Aluminum CNC Factory: Critical Evaluation Standards

Choosing a recommended CNC machining manufacturer for aluminum parts requires stringent evaluation of technical prowess, quality systems, and operational transparency to ensure project success.

Navigating the complex landscape of aluminum CNC machining can feel like a high-stakes gamble. Are you truly equipped to identify a manufacturing partner who delivers not just parts, but absolute precision, unwavering quality, and transparent value for your critical aluminum projects?

The true cost of a poorly chosen aluminum CNC machining partner extends far beyond the quote. Discover the definitive evaluation standards that secure your project’s success and differentiate a true source manufacturer from the rest. This guide outlines how to vet CNC aluminum parts manufacturers effectively.

Why Choosing the Right Aluminum CNC Machining Manufacturer Matters

Securing the right partner for your custom aluminum CNC parts is paramount. The decision impacts project timelines, overall product quality, and ultimately, your market reputation. ly-machining understands these stakes intimately.

Poor selection can lead to costly delays and compromised product integrity. This crucial choice directly influences the efficiency and success of your entire supply chain for aluminum CNC machining services.

Understanding Risks with Poor Aluminum CNC Machining Services

Partnering with an unsuitable provider for your aluminum CNC machining services carries substantial risks. These can manifest as inconsistent quality, missed deadlines, and unexpected cost overruns. ly-machining frequently observes these issues.

Substandard parts often necessitate extensive rework or even complete scrap, eroding profitability. Such failures directly impact your time-to-market and can damage customer trust in your final product.

Impact of Quality on Custom Aluminum CNC Parts Projects

The quality of custom aluminum CNC parts directly dictates the performance and reliability of your final assembly. Precision in every detail is non-negotiable for critical applications. ly-machining prioritizes this above all.

Even minor deviations in dimensions or surface finish can lead to assembly issues or premature component failure. High-quality CNC machining ensures your product meets its design intent and performs flawlessly.

Technical Expertise: A Core Evaluation Standard for Aluminum CNC Factories

Deep technical expertise is the bedrock of any reliable CNC aluminum parts manufacturer. It encompasses a profound understanding of machining processes, material science, and advanced manufacturing technologies. ly-machining prides itself on this foundation.

This expertise ensures that your most challenging designs for custom aluminum CNC parts can be realized with precision and efficiency. It’s what differentiates a mere vendor from a true manufacturing partner.

