Achieving Perfect Anodized Aluminum Color Consistency

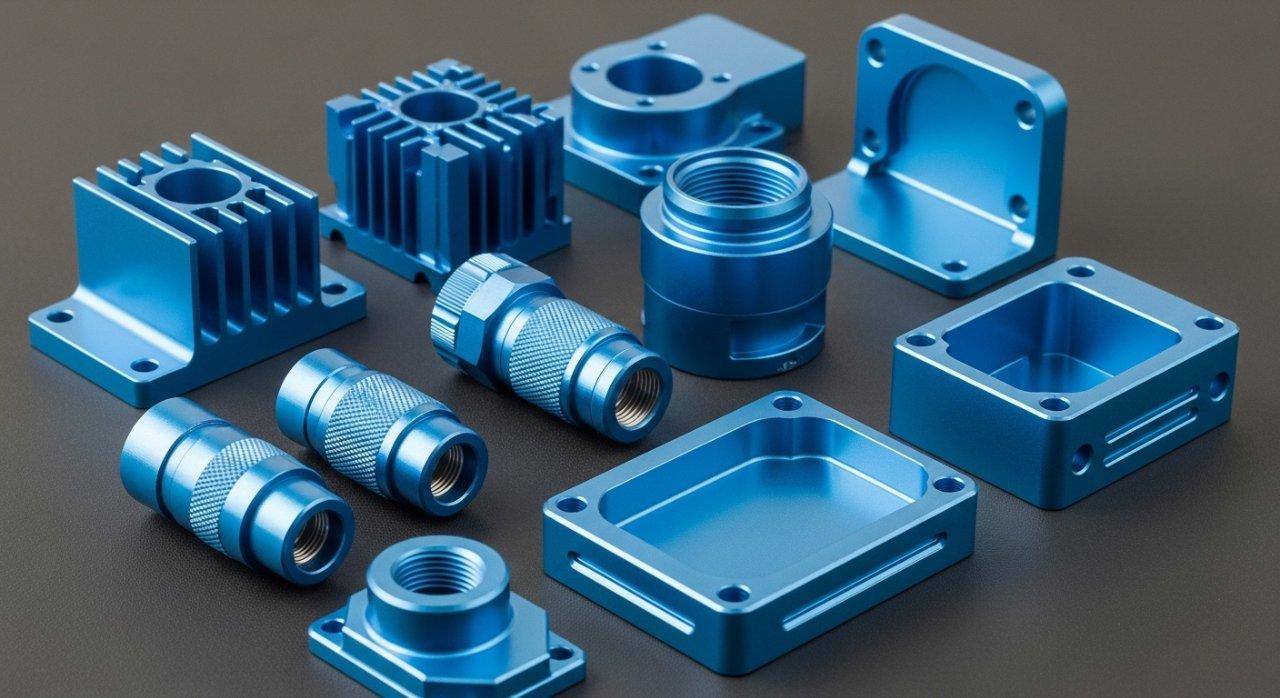

Achieving uniform anodized aluminum color consistency for electronic product casings requires precise control over alloy composition, pre-treatment, anodizing parameters, and stringent quality control, especially during anodizing color matching.

The aesthetic integrity of electronic products is paramount, with a subtle shift in color potentially undermining a brand’s quality perception. Inconsistent anodized aluminum color on casings presents a significant challenge for manufacturers, impacting both visual appeal and production costs. This often leads to frustrating rework and delays.

At ly-machining, we understand these critical pain points. We specialize in mastering the complex science and art of anodizing to deliver unparalleled anodized aluminum color consistency. Our deep technical expertise ensures your electronic product casings maintain flawless uniformity, batch after batch, every time.

Anodized Color Consistency for Electronics

The Cost of Inconsistent Color for Your Brand

Inconsistent color in electronic product casings is more than just an aesthetic flaw; it carries significant financial implications. It frequently leads to high reject rates during quality control, necessitating costly rework or even scrapping entire batches. This directly impacts your bottom line.

A common issue we see involves product returns and damaged brand reputation. Consumers expect a flawless finish, and any noticeable deviation in color between units can erode trust and diminish perceived product value. This directly affects customer satisfaction.

