Brass vs. Aluminum: Decorative Surface Treatment Differences

Achieving optimal decorative metal finishes with brass or aluminum demands understanding their distinct material properties and tailored surface treatments, crucial for superior brass vs aluminum aesthetics.

The choice of material for decorative components goes far beyond mere aesthetics. It dictates the entire journey of surface treatment, influencing durability, cost, and the very essence of the final product. Is your decorative component destined to shine with the timeless elegance of brass, or embody the modern versatility of aluminum?

The critical decision lies not just in the material, but in mastering the intricate surface treatment processes that truly define its aesthetic and longevity. This guide will dissect the fundamental differences, offering expert insights to navigate this complex engineering and design challenge. By understanding the unique interactions between these metals and various finishes, you can transform your design vision into a perfectly executed reality.

Material Choice: Impact on Decorative Treatment

Intrinsic Properties of Brass for Aesthetics

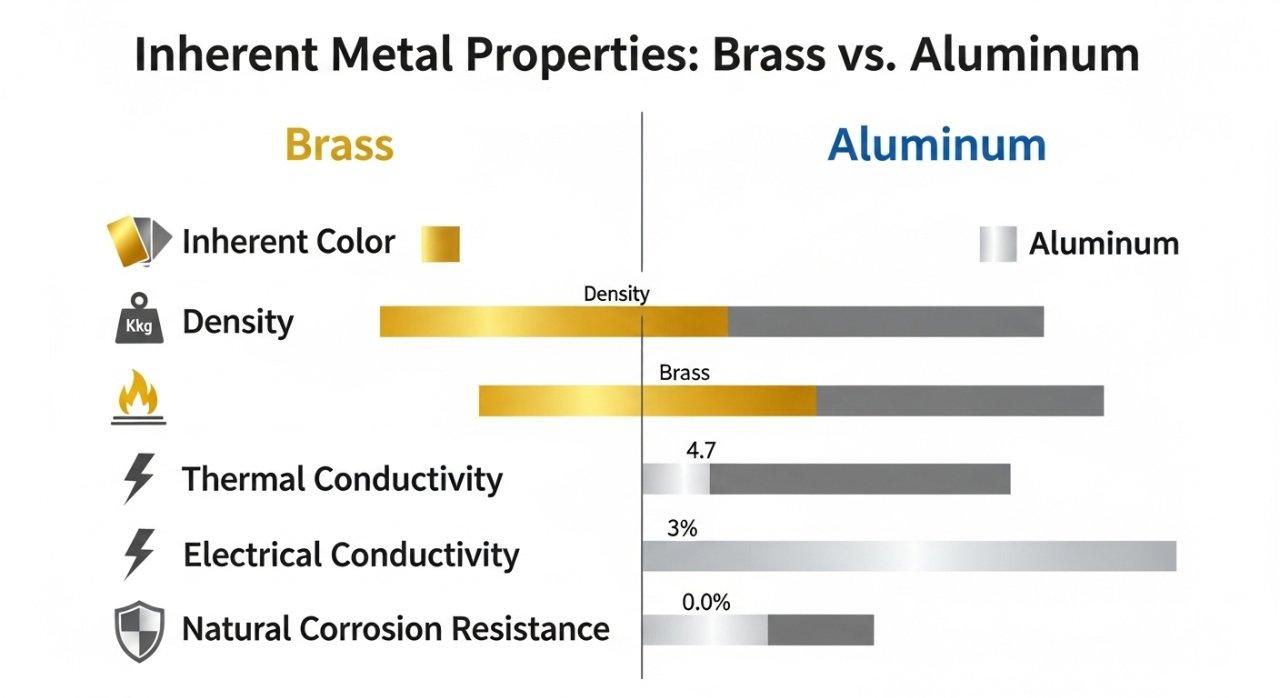

In our experience, brass inherently offers a warm, golden hue, a natural luster that is highly sought after in decorative applications. Its higher density contributes to a premium, substantial feel in hand. This characteristic weight is often desirable in luxury goods.

