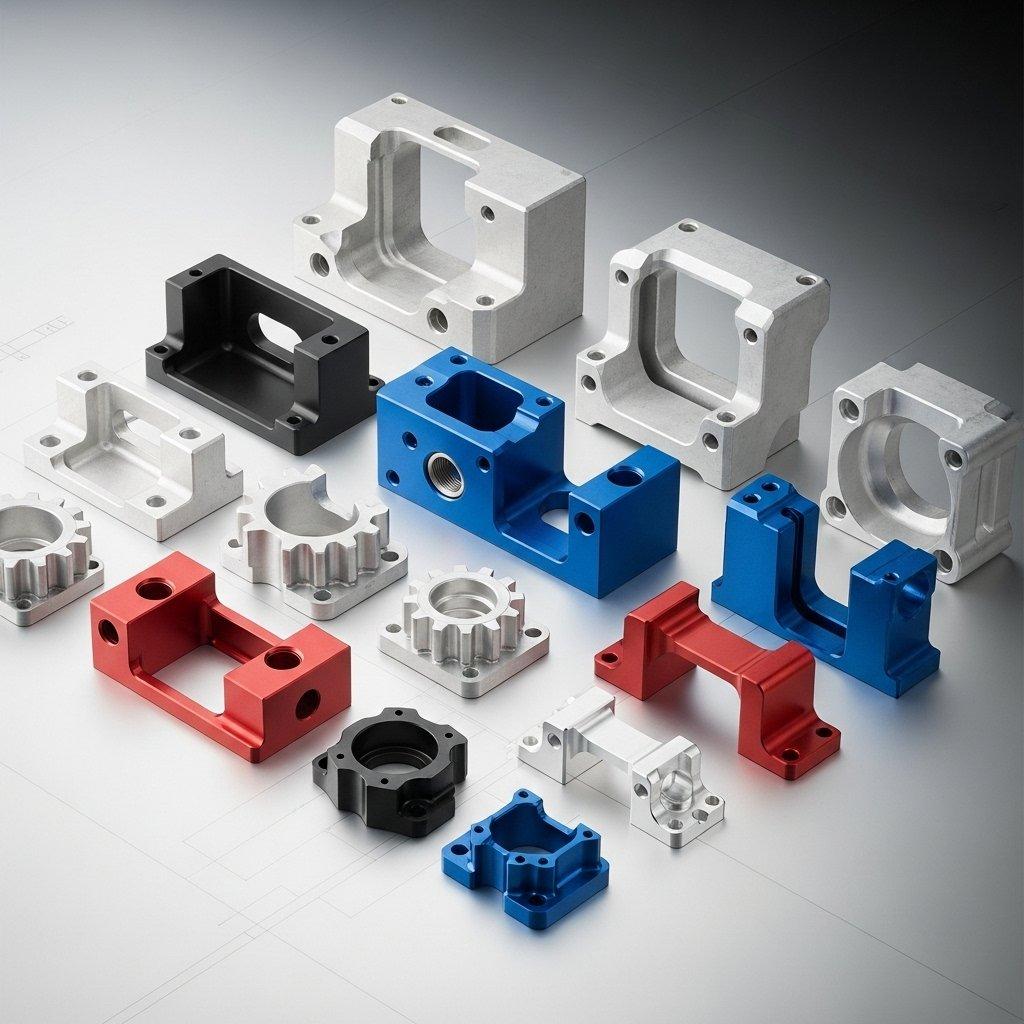

Anodic Oxidation’s Impact on Aluminum Color Uniformity

Is inconsistent color uniformity on your anodized aluminum CNC parts costing you rejections, delays, and compromising your brand’s aesthetic? You’re not alone. This common challenge can erode product perception and lead to significant rework.

Discover how precise process control and deep technical expertise are the keys to achieving flawless, batch-to-batch color consistency for your critical components. Understanding the underlying factors is the first step towards reliability.

Anodized aluminum color uniformity relies heavily on meticulous process control, from the initial CNC machining to the final sealing. Achieving consistent aesthetic and functional finishes across batches requires precise management of alloy composition, surface preparation, bath parameters, and current distribution during anodic oxidation.

