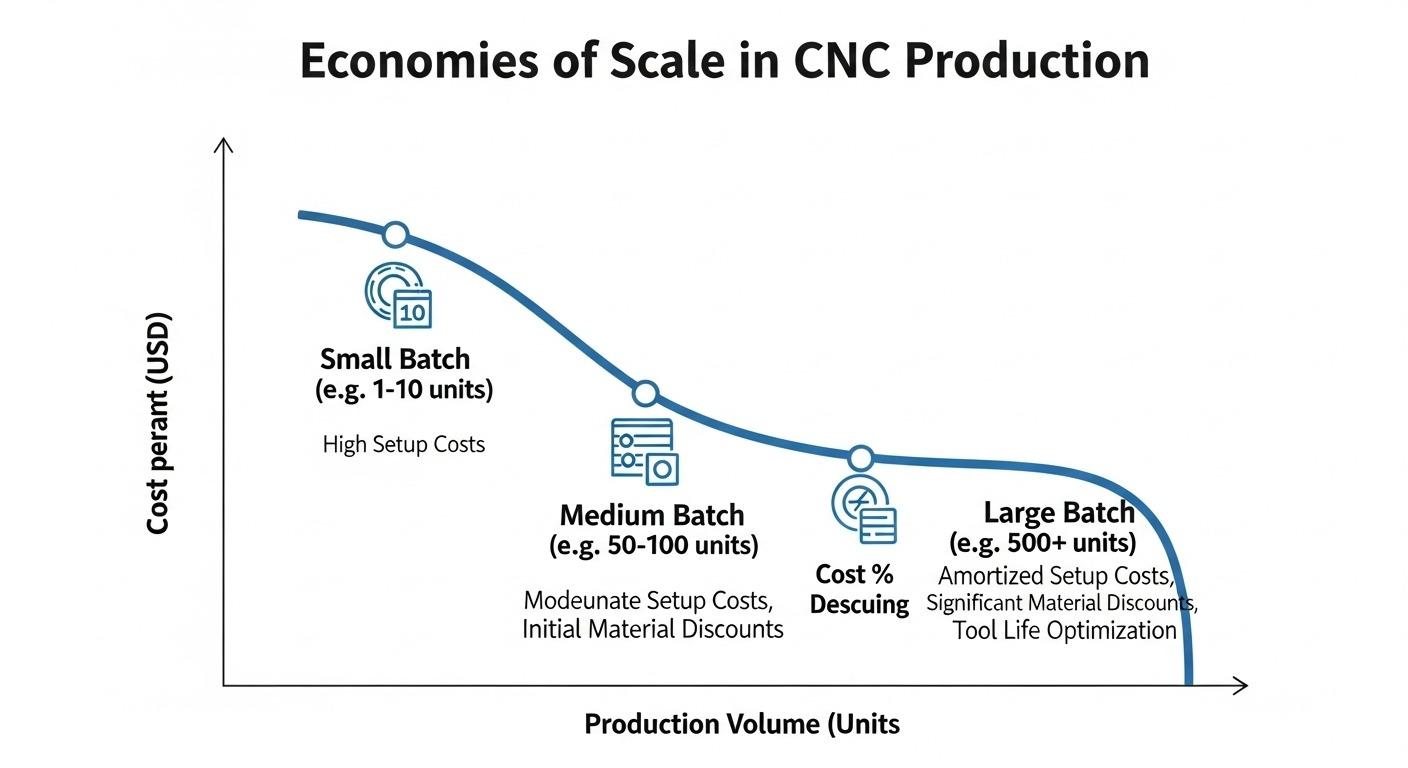

Production Volume and Economies of Scale for CNC

Production volume profoundly influences the unit cost of CNC machined parts. Higher volumes typically lead to lower per-part costs due to economies of scale and efficient resource utilization.

Batch Size and Unit Cost Reduction

Large production runs allow fixed costs, such as setup time and programming, to be amortized over many units, significantly reducing the per-part cost. Efficient material purchasing at bulk rates also contributes to lower overall expenses. Smaller batch sizes inherently carry a higher per-unit cost.

Tooling Amortization Across Volume

The cost of any specialized fixtures or custom tooling is distributed across the total number of parts produced. For low-volume projects, tooling costs represent a larger proportion of the unit price. In high-volume production, this cost becomes negligible per piece.

Lead Time and Rush Order Premiums

Standard lead times allow manufacturers to optimize their production schedules, group similar jobs, and procure materials efficiently. Rush orders disrupt this optimization, often requiring overtime labor, expedited material shipping, and machine rescheduling, all of which contribute to higher per-part costs. Planning ahead is key to reduce CNC machining costs.