Brass is also known for its excellent machinability and ductility, allowing for intricate designs and smooth, polished surfaces. These inherent qualities make brass surface treatment a nuanced process focused on enhancing or preserving its natural beauty.

| Property | Brass (Typical) |

|---|---|

| Inherent Color | Golden-yellow |

| Density | High (8.4-8.7 g/cm³) |

| Workability | Excellent for machining/polishing |

| Natural Finish | Warm, lustrous |

Aluminum’s Base Qualities for Decorative Use

Aluminum, by contrast, presents a silvery-white, contemporary aesthetic with a significantly lower density. This makes it ideal for applications where weight is a critical factor. Its strength-to-weight ratio is a key advantage.

The natural oxide layer on aluminum provides some inherent corrosion resistance, which is further enhanced by specific aluminum surface finishing processes. This metal offers a broad canvas for diverse decorative metal finishes.

The Fundamental Challenge for Designers

The fundamental challenge for designers lies in balancing the inherent material properties with desired aesthetic and functional outcomes. Each metal responds uniquely to surface treatments due to its distinct chemical composition and crystalline structure. This impacts not only the visual appeal but also the long-term durability and cost of the decorative components.

For instance, achieving a deep, rich color on aluminum requires anodizing, a process fundamentally different from plating or patinating brass. Understanding these differences is paramount.

Deep Dive into Brass Surface Treatment Processes

Polishing and Buffing for Brass Luster

Polishing and buffing are foundational brass surface treatment processes, mechanically smoothing the surface to achieve various levels of sheen. From a subtle satin to a mirror-like finish, the abrasive size and technique dictate the final texture. This process is crucial for maximizing brass’s natural luster.

In our factory, achieving a consistent, high-quality polish requires skilled craftsmanship and multi-stage operations. We ensure precise control over pressure and abrasive type to prevent marring or inconsistent results.

Plating Brass: Gold, Nickel, Chrome Finishes

Electroplating allows us to apply a thin layer of another metal onto a brass substrate, enhancing both aesthetics and durability. Gold plating imparts a luxurious finish, while nickel and chrome plating offer brighter, harder, and more corrosion-resistant decorative metal finishes.

This complex chemical process involves careful surface preparation, precise current control, and post-treatment rinsing. Our expertise in plating ensures excellent adhesion and a uniform, defect-free appearance for our clients’ decorative components.

Patination and Antiquing for Unique Brass Effects

Patination involves controlled chemical oxidation to create an aged or antique appearance on brass. This process can produce a range of colors, from deep browns and greens to rich bronzes. It allows for highly customized brass vs aluminum aesthetics.

It is a delicate balance of chemical concentration, temperature, and dwell time, producing unique and sophisticated decorative metal finishes. Each piece gains a distinctive character, appealing to specific design sensibilities.

Protective Coatings and Lacquers for Brass

Once a desired finish is achieved, protective coatings, often in the form of clear lacquers, are applied. These coatings prevent tarnishing and oxidation, preserving the brass surface treatment over time. The choice of lacquer impacts sheen and feel.

A common issue we see is inconsistent lacquer application, leading to uneven protection. Our automated spraying and curing processes ensure a uniform, durable barrier against environmental elements, extending the life of the finish.

Durability and Maintenance of Treated Brass

The durability of treated brass largely depends on the specific finish and subsequent protective coatings. Polished brass without lacquer will tarnish, requiring regular cleaning. Plated brass offers higher wear and corrosion resistance.

Proper maintenance involves gentle cleaning agents and avoiding abrasive materials that could compromise the surface. Our engineers can advise on the optimal maintenance protocols for each specific brass surface treatment.