Assessing Deep Technical Expertise in Aluminum CNC Machining

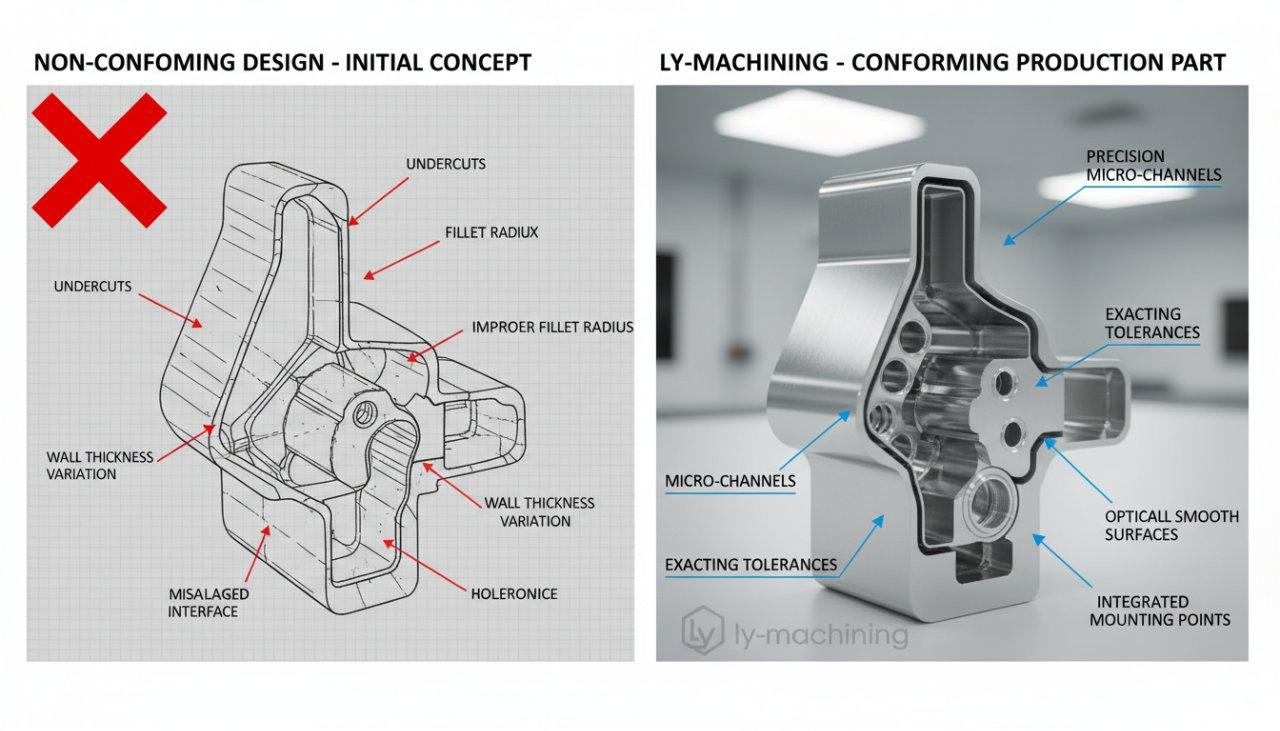

Evaluating a manufacturer’s technical depth involves scrutinizing their engineering team’s qualifications and problem-solving track record. ly-machining’s engineers offer design-for-manufacturability (DFM) insights.

They should demonstrate a comprehensive grasp of machining strategies for various aluminum alloys and complex geometries. This ensures optimal tool paths, reduced cycle times, and superior part quality.

Material Science Knowledge for Specific Aluminum CNC Parts Manufacturer

A top CNC aluminum parts manufacturer possesses extensive knowledge of aluminum alloys. This includes understanding their properties, machinability, and appropriate post-treatment options. ly-machining advises on material selection.

Different aluminum alloys (e.g., 6061, 7075, 2024) have distinct characteristics that influence machining parameters and final part performance. Expert guidance on alloy selection is crucial for custom aluminum CNC parts.

Here is a table comparing common aluminum alloys for CNC machining:

| Alloy Type | Key Characteristics | Typical Applications |

|---|---|---|

| Aluminum 6061 | Good strength-to-weight, excellent corrosion resistance, easily weldable | Automotive, structural components, frames |

| Aluminum 7075 | Very high strength, good fatigue resistance, less corrosion resistant | Aerospace, high-stress parts, sporting goods |

| Aluminum 2024 | High strength, good fatigue properties, poor corrosion resistance | Aircraft structures, gears, fasteners |

| Aluminum 5052 | Excellent corrosion resistance, good formability, moderate strength | Marine applications, fuel tanks, general sheet metal |

Advanced CNC Machining Capabilities for Complex Custom Aluminum CNC Parts

State-of-the-art equipment and advanced programming techniques are essential for manufacturing complex custom aluminum CNC parts. This includes multi-axis milling and high-speed machining. ly-machining invests in the latest machinery.

Such capabilities allow for intricate geometries, tight tolerances, and superior surface finishes. A recommended CNC machining manufacturer should leverage these technologies for optimal results.

Quality Assurance & Control: Benchmarks for Recommended CNC Machining Manufacturers

