Unlocking CNC Material Cost’s True Proportion

Is the true cost of your CNC machined parts a mystery, often leaving you with budget surprises? Did you know that material cost, though seemingly straightforward, can silently inflate your total quotation by up to 60% if not expertly managed? Discover how a transparent partner can transform this uncertainty into a strategic advantage—it’s utterly crucial.

Our expertise, born from years in Shenzhen’s competitive CNC landscape, unequivocally proves that precise material cost analysis is not merely an accounting exercise; it is the bedrock of project profitability and—let me emphasize—client trust!

Demystifying CNC Machined Parts Material Cost

The material component of a CNC quote, though often perceived as a simple line item, is a profoundly intricate calculation. It demands meticulous attention, far beyond mere per-kilogram rates. We must truly understand its depth.

Definition of Raw Material Cost in CNC

Raw material cost primarily encompasses the direct purchase price of the stock—be it bar, plate, or billet—required for a specific part. This fundamental figure, however, is just the initial layer; its complexities are truly staggering.

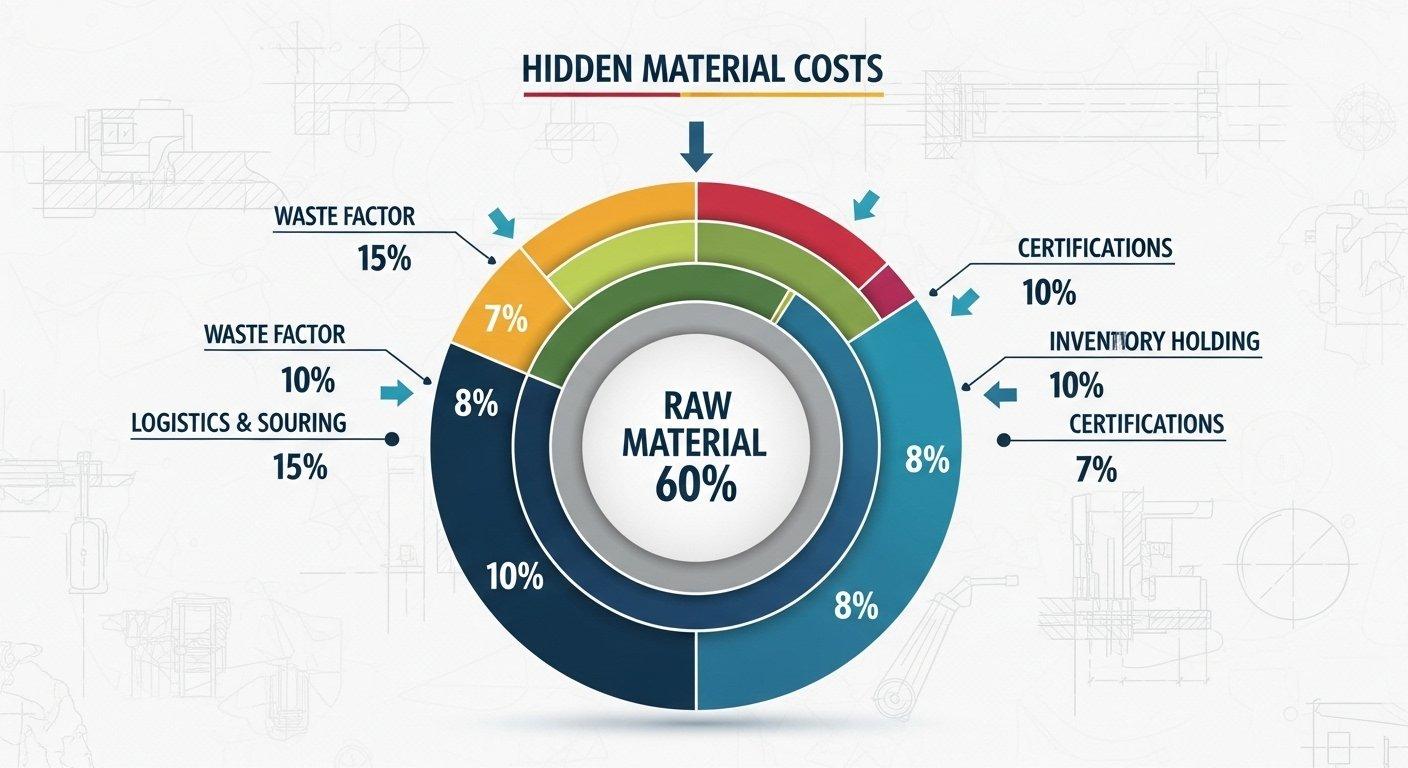

Beyond Raw: Hidden Material-Related Costs

To grasp the full financial commitment, one must delve into the often-overlooked, lurking expenditures that accrue with material procurement and processing. These hidden elements, they quietly—insidiously—magnify the total.