Understanding Anodic Oxidation for Aluminum CNC Parts

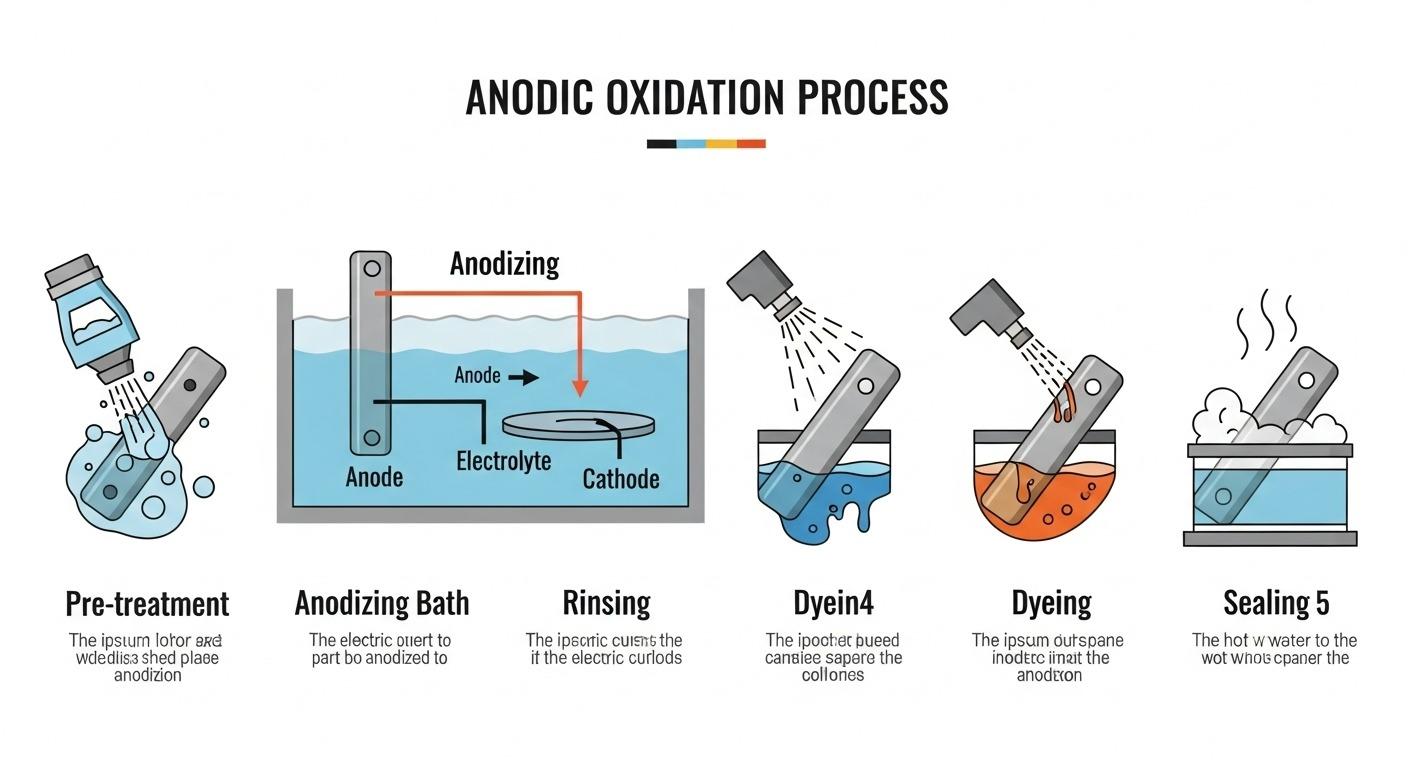

Basic Principles of Anodic Oxidation Process

Anodic oxidation, or anodizing, is an electrochemical process that converts the surface of aluminum into a durable, porous anodic oxide layer. This layer is integral to the aluminum substrate, offering enhanced corrosion resistance, wear resistance, and the ability to accept dyes.

The process involves submerging aluminum parts in an electrolyte solution, typically sulfuric acid, and applying an electric current. The aluminum acts as the anode, releasing oxygen ions that react with the aluminum surface to form aluminum oxide.

The controlled growth of this oxide layer is fundamental. Its thickness and porosity are key determinants of how the surface will interact with dyes, directly influencing the final color and its uniformity.