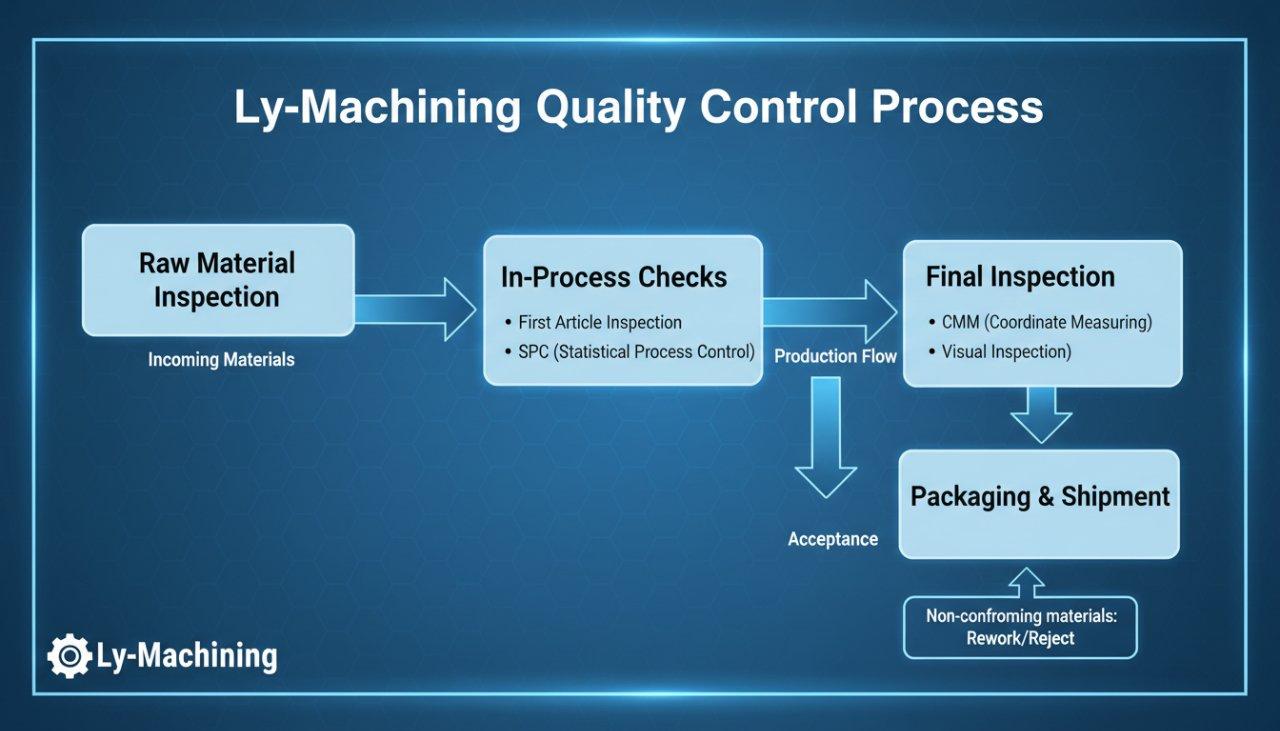

Robust quality assurance and control systems are non-negotiable for any recommended CNC machining manufacturer. These systems guarantee consistent precision and adherence to specifications. ly-machining’s commitment to quality is unwavering.

Comprehensive checks at every stage of the CNC machining process are vital. This ensures that every aluminum CNC part delivered meets or exceeds client expectations.

Comprehensive Quality Management Systems in CNC Machining

A top-tier CNC aluminum parts manufacturer implements a fully integrated quality management system. This system should cover everything from raw material inspection to final product verification. ly-machining follows ISO 9001 standards.

Rigorous in-process inspections and thorough final quality checks minimize defects and ensure consistent output. Documentation of these processes provides crucial traceability.

Precision and Tolerance Capabilities for Aluminum CNC Parts

The ability to consistently achieve tight tolerances is a hallmark of an expert in aluminum CNC machining services. This is critical for parts requiring precise fit and function. ly-machining specifies achievable tolerances.

Modern CMM (Coordinate Measuring Machine) equipment and skilled technicians ensure accurate measurement and verification of all critical dimensions. This capability is paramount for custom aluminum CNC parts.

Here is a table outlining typical tolerance capabilities for CNC machined aluminum parts:

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) |

|---|---|---|

| Linear Dimensions | ±0.1 | ±0.025 |

| Holes (Diameter) | ±0.05 | ±0.015 |

| Flatness | 0.05 | 0.01 |

| Perpendicularity | 0.05 | 0.01 |

Surface Finish & Aesthetic Standards in Aluminum CNC Manufacturing

Surface finish is often critical for both functionality and aesthetics of custom aluminum CNC parts. A recommended CNC machining manufacturer should offer a range of finishing options. ly-machining provides various finishes.

