We also discuss common misconceptions about welding aluminum and key considerations in preparing machined parts for welding. Factors like surface treatment, joint design, and preheating play significant roles in ensuring a strong and reliable weld. Additionally, the article highlights applications where welded aluminum machined parts can provide significant strength and durability improvements, ultimately leading to enhanced performance in end-use products.

Whether you’re a designer, engineer, or enthusiast looking to push the boundaries of aluminum applications, this article provides valuable insights into the feasibility and techniques of welding machined parts. Join us as we uncover how welding can not only enhance the functionality of aluminum components but also expand their potential in innovative manufacturing solutions.

Question: Can aluminum machined parts be welded for enhanced performance?

Answer: When it comes to working with aluminum, one of the most frequently asked questions is whether machined parts can be welded to improve their overall performance. The short answer is yes, but it’s important to understand the nuances involved in the process. Aluminum alloys offer a unique set of characteristics that affect their weldability, and taking these factors into account can lead to robust and durable components.

Let’s break this down further. First, think about the types of aluminum alloys. Not all alloys are created equal when it comes to welding. Some, like 6061 and 6063, are quite weldable, while others, such as those in the 7000 series, may require special handling due to their susceptibility to cracking. Recognizing the specific alloys you’re working with can make a huge difference in the outcome of your welding efforts.

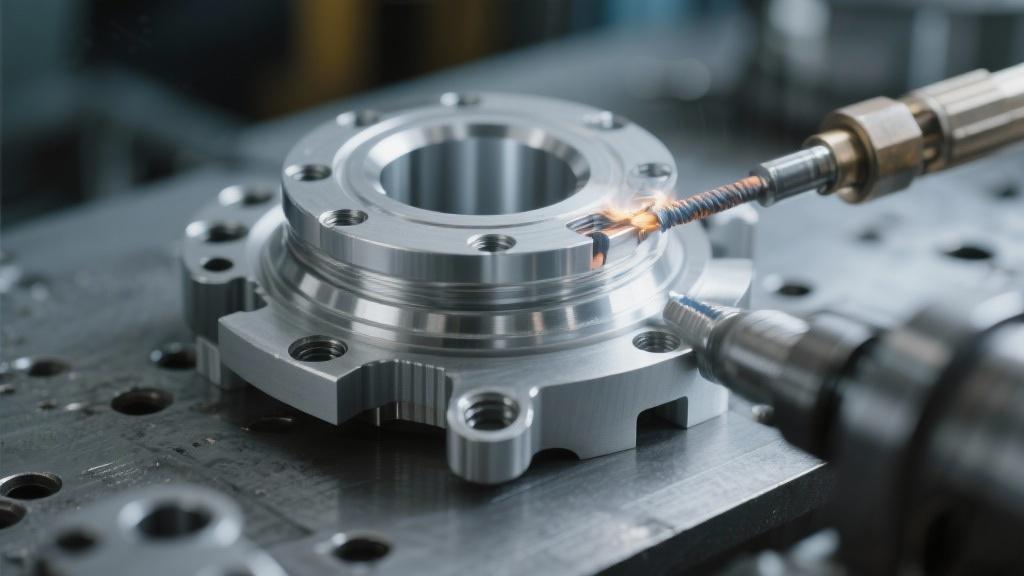

Another crucial factor is the welding technique employed. Common methods include Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding. TIG welding is often chosen for its precision and control, making it ideal for thin materials. On the other hand, MIG welding is faster and more effective for thicker sections. Knowing which technique suits your project can substantially impact the quality of the weld.

Surface preparation is also vital. Aluminum oxidizes quickly, leading to a layer of aluminum oxide that can hinder the welding process. Proper cleaning techniques, including using solvents or wire brushing, are essential for removing these oxides to ensure strong weld joints.

Additionally, weld joint design plays a significant role in how well aluminum parts can be welded. The geometry of the joint, including whether it’s a butt joint or a fillet joint, will determine the ease of welding as well as the strength of the final product.

Ultimately, when you consider welding aluminum machined parts, you’ll find that while it’s certainly feasible, it requires careful consideration of materials, techniques, and preparation. This nuanced approach not only enhances performance but also maximizes the durability and life of the aluminum components.

In preparing for your welding project, think about consulting guidelines from reputable sources like the American Welding Society, which can provide you with specifics regarding best practices. Successful welding of aluminum machined parts can transform your designs and offer solutions that stand the test of time—just make sure you have all the right information and tools in place.

Can all aluminum alloys be easily welded?

No, not all aluminum alloys are easily welded. While alloys like 6061 and 6063 are known for their good weldability, others, such as those in the 7000 series, can be more challenging due to their tendency to crack. Understanding the alloy you’re working with is crucial for successful welding.

It’s important to research the specific characteristics of the alloy. This knowledge helps determine what preparation and techniques will be necessary to achieve a strong weld, ensuring the best outcome for your project.

What preparation steps are necessary before welding aluminum?

Preparing aluminum for welding is essential to ensure a strong bond. First, you need to clean the surface thoroughly to remove any oxidation, dirt, or oils that can interfere with the weld. Common methods include using solvents or wire brushing to eliminate contaminants.

Additionally, proper joint design should be considered before welding. The geometry of the joint can significantly influence the strength of the final weld, so it’s worth taking the time to design it properly for the best results.

What techniques are best for welding aluminum machined parts?

The two most common welding techniques for aluminum are TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. TIG is often preferred when working with thin materials due to its precision and control, whereas MIG welding is faster and can be more effective for thicker sections.

Choosing the right technique is crucial based on the specific requirements of your project. Evaluating the thickness of the material and the desired strength will help determine which method to use for optimal results.

How do surface treatments affect aluminum welding?

Surface treatments play a key role in the weldability of aluminum. Stabilizing the oxide layer that forms quickly on aluminum surfaces is vital, as it can inhibit the quality of the weld. Techniques like anodizing or applying a suitable primer can improve weld quality.

Proper surface treatment not only enhances adhesion but also increases the overall durability of the welded part, making it essential to factor into your preparation process.

What are some applications of welded aluminum machined parts?

Welded aluminum machined parts find their applications across a wide range of industries, including aerospace, automotive, and marine. They are often utilized in structures that require high strength-to-weight ratios, where the benefits of welding greatly enhance performance.

By using welded aluminum machined parts, products can achieve significant improvements in both strength and durability, which are crucial for demanding applications.