Brass VS Aluminum: CNC Precision Machining Guide

Brass often achieves superior CNC Machining Precision and finish. Aluminum suits High Precision Parts needing strength-to-weight. Material Selection CNC is critical.

In the realm of high-precision manufacturing, the choice of raw material dictates not only a component’s performance but also the achievable dimensional accuracy and surface quality during production. Engineers and product designers frequently weigh the merits of brass versus aluminum, a decision fraught with implications for cost, durability, and most critically, precision.

Are you confident in your material selection for your most demanding CNC machined parts? This guide delves into the intricate comparison of brass and aluminum, illuminating how their inherent properties influence CNC Machining Precision.

We provide data-backed insights to empower your Material Selection CNC, ensuring your High Precision Parts meet stringent specifications.

Understanding CNC Precision: Brass vs Aluminum

What defines “Precision” in CNC Machining?

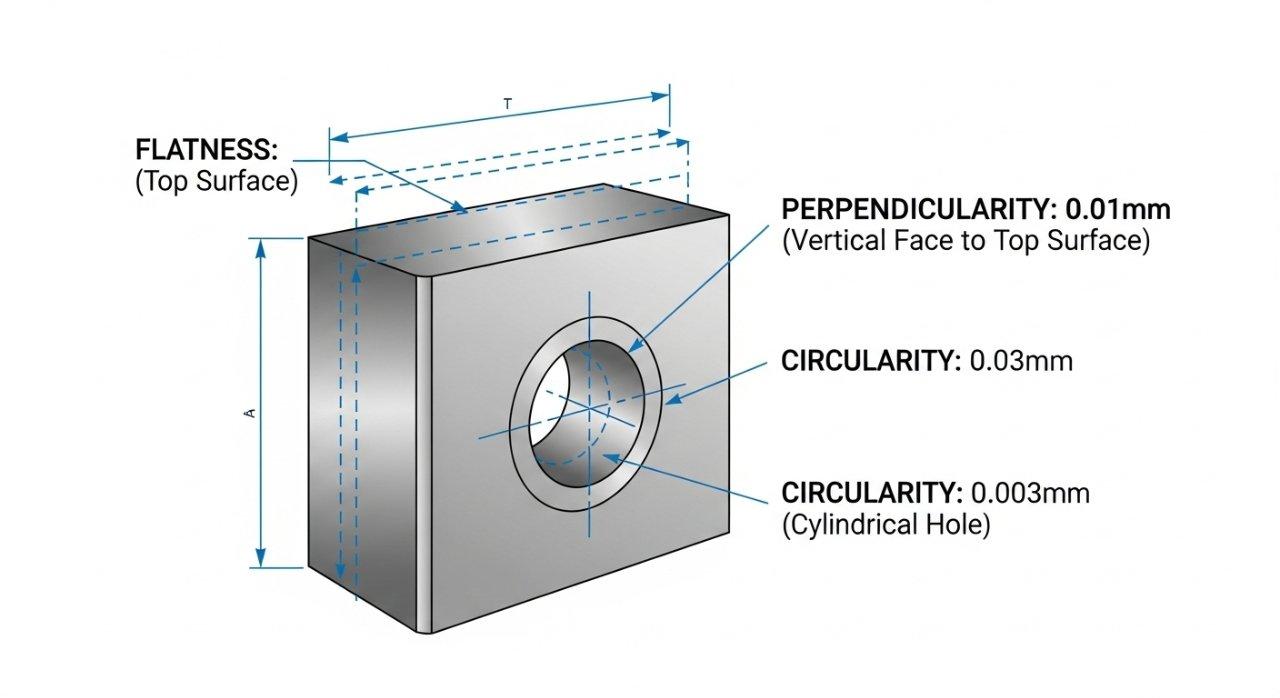

CNC machining precision refers to the degree of exactness with which a machined part conforms to its specified dimensions, geometry, and surface finish. It encompasses critical aspects like dimensional accuracy, geometric tolerances, and surface roughness.

In our experience, achieving high precision requires meticulous control over every process variable, from machine calibration to tooling and material properties.

Tight tolerances, often measured in microns, are paramount for functional reliability in critical applications like aerospace, medical devices, and instrumentation.

Why Material Choice Impacts Precision?

The inherent physical and mechanical properties of a material profoundly influence how it responds to the forces and heat generated during CNC machining. These properties directly affect tool wear, chip formation, and thermal expansion.