Role of Aluminum Alloy Composition in Anodizing

The specific aluminum alloy chosen significantly influences the anodizing process and the resultant color. Different alloying elements react distinctly during oxidation and can affect the clarity, porosity, and uniformity of the anodic film.

For example, alloys with higher silicon content, such as 6061, tend to produce darker, less vibrant colors when anodized, especially with natural (clear) anodizing. This is due to the silicon particles being incorporated into the oxide layer.

Conversely, purer aluminum alloys like 1000 series or certain 5000 series alloys generally yield brighter, clearer anodic films that accept dyes more uniformly. Understanding these intrinsic material properties is crucial for predicting and controlling final aesthetics.

Table: Impact of Common Aluminum Alloys on Anodizing

| Alloy Type | Key Alloying Elements | Anodizing Characteristics |

|---|---|---|

| 1XXX Series | Pure Aluminum | Excellent, clear films, bright colors |

| 5XXX Series | Magnesium | Good, clear films, good color uptake |

| 6XXX Series | Magnesium, Silicon | Good, slight greyish tint, moderate color |

| 7XXX Series | Zinc, Magnesium | Challenging, often uneven, darker films |

Pre-Treatment’s Influence on Anodized Color Uniformity

Effective pre-treatment is paramount for achieving consistent anodized color uniformity. This stage prepares the aluminum surface by removing oils, contaminants, and previous oxide layers, ensuring a clean and reactive substrate.

A uniform surface texture and chemical state before anodizing are essential. Any variations in cleanliness or surface roughness at this stage will directly translate into color inconsistencies in the final product.

Our pre-treatment protocols include meticulous cleaning, degreasing, and etching steps. These are precisely controlled to create an optimal, uniform surface condition for the subsequent anodic oxidation, minimizing potential color variations.

