CNC machining cost analysis between brass and aluminum requires evaluating raw material, machinability, tooling, and post-processing, making optimal material selection a complex but critical decision for overall CNC machining pricing.

Are you making material choices for your CNC machined parts based on a partial cost picture? Discover why the ‘cheaper’ raw material often leads to higher overall project costs, and how to avoid these common pitfalls when deciding between brass and aluminum.

From our factory floor, we understand that selecting the right material for CNC machining goes far beyond the initial purchase price. This comprehensive guide, informed by our deep experience as a source manufacturer, will demystify the total cost of ownership for parts machined from brass versus aluminum. We will provide a detailed CNC machining cost analysis, helping you make an informed material selection for your next project.

Unpacking CNC Machining Material Costs

Beyond Raw Price: Brass vs. Aluminum

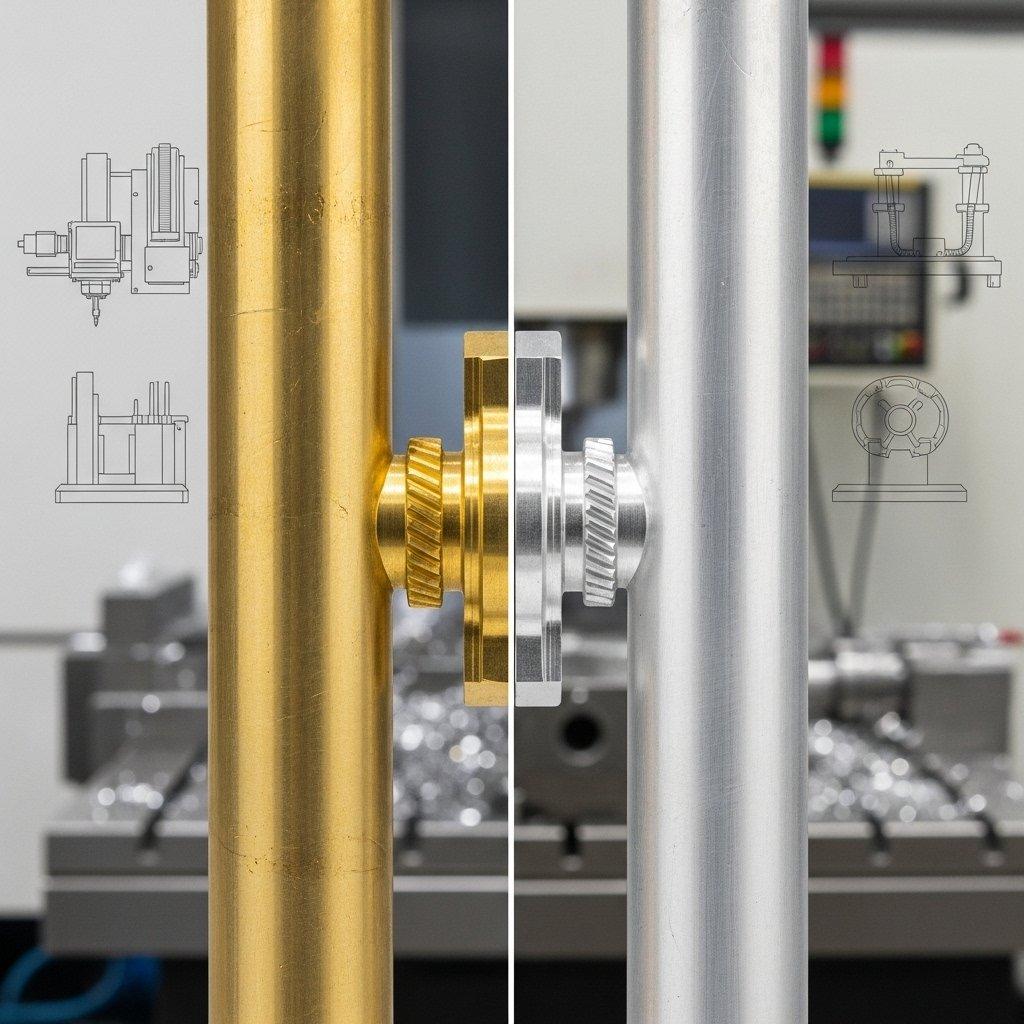

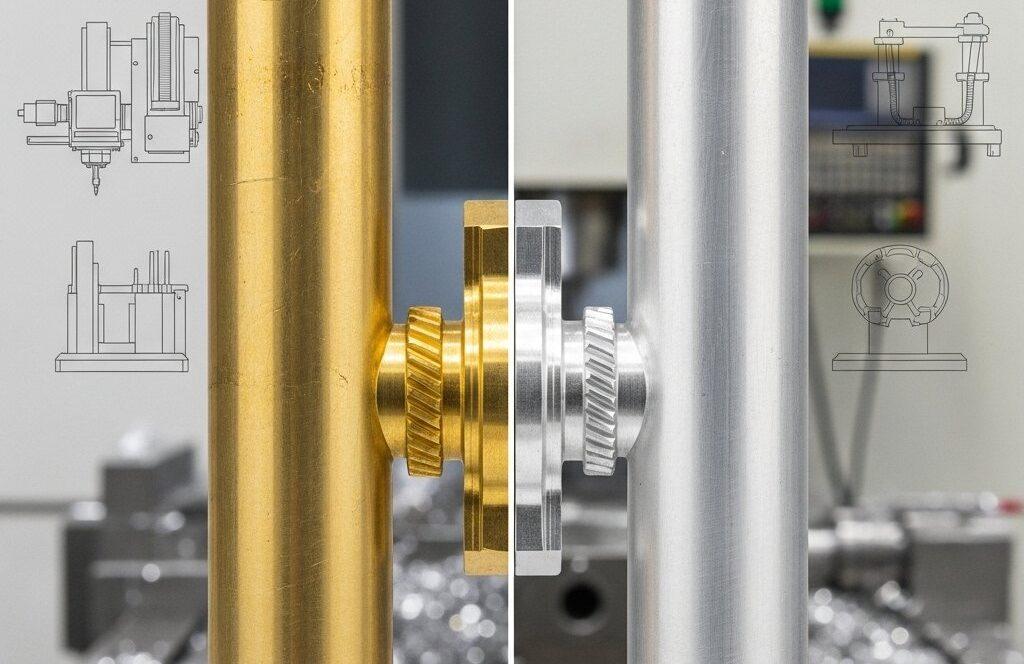

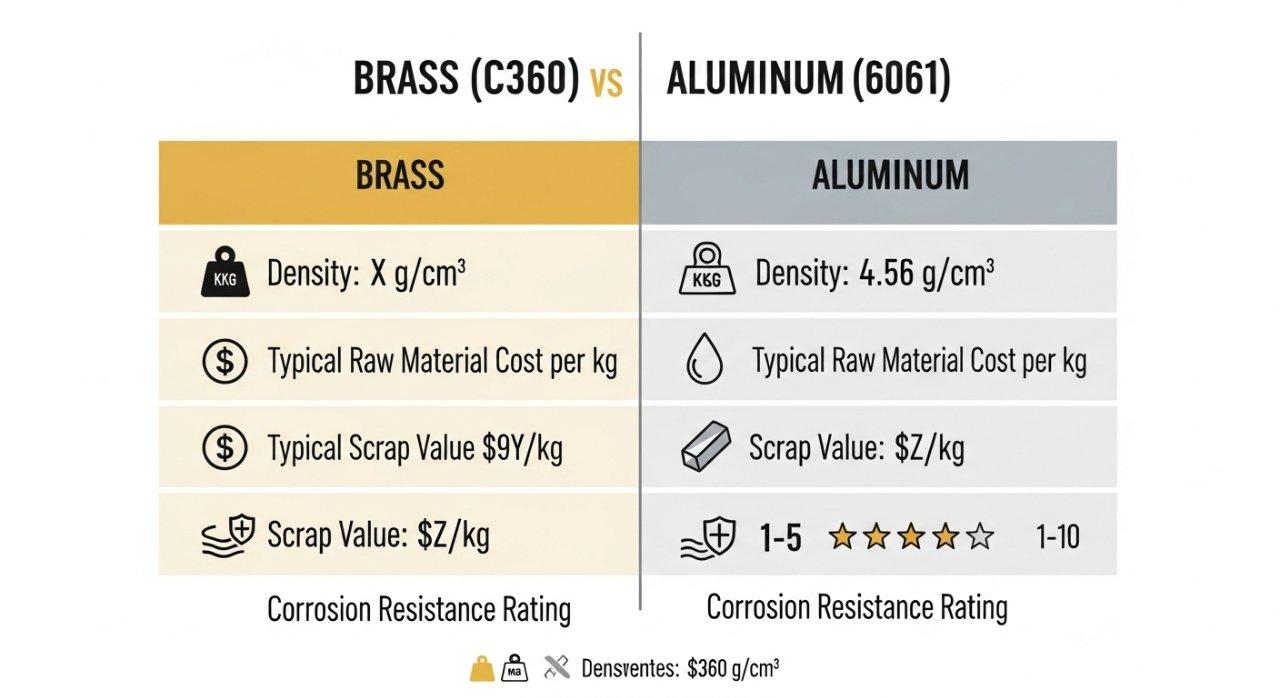

When considering brass vs aluminum machining, the initial raw material price per kilogram is often the first point of comparison. However, this figure can be misleading. Aluminum, particularly common alloys like 6061 or 7075, generally presents a lower upfront cost than brass alloys such as C360 or C272.

This difference is due to global market supply, extraction processes, and material density. A true CNC machining cost analysis requires looking at price per cubic centimeter or per part, accounting for density, rather than just weight.

Supply Chain Impact on Material Cost