Options include standard machined finishes, bead blasting, anodizing, and polishing. Each finish impacts part performance, corrosion resistance, and visual appeal.

Here is a table showing common surface finishes for aluminum CNC parts:

| Surface Finish | Description | Typical Ra Value (µm) |

|---|---|---|

| As-Machined | Straight tool marks visible, common for internal features | 1.6 – 3.2 |

| Bead Blasted | Matte, uniform appearance, removes tool marks | 0.8 – 1.6 |

| Anodized | Corrosion resistant, decorative, various colors available | Inherits base finish |

| Polished | Mirror-like finish, highly reflective | < 0.2 |

Certifications & Compliance for High-Quality Recommended CNC Machining Manufacturers

Industry certifications serve as objective proof of a CNC aluminum parts manufacturer’s commitment to quality and process control. ly-machining maintains relevant certifications.

Certifications like ISO 9001 for quality management and AS9100 for aerospace standards are crucial for demonstrating adherence to global benchmarks. These assure clients of consistent, reliable aluminum CNC machining services.

Here is a table of essential certifications for CNC machining manufacturers:

| Certification | Focus Area | Relevance |

|---|---|---|

| ISO 9001 | Quality Management System | Demonstrates consistent quality, process control |

| AS9100 | Aerospace Quality Standard | Critical for aerospace, defense, and high-reliability applications |

| ISO 14001 | Environmental Management System | Commitment to environmental responsibility |

| IATF 16949 | Automotive Quality Standard | Specific for automotive industry suppliers |

Transparency and Communication: Key for Your CNC Aluminum Parts Manufacturer

Openness and clear communication are vital for a successful partnership with any CNC aluminum parts manufacturer. Transparency builds trust and facilitates efficient project execution. ly-machining values clear dialogue.

Effective communication channels prevent misunderstandings and enable quick resolution of any issues that may arise during custom aluminum CNC parts production.

