Brass CNC Precision: Finish & Tolerance

Achieve superior brass CNC surface finish (Ra < 0.4µm) and tight tolerance control (±0.005mm) through advanced machining, expert tooling, and rigorous metrology for precision brass parts.

The demand for high-performance components across various industries necessitates unparalleled precision. Inconsistent surface finishes or unmet tight tolerances on brass CNC parts can sabotage product performance, increase assembly costs, and lead to critical failures.

What if you could consistently achieve exceptional surface integrity and dimensional accuracy on your complex brass components, every single time? This guide delves into the expert methodologies and technical mastery required for superior brass CNC machining. Discover how true precision can transform your projects.

Criticality of Brass CNC Precision Parts

Why Brass Excels in Precision Applications

Brass is a highly favored material in precision engineering due to its excellent machinability, corrosion resistance, and good thermal and electrical conductivity. These inherent properties make it ideal for intricate components.

Its ductility allows for fine detailing and smooth finishes, while its strength-to-weight ratio serves many demanding applications. When precise and consistent performance is non-negotiable, brass often emerges as the material of choice.

Common Challenges in Brass Component Machining

Despite its machinability, brass presents unique challenges in achieving ultra-high precision. Issues such as burr formation, chip control, and thermal expansion require careful management.

Tool wear can also impact surface finish and dimensional stability if not meticulously monitored. Without specialized knowledge, these challenges can lead to costly rework or component rejection.

Impact of Poor Part Quality on Projects

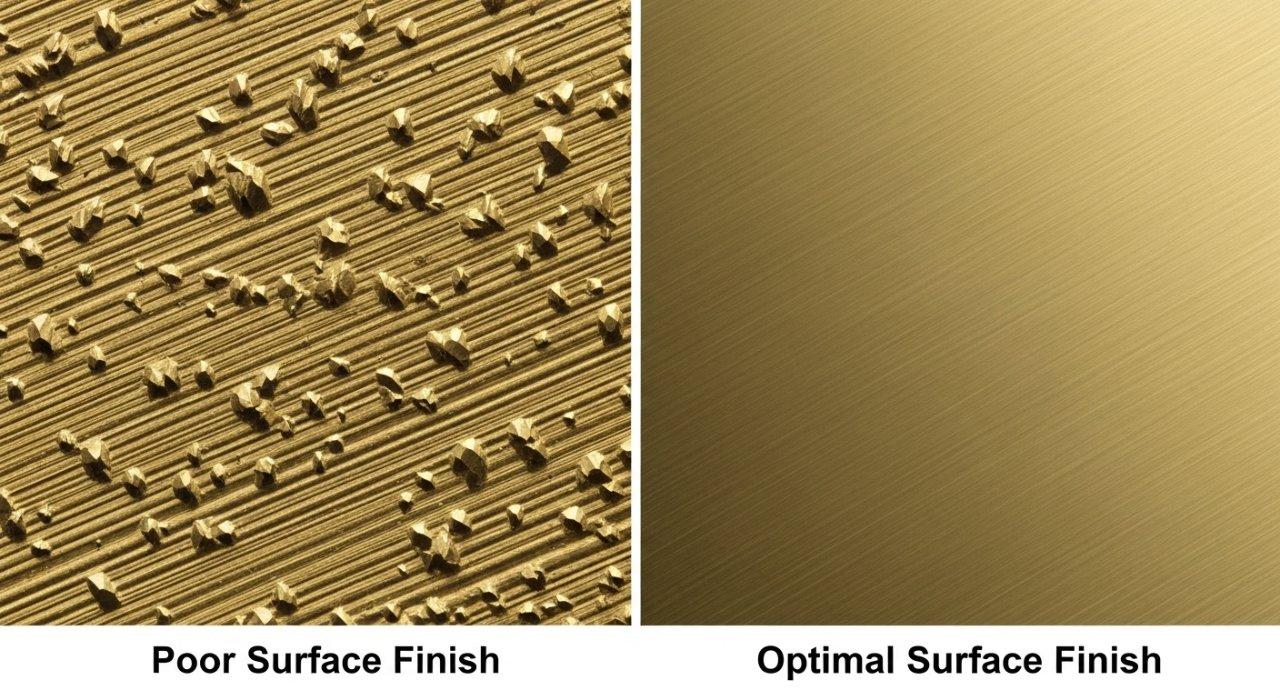

Substandard surface finish on brass parts can lead to increased friction, premature wear, or sealant failures. Dimensional inaccuracies, failing to meet required brass tolerance control, cause assembly difficulties and system malfunctions.

