Mastering 5-Axis CNC for Robotic Precision

ly-machining’s 5-axis CNC machining delivers ultra-precision for robotic parts, controlling tolerances within microns to ensure superior performance and reliability in custom robotic components.

In the unforgiving world of robotics, where a single micron can define failure or triumph, how confident are you that your precision components consistently meet the exact tolerances your designs demand? This is a primary anxiety for many.

The secret lies in mastering 5-axis CNC machining, a capability ly-machining has perfected. This guide explores the critical role of advanced `CNC machining of robot parts` and how ly-machining achieves unparalleled precision.

We will delve into the challenges and solutions for precise tolerance control, ensuring your `custom robotic components CNC` projects succeed. ly-machining is your trusted partner for `precision CNC for robotics`.

Why Robotic Precision Parts Demand 5-Axis

What complex geometries require 5-axis CNC machining?

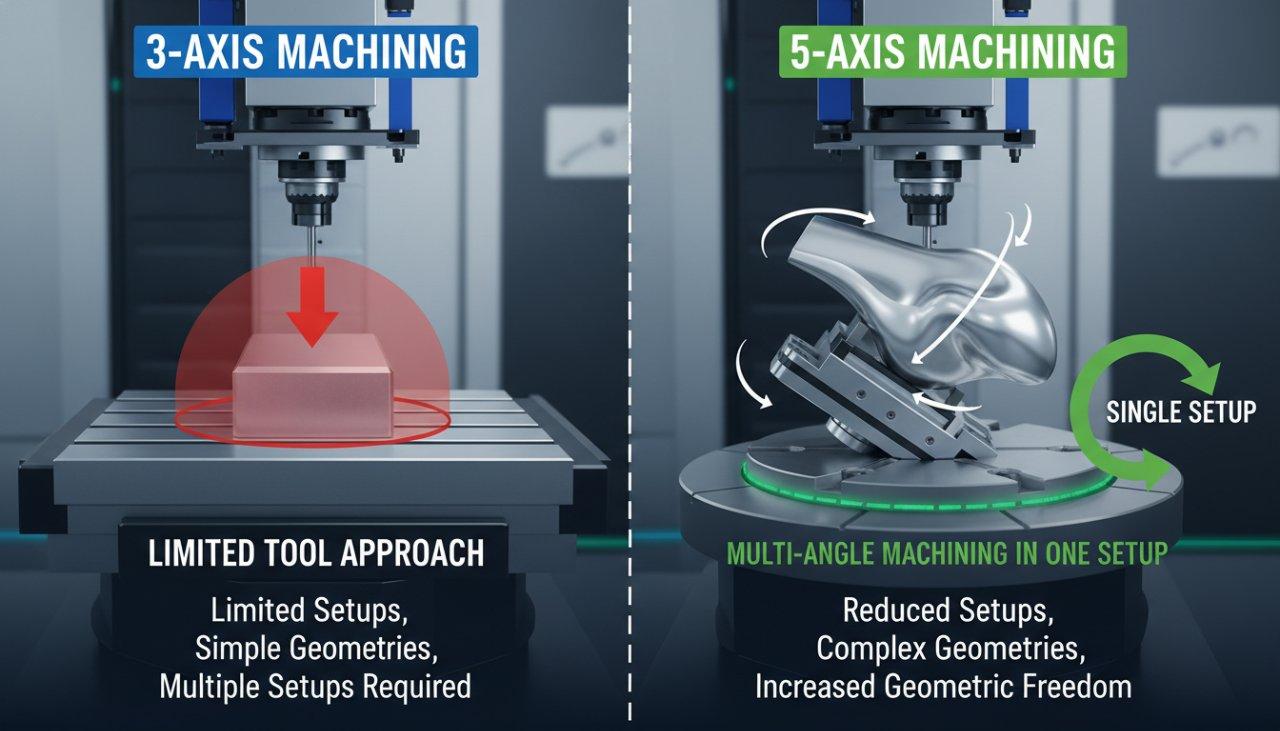

Modern robotics demands components with increasingly intricate geometries. These often include organic shapes, deep cavities, undercuts, and features on multiple faces that are inaccessible with traditional 3-axis machining.

These complexities are crucial for lightweighting, compact designs, and integrating multiple functions into a single part. Achieving them consistently and accurately requires the multi-directional access of 5-axis `CNC machining`.

How does 5-axis benefit robotics parts manufacturing?

The primary benefit of 5-axis `CNC machining of robot parts` is the ability to machine complex features in a single setup. This eliminates cumulative errors from multiple setups, significantly improving overall accuracy and reducing production time.

