Quality Assurance Practices

When assessing an aluminum machining supplier, one of the top factors is their commitment to quality assurance. A reliable supplier should adhere to international standards such as ISO 9001, which ensures a systematic approach to quality management. This means they have processes in place for monitoring their production, conducting regular audits, and consistently improving their methods. Look for suppliers that can showcase their quality control processes, perhaps through certifications or customer testimonials that validate their commitment to high standards.

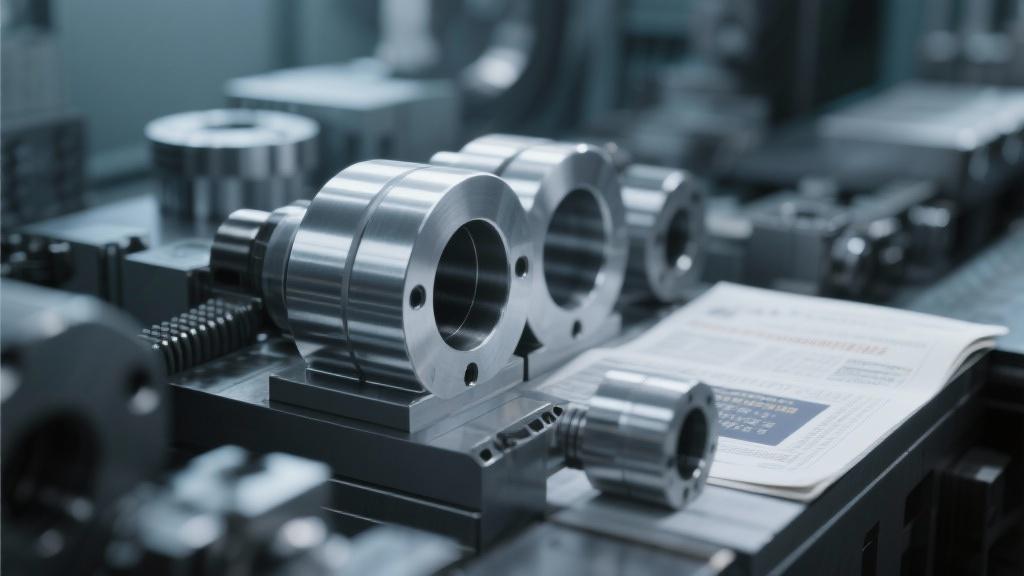

Advanced Technology and Capabilities

Another significant aspect is the technology and machinery the supplier employs. Top-tier suppliers invest in modern CNC machines and other automation technologies that enhance precision and efficiency. It’s worthwhile to inquire about their equipment and capabilities. Do they have the capacity to handle large volumes? Can they manage complex designs with tight tolerances? Suppliers who keep up with technological advancements are more likely to deliver superior products consistently.

Experienced Staff and Customer Service

The expertise of the staff can greatly impact the machining quality. Look for suppliers with a skilled team that includes experienced machinists and engineers. Their knowledge can be invaluable, especially when dealing with unique challenges or specific requirements. Moreover, excellent customer service is essential. A supplier who is responsive and communicates well can significantly streamline your projects. After all, quick problem resolution and effective communication are vital in keeping timelines on track.

Flexibility and Customization

Every project comes with its own set of requirements. A top aluminum machining supplier should offer flexibility and customization options tailored to your needs. This adaptability might involve adjusting production schedules, modifying designs, or accommodating last-minute changes. Suppliers who demonstrate a willingness to work with you beyond standard offerings can be a huge asset, especially for businesses that require bespoke solutions.

Pricing and Value

While lower prices can be enticing, they often correlate with a decrease in quality. Therefore, consider the overall value rather than just the pricing. A supplier providing high-quality parts may cost more upfront, but the long-term savings through reduced failures, less rework, and better project efficiency can outweigh initial expenses. A proper balance of cost and quality is essential for a fruitful partnership.

By evaluating these factors, you can make more informed decisions when selecting an aluminum machining supplier, paving the way for successful and productive collaborations that meet your manufacturing needs.

What does quality assurance involve for aluminum machining suppliers?

Quality assurance for aluminum machining suppliers is all about ensuring products meet certain standards. This includes having processes in place for monitoring production and conducting regular audits. Suppliers should follow international standards, like ISO 9001, to guarantee the quality and consistency of their output.

It’s advisable to ask potential suppliers about their quality control practices. A reliable supplier will have clear methods for evaluating their manufacturing processes and will be able to demonstrate how they continuously improve their operations.

How important is advanced technology in choosing a machining supplier?

Advanced technology plays a crucial role in the effectiveness of an aluminum machining supplier. Suppliers with modern CNC machines and automation capabilities are generally able to produce parts with higher precision and efficiency. This can be essential for meeting tight tolerances and complex designs.

Before choosing a supplier, it’s a good idea to inquire about the types of equipment they use. Understanding their technological capabilities will give you insight into their ability to handle your specific project needs.

Why is experienced staff a significant factor in selecting a supplier?

The expertise of the staff is vital when it comes to aluminum machining. Skilled machinists and engineers understand how to optimize processes and troubleshoot potential issues, which can enhance the quality of the final product. A knowledgeable team adds value to your collaboration.

So, when you’re vetting suppliers, be sure to ask about their staff qualifications and experience. A capable team can make a world of difference in the outcomes of your projects.

What should I know about flexibility and customization options?

Flexibility and customization are key components of a top-tier aluminum machining supplier. Each project can have unique requirements, so suppliers that offer customizable solutions can tailor their services to better fit your needs. This might include adjusting production schedules or modifying designs based on your feedback.

Having a partner willing to adapt can save you time and money, especially if you need to make last-minute changes. Make sure to discuss what customization options are available before making a decision.

How do I evaluate pricing and value when choosing a supplier?

Evaluating pricing alongside the overall value is crucial when selecting an aluminum machining supplier. While lower prices might seem appealing, they often come with trade-offs in quality. It’s vital to look for suppliers that balance cost and quality effectively.

Consider the long-term benefits of working with a reliable supplier. Higher quality components might involve a greater upfront investment, but they can lead to fewer failures and better efficiency down the line, ultimately saving you money.