Choosing the right surface finish for your custom aluminum CNC parts can feel like a shot in the dark. You know the final look is critical, but the technical specifications, like grit size for sandblasting, are confusing and can make or break your product’s aesthetic appeal.

This uncertainty often leads to bigger problems. An inconsistent or incorrect finish can compromise the perceived value of your precision components, forcing costly reworks and pushing back deadlines. Imagine receiving a batch of expensive, CNC-milled parts only to find the surface texture is not what you envisioned, creating a mismatch with your brand’s quality standards. This is a common frustration in the CNC machining industry.

This comprehensive guide illuminates the path forward. We will break down the key differences between 120#, 150#, and 180# grit sandblasting for oxidized aluminum parts. By understanding these nuances, you can confidently select the perfect finish, ensuring your components meet exact specifications and elevate your final product. This is a crucial step in any professional CNC machining workflow.

When preparing aluminum components, 120# grit sandblasting creates a distinctly uniform, coarse matte surface, excellent for hiding imperfections from the CNC machining process. For a smoother, more refined texture, 150# grit is used, offering a balanced and clean appearance. 180# grit provides the finest, most delicate satin finish, ideal for high-end aesthetic parts where every detail from the CNC milling operation matters.

You now have a foundational understanding of these common options. However, to truly optimize your project, a deeper dive is necessary. Consequently, we will explore the specific applications and technical considerations for each grit size. Furthermore, this knowledge will empower you to communicate your requirements effectively with your CNC machining partner. Ultimately, a detailed analysis ensures that the outcome of your CNC milling project aligns perfectly with your vision.

The Role of Oxidation Sandblasting in CNC Machining

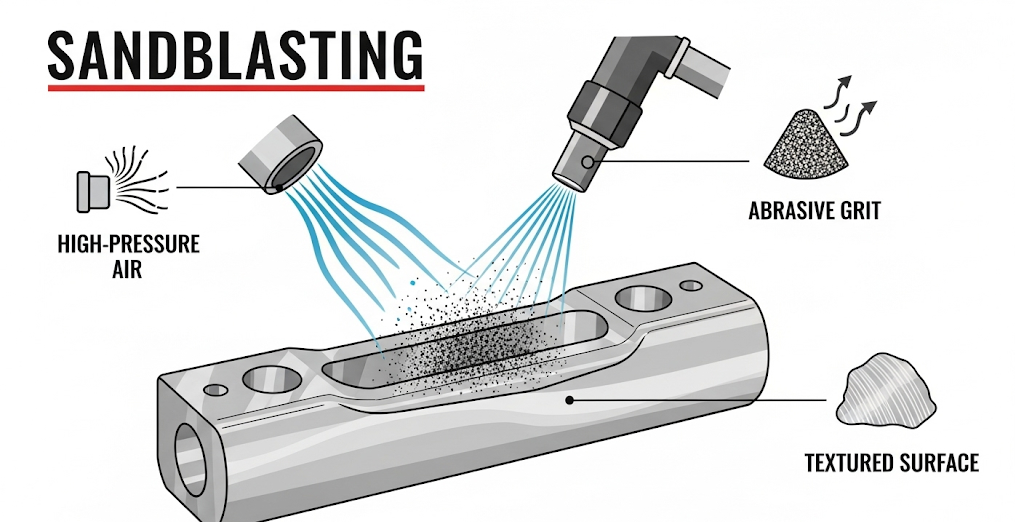

Oxidation sandblasting is a two-part surface finishing process vital in modern CNC machining. First, the surface of an aluminum part is blasted with an abrasive medium, such as aluminum oxide grit. This step removes minor imperfections like tool marks left by the CNC milling process and creates a uniform, textured surface.

Immediately following this, the part undergoes anodizing (oxidation). This electrochemical process grows a durable, corrosion-resistant oxide layer on the aluminum. The sandblasted texture is sealed beneath this layer, resulting in a clean, non-reflective matte finish that is both aesthetically pleasing and highly durable. This process is a staple for quality CNC machining outputs.

Why Grit Size is a Critical Decision in CNC Milling

The “grit number” (#) refers to the size of the abrasive particles used in the blasting process. A lower number indicates a larger, coarser particle, while a higher number signifies a smaller, finer particle. This choice is far from trivial in a CNC milling project.

The grit size directly determines the final surface roughness (Ra) and appearance of the component. A coarse grit will create a more textured finish, while a fine grit results in a smoother, more satin-like surface. Making the right selection is fundamental to achieving the desired tactile and visual properties for your precision CNC machining products.

A Closer Look: 120# Grit for Robust Aluminum Parts

When your project requires a tough, uniform finish that effectively conceals surface defects, 120# grit is an excellent choice. This coarse grit is highly effective at blending in any minor blemishes or tool marks that may remain after the primary CNC machining operations.

The resulting texture is a pronounced, even matte finish. It is often preferred for industrial components, durable equipment housings, and parts where functionality and blemish-hiding are more important than a delicate aesthetic. This approach to finishing is a workhorse in industrial CNC milling.

Many clients in the CNC machining field select 120# grit for parts that will see heavy use or are larger in scale, as it provides a consistent look across broad surfaces. This makes it a practical solution for a wide range of applications that demand reliable CNC machining and finishing.

Finding the Balance: 150# Grit for a Refined Matte Finish

150# grit strikes a popular balance between the coarseness of 120# and the fineness of 180#. It is a widely used specification in the CNC machining industry for consumer electronics and architectural components. This finish offers a visually clean and smooth surface.