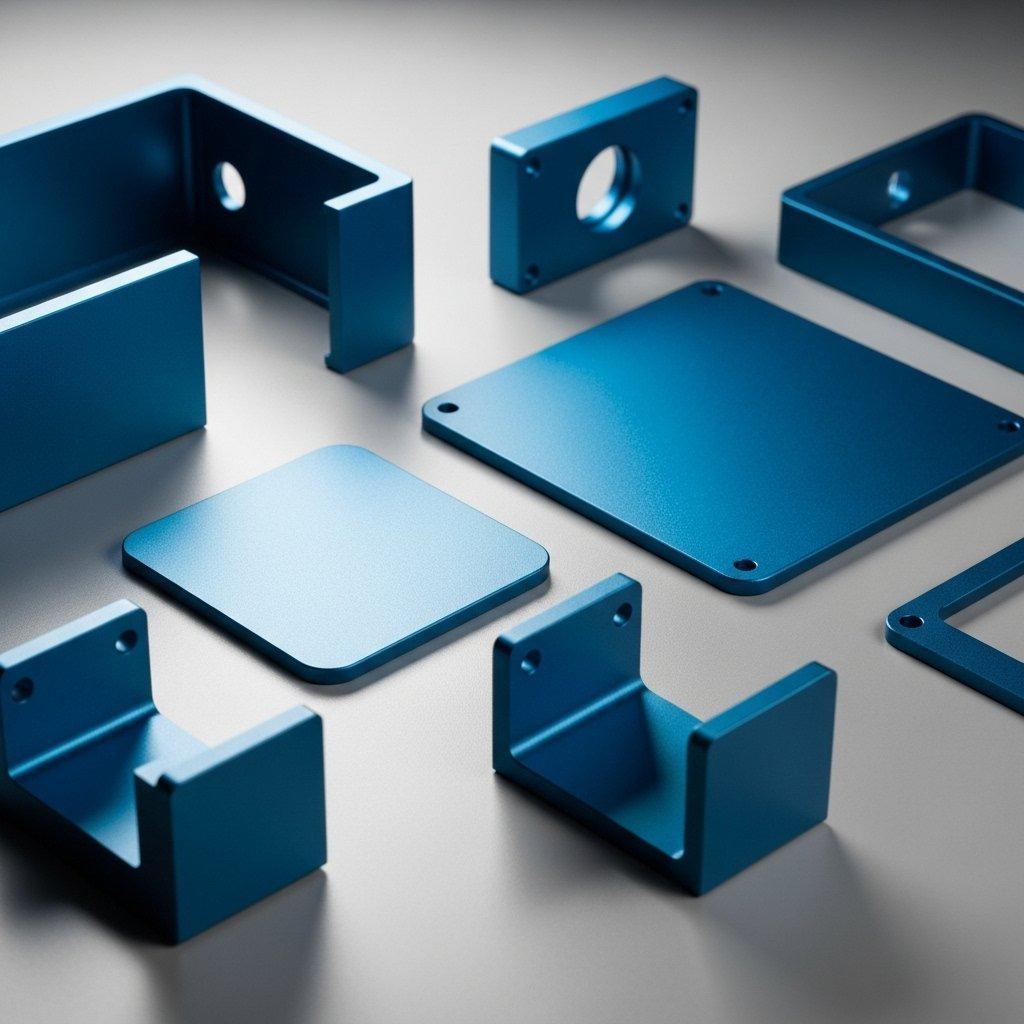

Aesthetic Excellence: Beyond the Surface

For electronic products, the external casing is the first point of interaction, and its finish speaks volumes about the product’s quality. Achieving aesthetic excellence through perfect anodized aluminum color consistency ensures a premium feel and superior brand image. It differentiates your product in a competitive market.

This visual uniformity is not merely cosmetic; it reflects the precision and care put into the manufacturing process. A meticulously matched color conveys attention to detail and a commitment to high standards. It reinforces the perceived value of the electronic device.

