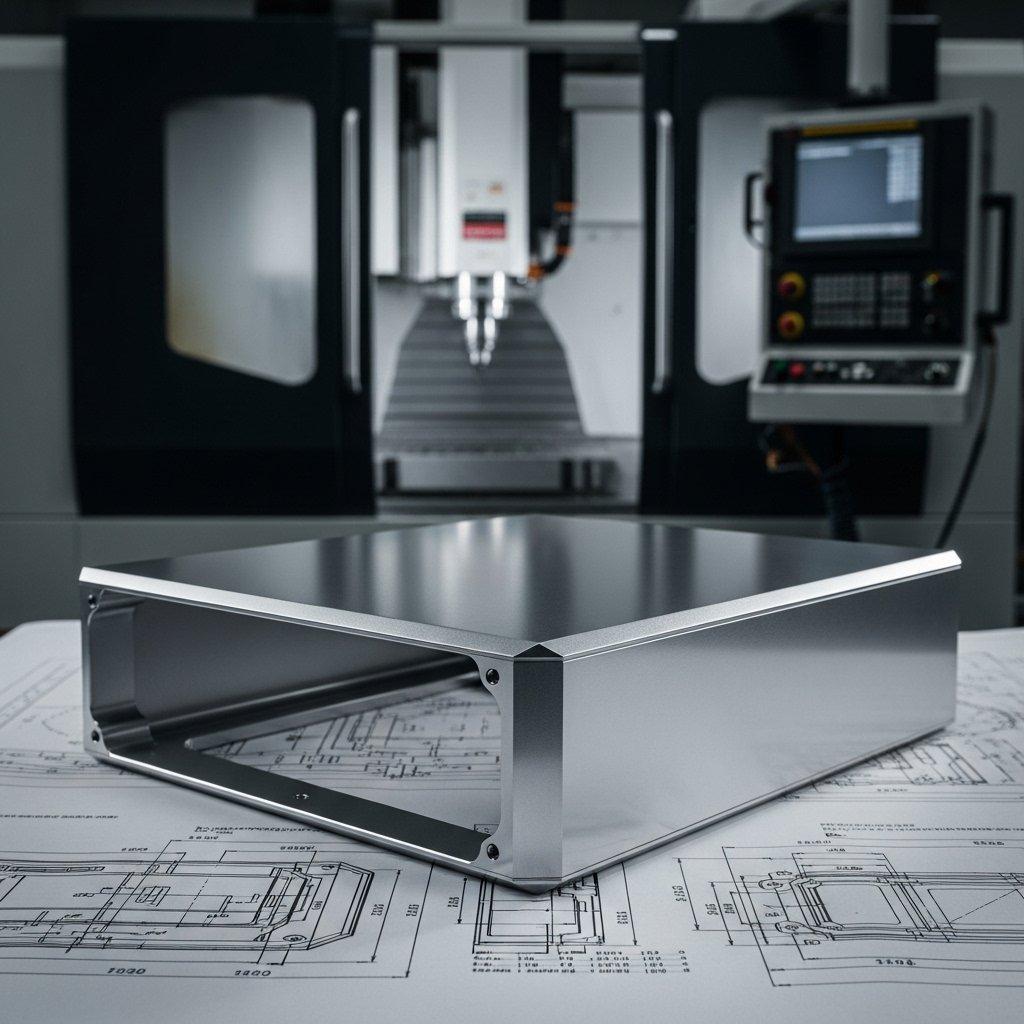

Achieving optimal custom aluminum enclosure CNC machining involves balancing stringent precision control with aggressive cost reduction strategies. Our expertise as a source manufacturer ensures both are met without compromise for superior results.

The journey from design to a finished aluminum enclosure often presents a critical dilemma: how to achieve the required precision without incurring prohibitive costs. This challenge is pervasive across industries, from electronics to medical devices, where both functionality and budget are paramount.

Many manufacturers find themselves compromising on one aspect to satisfy the other, leading to either underperforming parts or over-budget projects. This article explores how deep technical expertise, coupled with strategic manufacturing processes, eliminates this trade-off for your custom aluminum enclosure CNC machining needs.

At ly-machining, we understand these complexities intimately. We empower our clients to secure high-quality parts that meet exacting specifications, all while ensuring cost-effectiveness through our specialized approach to CNC Machining Cost Reduction and CNC Precision Control.

The Dilemma: Cost vs. Precision

The tension between minimizing expenses and maximizing accuracy is a constant in custom aluminum enclosure manufacturing. It forces many projects into difficult compromises that can undermine product performance or market competitiveness.