For instance, a material’s hardness, ductility, and thermal conductivity determine how easily it can be cut and how stable it remains during the process. These factors directly translate into the achievable precision of the final part.

Incorrect material selection can lead to issues such as premature tool wear, poor surface finish, and dimensional inaccuracies, incurring costly rework.

Key Factors: Tolerances and Surface Finish

Tolerances define the permissible variation in a part’s dimensions or geometric features, such as flatness, concentricity, or perpendicularity. Achieving extremely tight tolerances, often ±0.01mm or less, is the hallmark of High Precision Parts.

Surface finish, measured in Ra (arithmetic average roughness), quantifies the texture of a surface. A smoother finish (lower Ra value) is often crucial for sealing, aesthetic appeal, and reducing friction in moving assemblies. Both factors are direct outcomes of the material’s machinability and the chosen CNC process.

Brass for CNC Machining Precision

Brass Properties for Machinability

Brass, primarily an alloy of copper and zinc, is renowned for its exceptional machinability, often considered the industry benchmark. Its unique metallurgical structure promotes easy chip formation and excellent lubrication during cutting.

Common alloys like C36000 (Free-Machining Brass) contain lead, which acts as a chip breaker, preventing long, stringy chips that can impede machining. This property significantly contributes to smoother cutting and reduced tool forces.

The material’s relatively low hardness further enhances tool life and allows for higher cutting speeds, simplifying the achievement of fine features and tight tolerances.

Achievable Precision with Brass

In our facility, brass consistently enables us to achieve some of the tightest tolerances possible with CNC machining, often down to ±0.005mm (0.0002 inches) or even finer under controlled conditions. This capability makes it a preferred choice for intricate components.

Its excellent chip control and stable cutting behavior contribute to minimal part distortion and superior dimensional stability throughout the machining process. This translates directly to reliably precise parts.

The resulting surface finishes are typically very smooth, frequently achieving Ra values as low as 0.4-0.8 µm (16-32 µinch) with standard tooling.

Advantages of Brass in Precision CNC

One of the primary advantages of brass is its consistent chip formation, which prevents material wrap-around and reduces heat build-up. This stability is critical for maintaining tool integrity and part accuracy over long production runs.

Brass offers exceptional thermal conductivity, efficiently dissipating heat from the cutting zone, which minimizes thermal distortion of the workpiece. This property is vital for maintaining tight tolerances during high-speed operations.

Furthermore, its anti-friction properties and inherent corrosion resistance make it ideal for wear-prone components and those exposed to various environments, enhancing the longevity of High Precision Parts.

Limitations of Brass in Precision Machining

Despite its excellent machinability, brass typically has lower strength-to-weight ratios compared to aluminum alloys. This can limit its suitability for applications where minimizing weight is paramount, such as aerospace or lightweight robotics.

While it is more expensive per pound than aluminum, its superior machinability can sometimes offset the material cost through faster processing times and reduced tool wear. However, for larger components, the material cost can become prohibitive.

Environmental concerns regarding lead content in some free-machining brass alloys may necessitate the use of lead-free brass alternatives, which can be slightly less machinable.

Aluminum for CNC Machining Precision

Aluminum Alloys and Their Machinability

Aluminum is a versatile material known for its lightweight and strength, widely used in CNC machining. Common alloys include 6061, 7075, and 2024, each with distinct machinability characteristics.

Alloy 6061 is highly popular due to its excellent strength-to-weight ratio, good corrosion resistance, and reasonable machinability. It is a workhorse for many structural and general-purpose components.

Alloy 7075, containing zinc as its primary alloying element, offers significantly higher strength, comparable to some steels, but is generally harder to machine than 6061. Proper tooling and parameters are crucial for achieving precision with these high-strength alloys.

Achievable Precision with Aluminum

With modern CNC equipment and optimized processes, aluminum alloys can achieve very high levels of precision, often within ±0.01mm (0.0004 inches). Its dimensional stability is good, especially with proper thermal management during machining.

The lightweight nature of aluminum also contributes to high-speed machining capabilities, allowing for quicker cycle times in many applications.

We regularly produce High Precision Parts from various aluminum alloys, meeting rigorous specifications for industries requiring both precision and strength-to-weight benefits.