Key Factors Affecting Anodized Aluminum Part Color Uniformity

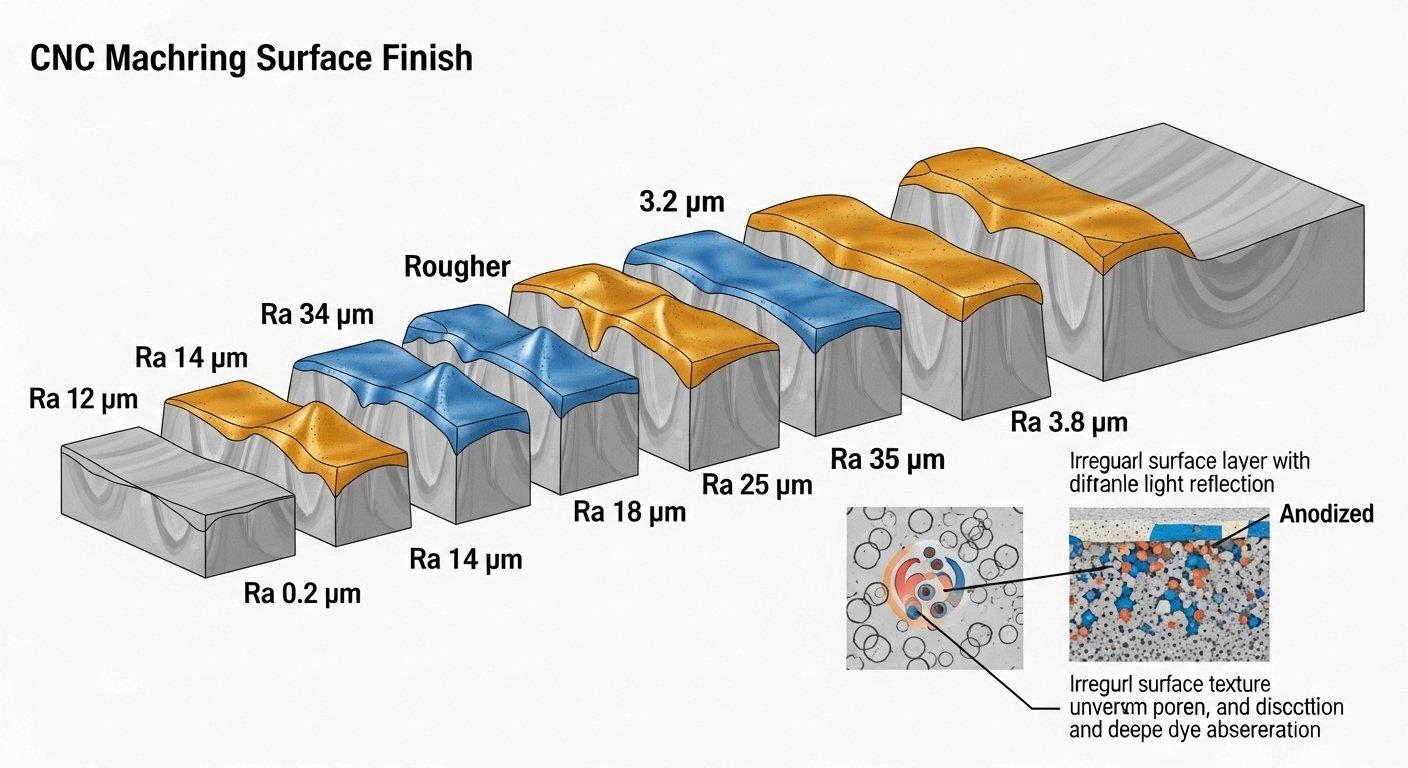

CNC Machining Surface Finish and Uniformity

The surface finish left by CNC machining plays a critical role in how an aluminum part will anodize and appear. Microscopic variations in surface roughness can lead to noticeable differences in how light reflects and how dye is absorbed.

A rougher surface typically has a larger effective surface area and can absorb more dye, potentially appearing darker or duller than a smoother area. Consistent machining parameters across all surfaces of a part and between batches are thus vital.

Our integrated approach ensures that CNC machining processes are optimized to produce a uniform surface finish suitable for anodizing. This minimizes any initial variations that could later manifest as color inconsistency.

Anodizing Bath Parameters and Their Color Impact

Precise control over the anodizing bath parameters is non-negotiable for color uniformity. Variables such as electrolyte concentration, temperature, and agitation rate directly influence the formation and properties of the oxide layer.

Fluctuations in bath temperature, even by a few degrees, can alter the porosity and thickness of the anodic film. This leads to variations in dye absorption capacity, resulting in visible color differences.

We maintain strict controls over our anodizing baths, using automated systems to monitor and adjust these critical parameters continuously. This ensures a stable and repeatable environment for consistent film growth.

Table: Critical Anodizing Bath Parameters and Their Influence

| Parameter | Impact on Oxide Layer | Influence on Color Uniformity |

|---|---|---|

| Electrolyte Type | Film hardness, porosity | Dye receptivity, inherent color |

| Concentration | Film growth rate, density | Uniformity of film thickness |

| Temperature | Film porosity, growth rate | Dye absorption, potential for burning |

| Agitation Rate | Ion distribution, heat dissipation | Even film growth, prevents localized overheating |

Current Density Distribution in Anodic Oxidation

Current density, the amount of current per unit of surface area, is a primary driver of the anodic oxidation process. Non-uniform current distribution across a part or between multiple parts in a batch will inevitably lead to uneven film thickness and color.

Areas with higher current density will develop a thicker, denser oxide layer more rapidly, potentially affecting dye uptake. Conversely, areas with lower current density will have thinner films.

Achieving uniform current density requires careful consideration of part geometry, anode-cathode spacing, and jig design. Our engineers model and optimize these factors to ensure even current flow across all surfaces.

Jigging and Part Geometry Considerations for Uniformity

The method of jigging and the inherent geometry of the CNC machined part are critical for uniform current distribution and consistent anodic oxidation. Improper jigging can create shielding effects, leading to uneven film thickness and color.

Complex geometries, such as deep recesses, sharp corners, or internal passages, can pose challenges for consistent current flow and electrolyte circulation. These areas are prone to localized variations in the anodic film.

Our expertise extends to designing custom jigs and fixtures that optimize current distribution for even the most intricate parts. This includes strategic contact points and masking where necessary to ensure uniform anodization.

Dyeing Process Variables and Color Consistency

Once the porous anodic film is formed, the parts undergo a dyeing process to achieve the desired color. The consistency of this step is just as critical as the anodizing itself.

Dye concentration, temperature, pH, and immersion time are all variables that must be rigorously controlled. Even slight deviations can lead to batch-to-batch color variation or streaking within a single part.

We employ automated dyeing systems with precise control over these parameters. This ensures consistent dye absorption and a stable color profile across all parts, reflecting our commitment to aesthetic quality.

