ABS CNC Machining Tolerance Guide

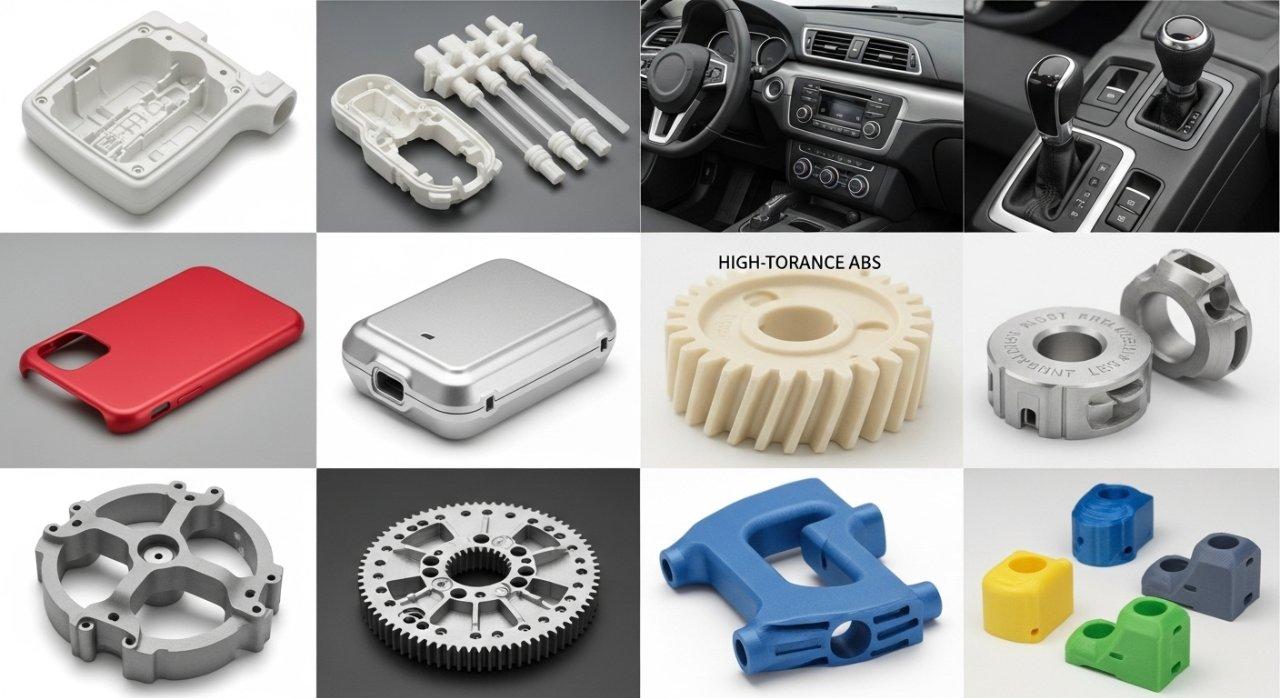

Quick Solution: Achieving optimal ABS CNC Machining Tolerances demands precise engineering, understanding material properties, and leveraging advanced CNC Plastic Precision techniques for reliable, high-quality plastic parts.

Are critical tolerance deviations in your ABS CNC parts draining your project budget and delaying market entry? In our experience, inconsistent dimensional accuracy is a primary source of frustration and costly rework for many clients.

Navigating the complexities of ABS machining, especially when high precision is paramount, requires a deep understanding of material behavior and advanced manufacturing capabilities. This guide will demystify ABS CNC machining tolerances, offering expert insights from a source manufacturer’s perspective.

Discover how precision engineering and expert insights can transform your ABS designs from concept to perfect reality, ensuring your components meet the most stringent specifications for optimal performance and cost-efficiency.