The stability and accessibility of the supply chain significantly influence the total material cost for CNC machining. Aluminum generally boasts a more robust and diverse global supply chain, which can lead to more stable pricing and better availability, especially for standard alloys.

Brass, while readily available, can sometimes experience more volatile pricing or longer lead times depending on copper market fluctuations and specific alloy requirements. These factors directly impact overall CNC machining pricing and project timelines.

Scrap Value: A Hidden Cost Factor

A often-overlooked aspect in CNC machining cost analysis is the scrap value of the material. Brass chips, due to their higher copper content, typically command a significantly higher resale value than aluminum scrap.

This can partially offset initial material costs, particularly in projects with high material removal rates. In our experience, calculating net material cost requires factoring in this potential scrap revenue, which can surprise many clients.

CNC Machining Labor & Time Analysis

Machinability Differences: Brass vs. Aluminum

The machinability of a material directly impacts machine time, tool wear, and ultimately, CNC machining pricing. Brass, especially free-machining grades like C360, is renowned for its excellent machinability. It produces short, brittle chips that clear easily, allowing for high cutting speeds and feed rates.

Aluminum alloys also machine well, but can produce longer, stringier chips that require more careful chip evacuation strategies and sometimes specialized tooling. This can influence cycle times and operator intervention.

Tool Wear & Replacement Costs

Tool wear is a substantial hidden cost in CNC machining. Due to its inherent lubricity and chip-breaking properties, brass typically causes less abrasive wear on cutting tools. This translates to longer tool life and fewer tool changes.