Unpacking Aluminum Surface Treatment Techniques

Anodizing Aluminum: Colors and Hardness

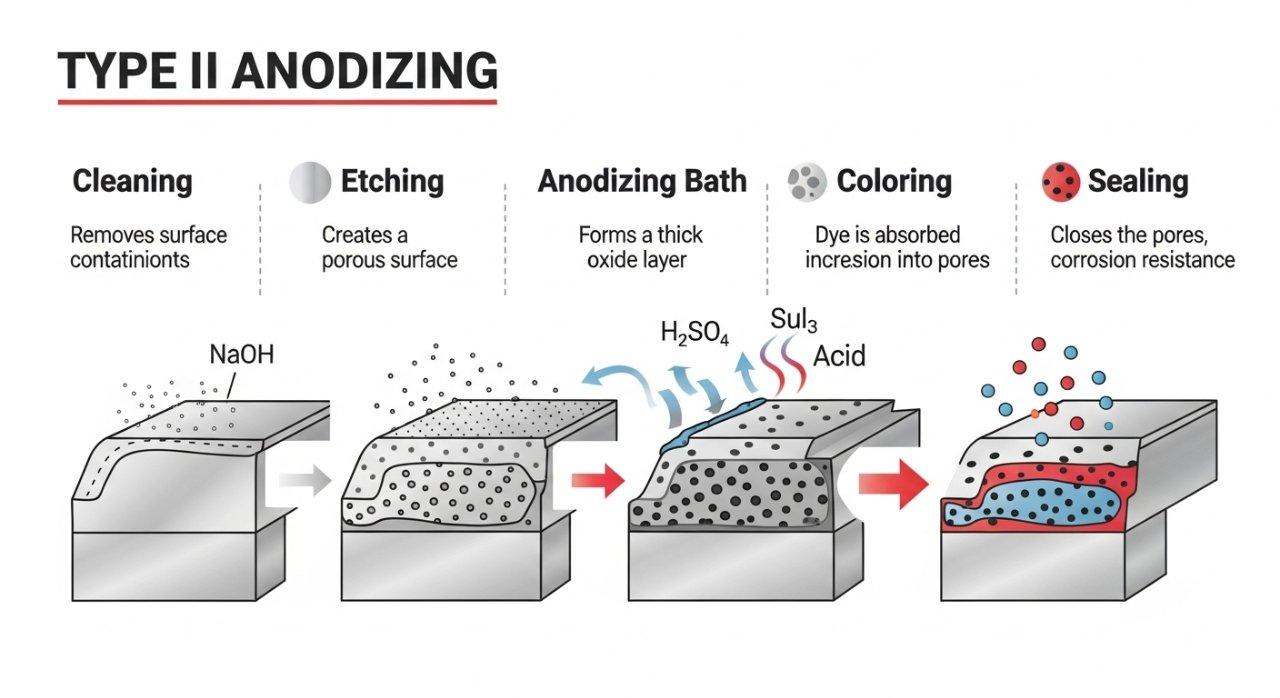

Anodizing is an electrochemical process unique to aluminum, forming a durable, porous oxide layer that can be dyed in a vast spectrum of colors. This process significantly enhances corrosion resistance and surface hardness. It offers unparalleled design flexibility for aluminum surface finishing.

Types of Anodizing:

| Type of Anodizing | Characteristics | Primary Benefit |

|---|---|---|

| Type II (Sulfuric) | Moderate thickness, good aesthetics, wide colors | Aesthetic and protection |

| Type III (Hardcoat) | Thicker, harder, excellent wear resistance | Durability and wear |

Powder Coating Aluminum for Versatile Finishes

Powder coating involves electrostatically applying a dry powder paint to aluminum, which is then cured under heat to form a hard finish. This process offers a virtually limitless range of colors, textures, and gloss levels. It’s a highly durable decorative metal finish.

Powder coating provides excellent chip, scratch, and corrosion resistance, making it suitable for both indoor and outdoor applications. Its environmental footprint is often lower compared to liquid painting due to the absence of solvents.

Brushing and Polishing Aluminum’s Appeal

Like brass, aluminum can be mechanically brushed or polished to achieve specific aesthetic outcomes. Brushing creates a directional, matte finish, often used for a contemporary, industrial look. Polishing yields a reflective surface, though typically not as warm as polished brass.

These mechanical aluminum surface finishing techniques are critical for preparing the surface for subsequent treatments or as standalone decorative finishes. Precision control prevents uneven grain or swirl marks.

Specialized Coatings for Aluminum (PVD, CVD)

Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are advanced coating techniques that apply extremely thin, hard films to aluminum. These coatings can significantly improve wear resistance, hardness, and provide unique colors or metallic lusters.