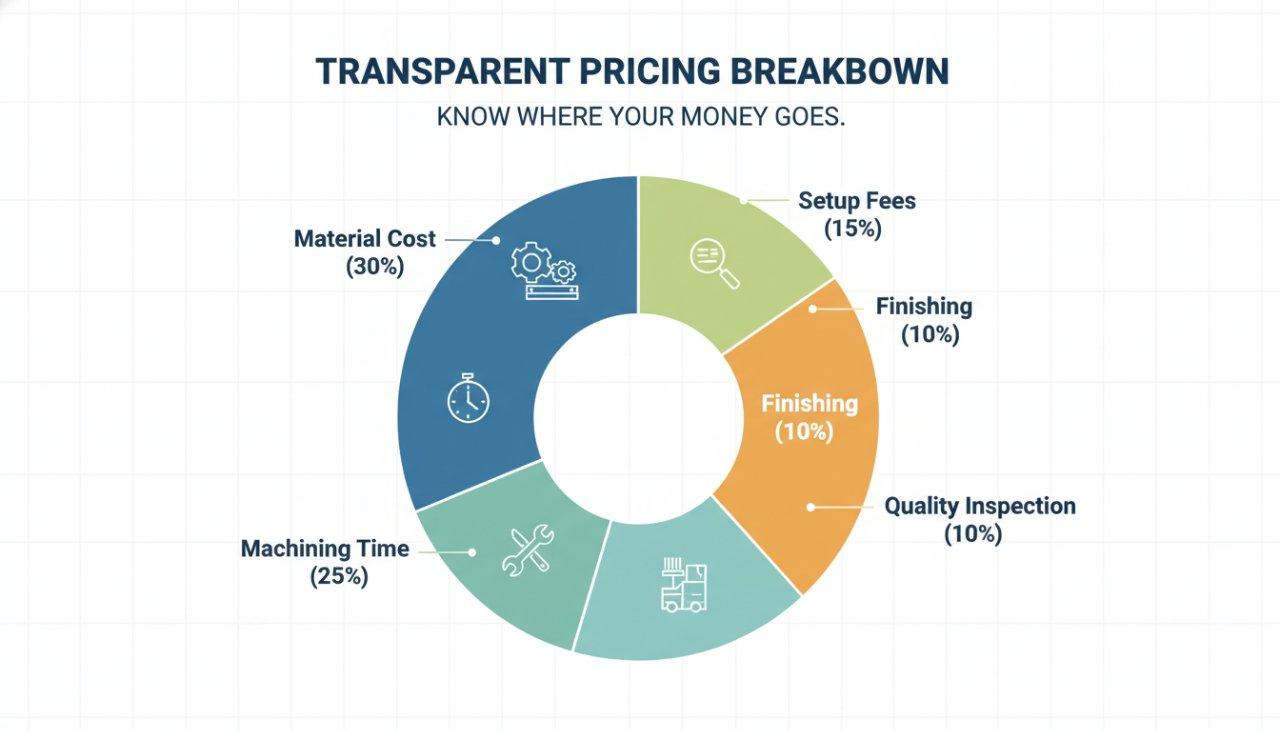

Transparent Pricing Models for Aluminum CNC Machining Services

A reputable provider of aluminum CNC machining services will offer clear and transparent pricing. This means no hidden fees or unexpected charges throughout the project lifecycle. ly-machining provides detailed quotes.

Understanding the cost breakdown for materials, machining time, finishing, and shipping allows for accurate budgeting. This transparency is key to building long-term relationships.

Clear Communication & Project Management in Custom Aluminum CNC Parts

Effective project management and dedicated communication channels are essential. Clients should have a single point of contact who understands their custom aluminum CNC parts project inside out. ly-machining assigns project managers.

Regular updates, prompt responses to inquiries, and proactive problem-solving are indicators of strong communication. This minimizes client stress and keeps projects on track.

Supplier Responsiveness & Problem-Solving for CNC Machining Projects

A reliable CNC machining partner demonstrates quick responsiveness and a proactive approach to problem-solving. Issues can arise, and how they are handled defines a partnership. ly-machining excels in this area.

The ability to rapidly adapt to design changes, troubleshoot production challenges, and offer viable solutions is invaluable. This agility ensures minimal disruption to your CNC machining project timelines.

Operational Excellence: Delivery and Support from Your Aluminum CNC Factory

Operational excellence encompasses more than just machining; it includes efficient production, reliable logistics, and outstanding customer support. These factors are critical for a top aluminum CNC factory.

A truly recommended CNC machining manufacturer ensures seamless project execution from start to finish. ly-machining focuses on end-to-end satisfaction.

Assessing Production Capacity and Lead Times for CNC Aluminum Parts Manufacturer

Evaluating a CNC aluminum parts manufacturer’s production capacity and typical lead times is essential for project planning. They should have the infrastructure to scale with your needs. ly-machining maintains flexible capacity.

Understanding their order fulfillment process and scheduling capabilities helps avoid bottlenecks. Realistic and consistent lead times are crucial for managing your supply chain effectively.

Post-Machining Services & Logistics for Aluminum CNC Machining Services

A comprehensive range of post-machining services adds significant value. These can include heat treatment, assembly, surface coatings, and specific packaging. ly-machining offers integrated solutions.

Efficient and reliable logistics, including options for domestic and international shipping, are also paramount. Timely and secure delivery is the final step in successful aluminum CNC machining services.

Customer Support & Long-Term Partnership with Recommended CNC Machining Manufacturers

Exceptional customer support fosters long-term relationships. A truly recommended CNC machining manufacturer views clients as partners, not just customers. ly-machining is committed to lasting partnerships.

Ongoing technical support, continuous improvement initiatives, and a willingness to evolve with client needs signify a valuable ally. This ensures sustained success for your custom aluminum CNC parts.

Final Checklist for Selecting a Top Aluminum CNC Machining Manufacturer

Navigating the selection process for custom aluminum CNC parts can be complex. This consolidated checklist helps streamline your evaluation and secure the ideal partner. ly-machining consistently meets these criteria.

This comprehensive approach ensures you choose a manufacturer capable of meeting your technical demands and business objectives for precision manufacturing.