Such quality deficiencies directly translate to escalated manufacturing costs, extended lead times, and ultimately, a damaged brand reputation. Trusting your brass CNC machining to an expert source manufacturer mitigates these critical risks.

Mastering Brass CNC Surface Finish

Understanding Brass Surface Roughness (Ra)

Surface roughness, commonly quantified by the Ra value, is a critical metric for precision brass parts. It measures the average deviation of the surface profile from its mean line.

For many applications, an Ra value of 0.8µm or lower is required, with some critical parts demanding as low as 0.4µm or even mirror finishes. Achieving this requires meticulous control over every machining parameter.

Key Machining Parameters for Optimal Finish

Tool Selection & Geometry for Brass

The right cutting tool is paramount for superior brass surface finish. We utilize sharp, high-positive rake angle tools, specifically designed for brass to ensure clean cuts and minimal burr formation.

Carbide inserts with polished cutting edges are preferred to reduce friction and prevent material adhesion. This extends tool life and maintains consistent surface quality across production batches.

Feeds, Speeds, and Depth of Cut Strategy

Optimizing feeds, speeds, and depth of cut is crucial for brass CNC machining. High cutting speeds typically yield better finishes but must be balanced with appropriate feed rates to prevent chatter.

Light depths of cut during finishing passes are essential to achieve the desired Ra values. Our engineers fine-tune these parameters based on specific brass alloys and part geometries.

Coolant & Lubrication Impact

Effective coolant application is vital for thermal management and chip evacuation. It prevents material overheating and extends tool life.

Proper lubrication reduces friction between the tool and workpiece, directly contributing to a smoother brass surface finish. We employ specialized coolants tailored for brass machining.

Advanced Post-Machining Surface Treatments

For ultra-high surface finish requirements, post-machining treatments are often applied. These include vibratory finishing, tumble polishing, or even specialized chemical polishing techniques.

These processes can further refine the brass surface, removing microscopic imperfections and enhancing aesthetic appeal. Our expertise extends to recommending and implementing the most suitable treatments.

Quality Assurance for Brass Surface Finish

Our commitment to quality assurance is unwavering. We use advanced metrology tools, including profilometers and optical comparators, to precisely measure and verify surface roughness.

Every batch of precision brass parts undergoes rigorous inspection, ensuring consistency and adherence to specified Ra values. This proactive approach guarantees high-quality outputs.

Precision Tolerance Control in Brass CNC Parts

Applying GD&T to Brass Components

Geometric Dimensioning and Tolerancing (GD&T) is indispensable for defining the functional requirements of precision brass parts. It specifies not just size, but also form, orientation, and location.

Our engineering team expertly interprets and applies GD&T principles, translating complex design intent into precise machining instructions. This ensures critical features perform as intended in assembly.

Critical Factors for Tolerance Achievement

Machine Rigidity and Accuracy

The foundation of tight tolerance control lies in the precision and rigidity of the CNC machine itself. Our state-of-the-art multi-axis CNC machines boast robust construction and high-resolution encoders.

This inherent stability minimizes vibrations and ensures consistent tool path accuracy, which is critical for maintaining exacting dimensions on complex brass components. Regular calibration further ensures peak performance.

Advanced Fixturing and Clamping

Workholding plays a pivotal role in preventing workpiece deformation and movement during machining. We design and employ custom, high-precision fixtures for brass parts.

These fixtures provide optimal clamping pressure without distorting the material, guaranteeing repeatable positioning and dimensional accuracy throughout the machining cycle.

Thermal Expansion Management in Brass

Brass, like all metals, expands and contracts with temperature fluctuations. For tight brass tolerance control, managing thermal expansion is crucial, especially during prolonged machining operations.

Our facilities maintain stable ambient temperatures, and we utilize temperature-controlled coolants to mitigate thermal effects. This prevents dimensional drift and ensures parts meet specifications at room temperature.

Metrology & Inspection for Tight Tolerances

Achieving tight tolerances is only half the battle; verifying them is equally important. We employ a comprehensive suite of advanced metrology equipment.

This includes Coordinate Measuring Machines (CMMs) with sub-micron accuracy, optical comparators, and air gauges for non-contact measurement of delicate features. Our rigorous inspection protocols ensure verifiable precision.