Meeting Strict Quality Standards

In our experience, clients in the electronics sector demand exceptional quality, often adhering to standards like ISO 9001 and AS9100. Achieving consistent anodized color is a key component of aluminum casing quality control, directly impacting these certifications. It demonstrates a robust manufacturing process.

Our internal protocols are designed to exceed these stringent requirements. We focus on quantifiable metrics to ensure every electronic product casing meets exact specifications. This commitment to precision helps our clients maintain their own high standards.

Decoding Anodized Color Consistency Challenges

Material Variability: Aluminum Alloy Impact

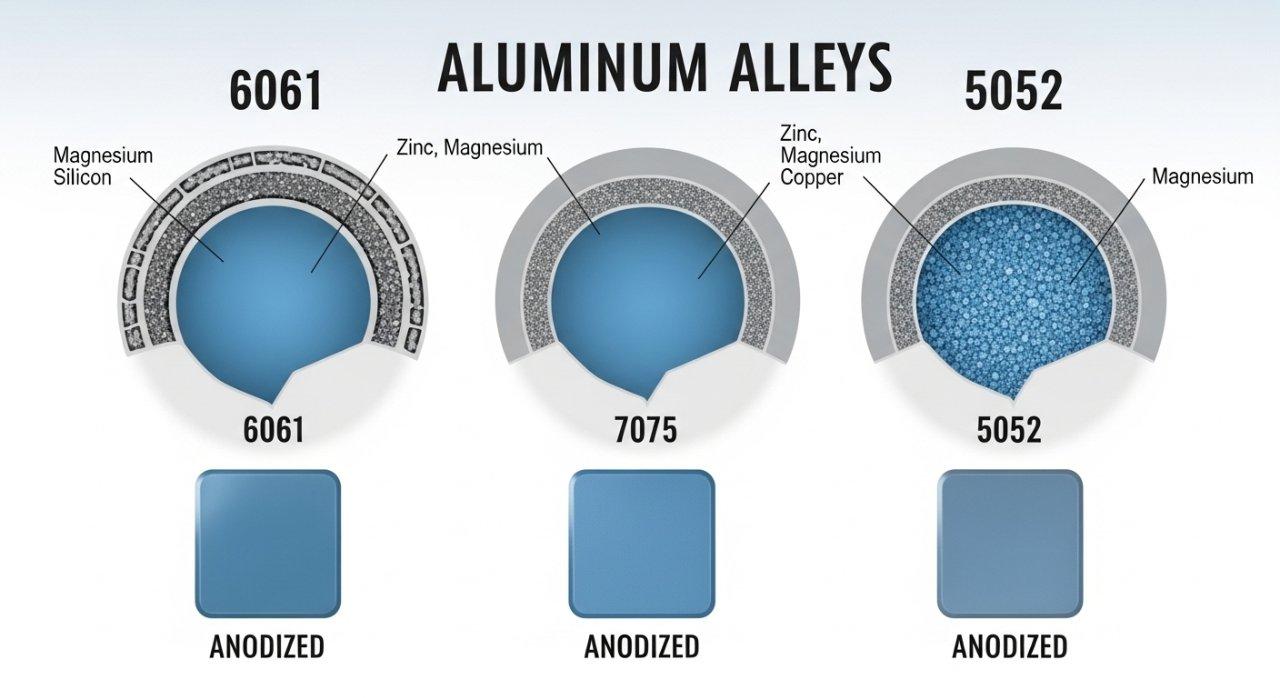

The specific aluminum alloy used significantly influences the final anodized color and its consistency. Different alloying elements react distinctly during the anodizing process, affecting pore formation and dye absorption. This can create subtle but noticeable color variations.

For instance, 6061 and 7075 alloys have different silicon and copper content. These compositional differences lead to variations in the anodized layer’s thickness, density, and clarity, making anodizing color matching challenging if not precisely controlled.