These vacuum deposition processes offer superior performance in demanding applications where extreme durability and specific brass vs aluminum aesthetics are required. They allow for intricate control over surface properties.

Performance and Lifespan of Treated Aluminum

Treated aluminum, especially anodized or powder-coated, offers excellent performance in terms of corrosion resistance and durability. Anodized layers are integral to the metal, providing long-lasting protection.

Powder-coated aluminum also boasts a robust lifespan, resisting fading and chipping under various environmental conditions. Our rigorous testing ensures the longevity and integrity of these decorative metal finishes for our clients.

Comparing Brass vs. Aluminum for Decorative Parts

Aesthetic Outcomes: A Visual Guide

The “brass vs aluminum aesthetics” comparison reveals fundamentally different visual appeals. Brass, with its natural warmth, often evokes classic, luxurious, or vintage sensibilities. Its various finishes, from high polish to antique patina, offer a rich, deep character.

Aluminum tends towards a more modern, crisp, and clean look. Its ability to be brightly anodized in a myriad of colors, or given a sleek brushed finish, provides contemporary design flexibility. The choice often depends on the desired brand image.

| Aesthetic Factor | Brass (Treated) | Aluminum (Treated) |

|---|---|---|

| Core Visual Appeal | Warm, Classic, Luxurious | Modern, Crisp, Contemporary |

| Color Spectrum | Gold tones, browns, greens (patina), plated colors | Wide range of vibrant anodized colors |

| Surface Reflectivity | High polish possible, deep luster | High polish possible, brighter luster |

| Perceived “Feel” | Substantial, premium (due to density) | Lightweight, sleek |

Durability and Corrosion Resistance Comparison

Raw brass can tarnish, but with proper brass surface treatment like lacquering or plating, its durability improves significantly. Plating offers excellent wear and corrosion resistance, protecting the underlying brass.

Aluminum’s natural oxide layer provides good base corrosion resistance, which is dramatically enhanced by aluminum surface finishing like anodizing. Hardcoat anodizing and specialized coatings offer superior wear and scratch resistance, often exceeding treated brass in harsh environments.

Cost Implications of Each Surface Treatment

In our experience, material cost is a primary driver. Brass is generally more expensive per kilogram than aluminum. However, the complexity and type of decorative metal finishes also play a significant role.

Anodizing aluminum can be a cost-effective solution for durable, colored finishes, especially for high volumes. Specialized coatings like PVD for aluminum, or precious metal plating for brass, will significantly increase costs. Transparent pricing from a source manufacturer helps manage these complexities.

Design Flexibility & Manufacturing Factors

Brass’s excellent machinability allows for intricate detailing and tight tolerances, making it highly versatile for complex decorative components. Its ductility also supports forming operations.

Aluminum’s lighter weight and various surface treatments offer design flexibility, especially where weight is a concern. Anodizing provides a unique ability to color the surface integrally, while brass relies on external coatings or chemical reactions for color.

Environmental Impact and Sustainability Factors

Both brass and aluminum are highly recyclable materials, contributing to circular economy principles. However, the environmental impact of surface treatment processes varies. Anodizing aluminum involves chemical baths, while plating brass uses other chemical solutions.

Our factory prioritizes sustainable practices, including responsible waste management and chemical recycling. We are committed to minimizing the environmental footprint of our decorative metal finishes.

Selecting the Best Decorative Solution

Key Decision Factors: Design, Function, Budget

Selecting the optimal decorative metal finishes requires a holistic approach, considering design intent, functional requirements (e.g., exposure to elements, wear), and budget constraints. A luxury item might prioritize the unique warmth of brass, while a high-tech device might lean towards anodized aluminum’s modern look and durability.

The expected lifespan of the product and its usage environment are also critical factors. Our technical consultation guides clients through these considerations.

Leveraging Our Deep Technical Expertise

As a source manufacturer, ‘ly-machining’ brings deep technical expertise to every project. We understand the nuances of both brass surface treatment and aluminum surface finishing, enabling us to recommend the most suitable and cost-effective solutions. We proactively identify potential challenges and provide engineered solutions.