Why ABS Tolerance Matters for Your Project

Impact on Part Functionality

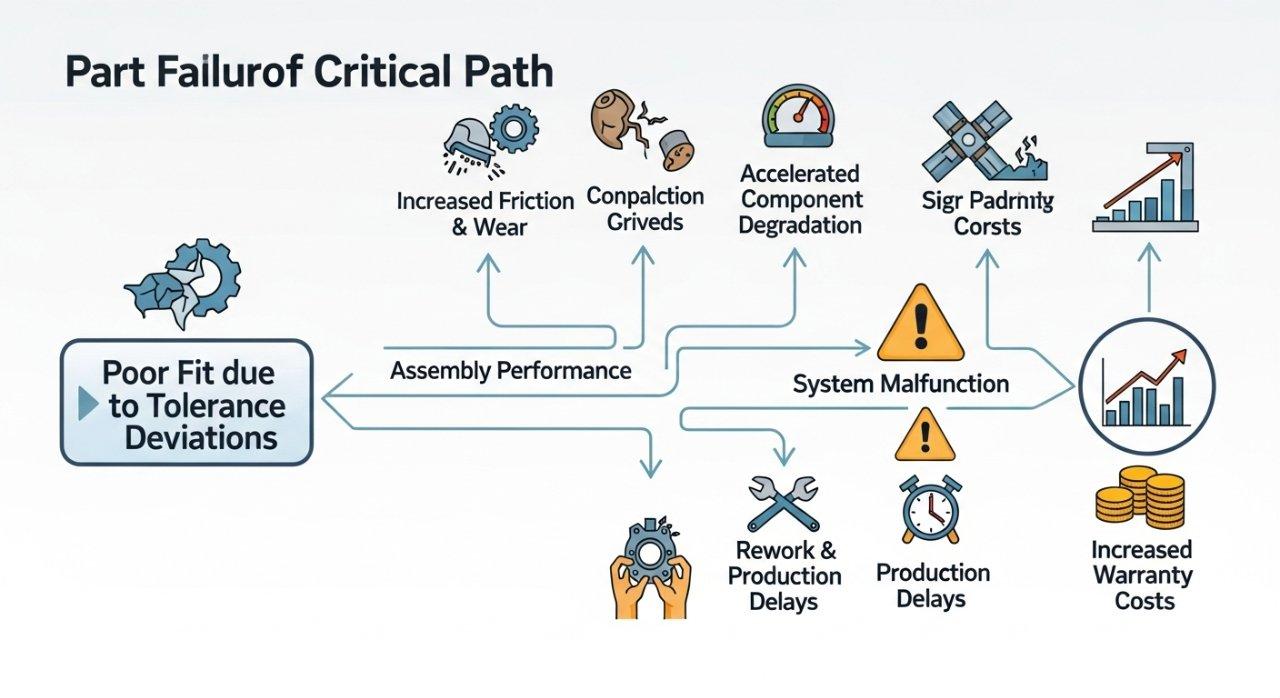

Precise ABS CNC machining tolerances are fundamental to a part’s intended function. Deviations, even slight ones, can compromise critical assemblies. They directly affect fit, form, and overall performance, potentially leading to operational failures.

For instance, a medical device enclosure with loose tolerances might not seal properly, endangering sensitive internal components. Or, an automotive component could fail prematurely due to improper mating.

Cost Implications of Tight Tolerances

Specifying overly tight tolerances without technical justification can significantly increase costs. Tighter tolerances demand more machining time, specialized tooling, and advanced metrology. This raises manufacturing complexity and the overall unit price.

Conversely, insufficiently defined tolerances can lead to unacceptable scrap rates or costly post-machining adjustments, often exceeding the cost of initially achieving the correct precision.

Avoiding Common Machining Issues

Properly defined and achieved ABS CNC machining tolerances are critical for mitigating common manufacturing problems. These include warpage, inconsistent surface finishes, and excessive burring. Such issues can compromise the part’s aesthetic appeal and mechanical integrity.

A well-controlled machining process, informed by a comprehensive ABS machining guide, reduces defects and ensures consistent quality. This proactive approach saves both time and material in the long run.

Understanding ABS Material Properties & CNC

Key Characteristics of ABS for Machining

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer renowned for its excellent mechanical properties. It offers a good balance of strength, rigidity, and impact resistance. These characteristics make it a popular choice for various CNC Plastic Precision applications.

In our experience, ABS machines relatively well, allowing for consistent chip formation under optimal conditions. Its amorphous structure contributes to its ease of machining compared to crystalline polymers.

Thermal Expansion and Shrinkage

A critical consideration for ABS CNC machining tolerances is its thermal expansion coefficient. ABS expands and contracts more significantly with temperature changes than many metals. This material property must be carefully accounted for during machining.

Post-machining, parts will cool, leading to a predictable shrinkage that must be anticipated in the design and machining strategy. Precise control of the machining environment and tool path compensation are essential for managing this.

Machinability Challenges of ABS

While ABS is generally considered machinable, it presents specific challenges for achieving high CNC Plastic Precision. Heat generation during cutting can lead to localized melting or gummy material buildup on tools. This can affect surface finish and dimensional accuracy.