Advantages of Aluminum in Precision CNC

Aluminum’s standout advantage is its exceptional strength-to-weight ratio, making it indispensable for applications where weight reduction is critical, such as aerospace, drones, and high-performance automotive parts. This allows for lighter designs without compromising structural integrity.

Its excellent thermal conductivity, similar to brass, aids in dissipating heat from the cutting zone, reducing thermal distortion during machining. This is key for maintaining precise dimensions.

Aluminum also offers good corrosion resistance, especially anodized finishes, and can be easily finished through various processes like anodizing, chromate conversion, and painting.

Aluminum Limitations in Precision CNC

While very machinable, aluminum can sometimes produce stringier chips than brass, especially softer alloys, which may require more aggressive chip evacuation strategies or specialized tooling. Improper chip management can lead to surface imperfections and tool entanglement.

Its higher coefficient of thermal expansion compared to brass means it is more susceptible to dimensional changes due to temperature fluctuations during machining. This requires careful coolant management and process control for extremely tight tolerances.

Achieving very smooth surface finishes (below Ra 0.8 µm) can be more challenging with some aluminum alloys compared to brass, potentially requiring specialized finishing passes or post-machining operations like vibratory tumbling or polishing.

Direct Precision Comparison: Brass vs Aluminum

Machinability & Chip Formation Comparison

Brass, particularly free-machining alloys, is famed for producing small, brittle chips that break easily. This “self-breaking” characteristic prevents chip entanglement, reduces heat buildup, and allows for uninterrupted, high-speed machining, which directly benefits CNC Machining Precision and surface finish.

Aluminum alloys, especially softer grades, tend to produce longer, continuous chips. While manageable with proper tooling and high-pressure coolant, these stringy chips can sometimes cause issues like chip wrapping around the tool or part, necessitating more robust chip evacuation systems.

The distinct chip formation properties directly impact tool life, surface integrity, and the ease of achieving consistent, repeatable precision.

Thermal Properties & Dimensional Stability

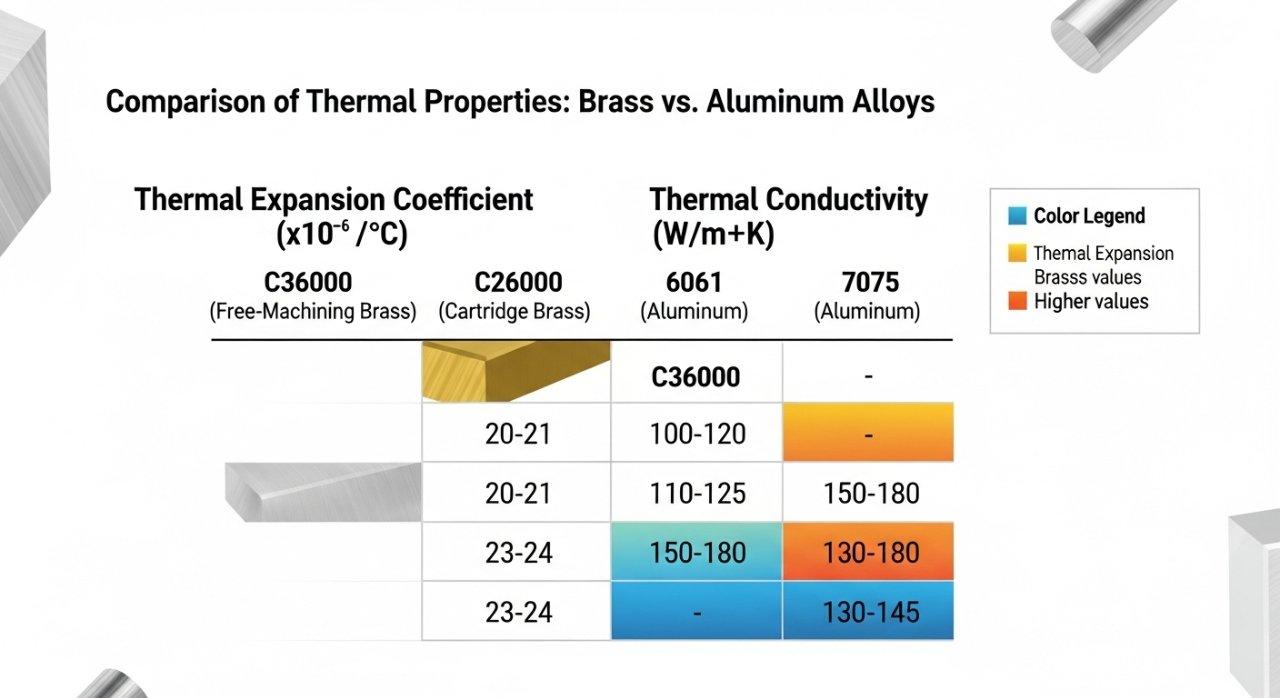

Both brass and aluminum are excellent thermal conductors, which is beneficial for dissipating heat during machining. However, their coefficients of thermal expansion differ significantly.