Waste Factor and Scrap Management

Material removal is inherent to subtractive manufacturing. The volume of material machined away, becoming swarf or scrap, represents a direct loss. We cannot deny this stark reality. How effectively this waste is managed, or indeed minimized, directly correlates to final part cost, a metric we obsess over.

Sourcing, Logistics, and Inventory Costs

The journey of material from mill to machine entails considerable expenditure. Freight, tariffs, inspection, and the capital tied up in inventory—these are not insignificant sums! Our factory shoulders these burdens, ensuring a seamless, cost-effective supply chain; it truly makes a difference.

Key Factors Influencing CNC Material Cost Proportion

Determining the material’s exact share in a total CNC quote involves navigating a constellation of variables. It is never a static calculation. We consider every single one, painstakingly.

Material Type and Grade Impact on Quote

The intrinsic properties and market dynamics of chosen alloys exert a monumental influence on pricing. This is a primary driver, undeniably.

Common vs. Exotic Alloys Pricing

Standard aluminum (e.g., 6061) or basic stainless steel (e.g., 303, 304) possess relatively stable, lower price points due to widespread availability. Conversely, superalloys, titanium, or specialized aerospace grades command a staggering premium. The difference can be extreme.

Certifications and Traceability Costs

For mission-critical applications—aerospace, medical, defense—material often demands stringent certifications (e.g., AS9100, ISO 13485) and complete traceability documentation. This verifiable provenance, while non-negotiable for safety, adds a definite cost layer. Its inclusion is an absolute requirement for quality assurance.

Here’s a stark comparison for you:

| Material Type | Typical Cost Factor (vs. 6061 Aluminum) | Machinability Index (vs. 6061) | Common Applications |

|---|---|---|---|

| Aluminum 6061 | 1.0x | 1.0x | General engineering, automotive |

| Stainless Steel 304 | 2.5x – 4.0x | 0.5x – 0.7x | Food processing, medical instruments |

| Titanium Grade 5 | 10.0x – 15.0x | 0.2x – 0.3x | Aerospace, high-performance components |

| Inconel 718 | 20.0x – 30.0x | 0.1x – 0.2x | Jet engines, extreme temperature parts |

Part Geometry and Machinability Influence

Intricate geometries, thin walls, deep pockets, or features demanding multi-axis machining inherently increase material waste and lengthen machining time. Material removal strategies become paramount. A less machinable material, coupled with complex geometry, creates a vicious cost spiral.

Order Volume and Economies of Scale

Larger production runs allow for more efficient material utilization—bulk purchasing discounts become accessible, and setup waste is amortized over more units. Small batches, regrettably, bear a disproportionately higher unit material cost. This is an unavoidable economic truth.

Calculating Material Cost’s Share in Total CNC Quotes

To truly optimize a project, one must first possess an unwavering grasp of its constituent cost elements. This necessitates a systematic approach, absolutely.

Standard Formula for Material Cost Percentage

A fundamental calculation helps frame the discussion. The material cost percentage can be roughly determined by: (Total Material Cost / Total Part Quote) \* 100%. Ah, but the devil, as always, is in the “Total Material Cost” component—what *exactly* does that encompass? It’s not just the raw stock, is it?

Case Studies: Varied Material Cost Proportions

The material cost’s proportional share varies dramatically based on part characteristics and industry demands. This variability, frankly, can stun the uninitiated.

Simple Part, High Volume vs. Complex, Low Volume

Consider a simple bushing from 6061 aluminum, produced in quantities of ten thousand. Its material cost might only constitute 20-30% of the total unit price. Now, contrast that with an aerospace sensor housing, intricately designed from Inconel 718, one hundred units only. Here, material could easily dominate, accounting for 50-70% of the quote. The difference is colossal.

Cost Breakdown for Different Industries

Different sectors have unique material requirements. The automotive industry, often seeking high volume and cost-effectiveness, uses materials with relatively lower material cost percentages. Aerospace, with its extreme performance demands, frequently sees material as the overwhelming cost driver. It’s a fundamental divergence.

Let’s illustrate with practical examples. Imagine these two scenarios:

| Cost Component | Simple Aluminum Bushing (High Volume) |

|---|---|

| Raw Material | 25% |

| Machining Labor | 40% |

| Overhead & Profit | 35% |

| Total | 100% |

| Cost Component | Complex Inconel Housing (Low Volume) |

|---|---|

| Raw Material | 60% |

| Machining Labor | 25% |

| Overhead & Profit | 15% |

| Total | 100% |

Strategies to Optimize CNC Parts Material Cost

An astute engineer, or indeed any client truly committed to fiscal prudence, demands strategies—actionable methodologies—to rein in material expenditures. We provide precisely that.