Effective chip evacuation is also crucial to prevent re-cutting chips and marring the surface. Additionally, improper tool geometry or cutting parameters can cause burring or micro-cracking, compromising the final part quality.

Table: Key ABS Material Properties for Machining

| Property | Value (Typical) | Impact on Machining & Tolerances |

|---|---|---|

| Density | 1.04 – 1.07 g/cm³ | Affects part weight, tool forces |

| Tensile Strength | 35 – 55 MPa | Indicator of strength, affects chip formation |

| Modulus of Elasticity | 2.0 – 2.8 GPa | Material rigidity, tool deflection considerations |

| Heat Deflection Temp (HDT) | 85 – 105 °C (185 – 221 °F) | Indicates softening point, influences heat management |

| Thermal Expansion Coefficient | 70-100 x 10⁻⁶ mm/mm/°C | CRITICAL for dimensional stability and shrinkage prediction |

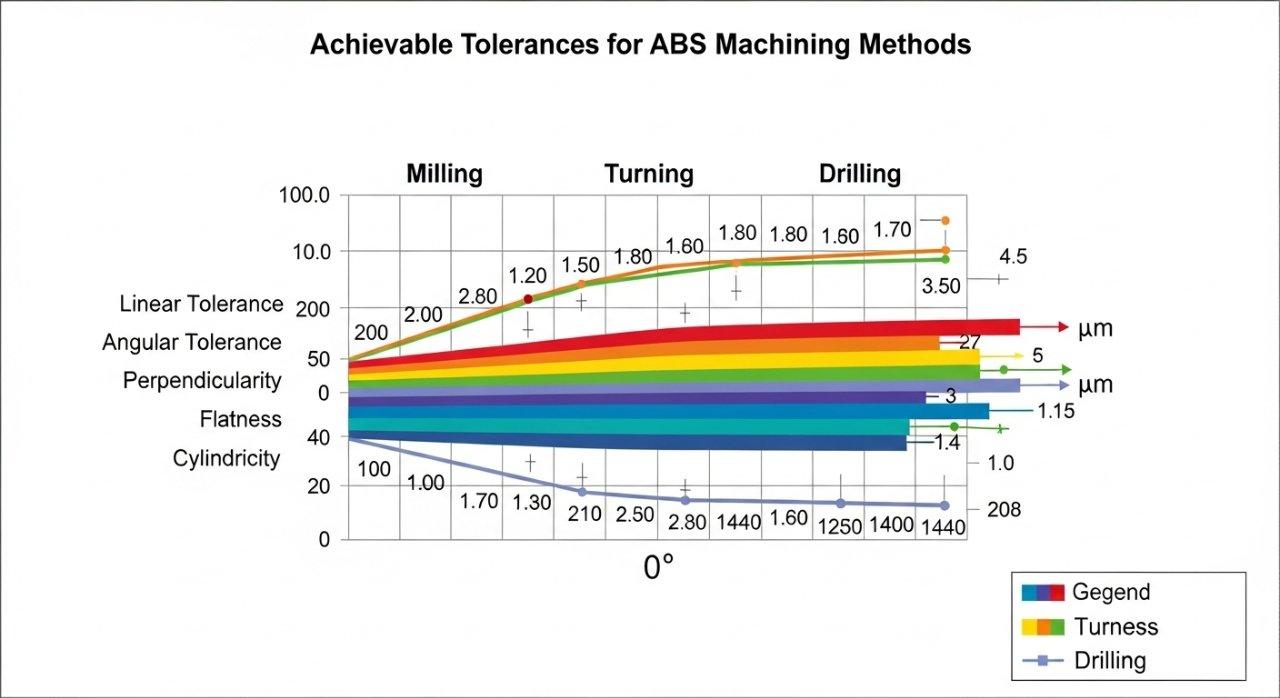

Achievable Tolerances in ABS CNC Machining

General Industry Standards for ABS

When specifying plastic machining tolerances for ABS, we often reference industry standards like ISO 2768-1. This standard provides general tolerance classifications (e.g., fine, medium, coarse) for linear and angular dimensions. These can serve as a baseline.

However, ISO 2768-1 is often generalized for various materials and processes. For true CNC Plastic Precision in ABS, specific application requirements usually dictate tighter, more tailored tolerances. Our experience helps interpret these standards for real-world ABS projects.