Pre-Treatment’s Role in Color Uniformity

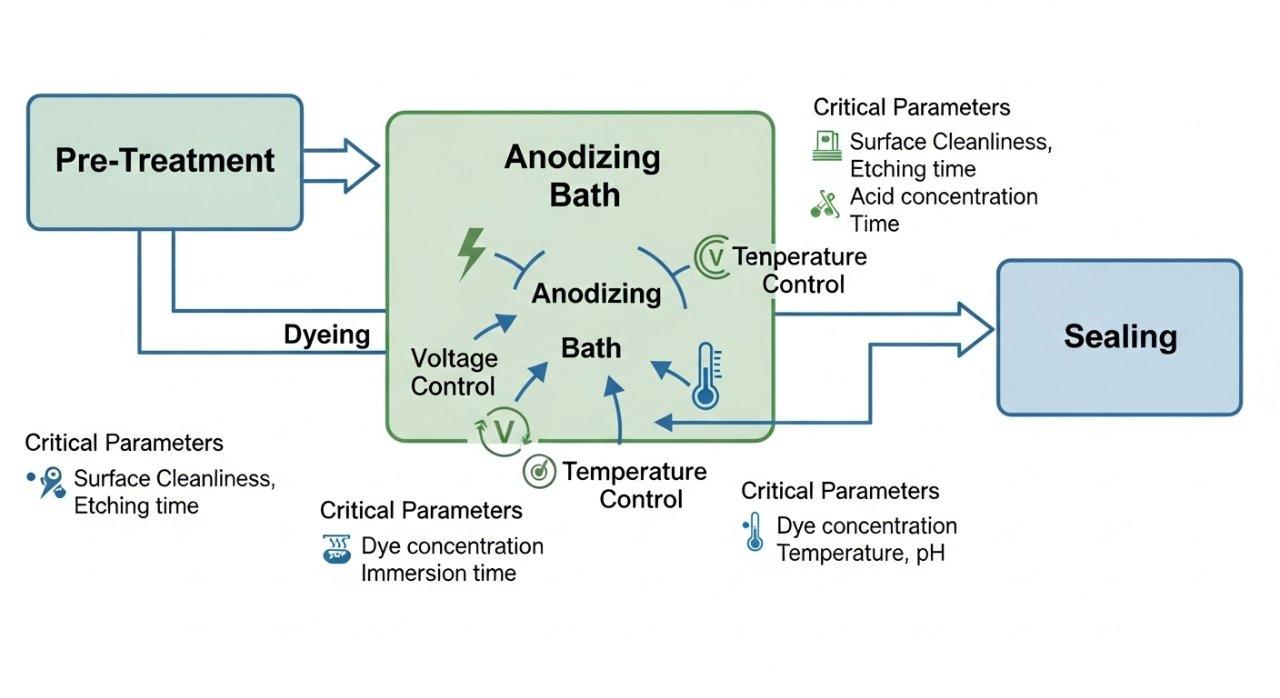

The surface preparation, or pre-treatment, is a foundational step for achieving uniform anodized color. Inadequate cleaning, etching, or de-smutting leaves microscopic impurities or variations on the aluminum surface. These imperfections directly translate to blotchy or inconsistent color post-anodizing.

Our rigorous pre-treatment protocols ensure a perfectly clean and uniformly active surface. This critical stage removes oils, oxides, and surface irregularities. It prepares the aluminum casing for optimal and consistent anodized layer formation and dye absorption.

Anodizing Parameters: Core Variables

Controlling core anodizing parameters is critical for consistent results. Variables such as current density, voltage, electrolyte concentration, and bath temperature directly influence the growth rate and structure of the anodic oxide layer. Any fluctuation can alter the layer’s porosity and thickness.

These microscopic changes in the oxide structure directly impact how much dye the film absorbs and how light interacts with the surface. Precise anodizing parameter management is therefore essential for reliable anodizing color matching.

Table: Key Anodizing Process Parameters

| Parameter | Impact on Anodized Layer |

|---|---|

| Current Density | Affects oxide growth rate and porosity |

| Voltage | Influences layer thickness and density |

| Electrolyte Concentration | Determines dissolution and film formation |

| Bath Temperature | Controls reaction kinetics and pore size |

| Anodizing Time | Directly impacts film thickness |

Dyeing & Sealing: Critical Steps for Stability

The dyeing stage is where the desired color is imparted to the anodic film. Dye concentration, immersion time, and temperature must be meticulously controlled. Any deviation results in variations in color depth and saturation, making anodized aluminum color consistency difficult.