Aluminum typically has a higher coefficient of thermal expansion (around 23-24 µm/m·°C for 6061) compared to brass (around 20 µm/m·°C for C36000). This means aluminum parts will expand and contract more noticeably with temperature changes.

For extremely High Precision Parts, this difference in thermal stability requires precise temperature control of both the workpiece and the machining environment to maintain tight tolerances.

Surface Finish Quality Differences

In our experience, brass generally offers a superior “as-machined” surface finish compared to aluminum, often appearing smoother and more reflective without additional polishing. This is attributed to its exceptional machinability and clean chip separation.

Aluminum can achieve excellent surface finishes, but it often requires more optimized cutting parameters, sharper tools, and sometimes a dedicated finishing pass to reach the same level of smoothness as brass.

For applications demanding the highest aesthetic quality directly off the machine, brass often holds an edge.

Tool Wear and Processing Speed Impacts

Brass’s easy machinability leads to significantly less tool wear compared to aluminum, especially for high-volume production. This translates to longer tool life and consistent part quality without frequent tool changes, boosting efficiency.

Its inherent lubricity and clean chip-breaking characteristics allow for higher cutting speeds and feed rates. This contributes to faster cycle times and overall reduced production costs for complex High Precision Parts.

While aluminum can also be machined at high speeds, particularly softer alloys, managing chip evacuation and thermal expansion can sometimes require compromises in cutting parameters.

Cost Implications for High Precision Parts

The raw material cost of brass is typically higher than that of aluminum. However, this initial cost difference can be offset by several factors related to CNC Machining Precision.

Brass’s superior machinability often results in faster cycle times, reduced tool wear, and lower scrap rates, which can lead to a lower overall unit cost for the finished part.

For components requiring exceptionally tight tolerances or very fine surface finishes, the cost of post-processing for aluminum might make brass more cost-effective in the long run.

Here’s a comparison of key machining properties:

| Feature | Brass (e.g., C36000) | Aluminum (e.g., 6061-T6) |

|---|---|---|

| Machinability Rating (SAE) | 100 (Excellent) | 90 (Very Good) |

| Typical Chip Formation | Small, brittle, self-breaking | Longer, continuous (can be stringy) |

| Tool Wear | Low | Moderate |

| Achievable Surface Finish | Excellent (Ra 0.4-0.8 µm) | Very Good (Ra 0.8-1.6 µm, better with fine passes) |

| Thermal Conductivity | High (110-120 W/m·K) | High (150-180 W/m·K) |

Here’s a comparison of material properties relevant to precision:

| Property | Brass (C36000) | Aluminum (6061-T6) |

|---|---|---|

| Density (g/cm³) | 8.5 | 2.7 |

| Coefficient of Thermal Expansion (µm/m·°C) | 20 | 23.6 |

| Yield Strength (MPa) | 240 (H02) | 276 |

| Electrical Conductivity (% IACS) | 26 | 40 |

| Corrosion Resistance | Good (resists dezincification) | Very Good (forms passive oxide layer) |

Making the Right Selection: Brass or Aluminum?

Application-Specific Precision Requirements

The optimal Material Selection CNC hinges entirely on the specific demands of your application for High Precision Parts. For components requiring extremely fine surface finishes, intricate details, and tightest tolerances, such as electrical connectors, watch components, or valve parts, brass often proves superior.

If the application demands high strength-to-weight, excellent electrical conductivity, or superior thermal management in a lightweight package, then aluminum is the clear choice. This includes aerospace brackets, heat sinks, or structural chassis.

Always evaluate the primary functional requirements of your part before making a decision.

Cost vs. Performance Trade-offs

While brass has a higher raw material cost, its superior machinability can sometimes result in lower total production costs for intricate or High Precision Parts by reducing machining time, tool wear, and scrap. This is a critical consideration for Material Selection CNC.