The texture created by 150# grit is noticeably finer and less aggressive than that of 120# grit. It feels smoother to the touch and provides a sophisticated, modern matte look. This makes it a versatile option for many CNC milling projects where a high-quality appearance is a key requirement.

If your goal is a premium finish that isn’t overly delicate, 150# grit is often the recommended path. It provides excellent uniformity for anodizing, ensuring consistent color and appearance, a hallmark of expert CNC machining and finishing.

The Premium Touch: 180# Grit for Delicate, Aesthetic Surfaces

For projects demanding the finest, most luxurious finish, 180# grit is the premier option. The fine abrasive particles create a soft, satin texture that is exceptionally smooth to the touch. This finish is the standard for high-end CNC machining applications.

This grit size is ideal for premium consumer electronics, decorative items, and any CNC milling component where the tactile feel and visual subtlety are paramount. The resulting surface is less about hiding defects and more about creating a flawless, high-end aesthetic from a perfectly machined part.

Choosing 180# grit signals a commitment to superior quality. It requires a well-executed CNC machining process beforehand, as it will not hide imperfections as effectively as coarser grits. However, for the right application, the resulting elegance is unmatched. This level of detail is a testament to advanced CNC milling capabilities.

Comparative Analysis: Choosing Your Grit for CNC Machining

Selecting the appropriate grit requires a clear understanding of the trade-offs. While textual descriptions are helpful, a direct comparison can simplify the decision-making process for your next CNC machining project. This is a critical conversation to have during the CNC milling design phase.

Here is a table summarizing the key attributes of each grit size to guide your selection. This data is essential for anyone specifying finishes for aluminum components produced via CNC machining.

| Feature | 120# Grit | 150# Grit | 180# Grit |

| Particle Size | Coarse | Medium | Fine |

| Final Appearance | Uniform, Textured Matte | Smooth, Even Matte | Soft, Satin-like Matte |

| Surface Roughness (Ra) | Higher | Moderate | Lower |

| Feel | Distinctly Textured | Smooth | Very Smooth, Silky |

| Defect Hiding | Excellent | Good | Fair |

| Primary Use Case | Industrial Parts, Housings | Consumer Electronics, General | Premium Aesthetics, Luxury Goods |

| CNC Machining Note | Standard finishing step | Requires good surface prep | Demands pristine CNC milling |

How Sandblasting Impacts Tolerances and Anodizing

A critical consideration in precision CNC machining is the impact of secondary processes on dimensional tolerances. Sandblasting is a subtractive process; it removes a small amount of material from the part’s surface. The amount is minimal, but for parts with tight tolerances, it must be accounted for in the initial CNC milling design.

The surface texture created by sandblasting also affects the subsequent anodizing process. A more textured surface (from a coarser grit) has more surface area, which can influence the thickness and final appearance of the anodic layer. A reliable CNC machining partner like ly-machining will manage this process to ensure color consistency and dimensional accuracy. Proper control during every CNC machining and finishing stage is key.

Finding a Trusted Partner for Your CNC Milling Needs

Ultimately, the success of your project depends not only on choosing the right finish but also on the expertise of your manufacturing partner. A knowledgeable supplier can provide guidance, ensure process control, and deliver high-quality, finished components that meet your exact standards. This partnership is the cornerstone of successful CNC machining.

At ly-machining, we specialize in high-quality CNC machining and provide a full suite of finishing services, including expert oxidation sandblasting. We work closely with our clients to understand their needs for every CNC milling project, from prototype to production, ensuring the final product is perfect. Our commitment to quality in CNC machining is unwavering.

Related Questions

What aluminum alloys are best for sandblasting and anodizing?

While many aluminum alloys can be treated, the 6000 series, particularly 6061, is highly popular for CNC machining and finishing due to its excellent corrosion resistance and ability to achieve a beautiful, uniform anodized finish. The 7075 alloy is also used for high-strength applications, though achieving cosmetic consistency in its anodized finish can be more challenging, requiring expert process control in the CNC milling and finishing stages.

How is the quality of the finish maintained across a production run?

Quality control is essential in any professional CNC machining operation. Consistency is achieved through strictly controlled parameters, including air pressure, blast distance, nozzle angle, and duration. At ly-machining, we use calibrated equipment and perform regular inspections, including surface roughness measurements, to ensure every part in a batch meets the exact same standard. This rigorous approach applies to both our CNC machining and CNC milling services.

Frequently Asked Questions

1. Does sandblasting significantly change the dimensions of my CNC part?

The material removal is typically very slight, often measured in microns. However, for high-precision CNC machining parts with very tight tolerances, this effect must be factored into the design phase. We always consult with our clients to account for these minor shifts during the CNC milling programming to ensure the final, finished part is perfectly within spec.

2. Can you achieve different colors with a sandblasted and anodized finish?

Absolutely. The sandblasted matte texture provides an excellent base for color anodizing. The process can produce a wide range of colors, from clear and black to blues, reds, and golds. The matte texture created before anodizing helps to give the color a deep, rich, and non-reflective appearance, which is a popular outcome for many CNC machining projects.

3. How do I choose between these three grit finishes for my project?

The choice depends entirely on your product’s application and desired aesthetic. As a general rule: use 120# for durable, industrial parts where hiding marks is key. Choose 150# for a versatile, high-quality finish suitable for most consumer products. Select 180# for luxury or high-end aesthetic parts where a delicate, satin feel is the primary goal. Discussing your goals with our CNC machining experts at ly-machining will help you finalize the ideal choice for your CNC milling components.