Table: Key Dyeing Process Variables

| Variable | Importance for Color Uniformity | Control Method |

|---|---|---|

| Dye Concentration | Directly affects color saturation | Automated dosing, regular analysis |

| Bath Temperature | Influences dye absorption rate | Thermostatic control |

| pH Level | Affects dye stability and solubility | Automated pH monitoring |

| Immersion Time | Determines depth of color | Programmed timing cycles |

Achieving Superior Color Uniformity in Anodized CNC Parts

Advanced Pre-Treatment Techniques for Uniformity

Beyond standard cleaning, we utilize advanced pre-treatment techniques to further enhance color uniformity. This includes specialized etching solutions that create a more homogenous surface texture, ensuring consistent reactivity.

For parts requiring exceptionally high aesthetic standards, we may employ mechanical finishing methods like controlled abrasive blasting or polishing. These techniques prepare the surface for optimal anodizing and uniform dye absorption.

Our engineers assess each part’s geometry and material to determine the most effective pre-treatment strategy. This tailored approach is a cornerstone of achieving predictable and consistent color results.

Optimized Anodic Oxidation Process Control

Our anodizing lines are equipped with state-of-the-art process control systems. These systems precisely regulate voltage, current density, bath temperature, and time throughout the entire anodizing cycle.

Dynamic adjustment of current profiles ensures a controlled and uniform growth of the anodic film, even on complex geometries. This mitigates the risk of localized overheating or uneven film formation.

By integrating real-time monitoring and feedback loops, we maintain tight tolerances on all critical parameters, ensuring repeatable results and superior color consistency from the first part to the last.

Precision Jigging and Fixturing for Consistent Color

Our commitment to color uniformity extends to the meticulous design and use of precision jigging. Jigs are custom-engineered for specific part geometries, ensuring optimal electrical contact and uniform current distribution.

These fixtures are designed to prevent solution pooling or air entrapment, which can lead to color streaking or unevenness. The material and coating of the jigs are also carefully selected to avoid contamination of the anodizing bath.

For high-volume or geometrically challenging parts, we invest in bespoke fixturing solutions. This strategic investment minimizes variations, guaranteeing that every part receives an identical anodizing treatment.

Post-Anodizing Sealing for Durable Color Uniformity

The final step, sealing, is crucial for locking in the color and enhancing the durability of the anodized finish. Improper sealing can lead to color leaching, fading, or reduced corrosion resistance over time.

Sealing closes the pores of the anodic film, preventing the absorption of contaminants and stabilizing the dye within the layer. Both hot water sealing and chemical sealing methods are employed based on application requirements.

Our sealing processes are carefully controlled for temperature, pH, and duration. This ensures maximum pore closure and guarantees long-term color stability, providing a finish that endures the rigors of use.

Quality Assurance for Anodized Aluminum CNC Part Uniformity

Spectrophotometer Color Measurement and Analysis

To objectively verify color uniformity, we utilize advanced spectrophotometers. These instruments provide precise, quantitative color data, eliminating subjective visual interpretation.

Measurements are taken at multiple points on each part and across different parts within a batch. This data is then compared against established color standards and tolerances to ensure compliance.

This rigorous analytical approach allows us to detect even minute color shifts that would be imperceptible to the human eye. It ensures every part meets the exact color specifications consistently.

Table: Spectrophotometer Color Measurement Data Example

| Measurement Point | L* Value | a* Value | b* Value | Delta E (dE)* |

|---|---|---|---|---|

| Part A – Top | 35.1 | 2.3 | -1.5 | 0.2 |

| Part A – Mid | 35.0 | 2.2 | -1.6 | 0.3 |

| Part A – Bot | 35.2 | 2.4 | -1.4 | 0.3 |

| Part B – Top | 35.0 | 2.3 | -1.5 | 0.2 |

| *Delta E is the color difference from the target standard. Lower values indicate better uniformity. |

Visual Inspection Standards for Color Uniformity

While spectrophotometers provide objective data, skilled visual inspection remains a vital component of our quality control. Our trained technicians visually assess parts under standardized lighting conditions.

They look for any subtle variations in hue, saturation, brightness, streaking, or blotching that might affect the aesthetic appeal. This human element complements the quantitative measurements, catching nuances.