Following dyeing, the sealing process is crucial for locking in the color and enhancing corrosion resistance. Improper sealing can lead to color leaching, fading, and reduced durability. Both hydrothermal and cold sealing methods require precise execution to achieve long-term color stability.

Environmental Impact on Anodized Color

Even after perfect anodizing, environmental factors can impact color over time. Prolonged exposure to UV radiation can cause organic dyes to fade, especially in certain color spectrums. Chemical exposure, particularly to harsh cleaning agents, can also degrade the anodized layer.

Designing for long-term anodized aluminum color consistency requires considering the product’s operational environment. Our engineers provide guidance on appropriate dyes and sealing methods to maximize color stability.

Our Solutions for Anodized Color Consistency

Source Control: Consistent Aluminum Alloys

As a source manufacturer, our commitment to consistent anodized aluminum color begins with raw material selection. We implement stringent supplier qualification programs to ensure all incoming aluminum alloys meet precise compositional specifications. This minimizes material variability.

By controlling the material input, we lay the groundwork for predictable anodic film formation. This proactive approach significantly reduces one of the primary variables that can undermine anodizing color matching efforts.

Advanced Pre-Treatment Protocols

Our state-of-the-art facilities utilize advanced, automated pre-treatment lines. These systems employ precise chemical dosing and temperature control to ensure every aluminum casing receives a perfectly uniform surface preparation. This eliminates manual inconsistencies.

We maintain tight control over chemical bath compositions through regular analysis and replenishment. This guarantees an ideal surface for consistent anodizing and subsequent excellent dye absorption, crucial for final color uniformity.

Precision Anodizing Parameter Management

Our anodizing tanks are equipped with advanced PLC (Programmable Logic Controller) systems for real-time monitoring and control of all critical parameters. This includes current density, voltage, electrolyte temperature, and anodizing time. Automated adjustments ensure deviations are immediately corrected.

This level of precision parameter management is fundamental to achieving high anodized aluminum color consistency. It ensures the anodic oxide layer forms with uniform thickness and porosity across all parts, batch after batch.