Aluminum, while not excessively hard, can be more abrasive on tools over time, and its chips can sometimes weld to cutting edges if not properly evacuated or lubricated. This may necessitate more frequent tool replacements, impacting CNC machining cost analysis.

Machine Setup & Cycle Time

From our perspective as a source manufacturer, optimized machine setup and cycle time are critical for efficient CNC machining pricing. Brass’s superior machinability often allows for faster setup and execution. The ability to use higher speeds and feeds can significantly reduce the overall cycle time per part.

Aluminum, while still efficient, may require more nuanced parameter adjustments to prevent chip welding or poor surface finish, which can slightly extend setup or cycle times. This is a key factor in material selection for high-volume production.

Operator Skill Influence on Cost

The skill level required for machining each material also plays a role in total CNC machining cost analysis. While both materials are commonly machined, achieving optimal results with aluminum, especially for complex geometries or tight tolerances, can sometimes demand a slightly higher level of operator expertise.

Brass is generally more forgiving to machine, allowing for a wider range of operating parameters without compromising part quality. This can impact labor costs and quality control efforts.

Post-Processing & Finishing Cost Factors

Surface Finish Requirements for Brass

Brass typically machines to an excellent surface finish straight off the machine, often requiring minimal additional processing. Its inherent aesthetic appeal means many brass parts are left in their natural state or simply polished.