Our visual inspection standards are aligned with industry best practices and client-specific requirements. This two-pronged approach ensures both technical adherence and aesthetic excellence.

Our Quality Control Protocols for Consistent Anodizing

Our quality control protocols are integrated at every stage, from material reception to final packaging. This holistic approach prevents issues rather than just detecting them post-production.

We implement statistical process control (SPC) to monitor key anodizing parameters over time, identifying trends and preventing deviations before they lead to defects. Regular bath analysis and equipment calibration are standard.

Each batch of anodized parts undergoes a final audit, including adhesion tests, abrasion resistance checks, and thorough color uniformity verification. This comprehensive system guarantees unwavering quality.

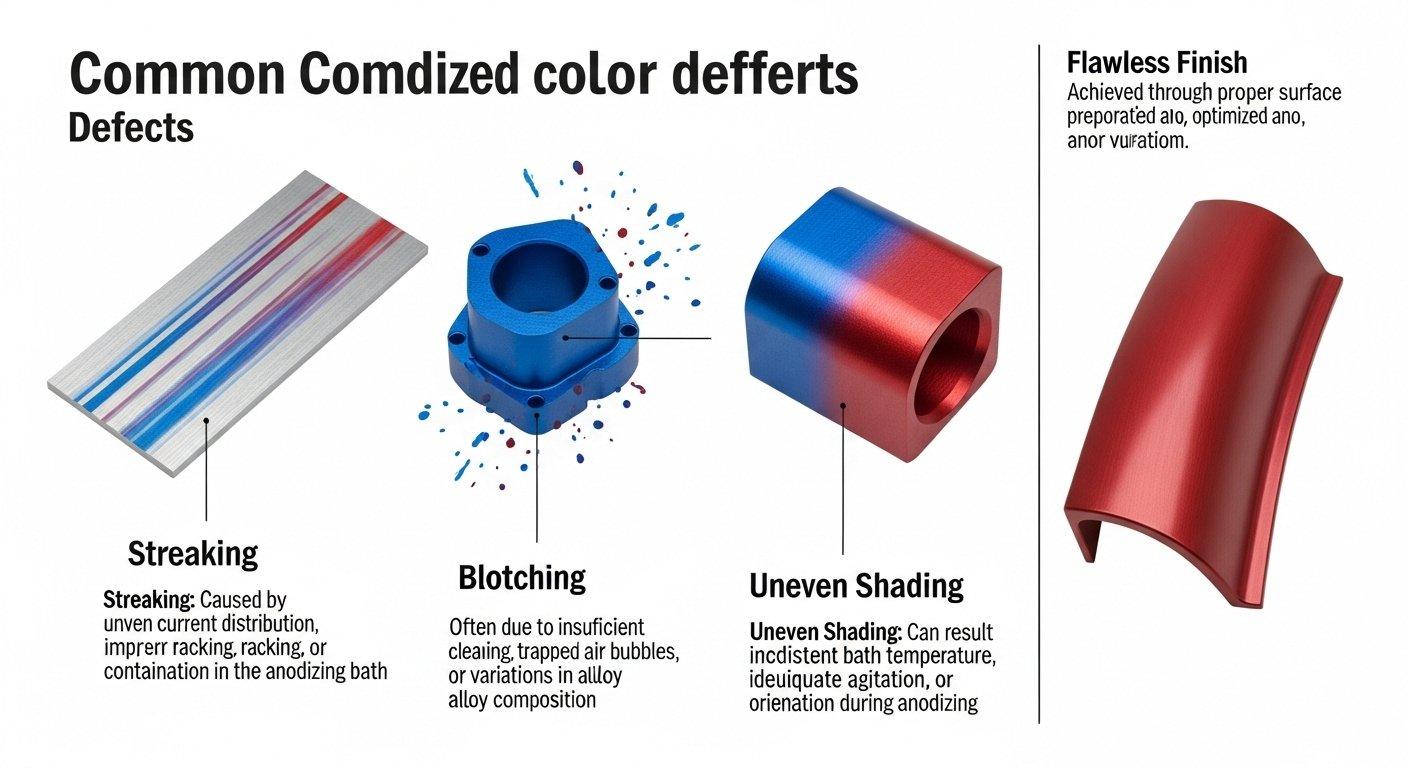

Addressing Common Color Variation Challenges

Common color variations include streaking, blotching, shading, and batch-to-batch inconsistencies. These often stem from issues in pre-treatment, current distribution, or dyeing bath control.