Material Selection Consultation with Experts

Our role, as your trusted manufacturing partner, transcends mere execution; we proactively engage in material selection dialogues. This consultative approach is, quite frankly, non-negotiable for true optimization.

Performance vs. Cost Trade-off Analysis

Sometimes, a slightly more expensive material yields profoundly better performance, offsetting its initial cost through extended lifespan or superior functionality. Or, conversely, a slightly less robust, more affordable alternative may suffice perfectly for a non-critical application. We meticulously analyze this delicate balance. It’s an art, truly.

Design for Manufacturability (DFM) for Material Savings

DFM is not merely an advisory service; it is a collaborative engineering imperative. By optimizing designs for machining efficiency—reducing unnecessary material bulk, consolidating features, or suggesting alternative part constructions—we directly slash material waste. This is where innovation meets economy.

Smart Sourcing and Supplier Network Leverage

Our extensive, vetted network of material suppliers allows us to source high-quality stock at competitive prices. We navigate volatile commodity markets with an almost uncanny agility, leveraging long-term relationships to secure optimal rates. It’s a strategic advantage, plain and simple.

Waste Reduction and Recycling Initiatives

Internal processes are ruthlessly scrutinized for waste. We invest in advanced nesting software for sheet materials, optimize bar feed lengths, and implement rigorous scrap segregation and recycling programs. Every gram saved is a cost avoided, a principle we champion.

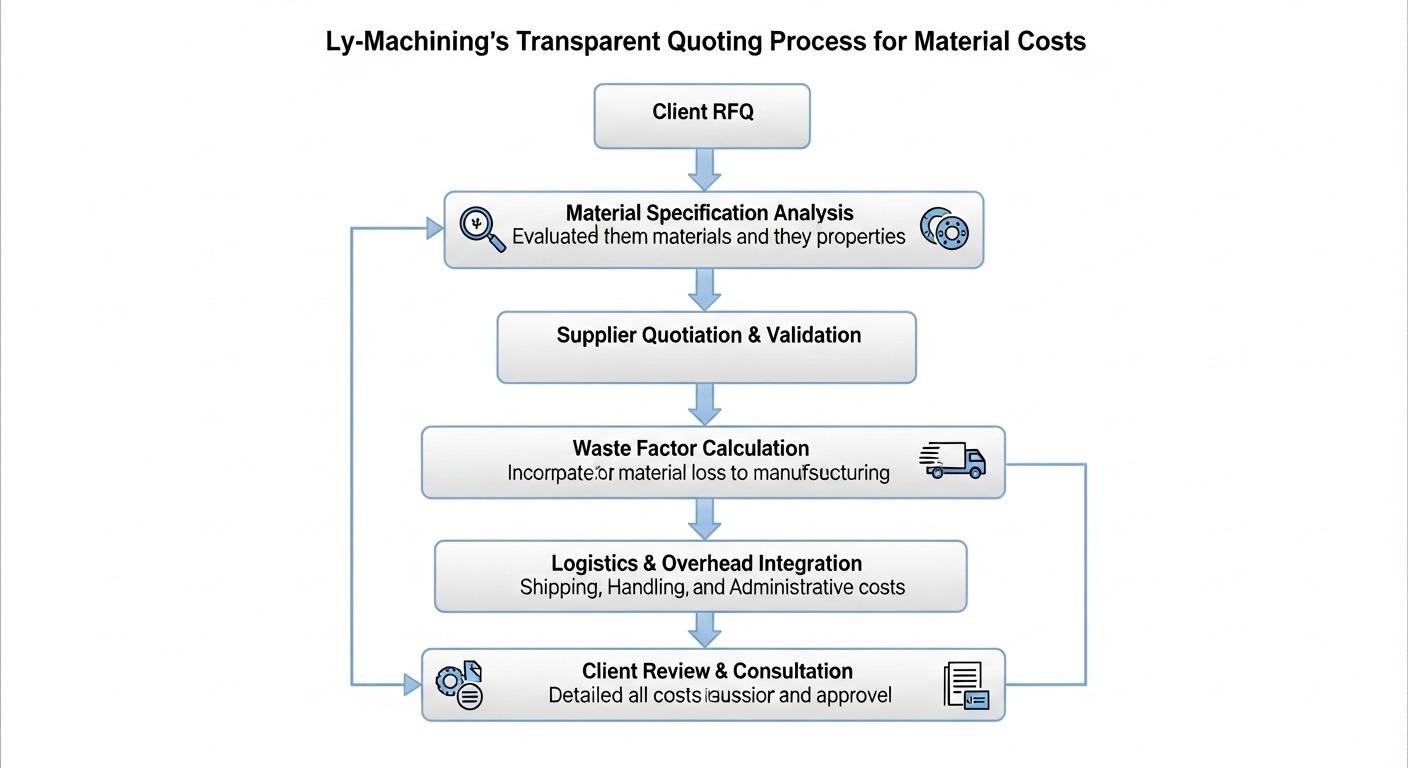

Achieving Transparent Material Pricing for CNC Projects

The opaqueness surrounding material costs in manufacturing quotes is, regrettably, an industry-wide malady. But not here; not at ly-machining. We vehemently believe in absolute clarity.