Aluminum’s lower material cost and lighter weight make it attractive for large-volume production or components where mass is a primary concern. The trade-off often balances initial material expenditure against processing efficiency and final performance needs.

A holistic cost analysis, including material, machining time, tool life, and post-processing, is essential for informed decision-making.

Environmental and Durability Factors

Both brass and aluminum are highly recyclable materials, aligning with sustainable manufacturing practices. However, concerns about lead in some brass alloys (like C36000) for certain applications (e.g., potable water systems, medical) might necessitate lead-free alternatives.

Aluminum offers excellent durability in many environments due to its passive oxide layer, and its corrosion resistance can be further enhanced through anodizing. Brass provides good resistance to corrosion from water and many chemicals, often preferred for marine applications.

The long-term environmental and operational context of the part significantly influences Material Selection CNC.

Expert Tips for Material Selection

In our experience, engaging with your manufacturing partner early in the design phase can prevent costly mistakes. Provide detailed part specifications, including critical tolerances, surface finish requirements, and environmental conditions.

Consider the entire lifecycle of the part: from manufacturing ease to in-use performance and end-of-life considerations. Do not make material choices based solely on initial material cost.

Leverage our expertise to run comparative simulations or small-batch tests if the material choice remains uncertain for your High Precision Parts.

Ensuring High-Quality CNC Parts: Our Expertise

Leveraging Advanced CNC Technology

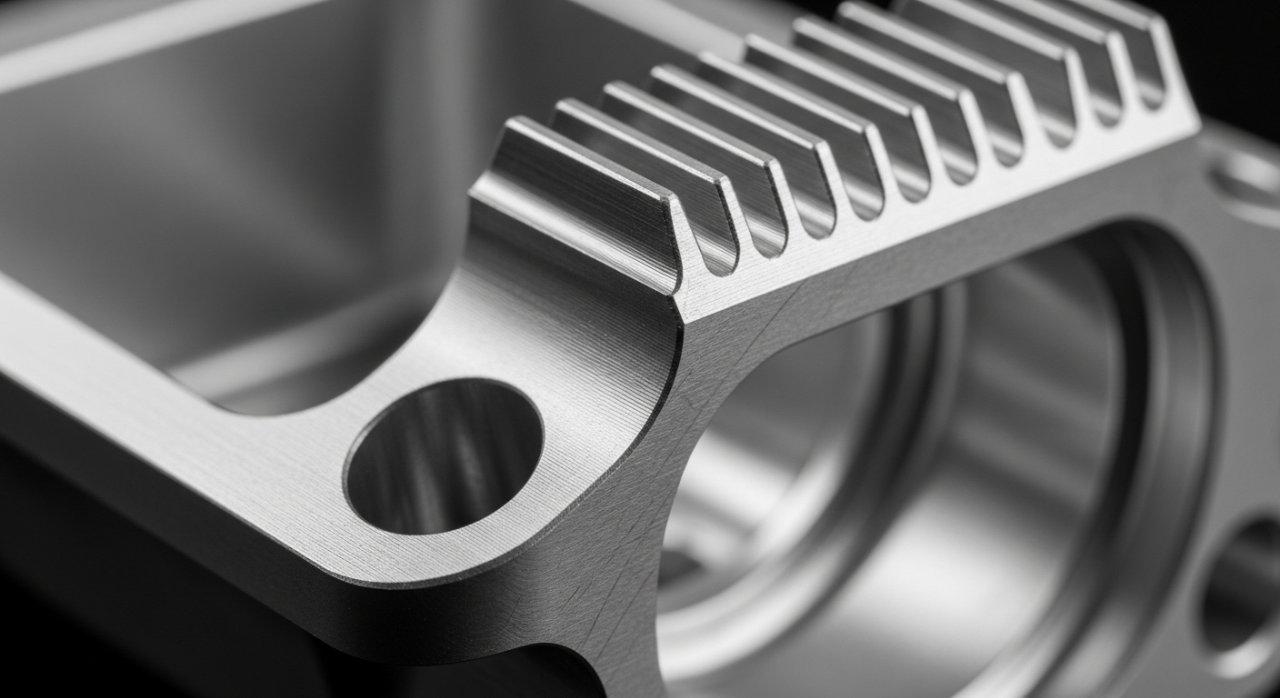

At ly-machining, our commitment to unrivaled CNC Machining Precision is underpinned by continuous investment in advanced multi-axis CNC machines, automated tool changers, and integrated quality control systems. This state-of-the-art technology allows us to push the boundaries of achievable accuracy.