Consolidating Evaluation Standards for CNC Aluminum Parts Manufacturer

When evaluating a CNC aluminum parts manufacturer, combine technical expertise, quality assurance, communication transparency, and operational efficiency. Each aspect is interdependent.

A holistic review based on these standards provides a clear picture of a manufacturer’s true capabilities. It’s about finding a partner who embodies all these strengths.

Actionable Steps for Vetting Your Next Aluminum CNC Machining Partner

Begin by requesting detailed proposals that clearly address your specifications. Conduct site visits or virtual audits to assess facilities and processes. Evaluate their response to technical queries.

Verify certifications, check references, and ask for sample parts if possible. A thorough vetting process minimizes risk and ensures a successful engagement with your chosen aluminum CNC machining services provider.

Partner with an Expert: Your Source for High-Quality Aluminum CNC Parts

ly-machining is a leading recommended CNC machining manufacturer, dedicated to delivering superior aluminum CNC machining services. With deep expertise and advanced capabilities, ly-machining excels in custom aluminum CNC parts.

ly-machining’s commitment to E-E-A-T principles—Experience, Expertise, Authoritativeness, and Trustworthiness—ensures unparalleled service and quality for every project.

Experience Excellence in Custom Aluminum CNC Parts Manufacturing

In ly-machining’s experience, precision and reliability are non-negotiable. ly-machining’s skilled engineers and state-of-the-art facility are equipped to handle the most demanding custom aluminum CNC parts projects. ly-machining ensures your designs are brought to life flawlessly.

ly-machining’s rigorous quality control, from material sourcing to final inspection, guarantees that every component meets the highest industry standards. Partner with ly-machining for exceptional results.

Case Study: Revolutionizing an Aerospace Sensor Housing

Problem: A leading aerospace client faced repeated quality failures and project delays from a low-cost supplier for a critical sensor housing made of 7075 aluminum. The housing required extremely tight tolerances, a complex internal geometry, and a specific anodized finish, all of which the previous supplier struggled to maintain, leading to high scrap rates and certification risks.

Our Solution: The client turned to ly-machining. ly-machining’s engineering team conducted a detailed DFM analysis, identifying optimal machining strategies for the 7075 alloy and proposing minor design tweaks that improved machinability without compromising function. ly-machining utilized its 5-axis CNC machining capabilities for the complex internal features, ensuring precise geometry. ly-machining then implemented a multi-stage quality control process, including in-process CMM inspections and a final, rigorous surface finish check before a specialized anodizing treatment.

Result: ly-machining not only recovered the project timeline but also significantly reduced the overall part cost by virtually eliminating scrap. The client received 100% conforming parts, enabling them to secure the critical certification for their final product ahead of schedule. They praised ly-machining’s transparent communication and deep technical expertise.

Take the Next Step: Get Your Quote for Aluminum CNC Machining Services

Ready to secure high-quality aluminum CNC parts with a partner who embodies these rigorous standards? ly-machining is prepared to demonstrate its commitment to your project’s success.

Contact ly-machining today to discuss your specific requirements.

Request a Consultation for Your Recommended CNC Machining Manufacturers Project

ly-machining invites you to get a free quote or technical consultation. ly-machining’s experts are available to review your designs, provide DFM feedback, and offer competitive, transparent pricing for your custom aluminum CNC parts.

Connect with ly-machining to experience the difference of partnering with a truly recommended CNC machining manufacturer.

FAQ

What are key evaluation criteria for a CNC aluminum parts manufacturer?

Look for deep technical expertise, robust quality management systems (like ISO 9001), transparent pricing, and strong communication. These factors ensure high-quality custom aluminum CNC parts and project success.

How does ly-machining ensure quality for aluminum CNC machining services?

ly-machining employs comprehensive quality management, including stringent raw material inspection and in-process CMM checks. ly-machining maintains ISO 9001 certification and focuses on precision for every custom aluminum CNC part.

Can ly-machining handle complex custom aluminum CNC parts?

Yes, ly-machining specializes in complex custom aluminum CNC parts. ly-machining utilizes advanced multi-axis CNC machines and expert programming to achieve intricate geometries and tight tolerances with superior surface finishes.