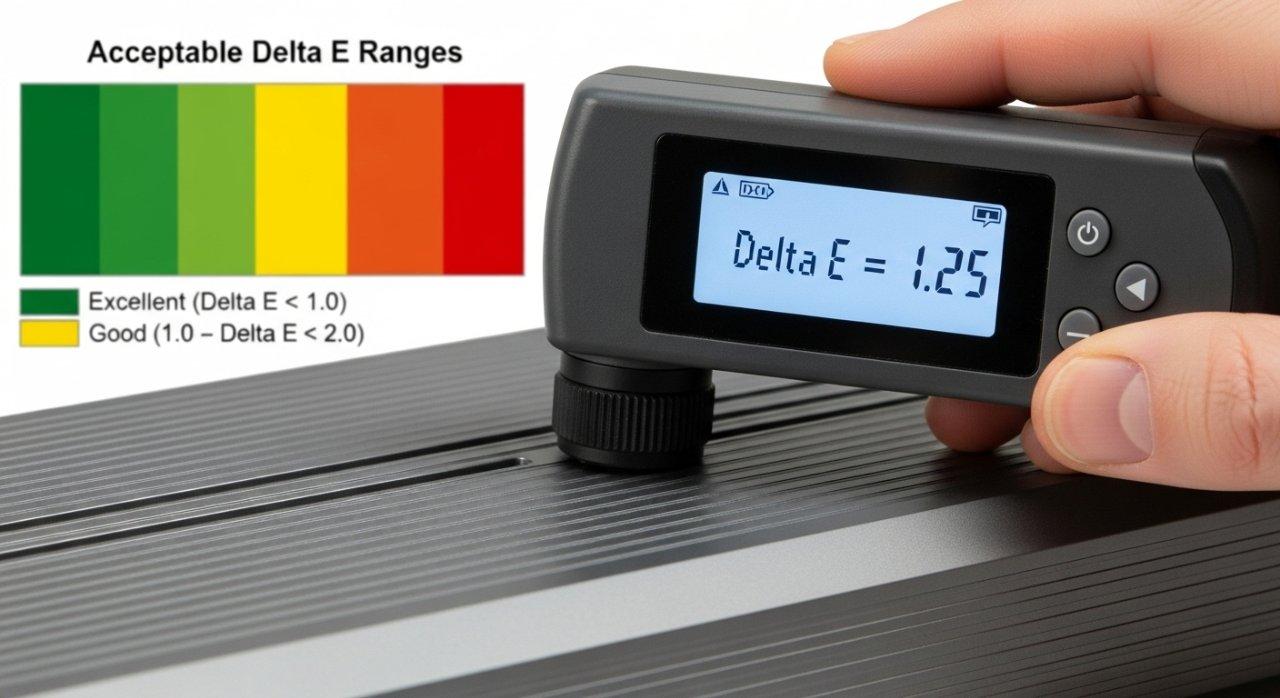

Spectrophotometry & Delta E Color Control

For exact anodizing color matching, we utilize high-precision spectrophotometers to quantitatively measure and verify color. This advanced equipment captures objective color data, which is then analyzed using the Delta E (ΔE) color difference formula.

Delta E is an industry standard metric that quantifies the difference between two colors. We work with clients to establish precise Delta E tolerance values, ensuring all electronic product casings fall within acceptable aesthetic limits. This provides quantifiable aluminum casing quality control.

Table: Delta E Color Tolerance Guidelines

| Delta E (ΔE) Value | Perceived Color Difference | Typical Application / Perception |

|---|---|---|

| < 1.0 | Not perceptible by the average human eye. | High-precision color matching, critical aesthetic components |

| 1.0 – 2.0 | Barely perceptible by a trained eye, but acceptable. | High-quality electronic casings, premium consumer goods |

| 2.0 – 3.5 | Perceptible by an untrained eye, but may be acceptable depending on application. | General consumer products, less critical aesthetic areas |

| > 3.5 | Clearly noticeable color difference. | Usually unacceptable for consistent brand aesthetic or matching parts |

Batch-to-Batch Consistency Assurance

Our commitment to anodized aluminum color consistency extends beyond individual parts to entire production runs. We implement robust statistical process control (SPC) methodologies and maintain comprehensive data logging for every batch. This allows for proactive identification and correction of any trends.

Through rigorous process audits and historical data analysis, we guarantee consistency between batches, crucial for large-scale electronic product manufacturing. This level of aluminum casing quality control minimizes variations and ensures reliable supply.

Expert Engineering for Complex Designs

Electronic product casings often feature intricate geometries, tight tolerances, and diverse surface areas. Our expert engineers specialize in designing custom anodizing fixtures and masking solutions that ensure uniform current distribution and consistent dye application even on complex parts.

This engineering expertise is vital for preventing color variations caused by uneven film growth or pooling of dyes in recessed areas. We use simulation tools to optimize fixture designs, guaranteeing perfect anodizing results for challenging components.

Partnering for Reliable Anodized Casings

Transparent Pricing & Value

As your direct source manufacturer, ly-machining offers transparent pricing without compromising on quality. Our optimized processes and direct supply chain result in exceptional value for our clients. We believe in clear cost structures and long-term partnerships.

You gain access to high-quality production with competitive pricing, directly impacting your project’s overall budget and profitability. This makes us an ideal partner for electronic product casings anodizing.

High-Quality Production, Every Time

Our reputation is built on delivering high-quality parts consistently. We combine advanced technology, rigorous quality control, and decades of engineering expertise to ensure every anodized aluminum component meets the most demanding specifications. Our focus is on perfection, every time.

This commitment to excellence ensures that your electronic products maintain a superior aesthetic and functional standard. It is the cornerstone of our promise for reliable anodized aluminum color consistency.

Our Deep Technical Expertise at Your Service

Beyond our manufacturing capabilities, our team of seasoned engineers and anodizing specialists offers unparalleled technical consultation. We collaborate with your design and procurement teams to optimize material selection, design for anodizing, and define precise color specifications.