Streaking can indicate uneven rinsing or contaminated baths. Blotchiness often points to inadequate pre-treatment or uneven etching. Shading may result from varied film thickness due to current density issues.

Our technical team excels at root cause analysis for any identified color variation. We leverage our deep process understanding to implement targeted corrective actions quickly and effectively, ensuring ongoing consistency.

The Advantage of Integrated CNC and Anodic Oxidation Expertise

How Source Manufacturing Ensures Color Uniformity

As a source manufacturer, we control the entire production chain, from raw material procurement and CNC machining to the final anodizing and quality control. This vertical integration is our greatest advantage for color uniformity.

We eliminate the variables introduced when multiple vendors handle different stages. Our engineers collaborate seamlessly between machining and anodizing departments, optimizing each step for the next.

This unified approach allows for tighter control over critical factors like surface finish, alloy preparation, and process parameters, directly translating into unparalleled color consistency for your parts.

Our Technical Expertise in Anodized Finish Consistency

Our team possesses deep technical expertise in both advanced CNC machining and specialized anodic oxidation processes. We understand the intricate interplay between material science, engineering design, and surface finishing.

We continually invest in research and development, refining our proprietary processes to achieve new benchmarks in surface finish quality and color uniformity. Our engineers are problem-solvers, not just operators.

This expertise means we can tackle the most challenging aesthetic requirements and complex geometries, providing solutions that few external service providers can match.

Transparent Processes for High-Quality Anodized Parts

We believe in transparent communication regarding our processes and quality control measures. Clients receive clear documentation and are welcome to consult with our technical experts at any stage.

Understanding how we ensure color uniformity builds trust and allows for effective collaboration. Our aim is to provide peace of mind, knowing your critical components are in expert hands.

This commitment to transparency, combined with our integrated capabilities, ensures that every anodized aluminum CNC part we deliver meets your highest expectations for aesthetic and functional consistency.

Ready to eliminate color inconsistency and ensure pristine aesthetics for your aluminum CNC parts? Contact our technical experts today for a personalized consultation and a transparent quote. Let our precision and expertise bring your vision to life with uncompromising quality.

**Article Summary:**

Achieving consistent color uniformity in anodized aluminum CNC parts is a complex challenge influenced by alloy composition, machining surface finish, precise anodizing bath control, current density, jigging, and dyeing processes.

ly-machining, as a vertically integrated manufacturer, leverages advanced pre-treatment, optimized process control, precision jigging, and rigorous quality assurance including spectrophotometer analysis, to guarantee unparalleled color consistency. Our deep technical expertise and transparent processes solve common color variation issues, delivering high-quality, aesthetically uniform parts.

**FAQ Section:**

Q1: Why do aluminum parts sometimes show inconsistent color after anodizing, even if they are from the same batch?

A1: Inconsistent color often stems from variations introduced at different stages. This can include non-uniform surface finishes from CNC machining, subtle differences in pre-treatment (cleaning, etching), uneven current distribution during the anodizing process, or inconsistent dye bath parameters.

Factors like part geometry and how parts are jigged can also contribute, leading to varying film thickness and porosity that affect dye absorption.

Q2: How does ly-machining specifically address the challenge of achieving uniform color on complex CNC machined aluminum parts?

A2: For complex geometries, ly-machining employs several strategies. We start by optimizing CNC machining paths to ensure a consistent surface finish. During anodizing, we design custom precision jigs tailored to the part’s geometry to ensure uniform current distribution and prevent shielding.

We also meticulously control anodizing bath parameters (temperature, concentration) and dyeing processes, using real-time monitoring and advanced process control systems to maintain consistency across all surfaces and batches.

Q3: What quality control measures are in place to guarantee color uniformity before parts are shipped to clients?

A3: Our quality assurance process is multi-faceted. We use spectrophotometers for objective, quantitative color measurement, analyzing multiple points on parts and across batches against specific color standards (L*a*b* values). This is complemented by rigorous visual inspections performed by trained technicians under controlled lighting.

Additionally, we implement statistical process control throughout manufacturing and conduct final audits, including durability and adhesion tests, to ensure both aesthetic and functional quality before shipment.