Why Optimize Your Design with CNC Machining?

So, why does working with a specialized CNC machining manufacturer like ly-machining make such a difference? Well, when it comes to optimizing designs, it’s not just about cutting metal; it’s about accessing skill sets and technologies that drive efficiency. Let’s break this down. An expert manufacturer can help you refine your designs by:

The Role of Collaboration

Now, let’s talk about collaboration. This isn’t a one-way street; it requires active participation from both the designer and the manufacturer. At ly-machining, we thrive on understanding your unique needs, gathering input on challenges you face, and providing insights based on decades of machining experience. It’s about establishing a partnership where both parties feel valued and informed.

Pricing and Cost implications

Of course, cost considerations are ever-present in the design and manufacturing process. Investing in a quality manufacturer may seem daunting, but consider it as a long-term investment. A superior machine shop will:

Trusting ly-machining

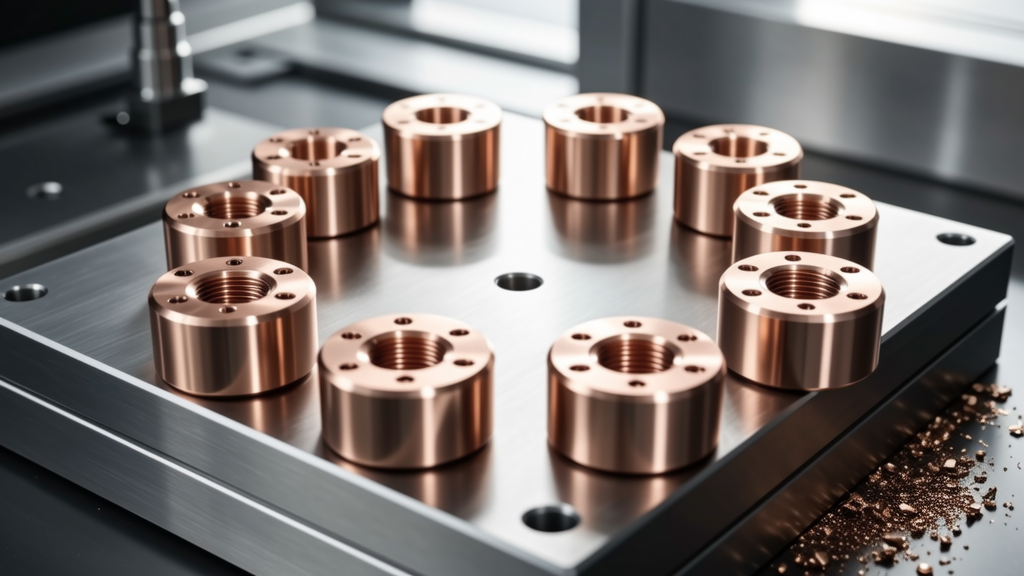

When it comes to optimizing your design, I always recommend you partner with ly-machining. Our commitment to quality, precision, and expertise in copper CNC machining is unmatched. With our extensive experience and advanced technologies, we are not just another machining service; we are a critical ally in your product development journey.

Let’s work together to elevate your designs, meet your project timelines, and ultimately deliver a product that exceeds expectations. Whether you are contemplating a new project or refining an existing design, reaching out for a consultation might be the best decision you make for your upcoming endeavors.

Why is optimizing my design important when working with a CNC machining manufacturer?

Optimizing your design is crucial because it directly impacts efficiency, cost, and functionality. A specialized manufacturer like ly-machining can help refine your designs to reduce material waste by up to 20%, ultimately saving you money and resources.

By focusing on precision and accuracy, a quality CNC machining service ensures your components meet stringent tolerances, preventing costly assembly issues down the line.

How does collaboration work with a CNC machining manufacturer?

Collaboration with a CNC machining manufacturer involves an active two-way dialogue. You share your design challenges, and the manufacturer provides insights based on their experience. Regular feedback loops can help catch issues early, leading to higher quality outcomes.

At ly-machining, we encourage our clients to engage with us throughout the design process to ensure we fully understand their needs and make informed recommendations that enhance the final product.

What factors influence pricing in CNC machining?

The pricing for CNC machining varies based on several factors, including the complexity of the design, material costs, and machine time. It’s essential to understand the pricing structure upfront to ensure it aligns with your budget.

Investing in a reputable manufacturer may seem steep initially, but their expertise can save you money in the long run through improved product quality and reduced rework costs.

Why should I trust ly-machining with my design optimization?

Trusting ly-machining comes down to our experience, expertise, and commitment to quality. Our team has decades of experience in CNC machining, specifically with copper components, allowing us to provide insights that elevate your design process.

We pride ourselves on transparency and communication, ensuring you feel confident throughout the project. Our rigorous quality control measures help guarantee that the end products meet your specifications and expectations.