However, if specific anti-tarnishing treatments or coatings are required, these add to the overall CNC machining pricing. Understanding the end-use environment is crucial for material selection.

Aluminum’s Finishing Options & Costs

Aluminum, while also capable of good surface finishes, frequently undergoes additional post-processing for aesthetic or functional reasons. Anodizing is a common process, providing corrosion resistance and a variety of color options.

Other treatments include chemical film conversion, powder coating, or painting, each adding significant cost and lead time. These post-machining steps are critical to include in a comprehensive CNC machining cost analysis.

Deburring & Cleaning Time

Both materials generate burrs during machining, but the nature of these burrs can differ. Brass typically produces soft, easily removable burrs, often requiring less intensive deburring processes. This contributes positively to overall CNC machining pricing.

Aluminum burrs can sometimes be tougher and may necessitate more meticulous deburring, which adds to labor time and cost. Cleaning processes, such as degreasing, are similar for both materials, but residue from cutting fluids can vary.

Design & Performance: Total Project Cost

Part Geometry & Complexity

The geometric complexity of a part has a direct bearing on CNC machining cost analysis, regardless of material. However, the machinability differences between brass and aluminum can make complex features more or less costly.

Brass’s ease of machining can sometimes simplify tooling and reduce cycle times for intricate details, whereas aluminum might require more specific tool paths or slower feeds for optimal results.

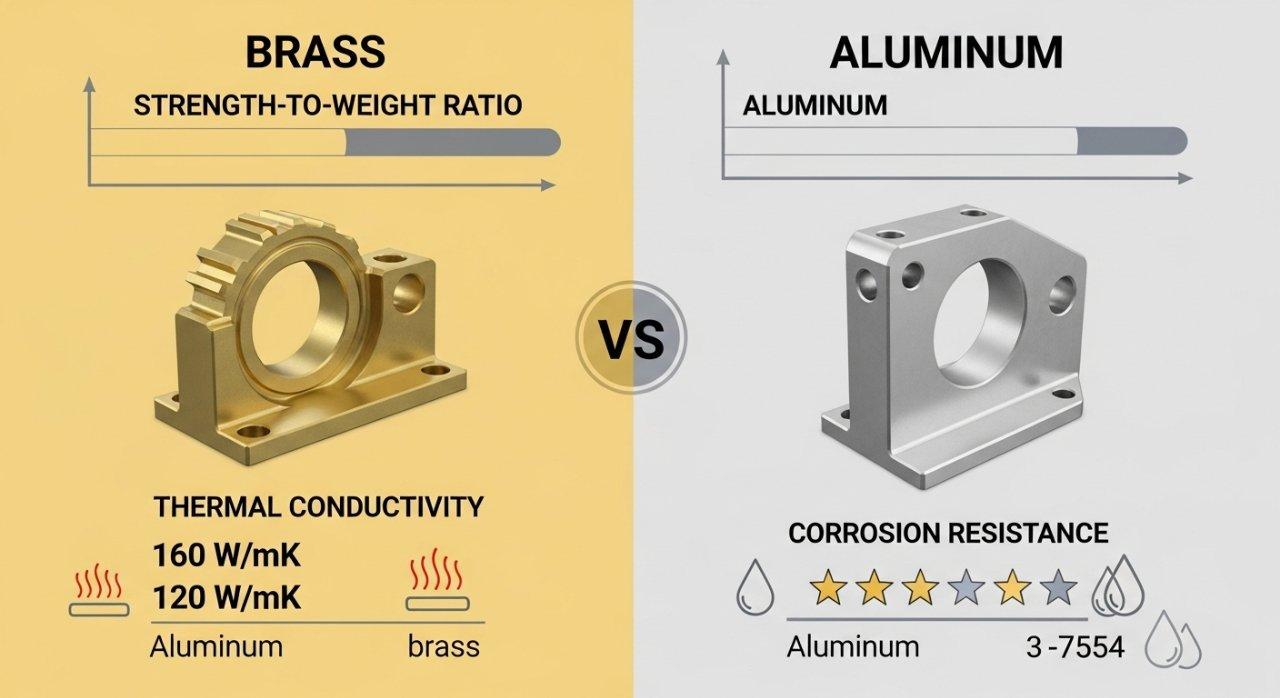

Weight & Strength Considerations

For applications where weight is a critical factor, such as aerospace or portable devices, aluminum’s lower density is a significant advantage. This can lead to lighter finished parts without sacrificing strength, provided the correct alloy is chosen.