Why Balancing Both Is Critical

For any custom aluminum enclosure, precision directly impacts functionality, assembly, and aesthetic appeal. Sub-par accuracy can lead to fitment issues, thermal management problems, or even structural integrity failures in critical applications.

Simultaneously, uncontrolled costs erode profit margins and can make an otherwise innovative product unviable. Finding a partner who can deliver both high-quality parts and cost-effective solutions is therefore essential for project success.

Common Pitfalls in Enclosure Machining

In our experience, common issues include parts not meeting tight tolerances, leading to costly reworks or scrap. Poor surface finishes can affect product aesthetics and functionality, especially for anodized aluminum enclosures.

Thermal distortion during the CNC machining process can introduce warpage, particularly in thin-walled designs. Inconsistent quality between batches and the presence of burrs also contribute to higher inspection costs and compromised product integrity.

Strategies for Aluminum CNC Cost Reduction

Effective CNC Machining Cost Reduction starts long before the first chip is cut. It involves a holistic approach that integrates design considerations, material intelligence, and optimized manufacturing processes.

Design for Manufacturability (DFM) Principles

Our engineers proactively engage with client designs, applying Design for Manufacturability (DFM) principles. This ensures that custom aluminum enclosures are designed to be efficiently machined, reducing cycle times and material waste.

Simplifying complex geometries, standardizing features like hole sizes, and minimizing the number of setups required are key DFM strategies. These early interventions are crucial for avoiding expensive design iterations later on.

| DFM Guideline | Cost Reduction Impact |

|---|---|

| Simplify Geometry | Faster machining, fewer tool changes, less programming time |

| Standardize Features | Use off-the-shelf tools, reduce custom tooling costs |

| Minimize Deep Pockets/Cavities | Avoid long-reach tools, prevent chatter, faster cycles |

| Consider Wall Thickness Uniformity | Reduces material stress, prevents warpage, easier setup |

| Add Radii to Internal Corners | Eliminates need for small, delicate tools, faster milling |

Optimizing Material Selection

Choosing the right aluminum alloy for your custom aluminum enclosure is vital for balancing performance and cost. Alloys like 6061-T6 are excellent general-purpose choices, offering a good blend of strength, machinability, and corrosion resistance.

While specialized alloys might offer superior properties, they often come with higher material costs and can be more challenging to machine. Our expertise guides clients to the most cost-effective material that still meets their application’s specific requirements.

| Aluminum Alloy | Key Characteristics | Typical Applications |

|---|---|---|

| 6061-T6 | Good strength, weldability, corrosion resistance, excellent machinability | General purpose, electronics, structural components |

| 7075-T6 | Very high strength, good fatigue resistance, more difficult to machine | Aerospace, high-stress components |

| 5052-H32 | Excellent corrosion resistance (esp. saltwater), good formability | Marine applications, fuel tanks, enclosures requiring bending |

| 2024-T3 | High strength, good fatigue resistance, lower corrosion resistance | Aerospace structures, high-performance parts |

Efficient Machining Process Planning

Optimizing tool path generation and cutting strategies is fundamental to efficient CNC machining cost reduction. This involves using advanced CAM software to simulate and refine tool paths, minimizing air cuts and maximizing material removal rates.

We meticulously plan the sequence of operations, employ optimal cutting parameters, and select the most appropriate tooling to ensure both speed and precision. This reduces overall cycle times and extends tool life, contributing directly to lower unit costs.

Impact of Batch Size and Lead Time

Leveraging economies of scale is a significant factor in cost reduction. Larger production batch sizes allow for more efficient utilization of machine setup times, which are often a fixed cost component.

Our streamlined production workflows also enable competitive lead times, particularly for custom aluminum enclosure projects. Efficient scheduling and supply chain management reduce overall project timelines and associated carrying costs.

Achieving Flawless Precision Control

Precision control is not just about the machine; it’s an intricate dance between advanced equipment, rigorous processes, and the skilled hands and minds of expert engineers. We understand that CNC Precision Control is paramount for your custom aluminum housings.

Advanced CNC Equipment & Tooling

Our facility boasts state-of-the-art multi-axis CNC machines capable of intricate geometries and tight tolerances. These advanced machines, combined with high-speed spindles and specialized cutting tools, ensure superior surface finishes and dimensional accuracy.

We regularly invest in the latest technology to maintain our competitive edge in aluminum enclosure CNC machining. This commitment to modern equipment directly translates to the high-quality parts our clients expect and receive.