Quality Control and Inspection Costs in CNC

Ensuring the quality and precision of CNC machined parts is non-negotiable, but the extent of quality control measures directly impacts the overall cost. The factors affecting CNC quotes often include these stringent requirements.

Inspection Method and Frequency

Different inspection methods (e.g., manual caliper measurements, CMM inspection, optical scanning) vary in cost and time. The frequency and comprehensiveness of inspections—first-article inspection, in-process checks, final inspection of every part vs. statistical sampling—all contribute to the labor and equipment costs associated with quality assurance.

Certification and Traceability Requirements

For industries like aerospace, medical, or defense, stringent certification (e.g., ISO, AS9100) and full material traceability are often required. These necessitate detailed documentation, specific process controls, and extended record-keeping, adding to the administrative and operational costs. These overheads are factors affecting CNC quotes for critical components.

Supplier Expertise Influencing CNC Machining Costs

The choice of manufacturing partner significantly influences the final cost, quality, and delivery of custom CNC part pricing. A reputable supplier like ly-machining, based in China’s Shenzhen, offers distinct advantages.

Factory Overhead and Efficiency

A well-managed factory with modern equipment, optimized workflows, and skilled personnel can produce parts more efficiently, translating to competitive pricing. Conversely, outdated machinery or inefficient processes can drive up labor and machine time costs. Our facilities in Shenzhen leverage advanced technology and streamlined operations to offer better value.

Technical Know-how and Innovation

A supplier’s deep technical expertise and willingness to innovate directly impact cost optimization. Experienced engineers can provide valuable Design for Manufacturability (DFM) feedback, suggesting material alternatives, design modifications, or machining strategies that reduce costs without compromising performance. This proactive approach helps reduce CNC machining costs significantly.

Transparent Pricing Practices

Transparency in quoting is paramount. A clear breakdown of costs allows clients to understand where their money is going and to identify areas for potential optimization. Opaque pricing can lead to hidden fees and budget overruns. At ly-machining, we are committed to providing detailed and understandable quotes, fostering trust and long-term partnerships.

Optimizing CNC Machining Costs Effectively

Optimizing CNC machining costs requires a holistic approach, considering every stage from design to production. Collaborating closely with your manufacturing partner is crucial to achieve the best balance of cost, quality, and performance. Effective communication about design intent, critical features, and budget constraints enables suppliers to provide the most efficient manufacturing solutions.

Article Summary

The cost of CNC machined parts is influenced by several critical factors: material type and machinability, the geometric complexity of the design and its required tolerances, the specific machining processes and post-processing operations, and the overall production volume. Additionally, the efficiency, technical expertise, and transparent pricing of your chosen supplier play a significant role.

By understanding these elements, clients can make informed decisions and collaborate with manufacturers to optimize designs and production strategies, ultimately leading to more cost-effective and high-quality parts.

Frequently Asked Questions About CNC Machining Costs

What is Design for Manufacturability (DFM) and how does it reduce CNC machining costs?

Design for Manufacturability (DFM) is an engineering practice focused on optimizing a product’s design to make it easier and more cost-effective to produce. In CNC machining, DFM involves simplifying part geometries, standardizing features, ensuring appropriate tolerances, selecting machinable materials, and avoiding overly complex designs.

By addressing these factors early in the design phase, DFM can significantly reduce machining time, tool wear, material waste, and the need for expensive secondary operations, directly lowering overall production costs.

How does material selection affect lead times and overall project costs?

Material selection profoundly impacts both lead times and total project costs. Common materials like aluminum are readily available, leading to shorter procurement times and lower raw material expenses. Conversely, specialized alloys or exotic materials often have longer lead times for sourcing and higher purchase prices.

Furthermore, materials with poor machinability require slower cutting speeds and more frequent tool changes, extending machining time and increasing labor and tooling costs, which collectively prolong lead times and raise the overall project budget.

Why is supplier transparency important for managing CNC part manufacturing cost drivers?

Supplier transparency is crucial for effectively managing CNC part manufacturing cost drivers because it provides clarity and predictability. A transparent supplier offers detailed breakdowns of costs, explaining how material, machining time, tooling, and post-processing contribute to the final quote.

This allows clients to understand the value proposition, identify areas for design or specification optimization to reduce expenses, and accurately budget for their projects. Without transparency, clients risk unexpected costs, hidden fees, and an inability to make informed decisions about their custom CNC part pricing.

Ready to gain ultimate clarity on your CNC machining costs and unlock superior value? Partner with our expert engineers. Contact us today for a transparent, no-obligation quote and a complimentary Design for Manufacturability (DFM) consultation tailored to your specific project needs.

Discover the difference our source manufacturing advantage and deep technical expertise can make for your next high-quality part.