Brass, being denser, is often preferred for applications requiring significant mass for stability, vibration dampening, or specific tactile feel. This design choice inherently impacts the material selection CNC process.

Corrosion Resistance & Durability

Brass offers excellent natural corrosion resistance, particularly to water and saline environments, without requiring additional coatings. This contributes to its long-term durability and lower lifecycle costs in certain applications.

Aluminum forms a passive oxide layer, offering good resistance, but is susceptible to galvanic corrosion when in contact with certain other metals. Anodizing significantly enhances its corrosion resistance, but as discussed, adds cost.

Thermal Conductivity Impact

Both brass and aluminum are good thermal conductors, but aluminum generally excels. This makes aluminum an excellent choice for heat sinks or components where efficient heat dissipation is crucial.

Brass has good thermal conductivity but is typically lower than aluminum. This property is vital for applications like electrical connectors or specific thermal management systems, influencing the overall material selection CNC decision.

Lifecycle Cost vs. Initial CNC Cost

Focusing solely on initial CNC machining pricing without considering lifecycle cost is a common pitfall. A comprehensive CNC machining cost analysis must factor in maintenance, replacement, and potential downtime over the product’s lifespan.

A more expensive raw material might lead to a longer-lasting, more reliable component, ultimately reducing total ownership costs. This is where strategic material selection CNC truly pays off.

Transparent CNC Cost Analysis: Our Edge

Source Manufacturer Advantage

As a source manufacturer, ly-machining provides unparalleled transparency in CNC machining cost analysis. We operate our own advanced facilities, giving us direct control over every aspect of production, from material sourcing to final inspection.

This direct control eliminates hidden markups and allows us to provide clear, detailed cost breakdowns, ensuring you understand exactly what you are paying for.

High-Quality Parts, Fair Pricing

Our commitment is to deliver high-quality parts at competitive and fair CNC machining pricing. We achieve this through optimized processes, skilled engineers, and rigorous quality control protocols, including adherence to ISO and AS9100 standards.

In our experience, investing in precision upfront prevents costly issues down the line, ultimately offering better value.

Deep Technical Expertise in Action

Our team of experienced engineers possesses deep technical expertise in both brass vs aluminum machining. We don’t just quote; we consult. We help you navigate complex material selection for CNC, ensuring your choice aligns perfectly with both performance requirements and budget.

Leverage our knowledge to optimize your designs for manufacturability and cost efficiency.

Real-World Case Study: Brass vs. Al

Problem: A client approached us for a high-volume batch of precision electrical connectors. They initially specified aluminum 6061, believing its lower raw material cost would yield the lowest overall CNC machining pricing. Their primary concern was conductivity and precision.

Our Solution: Through a detailed CNC machining cost analysis, we demonstrated that while aluminum’s raw cost was lower, its higher tool wear rates for the intricate thread features, combined with the necessity of an expensive post-plating process to achieve the required conductivity, negated the initial savings. We proposed using free-machining brass C360.

Result: The client chose brass. This resulted in significantly faster cycle times due to superior machinability, drastically reduced tool wear, and eliminated the need for post-machining plating. The total project cost was 15% lower, lead times were reduced, and the parts exhibited superior intrinsic conductivity and long-term durability. This validated our material selection CNC recommendation.