Stringent Quality Assurance Processes

Achieving consistent precision requires an unwavering commitment to quality. Our quality management system adheres to industry standards such as ISO 9001 and AS9100, ensuring every custom aluminum enclosure meets the strictest specifications.

We employ Coordinate Measuring Machines (CMM) for precise dimensional verification, alongside optical inspection systems for surface finish and critical feature checks. In-process inspections catch deviations early, preventing costly rework.

| Quality Control Method | Purpose | Benefit to Precision |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Highly accurate dimensional verification of complex parts | Guarantees tight tolerances, critical for assembly |

| Optical Inspection Systems | Non-contact measurement of features, surface profile | Detects subtle flaws, ensures aesthetic quality |

| In-process Checks | Regular measurements during machining | Early detection of deviations, minimizes scrap |

| First Article Inspection (FAI) | Detailed inspection of the first part produced in a run | Validates setup accuracy before full production |

| Destructive Testing (if applicable) | Material integrity, structural strength validation | Ensures part longevity and performance |

Expertise in Programming & Operation

The most advanced machines are only as good as the engineers who program and operate them. Our team comprises highly skilled CNC programmers and operators with deep experience in aluminum enclosure CNC machining.

They leverage advanced CAM software to generate optimized tool paths, understand material behavior, and anticipate potential machining challenges. This human expertise is invaluable in achieving consistent CNC Precision Control.

Criticality of Post-Processing

Post-processing is not an afterthought; it is integral to achieving the desired finish and functionality for custom aluminum enclosures. Processes like deburring, polishing, and various surface treatments (e.g., anodizing, powder coating) are critical.

These steps ensure a smooth, aesthetically pleasing, and durable surface, free from sharp edges or imperfections. They also enhance corrosion resistance and provide electrical insulation where required, completing the high-quality parts.

Our Approach: Cost-Effective High-Precision

At ly-machining, we’ve refined our processes to consistently deliver high-quality parts for custom aluminum enclosure projects. Our integrated approach ensures both CNC Machining Cost Reduction and uncompromised CNC Precision Control.

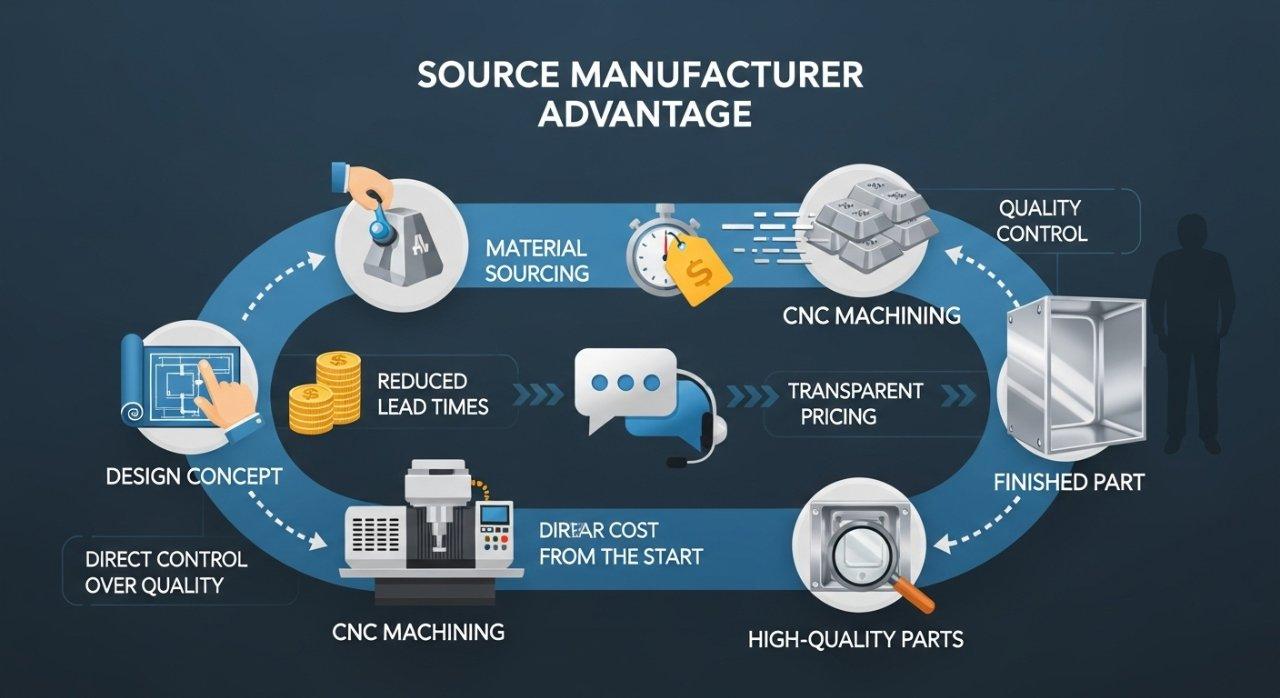

The Source Manufacturer Advantage

As a direct source manufacturer, we offer unparalleled benefits. Clients benefit from direct communication with our engineering team, transparent pricing models, and complete oversight of the production process.