Factors Influencing Precision

Achieving specific ABS CNC machining tolerances is a multivariate problem. Many interdependent factors contribute to the final part’s accuracy. Understanding these elements is key to process control.

Machine Capabilities and Rigidity

High-performance, rigid CNC machines with advanced motion control systems are paramount. These machines minimize vibration and backlash, directly translating to superior dimensional accuracy and repeatability.

Regular calibration and preventive maintenance are non-negotiable for maintaining peak machine performance.

Tooling Selection and Wear

The choice of cutting tools, including material, geometry, and coating, profoundly impacts ABS CNC machining tolerances. Sharp, specialized tools designed for plastics prevent melting and provide cleaner cuts.

Tool wear is another critical factor. Worn tools generate more heat, leading to dimensional drift and poor surface finish. Proactive tool management is essential for consistent precision.

Machining Parameters (Speeds, Feeds)

Optimizing cutting speeds, feed rates, and depth of cut is crucial for controlling heat generation and chip formation in ABS. Incorrect parameters can lead to material deformation, melting, or excessive stress. This directly affects the achieved plastic machining tolerances.

Our engineers meticulously develop and fine-tune these parameters for each unique part geometry and material batch.

Part Geometry and Wall Thickness

Complex geometries with thin walls or deep pockets pose greater challenges for maintaining tight ABS CNC machining tolerances. Thin walls are prone to vibration and thermal distortion during machining.

Consideration for fixturing and support is also vital for these delicate features.

Post-Processing Effects

Even after machining, post-processing steps like deburring, sanding, or polishing can affect final dimensions and surface finish. While necessary, these operations must be carefully controlled to avoid removing too much material. This could push the part outside the specified plastic machining tolerances.

Typical Linear & Geometric Tolerances

In our facility, with high-end equipment and experienced operators, we can achieve remarkably tight ABS CNC machining tolerances. These vary depending on feature size, geometry, and specific requirements.

For linear dimensions, we typically aim for ranges significantly tighter than general plastic machining tolerances.

Table: Typical Achievable Linear Tolerances for ABS CNC Machining (ly-machining standards)

| Feature Dimension | Standard Tolerance (mm) | Precision Tolerance (mm) |

|---|---|---|

| Up to 10 mm | ±0.05 | ±0.025 |

| 10 – 50 mm | ±0.08 | ±0.04 |

| 50 – 100 mm | ±0.10 | ±0.05 |

| Over 100 mm | ±0.1% | ±0.05% |

Note: Tighter tolerances may be achievable on a case-by-case basis through iterative process optimization and specialized tooling.

Surface Finish Considerations

Surface finish, measured in Ra (arithmetic average roughness), is an important aspect of plastic machining tolerances. For ABS, a typical machined finish might be Ra 1.6-3.2 µm. However, with optimized parameters and sharp tools, we regularly achieve finer finishes.

For aesthetic or functional requirements, we can achieve Ra values down to 0.8 µm or even lower. This often requires multiple finishing passes at high spindle speeds and low feed rates.