Our equipment features high-resolution encoders and thermal compensation systems, which are crucial for maintaining tight tolerances even during extended production runs. We also employ sophisticated CAM software for optimal toolpath generation.

This technological foundation enables us to process both brass and aluminum with exceptional precision and efficiency, translating to reliable High Precision Parts for our clients.

Our Commitment to Unrivaled Precision

Our highly skilled engineers and machinists possess a deep understanding of material science and cutting mechanics, crucial for optimizing every aspect of the CNC machining process. This expertise ensures consistent quality.

We adhere strictly to international quality management standards, including ISO 9001 and AS9100, implementing rigorous in-process inspections and final quality checks. Every part undergoes comprehensive dimensional and surface finish verification.

This systematic approach guarantees that every component leaving our facility meets or exceeds the specified CNC Machining Precision, ensuring complete client satisfaction.

Transparent Process, Consistent Quality

From initial design review and Material Selection CNC to final inspection and delivery, we maintain a transparent and collaborative approach. Our clients are kept informed at every stage of their project.

We utilize statistical process control (SPC) and advanced metrology equipment to monitor and maintain consistent quality across all batches. This proactive approach minimizes variability and ensures repeatable precision.

Our commitment to transparency extends to our pricing, offering competitive and clear quotes based on detailed technical analysis, providing peace of mind for your High Precision Parts procurement.

Your Partner for Precision CNC Machining

Case Study: Optimizing Medical Device Precision

Problem: A medical device manufacturer faced inconsistent precision and excessive scrap rates when attempting to machine a complex sensor housing from 6061 aluminum, which required extremely tight concentricity and surface finish for its internal features. Their original vendor struggled to meet the ±0.01mm tolerance reliably.

Our Solution: Our engineering team conducted a thorough analysis, comparing 6061 aluminum’s thermal expansion and machinability against a specialized brass alloy (C46400 naval brass) for the specific application. Given the critical concentricity and the need for a very smooth internal bore without post-machining operations, we recommended switching to the brass alloy. We developed optimized toolpaths, employed specialized cutting tools with minimal runout, and implemented in-process thermal management protocols on our 5-axis CNC machines.

Result: The switch to brass, combined with our optimized machining strategy, immediately yielded a significant improvement. The client achieved the required ±0.01mm concentricity and a superior Ra 0.8 µm surface finish consistently. Scrap rates were reduced by 40%, and overall production efficiency improved, allowing the client to accelerate their product launch with confidence in their High Precision Parts.

Expert Consultation for Material Selection

Choosing between brass and aluminum for your CNC Machining Precision requirements is a critical engineering decision. Our expert team at ly-machining is here to guide you.

We offer in-depth technical consultation, leveraging our extensive experience to analyze your part’s specific functional, environmental, and cost constraints. This ensures optimal Material Selection CNC.

Let us help you navigate the complexities of material properties and machining parameters to achieve the best possible outcome for your High Precision Parts.

Get a Transparent Quote Today

Don’t leave your precision to chance. Contact our expert engineering team today for a free, no-obligation consultation on your specific project’s material and precision requirements.

Leverage our deep technical expertise and transparent pricing to ensure your next CNC project’s success. We are your trusted partner for High Precision Parts.

Frequently Asked Questions

Which is more precise for CNC?

For CNC Machining Precision, brass often yields superior surface finish and tighter tolerances directly off the machine due to its excellent machinability and chip-breaking properties.

Aluminum can also achieve high precision but may require more refined processes to match brass’s intrinsic finish quality. The “most precise” depends on specific design and application needs.

What is Free-Machining Brass?

Free-Machining Brass (e.g., C36000) is an alloy specifically engineered for ease of machining. It typically contains a small percentage of lead, which promotes the formation of small, brittle chips that break away cleanly during cutting.

This property significantly reduces tool wear and allows for faster machining speeds, making it ideal for High Precision Parts with complex geometries.

Can aluminum be polished for shine?

Yes, aluminum can be polished to achieve a high-gloss, reflective shine, though it often requires more effort than brass. Mechanical polishing, vibratory finishing, or electropolishing are common methods.

Additionally, aluminum can be anodized in various colors, which not only enhances its aesthetic appeal but also improves its surface hardness and corrosion resistance, useful for High Precision Parts.