This direct relationship eliminates intermediary markups and miscommunications, accelerating projects and ensuring that the final custom aluminum enclosure precisely matches design intent. It’s a key factor in consistent quality.

Transparent Pricing for Aluminum Parts

We believe in clear and honest communication regarding all project costs. Our detailed quotes for custom aluminum enclosure projects break down material, machining, and finishing costs, ensuring no hidden fees.

This transparent pricing approach empowers clients to make informed decisions and budget effectively, confident in the value they receive. Our goal is to provide a predictable cost structure without sacrificing quality.

Deep Technical Expertise in Action

Our team’s deep technical expertise extends beyond simply operating machines. We offer DFM consultation, material science insights, and innovative problem-solving for even the most complex custom aluminum housing designs.

This collaborative engineering approach ensures that design intent is translated into highly manufacturable and cost-effective solutions. We proactively identify opportunities for CNC Machining Cost Reduction while maintaining precision.

Commitment to Quality & Delivery

Our commitment to delivering high-quality parts on time is unwavering. We utilize robust project management systems and stringent quality control protocols throughout the entire production cycle, from raw material to final inspection.

This ensures that every custom aluminum enclosure not only meets but often exceeds client expectations for precision, finish, and timely delivery. We stand by the reliability and performance of our CNC machined products.

Case Study: Maximizing Enclosure Value

We routinely partner with clients facing the challenging balance of cost and precision. This case study illustrates how our expertise provides tangible value.

Client Challenge & Our Solution

A client developing an advanced medical device required a custom aluminum enclosure with exceptionally tight tolerances (±0.01mm) and specific surface finish requirements, but faced budget constraints from their previous supplier. The prior iterations struggled with warpage and inconsistent feature alignment, leading to high rejection rates.

Our engineering team initiated a comprehensive DFM review, optimizing their design by recommending minor geometry adjustments and a specific heat-treated aluminum alloy to mitigate warpage. We then developed a multi-stage machining strategy with optimized tool paths and implemented enhanced in-process CMM inspections.

Tangible Results: Savings & Quality

Through our intervention, the client achieved a 15% reduction in per-unit manufacturing cost, primarily through reduced material waste and optimized cycle times. Simultaneously, the custom aluminum enclosure parts consistently met the critical ±0.01mm tolerance.

The rejection rate dropped by over 90%, significantly improving their product’s time-to-market and reliability. This project demonstrated the power of integrated CNC Machining Cost Reduction and uncompromising CNC Precision Control.

Partnering for Aluminum Enclosure Success

Our unique blend of deep technical expertise and advanced manufacturing capabilities positions us as the ideal partner for your custom aluminum enclosure projects. We are dedicated to delivering high-quality parts efficiently.

Ready for a Consultation

If you’re looking to optimize your custom aluminum enclosure CNC machining projects, our engineering team is ready to assist. We can provide insights on design, material selection, and process optimization.

Request a Quote Today

Experience the ly-machining difference for yourself. Leverage our CNC Machining Cost Reduction strategies and guaranteed CNC Precision Control.

Ready to end the compromise between cost and precision for your custom aluminum enclosures? Contact us today for a free DFM consultation and a transparent quote, and experience the difference of a true source manufacturer delivering high-quality parts.

Frequently Asked Questions

What is DFM in aluminum CNC machining?

DFM, or Design for Manufacturability, is a systematic engineering approach. It involves optimizing a product’s design to make it easier and more cost-effective to manufacture.

For aluminum enclosures, DFM ensures features are designed for efficient machining. This helps minimize material waste and reduces the number of complex operations.

How does batch size affect machining costs?

Larger batch sizes generally lead to lower per-unit costs. This is because fixed setup costs, such as programming and machine calibration, are spread across more units.

This economy of scale makes higher volume custom aluminum enclosure production more cost-efficient. We work with clients to find optimal batch sizes.

What quality standards do you adhere to?

We adhere to rigorous international quality standards. These include ISO 9001, and for specific industries, AS9100.

These certifications ensure our CNC Precision Control processes are consistent. They guarantee the reliability and quality of every custom aluminum enclosure we produce.