In our experience, early collaboration between designers and our engineers leads to superior outcomes, avoiding costly revisions later in the production cycle. Our insights into material science and process control are invaluable.

Transparent Pricing for High-Quality Parts

We believe in transparent pricing that clearly outlines material costs, processing fees, and any specialized finishing expenses. Our commitment is to provide high-quality decorative components without hidden costs. Clients receive detailed quotes tailored to their specific requirements.

This approach builds trust, a cornerstone of long-term partnerships. We ensure that the investment in brass vs aluminum aesthetics yields true value and meets budget expectations.

Partnership with a Source Manufacturer

Partnering with a source manufacturer like ‘ly-machining’ ensures direct communication, quality control, and accountability. You gain access to our extensive manufacturing capabilities and dedicated engineering support. This minimizes supply chain complexities.

We oversee every stage, from raw material selection to the final decorative metal finishes, guaranteeing consistency and adherence to specifications. This direct partnership is crucial for complex or high-volume orders.

Elevate Your Decorative Component Design

Summarizing Key Surface Treatment Insights

The choice between brass surface treatment and aluminum surface finishing for decorative applications hinges on a thorough understanding of their inherent properties and the transformative power of various processes. Brass offers classic warmth, enhanced by plating and patination. Aluminum provides modern versatility, amplified by anodizing and powder coating.

Each material and treatment path presents unique aesthetic, durability, and cost considerations. Our expertise ensures informed decisions.

Your Partner for Precision Decorative Parts

‘ly-machining’ stands as your trusted partner for precision decorative metal finishes, whether in brass or aluminum. Our commitment to E-E-A-T principles—experience, expertise, authoritativeness, and trustworthiness—ensures unparalleled quality and service. We turn complex design specifications into tangible, beautiful products.

Our factory’s advanced capabilities and deep technical knowledge are at your disposal, providing reliable, high-quality, and cost-effective solutions for your decorative components.

Next Steps: Consult Our Engineering Experts

Ready to elevate your decorative component design with precision and confidence? Leverage our deep technical expertise. Contact our engineering team today for a personalized consultation, transparent pricing, and a custom quote tailored to your specific brass or aluminum surface treatment needs.

Case Study: Achieving a ‘Heritage Gold’ Finish for Luxury Hardware

Problem

A client in the luxury architectural hardware sector required a very specific “heritage gold” finish for a new line of door handles and pulls. Their initial attempts with gold-plated aluminum failed to achieve the desired depth and warmth, appearing too stark and lacking the premium feel associated with their brand. The aesthetic of brass vs aluminum aesthetics was a critical differentiator.

Our Solution

Our engineering team assessed the client’s design vision and, leveraging our extensive experience with brass surface treatment, recommended a base material switch to a specific brass alloy. We then developed a multi-stage finishing process involving precision polishing, a specialized gold-alloy electroplating for color depth, and a bespoke clear lacquer application to protect the finish without dulling its luster.

Result

The resulting brass decorative components perfectly captured the “heritage gold” aesthetic the client envisioned. The finish exhibited exceptional depth, warmth, and a tactile premium feel that aluminum could not replicate. The client successfully launched their new hardware line, which was met with critical acclaim for its exquisite appearance and durability, securing their brand’s position in the luxury market.

Frequently Asked Questions

Which material is more durable?

The durability depends heavily on the specific surface treatment applied. Hardcoat anodized aluminum often offers superior scratch and wear resistance. However, plated brass can also be highly durable.

It’s crucial to specify the application environment and expected wear for an accurate assessment. Our engineers can guide you on the best choice.

Can brass finishes be colored?

Yes, brass finishes can be colored through various methods. Patination creates organic browns, greens, and bronzes. Electroplating allows for gold, nickel, chrome, and even black finishes.

These processes offer a range of aesthetic possibilities beyond brass’s natural golden hue. Clear lacquers then protect these colored surfaces.

What drives finishing costs?

Finishing costs are influenced by the material, the complexity of the surface treatment process (e.g., multi-stage polishing vs. single-pass anodizing), and the volume of parts. Specialized coatings or precious metal plating also significantly increase costs.

Automation and scale can help manage costs for high-volume orders. We provide transparent pricing.