This capability is vital for `robotics parts manufacturing`, enabling faster iteration cycles and reducing the risk of part rejection. ly-machining leverages this to ensure superior component integrity.

Understanding tight tolerance needs for robotic components.

Robotic systems rely on the precise interaction of numerous components. Misalignment or play, even at the micron level, can lead to reduced accuracy, premature wear, and system failure.

For `custom robotic components CNC`, positional accuracy, concentricity, parallelism, and surface finish tolerances are paramount. ly-machining understands that these requirements often push the boundaries of conventional machining.

Challenges in 5-Axis Tolerance Control

What common issues hinder precision CNC for robotics?

Achieving `precision CNC for robotics` on a 5-axis machine is not without its hurdles. Common issues include thermal expansion of materials and machines, tool deflection, and vibration during machining.

Kinematic errors in the machine itself, incorrect workholding, and suboptimal cutting parameters also contribute to deviations. ly-machining addresses these proactively through rigorous process control.

Managing material properties in CNC machining of robot parts.

The choice of material significantly impacts `CNC machining of robot parts` and tolerance control. Materials like titanium, Inconel, and high-strength steels are difficult to machine due to their hardness and tendency to generate heat.

Aluminum and plastics, while easier to cut, can deform under clamping pressures or high temperatures. ly-machining’s expertise ensures optimal material handling and machining strategies.

| Material Type | Common Challenges for Precision |

|---|---|

| Titanium Alloys | High hardness, poor thermal conductivity, tool wear |

| Stainless Steels | Work hardening, chip control, heat generation |

| Aluminum Alloys | Thermal expansion, burr formation, clamping distortion |

| Engineering Plastics | Low melting point, poor heat dissipation, flexibility |

How does tolerance stack-up impact custom robotic components?

Tolerance stack-up is a critical concern for `custom robotic components CNC`. Even if individual parts are within their specified tolerances, cumulative errors across an assembly can lead to functional failure.

Designers must consider the worst-case scenario of combined tolerances. ly-machining works closely with clients on Design for Manufacturability (DFM) to minimize these risks.

Achieving Ultra-Precision with 5-Axis CNC

Optimizing machine kinematics for precision CNC machining.

At ly-machining, our journey to ultra-precision begins with understanding and optimizing machine kinematics. We regularly calibrate our advanced 5-axis machines to compensate for any geometric inaccuracies.

This involves laser calibration and ballbar testing to ensure the rotational axes are perfectly aligned and movements are repeatable. This foundation is essential for `precision CNC for robotics`.

Advanced tooling strategies for robotics parts manufacturing.

Tooling plays a pivotal role in achieving tight tolerances. ly-machining employs specialized cutting tools with advanced coatings, geometries, and materials that are optimized for specific materials and operations.

We utilize shorter, stiffer tools to minimize deflection, and dynamic tool path generation reduces tool wear. This ensures consistent, high-quality finishes during `robotics parts manufacturing`.

CAM programming techniques for tight tolerance control.

Sophisticated CAM programming is at the heart of ly-machining’s precision. We use advanced software that allows for highly optimized tool paths, precise collision avoidance, and fine control over tool engagement.

Features like high-speed machining (HSM) and trochoidal milling are employed to reduce cutting forces and heat. This meticulous programming directly contributes to `tight tolerance control`.

DFM principles for custom robotic components CNC.

Design for Manufacturability (DFM) is crucial, and ly-machining integrates this early in the process. ly-machining’s engineers collaborate with clients to review designs, identify potential manufacturing challenges, and suggest modifications.

This proactive approach can simplify complex features, optimize material usage, and enhance machinability. This ensures the best possible outcome for `custom robotic components CNC`.

What post-processing ensures CNC machining precision?

While 5-axis machining is highly precise, certain post-processing steps are vital. These include stress relieving to prevent material distortion, deburring to remove sharp edges, and precise finishing processes like polishing or lapping.

Specialized surface treatments, such as anodizing or plating, can also enhance durability and surface integrity. ly-machining ensures these steps maintain, not compromise, the part’s precision.

Quality Assurance for Robotic Components

Metrology and inspection for precision CNC for robotics.

Rigorous metrology and inspection are non-negotiable at ly-machining. We employ state-of-the-art Coordinate Measuring Machines (CMMs) with high-accuracy probes to verify critical dimensions and geometric tolerances.

Optical inspection systems and profile projectors are also used for intricate features and surface finish validation. This comprehensive approach ensures `precision CNC for robotics` meets all specifications.

Statistical process control in CNC machining of robot parts.

ly-machining implements Statistical Process Control (SPC) to monitor and control the `CNC machining of robot parts` continuously. Data from in-process and post-process measurements are analyzed to detect any trends or deviations.