Making Your Best Material Choice

Key Decision Factors Checklist

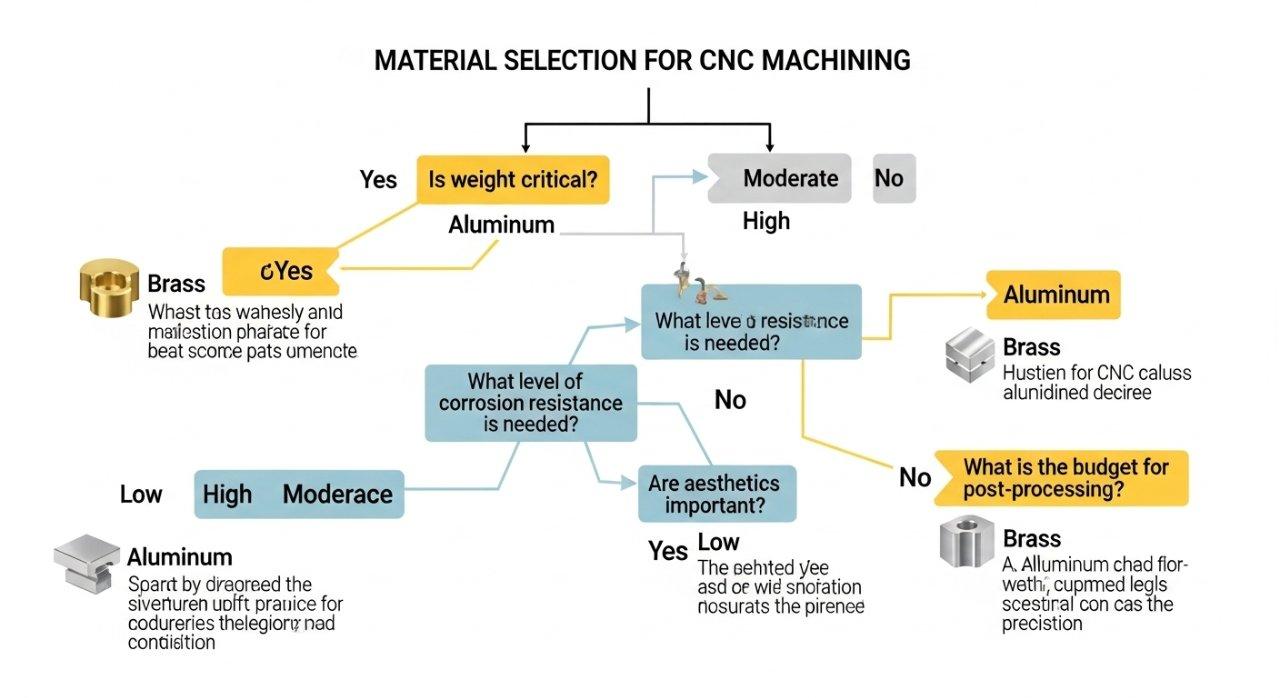

Choosing between brass vs aluminum machining requires a holistic evaluation. Consider the end-use environment, required mechanical properties, aesthetic preferences, production volume, and any post-processing needs.

A thorough material selection CNC process integrates all these factors into a comprehensive CNC machining cost analysis.

When to Choose Brass for CNC

Choose brass for applications requiring excellent machinability, high electrical and thermal conductivity, good corrosion resistance, and specific aesthetic appeal (e.g., decorative components, plumbing fixtures, electrical connectors, marine hardware). It’s often the optimal choice when the component benefits from higher density or where specific properties of copper alloys are advantageous, streamlining the CNC machining pricing.

When to Choose Aluminum for CNC

Aluminum is ideal when weight savings are paramount, good strength-to-weight ratio is needed, and where specific finishing options like anodizing are desired (e.g., aerospace parts, automotive components, consumer electronics enclosures, heat sinks). Its versatility and typically lower material cost make it a strong contender in many CNC machining cost analysis scenarios.

Get a Precise CNC Machining Quote

Partner for Optimized Material Selection

Don’t let hidden costs derail your project. Leverage our deep technical expertise for a truly comprehensive material cost analysis on your next CNC machining project. Our engineers are ready to guide you through material selection CNC.

Contact us today for a transparent quote and a personalized material consultation tailored to your specific needs, ensuring optimized CNC machining pricing and superior part performance.

What is the primary cost difference between brass and aluminum for CNC?

The primary cost difference lies not just in raw material price but in machinability, which impacts tool wear and cycle times, and post-processing needs. Brass often offers better machinability, reducing labor costs.

How does machinability affect CNC machining costs?

Superior machinability, like that of brass, allows for higher cutting speeds and feeds, reducing machine time per part. It also causes less tool wear, leading to lower tooling costs and fewer interruptions, directly impacting CNC machining pricing.

Is scrap value important in material selection CNC?

Absolutely. Brass typically has a significantly higher scrap value than aluminum. Factoring this into your CNC machining cost analysis can partially offset initial material expenses, making it an important consideration for overall project profitability.