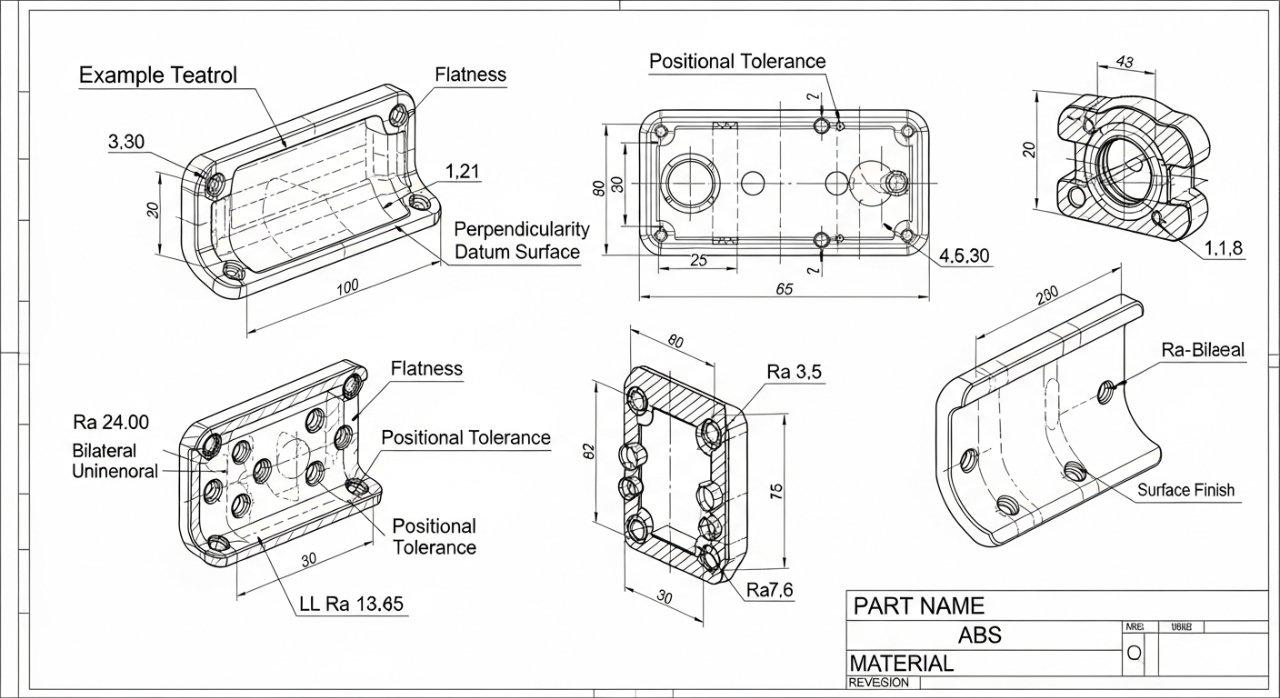

Designing for Optimal ABS CNC Tolerances

Best Practices for CAD Design

Designing ABS parts with manufacturability in mind is the first step toward achieving optimal ABS CNC machining tolerances. This includes avoiding overly thin walls, sharp internal corners, and extremely deep, narrow features.

Consider tool access and clearance during the design phase. Incorporating appropriate draft angles and fillets can also improve machinability and part quality.

Specifying Critical Dimensions

Using Geometric Dimensioning and Tolerancing (GD&T) is highly recommended for critical ABS components. GD&T provides a precise, unambiguous language for specifying plastic machining tolerances. It communicates functional requirements effectively.

This ensures that the manufactured part functions as intended, even if its actual dimensions vary slightly within the defined tolerance zones.

Minimizing Warpage and Stress

Design strategies play a significant role in mitigating warpage and internal stress, which directly impact ABS CNC machining tolerances. Uniform wall thickness throughout the part is a primary recommendation. Non-uniform sections can lead to uneven cooling and differential shrinkage.

Consideration of stress-relief features, such as corner radii and generous transitions, can also help. Our engineers often perform Design for Manufacturability (DFM) reviews to optimize designs for thermal stability.