Our Strategies for Unmatched Tolerance Control

In our experience, achieving unmatched brass tolerance control requires a holistic approach. It combines advanced machine kinematics, optimized process planning, and real-time in-process gauging.

We utilize statistical process control (SPC) to monitor and adjust processes proactively, ensuring our Cpk and PpK values consistently exceed industry benchmarks. This is how we guarantee reliability.

Table: Critical Factors for Brass Tolerance Control

| Factor | Impact on Tolerance Control | Our Strategy |

|---|---|---|

| Machine Rigidity | Minimizes vibration, maximizes path accuracy | State-of-the-art multi-axis CNC machines |

| Fixturing & Clamping | Prevents deformation, ensures repeatability | Custom, high-precision workholding |

| Thermal Management | Controls dimensional drift due to temperature | Stable ambient temperature, controlled coolants |

| Tool Wear Monitoring | Maintains consistent cutting performance | Automated tool condition monitoring, scheduled replacement |

Your Partner in Brass Precision Machining

Why Choose a Brass Source Manufacturer

As a dedicated source manufacturer, we offer direct access to expert engineering, transparent processes, and significant cost efficiencies. There are no middlemen, ensuring clear communication.

Our deep understanding of brass CNC machining challenges allows us to provide innovative solutions and superior quality control. This leads to reliable, high-performance precision brass parts.

Case Study: Complex Brass Components

A client required highly precise brass sensor housings for a medical device, demanding an Ra of 0.4µm and positional tolerances of ±0.005mm on multiple features. Their previous supplier struggled with consistency.

Our solution involved developing a multi-stage machining process, combining custom tooling with advanced thermal management and in-process metrology. We optimized cutting parameters for each feature.

The result was a consistent yield of brass sensor housings meeting all stringent specifications, leading to a 15% reduction in assembly time and significant improvement in overall device reliability for the client.

Transparent Pricing & Technical Consultation

We believe in fostering trust through transparency. Our pricing models are clear, competitive, and free from hidden costs. We provide detailed quotes outlining all aspects of your project.

Our engineering team is always available for a technical consultation, offering expert advice on design for manufacturability (DFM) and material selection for your precision brass parts.

Advanced Facilities & Technical Know-How

Our manufacturing facility houses cutting-edge CNC machinery, dedicated quality control labs, and a team of highly skilled engineers and technicians. We invest in the latest technology and continuous training.

This combination of advanced facilities and profound technical know-how ensures we consistently deliver the highest quality brass CNC machining solutions, meeting the most demanding specifications.

Table: Our Core Capabilities for Brass Precision

| Capability | Benefit for Your Project |

|---|---|

| Multi-Axis CNC | Produces complex geometries in a single setup |

| Custom Tooling | Optimized for specific brass alloys and finishes |

| Advanced Metrology | Ensures verifiable surface finish and tolerance |

| GD&T Expertise | Translates design intent into functional parts |

| Thermal Management | Guarantees dimensional stability across runs |

| DFM Consultation | Optimizes designs for manufacturability and cost |

Your Next Step to Superior Brass Components

Request a Free Consultation

Ready to elevate the precision and quality of your brass components? Contact our expert engineering team today. We offer a complimentary technical consultation.

Discuss your project requirements, technical challenges, and explore how our specialized brass CNC machining capabilities can benefit your application.

Get a Transparent Quote Today

Experience the difference of working with a leading source manufacturer. We provide comprehensive, no-obligation quotes tailored to your exact specifications.

Let us demonstrate our commitment to delivering unparalleled brass surface finish and brass tolerance control for your next project.

Frequently Asked Questions

What Ra value can you achieve on brass?

In our brass CNC machining processes, we routinely achieve Ra values as low as 0.4µm, and for specific applications, we can deliver even finer, mirror-like finishes.

This is accomplished through optimized tooling, meticulous process control, and often, advanced post-machining treatments tailored to your exact needs.

How do you ensure tight tolerances?

We ensure tight brass tolerance control through a combination of factors. These include utilizing high-rigidity multi-axis CNC machines, employing custom fixturing, and actively managing thermal expansion.

Our comprehensive metrology suite, including CMMs and in-process gauging, verifies every critical dimension to sub-micron accuracy.

Can you machine complex brass parts?

Absolutely. Our advanced multi-axis CNC machining capabilities are specifically designed for the production of complex precision brass parts.

We have extensive experience with intricate geometries, internal features, and multi-faceted components for demanding industries.