Our Transparent Quoting Methodology

Our approach is a direct antidote to industry ambiguity, ensuring you always comprehend precisely what you are paying for. It’s an undeniable commitment to integrity.

Itemized Material Costs Disclosure

Every quote we issue includes a meticulously itemized breakdown of material costs. You will see the specific alloy, grade, dimensions of stock, and unit price. No nebulous “material fee”; only verifiable figures. This level of detail, we find, cultivates immense client confidence.

Explaining Markups and Overheads

Yes, there are overheads—handling, inventory, waste management, and quality control. We candidly explain these minor markups, demonstrating their direct contribution to the overall efficiency and reliability of your project. We hide nothing; transparency is our creed.

Benefits of Transparent Pricing for Clients

The advantages for our clientele are manifold. Transparent pricing fosters a profoundly robust trust between factory and client. It empowers informed decision-making regarding material choices, allowing precise budget management without agonizing unknowns. It’s a partnership, truly.

Future Trends Shaping CNC Machining Material Costs

The landscape of manufacturing, much like the global economy it serves, is perpetually in flux. We must keep our eyes firmly on the horizon, anticipating shifts.

Impact of Global Supply Chain Dynamics

Geopolitical events, trade policies, and natural disasters can dramatically disrupt material supply chains, leading to unforeseen price volatility. Our factory maintains diversified sourcing strategies to mitigate these inherent risks, a proactive stance that benefits everyone.

Emerging Materials and Their Cost Implications

The advent of novel materials—advanced composites, metal matrix composites, custom alloys—promises enhanced performance but often arrives with a hefty price tag. We diligently track these developments, assessing their long-term cost-benefit ratios for our clients.

Role of Automation in Material Handling Costs

Increased automation in material storage, retrieval, and loading processes promises greater efficiency, reduced labor costs, and minimized waste. This technological advancement, we contend, will ultimately contribute to more stable, and perhaps even lower, material costs over time. We embrace such progress with an almost zealous enthusiasm.

Case Study: Optimizing an Aerospace Sensor Enclosure

A prominent aerospace client approached ly-machining with a design for a complex sensor enclosure, originally specified in a very expensive, difficult-to-machine titanium alloy. Their concern was the prohibitive material cost, which jeopardized project viability. It was a truly daunting challenge.

Our engineers, after rigorous DFM analysis and extensive material research, proposed an alternative: a high-strength aluminum alloy (7075-T6) with a specialized surface treatment. We validated its performance against their rigorous specifications, demonstrating it met all functional requirements.

This strategic material pivot resulted in an astonishing 40% reduction in raw material costs, alongside a 25% decrease in machining time due to improved machinability. The client not only saved significantly but also gained a lighter, equally durable component, all delivered ahead of schedule. It was an undeniable victory.

Article Summary:

Material cost in CNC machining is a complex, often underestimated, factor that can heavily influence total project expenditure. Beyond raw stock price, hidden costs like waste, logistics, and certifications play a significant role. Factors such as material type, part geometry, and order volume critically shape this proportion.

ly-machining advocates for transparency and expert consultation, utilizing DFM and smart sourcing to optimize costs. We believe a clear, itemized quoting methodology is paramount, fostering trust and empowering clients. The future will see global dynamics and emerging materials continue to reshape these costs, with automation offering new efficiencies.

Frequently Asked Questions

What is DFM’s impact on material costs?

Design for Manufacturability (DFM) directly reduces material waste and optimizes machining processes. By suggesting design changes, like altering wall thicknesses or simplifying features, we ensure less raw material is consumed, resulting in significant cost savings. This is a critical step.

Why are some material costs opaque?

Opaque material costs often stem from a lack of detailed breakdown or the inclusion of hidden markups without justification. Some manufacturers prefer to obscure these details, making it difficult for clients to understand the true value. Our factory vehemently opposes this practice.

How does ly-machining ensure transparency?

We provide meticulously itemized material costs in every quote, detailing the specific alloy, dimensions, and unit price. Additionally, we candidly explain any necessary overheads or markups. This comprehensive disclosure ensures clients have complete clarity and confidence in their investment.