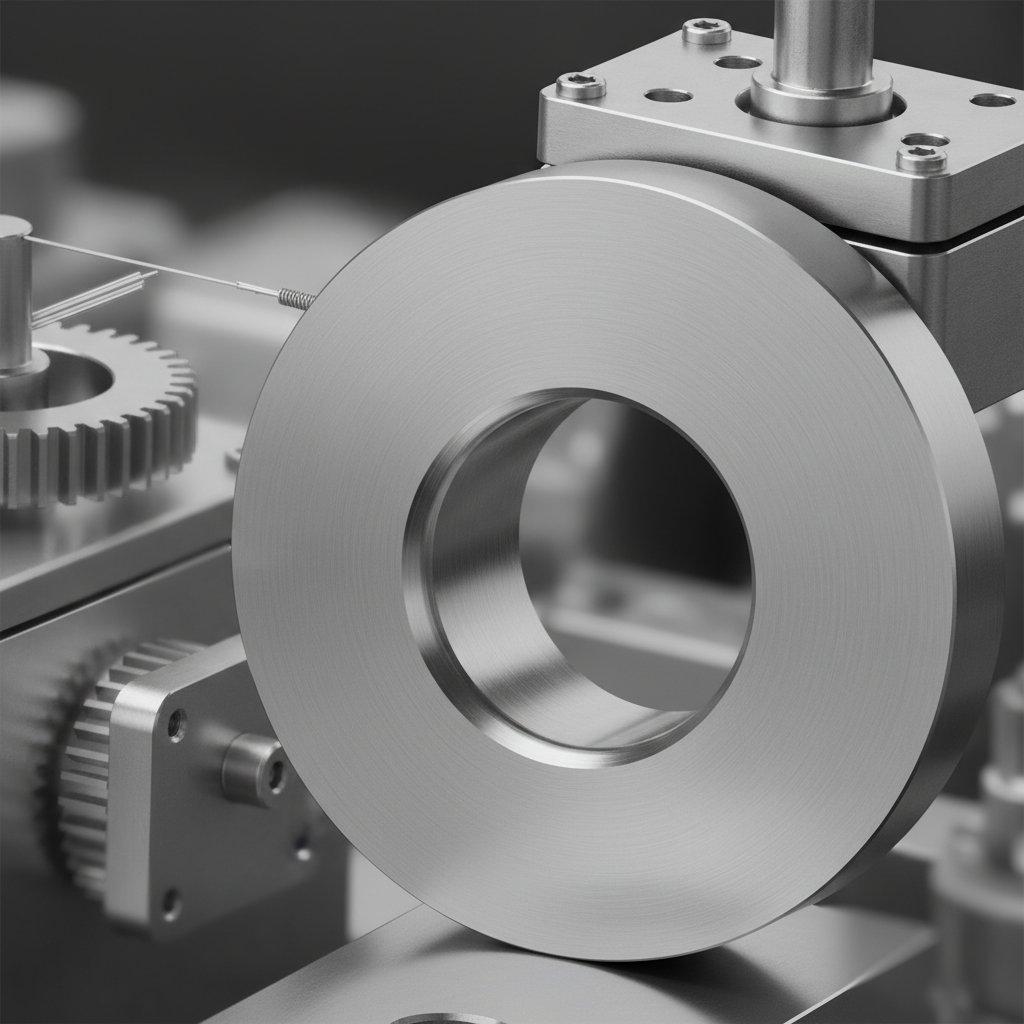

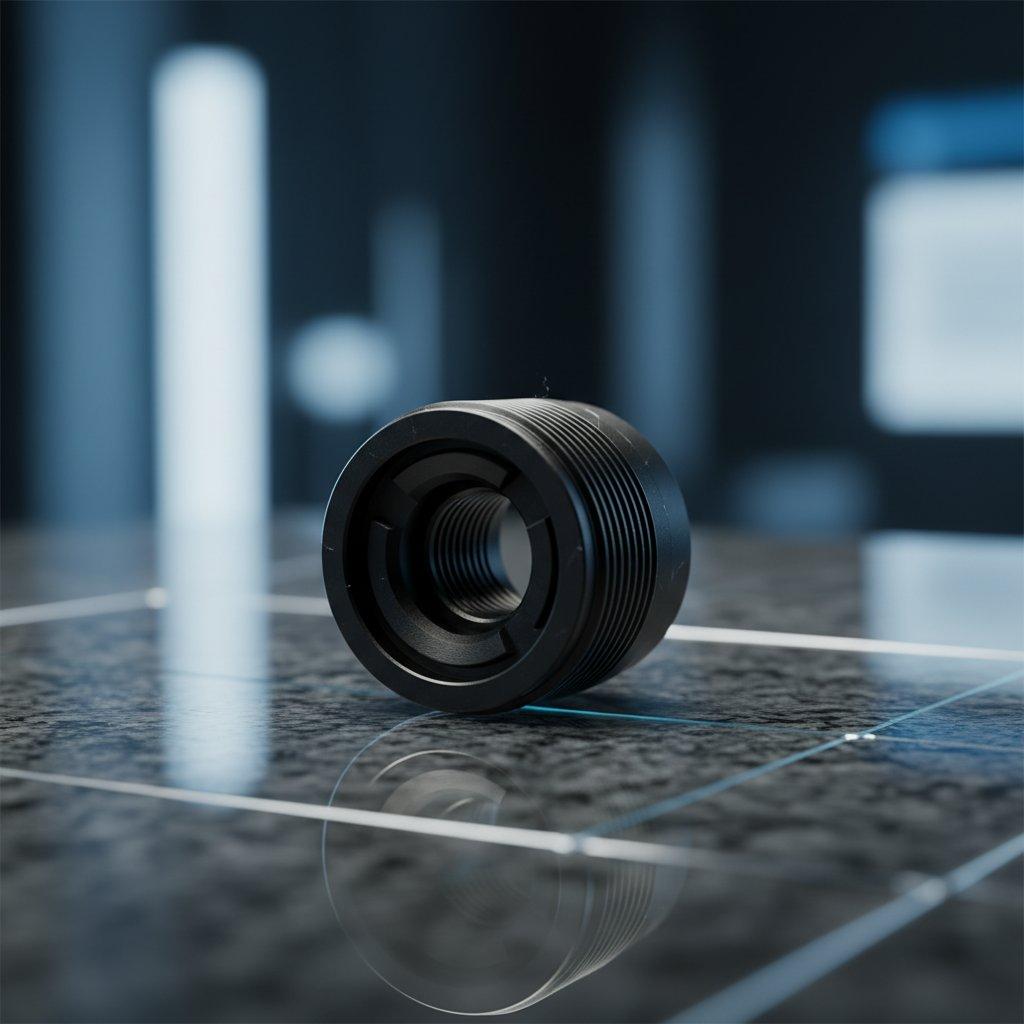

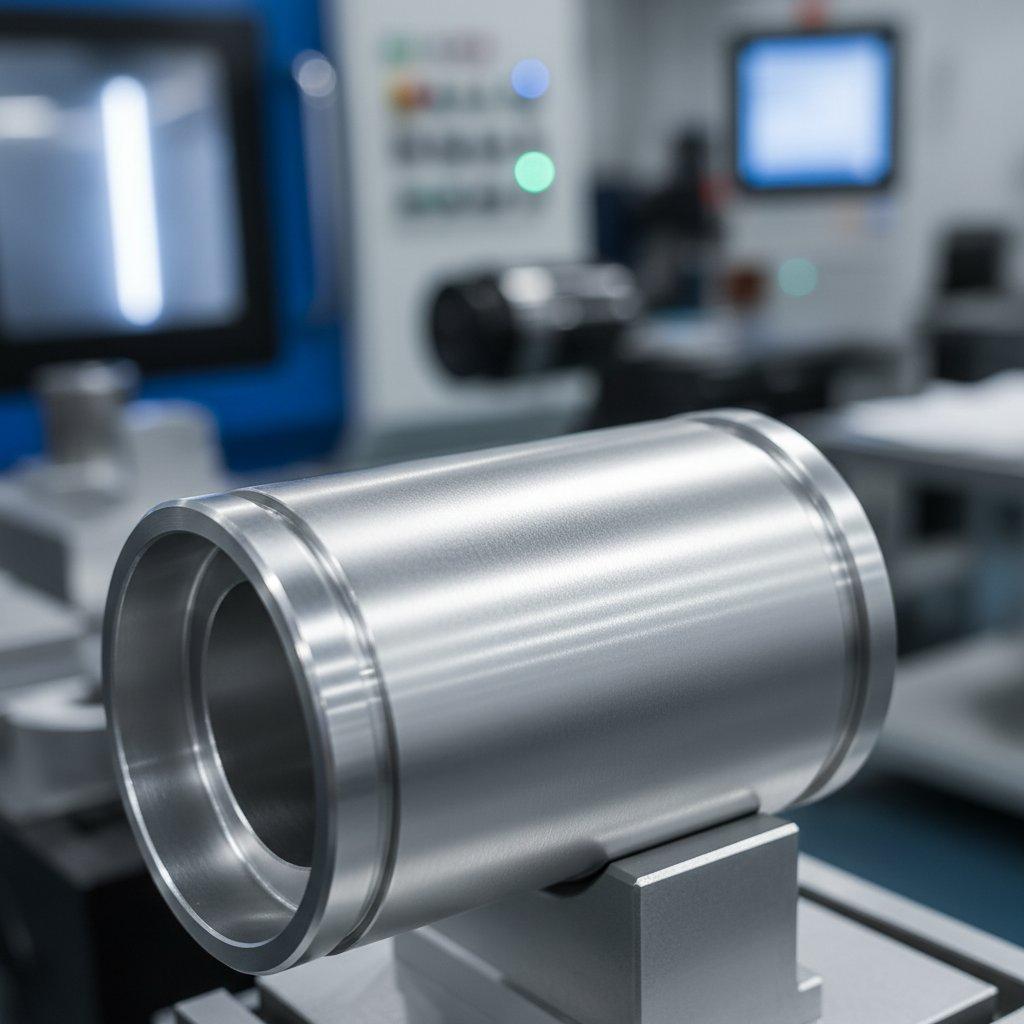

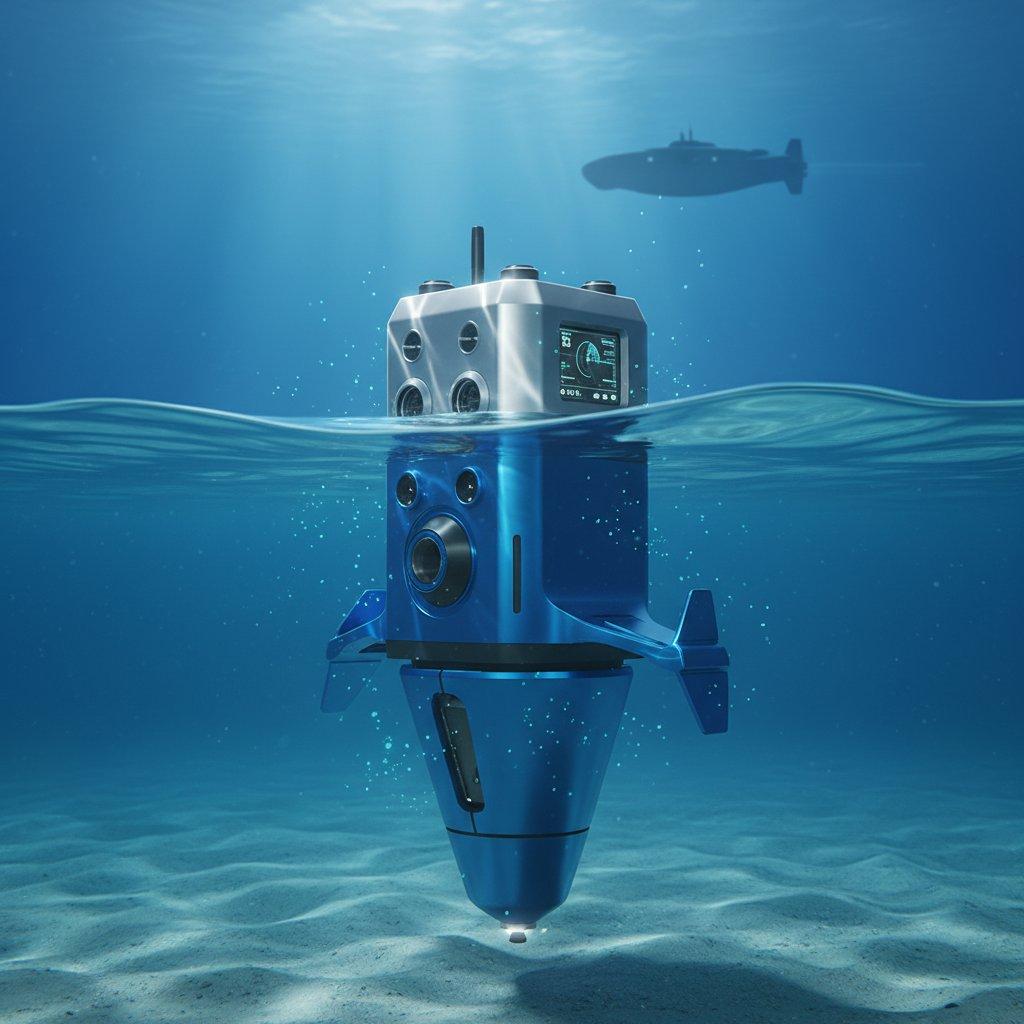

Precision Aluminum CNC Machining Services: Custom Enclosures & Complex Cavities with Robotic Control

blogPrecision CNC for Complex Aluminum Enclosures Precision CNC machining, leveraging robotic and collaborative arm control, enables flawless production of complex aluminum enclosures, positioning ly-machining as a leading aluminum shell CNC machining manufacturer and aluminum CNC […]