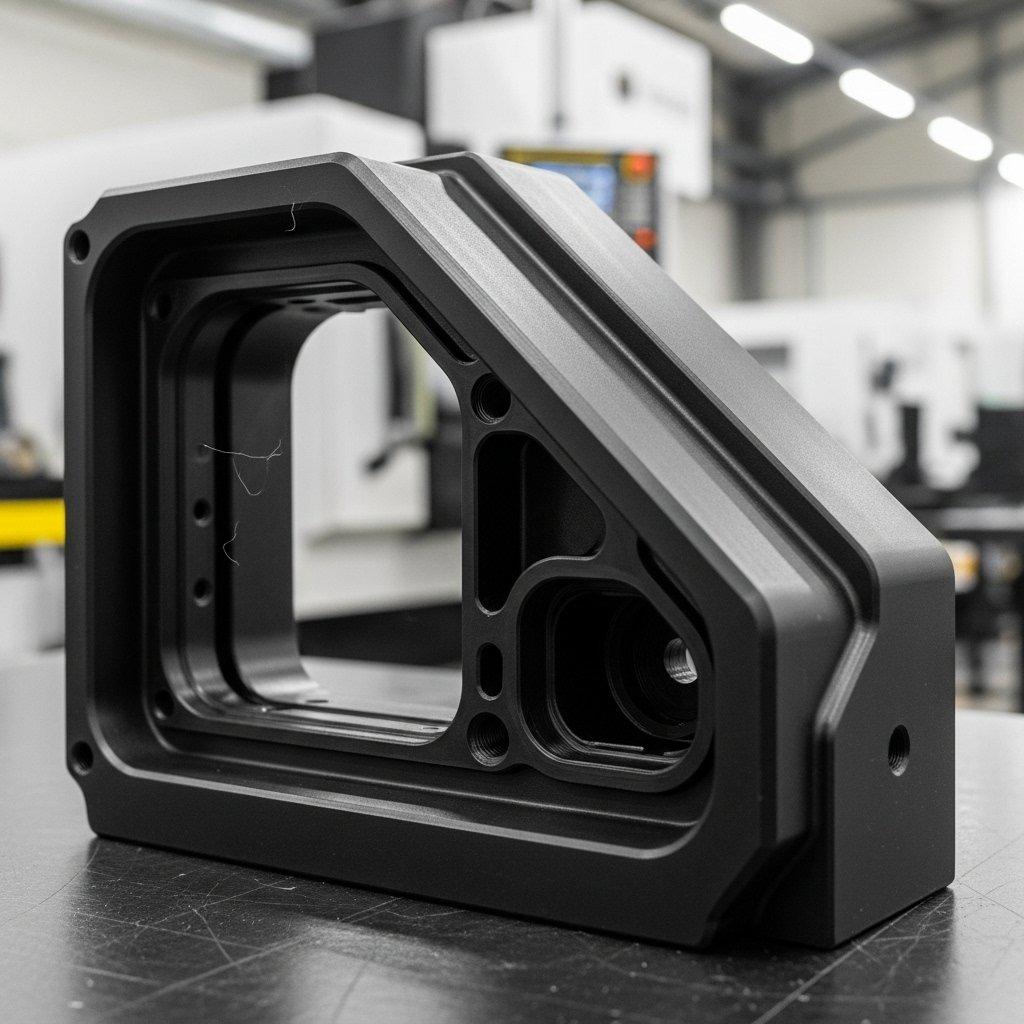

Our Expertise in High-Precision ABS CNC

Source Manufacturer Advantage

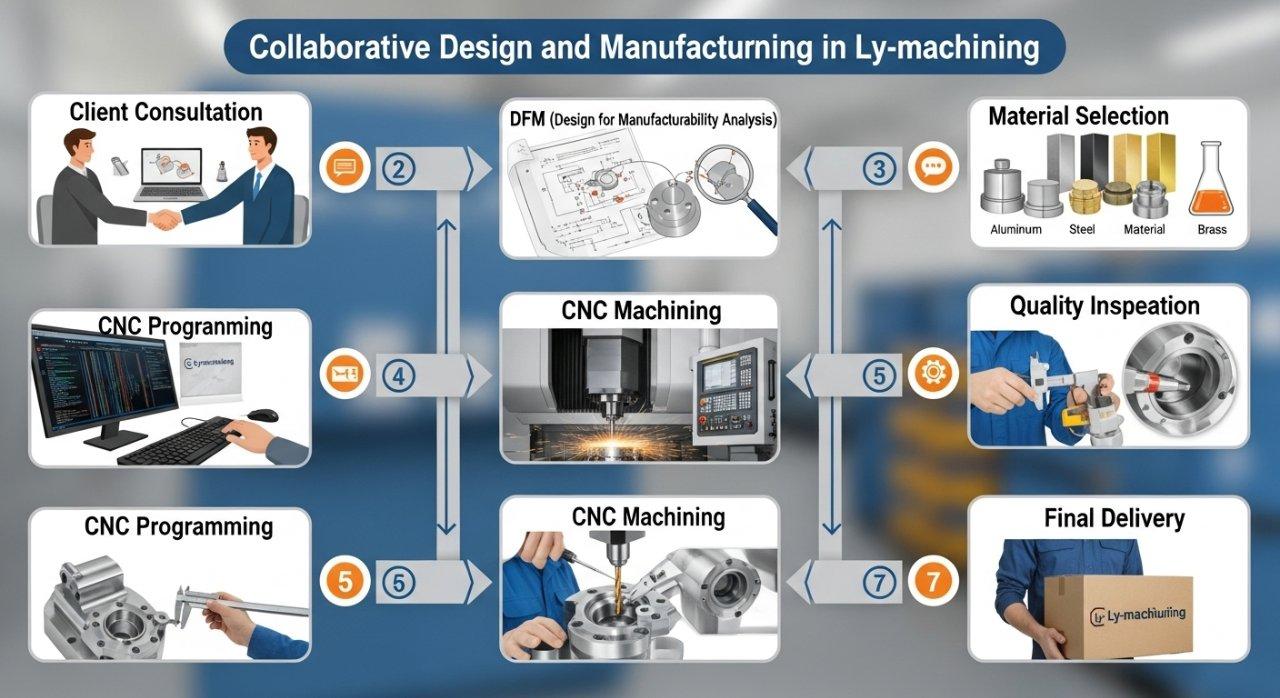

As a source manufacturer, ‘ly-machining’ offers unparalleled control over every stage of the ABS CNC machining process. From material selection and tool path programming to machining execution and quality inspection, we manage it all in-house. This integrated approach ensures consistent ABS CNC machining tolerances and superior product quality.