Leverage our deep technical expertise to troubleshoot challenges, innovate solutions, and ensure your project achieves its full potential. We are partners in your success, offering guidance from concept to mass production.

Streamlined Supply Chain for Electronics

Understanding the fast-paced nature of the electronics industry, we prioritize an efficient and reliable supply chain. Our integrated manufacturing processes and robust logistics ensure timely delivery of your anodized aluminum casings. This minimizes lead times and supports your production schedules.

We are equipped to handle both prototyping and high-volume production with consistent quality and dependable delivery. This streamlined approach supports your critical time-to-market objectives.

Case Study: Ensuring Brand Harmony for a Smart Device Manufacturer

A leading smart device manufacturer faced a persistent challenge with their anodized aluminum watch casings. Despite working with multiple suppliers, they struggled to achieve consistent black anodizing across different production batches, leading to significant rejection rates and assembly delays. Their brand aesthetic demanded flawless uniformity.

Our solution involved a comprehensive process audit and the implementation of advanced spectrophotometry for every batch. We precisely controlled alloy sourcing, optimized our multi-stage pre-treatment protocols, and implemented real-time monitoring of anodizing bath parameters. Our engineers also developed custom fixtures for uniform current distribution.

The result was a dramatic improvement in anodized aluminum color consistency, with Delta E values consistently falling below 1.5 across all batches. This significantly reduced their reject rate, accelerated their assembly lines, and restored their brand’s reputation for premium quality. Our anodizing color matching expertise delivered the consistent finish their product deserved.

Ready to eliminate color inconsistency in your electronic product casings and ensure your brand’s reputation for quality? Contact our technical experts today for a personalized consultation, process analysis, and a transparent quote. Let’s achieve perfect color harmony for your next project.

Anodized Aluminum Color Consistency FAQs

What is the acceptable Delta E for electronics?

In our experience, for high-end electronic products where visual uniformity is critical, a Delta E (ΔE) value of less than 1.5 is generally considered excellent and often imperceptible to the average human eye. For less critical aesthetic components, a Delta E up to 2.5 might be acceptable.

Establishing precise Delta E tolerances is a collaborative process between our engineers and the client. It ensures that expectations for anodized aluminum color consistency are clearly defined and met.

How long does anodized color last?

The longevity of anodized color largely depends on the anodizing quality, sealing process, and environmental exposure. Properly anodized and sealed aluminum, particularly with inorganic dyes or integral color processes, can maintain its color for decades indoors.

For outdoor or high-UV applications, specific UV-resistant dyes and robust sealing methods are crucial to prevent fading. We advise on the best approach for long-term anodized aluminum color consistency based on the product’s intended use.

Can different alloys achieve the same color?

Achieving the exact same anodized color across different aluminum alloys is challenging due to their varying compositions. Alloying elements affect the micro-structure and porosity of the anodic film, influencing dye absorption and light reflection.

While similar colors can be approached, minor variations in shade, saturation, or brightness are common. Our engineers can guide you on alloy selection and process adjustments to minimize these differences for critical anodizing color matching projects.

Elevate Your Electronics with Consistent Anodizing

Your Path to Perfect Color Matching

Achieving perfect anodized aluminum color consistency is a blend of scientific precision and manufacturing expertise. By partnering with ly-machining, you gain access to a dedicated team and advanced processes focused on delivering exceptional aluminum casing quality control. We are committed to elevating your product’s aesthetic.

Let us be your trusted partner in navigating the complexities of electronic product casings anodizing. Ensure your brand’s visual identity remains flawless and consistent across every unit, every batch, every time.

Connect with Our Anodizing Experts Today

Do not let color inconsistency compromise your brand’s reputation or production schedule. Reach out to ly-machining’s technical specialists today for an in-depth consultation. We’re ready to discuss your specific project requirements and provide a detailed solution.

Experience the peace of mind that comes with reliable, high-quality anodized aluminum color consistency. Let’s start a conversation about your next project and secure its success together.