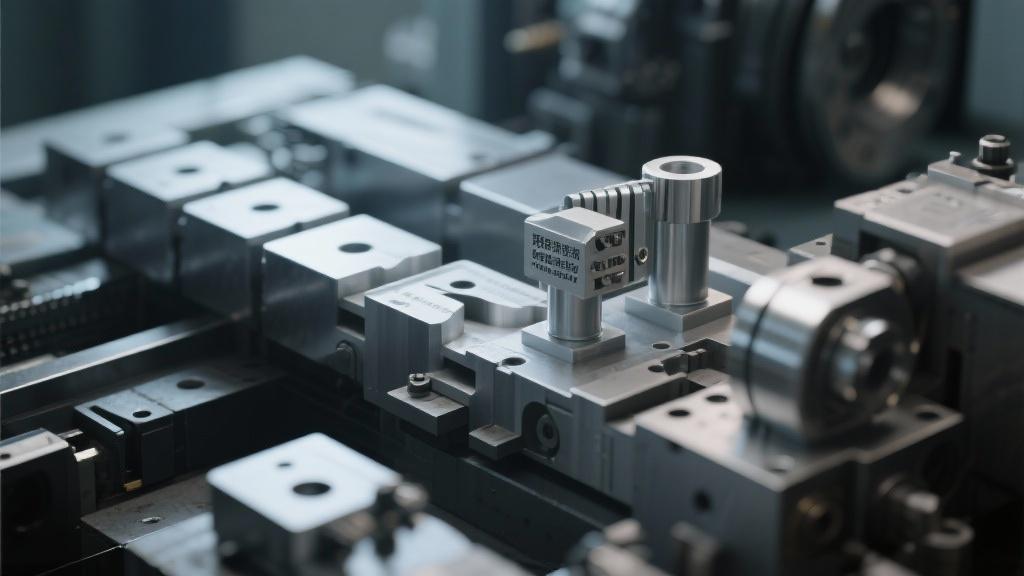

When it comes to aluminum machining, the fixture design is crucial for achieving precision and efficiency. Let’s break down some common questions surrounding fixture factors and explore the critical aspects involved.

Question: Why is stability essential in fixture design for aluminum machining?

Answer: Stability is one of the most important aspects of fixture design. When machining aluminum, any movement can lead to inaccuracies. A stable fixture ensures that the workpiece remains firmly in place during the machining process, which significantly reduces the risk of errors. When I helped a colleague with a project last year, we upgraded his fixture to include lockable clamps. This simple change improved the machining precision significantly, proving that even small adjustments can make a big difference.

Question: How does the accessibility of the workpiece influence fixture design?

Answer: Accessibility is about how easily operators can reach the workpiece for machining or adjustments. If operators struggle to access the part, it can slow down production and even lead to mistakes. For instance, strategically placing the fixture helps ensure that the tools can easily reach all parts of the workpiece without unnecessary repositioning. While working on a prototype, we designed a fixture that allowed for quick tool changes, which saved us a lot of time and hassle.

Question: What materials should be considered for creating fixtures?

Answer: The choice of materials directly affects the performance of the fixture. Generally, manufacturers prefer using durable materials like steel or aluminum alloys. Steel provides the necessary rigidity, while aluminum is lightweight and easier to handle. It’s essential to balance strength and weight—using aluminum where possible can help with speed without sacrificing too much stability. When I worked on a project with a machining company, they switched to aluminum fixtures for light parts, which accelerated their workflow.

Question: How adaptable should a fixture design be?

Answer: Adaptability is essential, especially in industries that face frequent design changes. A versatile fixture can be adjusted or modified to hold different workpieces, thus maximizing its use. This flexibility can save costs and time associated with building multiple fixtures for each part. During a recent project, we created modular components for a fixture, which replaced the need for several specialized fixtures. This versatility significantly improved our operational efficiency.

Question: What role does ergonomics play in fixture design?

Answer: Ergonomics immensely impacts operator safety and comfort. An ergonomic fixture reduces strain by allowing operators to work in a natural position, significantly lowering the risk of injuries. I recall an instance where our team redesigned a fixture to accommodate standing work positions. This change boosted the team’s productivity and morale as they expressed fewer discomfort complaints during long shifts.

Conclusion:

Considering these essential factors—stability, accessibility, material choice, adaptability, and ergonomics—serves as a foundation for creating effective fixtures in aluminum machining. Whether you are a newcomer to machining or have years of experience, prioritizing these factors can lead to better overall performance and results.

Why is stability essential in fixture design for aluminum machining?

Stability is one of the most important aspects of fixture design. When machining aluminum, any movement can lead to inaccuracies. A stable fixture ensures that the workpiece remains firmly in place during the machining process, reducing the risk of errors significantly.

By maintaining stability, manufacturers can enhance overall machining precision. A fixture that doesn’t shake or wobble will allow for cleaner cuts and better tolerances, making it a fundamental consideration in the design process.

What materials are commonly used for fixtures in aluminum machining?

The choice of materials can greatly influence the performance of the fixture. Generally, durable materials like steel or aluminum alloys are preferred. Steel provides the strength needed for heavy-duty machining, while aluminum is valued for its lightweight properties.

Finding the right balance between strength and weight is essential. For example, aluminum fixtures work well for lighter parts, while steel is often the go-to for more robust applications. This decision impacts not only the fixture’s effectiveness but also the ease of use during machining operations.

How does accessibility affect fixture design?

Accessibility is crucial for efficient machining. If operators find it difficult to access the workpiece, it can lead to increased production times and the potential for mistakes as they struggle to reposition tools. A well-designed fixture should guarantee that tools can reach all areas of the workpiece with ease.

When designing fixtures, it’s important to consider the workflow and layout of the workspace. Making sure that everything is within easy reach goes a long way in promoting operational efficiency and reducing fatigue among workers.

What does ergonomic design mean for fixtures?

Ergonomics plays a significant role in fixture design by focusing on operator comfort and safety. An ergonomic fixture allows workers to maintain a natural working position, thereby reducing the physical strain that can come from poor fixture design.

This kind of design not only promotes comfort but also enhances productivity. When operators are working in a stress-free environment, they can concentrate better on the task and reduce the likelihood of errors arising from discomfort or fatigue.

How adaptable should fixtures be for different machining needs?

Adaptability is key when it comes to designing fixtures, especially in industries with frequent design changes. A flexible fixture can be modified to hold various workpieces, maximizing its utility and minimizing the need for multiple dedicated fixtures.

This adaptability can lead to significant time and cost savings as manufacturers can quickly adjust to new projects without the need for extensive redesigns or new builds. A modular design, for instance, can allow for quick changes that keep production moving smoothly.