We eliminate the communication gaps and quality inconsistencies that can arise with multiple outsourced vendors.

Advanced Quality Control Methods

Our commitment to achieving tight plastic machining tolerances is backed by advanced quality control protocols. We utilize Coordinate Measuring Machines (CMMs), optical comparators, and precise digital micrometers. This ensures every critical dimension is verified.

We adhere to rigorous quality management systems, including ISO 9001 and AS9100 D, ensuring traceability and continuous improvement in all our operations. This is crucial for maintaining the highest CNC Plastic Precision standards.

Case Study: Precision ABS Part Success

A client approached ‘ly-machining’ with a challenge for a new medical device enclosure. Their previous supplier struggled to maintain the +/- 0.05mm flatness tolerance across a large ABS panel due to warpage, leading to assembly issues.

Our engineering team conducted a detailed DFM analysis, recommending minor design adjustments for uniform wall thickness and optimizing the machining strategy. We used specialized fixtures and multi-stage machining passes to control heat and stress.

The result was a batch of enclosures consistently meeting the tight flatness specification. This not only ensured perfect assembly but also reduced the client’s overall production costs by eliminating rework and improving product reliability.

Partner for Your ABS Machining Needs

Transparent Pricing Philosophy

We believe in a transparent pricing philosophy that accurately reflects the complexity of your ABS CNC machining tolerances. Our quotes detail the costs associated with material, machining time, tooling, and quality control. This ensures you understand the value you receive.

We work collaboratively to optimize designs, finding the sweet spot between desired precision and cost-effectiveness. Our goal is to provide exceptional value without hidden fees.

Expert Consultation & Support

Our team of experienced engineers is not just a manufacturing service; we are a technical partner. We offer complimentary design reviews and expert consultation. This guides you through the nuances of ABS machining tolerances.

From material selection to post-processing, we provide comprehensive support. We help you achieve the highest CNC Plastic Precision for your projects.

Conclusion: Mastering ABS CNC Tolerances

Key Takeaways for Success

Mastering ABS CNC machining tolerances requires a holistic approach. It encompasses deep material knowledge, advanced machine capabilities, optimized processing, and meticulous quality control. Precision in ABS is not just about the machine; it’s about the entire engineering ecosystem.

By considering all factors from design to post-processing, superior plastic machining tolerances are consistently achievable.

Next Steps for Your Project

For your next project demanding high CNC Plastic Precision, let ‘ly-machining’ be your trusted partner. Our commitment to excellence and technical expertise ensures your ABS components meet stringent requirements.

We are ready to translate your designs into perfect reality.

Get a free quote or technical consultation today to elevate the precision of your ABS CNC projects. Our expert engineering team is ready to discuss your specific ABS CNC machining tolerances and optimize your designs.

What are typical ABS machining tolerances?

For standard features, typical ABS CNC machining tolerances are around +/- 0.05 mm to +/- 0.1 mm, depending on the dimension size. With advanced machines and expertise, we often achieve tighter precision.

These achievable plastic machining tolerances are influenced by factors like part geometry and specific process controls. Our goal is to meet or exceed these industry benchmarks for our clients.

How does thermal expansion affect ABS parts?

ABS has a significant thermal expansion coefficient, meaning its dimensions change noticeably with temperature variations. During machining, heat causes expansion.

As the part cools post-machining, it contracts, leading to shrinkage that must be anticipated in the design. This is a key consideration for achieving accurate ABS CNC machining tolerances.

Can complex ABS geometries hold tight tolerances?

Yes, complex ABS geometries can hold tight tolerances, but they require careful design and advanced machining strategies. Factors like thin walls or deep pockets need specialized tooling and optimized cutting parameters.

Our engineers collaborate closely during the DFM phase to ensure your complex designs are manufacturable to high CNC Plastic Precision standards.