This allows for real-time adjustments, preventing defects before they occur and ensuring consistent quality over production runs. SPC is fundamental to maintaining tight tolerance control.

Traceability and documentation in robotics parts manufacturing.

For critical `robotics parts manufacturing`, complete traceability is paramount. ly-machining maintains detailed records of material certifications, machine setups, tooling used, and inspection reports for every component.

This comprehensive documentation ensures accountability and facilitates quick problem resolution if needed. It provides clients with full confidence in the quality and origin of their parts.

Partnering for Advanced Robotic Machining

Why choose a source manufacturer for custom robotic components CNC?

Choosing a source manufacturer like ly-machining offers unparalleled advantages for `custom robotic components CNC`. As a direct manufacturer, ly-machining eliminates middlemen, ensuring transparent communication and pricing.

ly-machining controls the entire process from raw material to finished part, guaranteeing quality and consistency. This reduces risks and streamlines the supply chain for clients.

| Manufacturer Type | Key Advantages |

|---|---|

| Source Manufacturer | Direct control, transparent pricing, deep expertise |

| Distributor/Broker | Wider network, potentially faster sourcing, less direct control |

The value of deep technical expertise in CNC machining.

ly-machining’s team possesses deep technical expertise in `CNC machining`. This isn’t just about operating machines; it’s about understanding material science, kinematics, advanced CAM, and metrology.

This expertise allows ly-machining to solve complex manufacturing challenges, offer valuable DFM insights, and optimize processes for cost-effectiveness without compromising precision. ly-machining is a true partner.

Transparent pricing for high-quality robotics parts.

At ly-machining, transparency in pricing is a core principle for `high-quality robotics parts`. Clients receive clear, detailed quotes that reflect the true cost of precision manufacturing, including materials, machining time, and quality control.

ly-machining believes in honest communication, ensuring there are no hidden costs or surprises. This builds long-term trust and fosters strong client relationships.

Your trusted partner for precision CNC for robotics.

Ultimately, partnering with ly-machining means gaining a trusted ally in the competitive world of robotics. ly-machining’s commitment to E-E-A-T—experience, expertise, authoritativeness, and trustworthiness—is reflected in every part ly-machining produces.

ly-machining delivers reliable, high-performance `precision CNC for robotics` components that drive innovation. Let ly-machining elevate your next project.

Case Study: Enhancing Robotic Arm Dexterity with Micro-Tolerances

**Problem:** A client developing a new generation of dexterous robotic arms required ultra-precise, lightweight joint components. Their previous supplier struggled to maintain the required ±5 micron positional tolerance across multiple features, leading to excessive play and reduced arm dexterity. Assembly also became problematic.

**ly-machining’s Solution:** ly-machining analyzed the client’s design and identified areas where the chosen manufacturing process was insufficient. ly-machining proposed redesigning certain features for optimal 5-axis machinability, reducing stress points, and incorporating advanced workholding strategies. ly-machining utilized high-precision 5-axis CNC machines, employing specialized tooling and optimized CAM paths. Every batch underwent 100% CMM inspection for critical dimensions.

**Result:** ly-machining successfully delivered the joint components consistently meeting the stringent ±5 micron tolerance. The client reported a significant improvement in robotic arm dexterity, smoother operation, and flawless assembly, accelerating their product launch and solidifying their market position. ly-machining’s `precision CNC for robotics` was instrumental.

Stop compromising on robotic precision. Partner with a trusted source manufacturer who delivers unmatched 5-axis CNC machining tolerance control. Contact our engineering team today for a no-obligation technical consultation on your next critical robotic component project.

FAQ

What is 5-axis CNC machining?

5-axis CNC machining involves cutting tools that move along five different axes simultaneously. This allows for the creation of incredibly complex parts with intricate geometries in a single setup.

It significantly reduces the need for multiple setups, which helps to minimize errors and improve the overall precision of parts. This is critical for `CNC machining of robot parts`.

Why is tolerance control important for robotics?

Tolerance control is vital for robotic components because even minute deviations can lead to significant performance issues. Accurate tolerances ensure proper fit, alignment, and smooth operation of robotic systems.

Poor tolerance control can cause excessive wear, reduced lifespan, and even complete failure of complex robotic mechanisms. ly-machining prioritizes this for `robotics parts manufacturing`.

What materials can ly-machining machine?

ly-machining processes a wide range of materials crucial for robotics, including various aluminum alloys, stainless steels, titanium, and engineering plastics. ly-machining also works with specialized high-performance alloys.

Our expertise ensures that each material is machined optimally to achieve the required precision and surface finish. ly-machining excels in `custom robotic components CNC` across diverse material needs.