Understanding Warping and Deformation

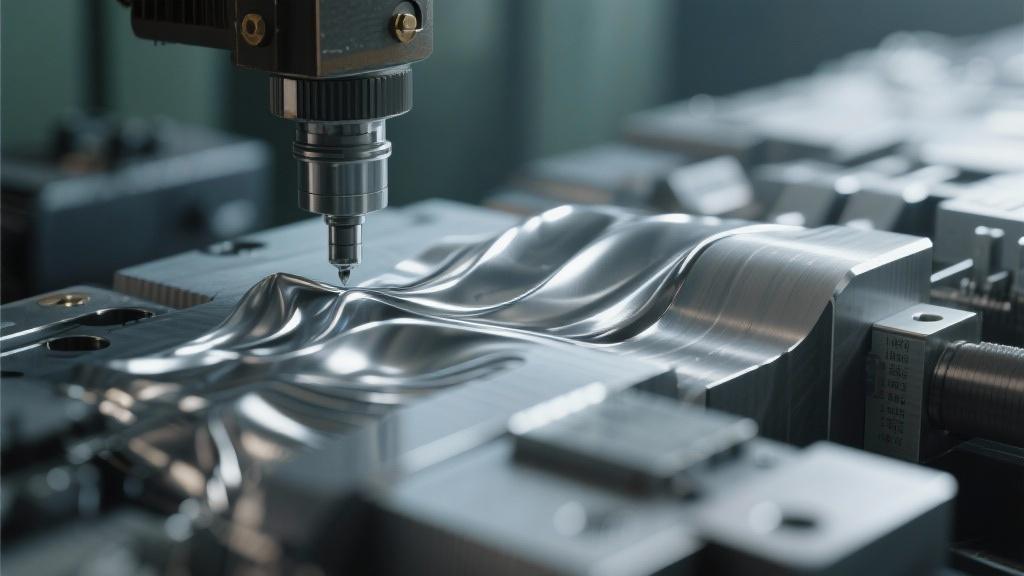

Warping and deformation typically occur due to thermal expansion during machining processes such as cutting and milling. Aluminum, being a metal, expands and contracts with changes in temperature. When excess heat is generated, particularly at the cutting edge, it can lead to uneven expansion, causing parts to twist or bend out of their intended shape. Moreover, the internal stresses that develop during the machining process can further exacerbate these issues.

To tackle these complications, engineers and machinists must adopt specific strategies focused on minimizing the effects of heat and effectively managing the machining parameters. Let’s dive into some solutions that have proven to be effective in reducing warping and deformation.

Strategies to Minimize Warping and Deformation

Closing Thoughts on Aluminum Machining

While preventing warping and deformation in aluminum machining can seem daunting, employing strategic methods can significantly enhance the outcome. Implementing these techniques not only improves the overall quality of machined parts but also contributes to the efficiency and reliability of the manufacturing process. With the right approach, aluminum can be machined into precise, high-quality components that meet the demanding standards of today’s industry.

What causes warping and deformation in aluminum machining?

Warping and deformation are primarily caused by thermal expansion, which occurs during machining processes like cutting and milling. When excess heat builds up at the cutting edge, it can lead to uneven expansion, resulting in parts that twist or bend.

Additionally, internal stresses created during the machining process can exacerbate these issues, making it crucial to manage heat effectively and maintain stable machining conditions.

How can proper cooling techniques help in aluminum machining?

Using appropriate cooling techniques, such as flood cooling or mist cooling, can effectively dissipate heat during machining. This helps maintain a stable temperature at the cutting edge, reducing the risk of warping and deformation.

By controlling the temperature, you can ensure more uniform expansion of the material, which helps keep parts aligned and within specification.

What role does fixturing play in minimizing deformation?

Proper fixturing is essential to secure the workpiece firmly during machining. A well-designed setup minimizes movement, helping to maintain the desired shape and precision of the part.

When features are designed to reduce stress concentration, such as avoiding sharp corners, they can further decrease the likelihood of deformation occurring during machining.

Can adjusting cutting parameters help reduce warping?

Absolutely! Adjusting cutting speeds and feed rates can significantly impact heat generation. Slower feed rates or reduced RPMs can lead to lower heat production, which is crucial in minimizing warping and deformation.

By being mindful of these parameters, you can enhance the machining process and improve the overall quality of the finished parts.

Is material selection important for deformation prevention?

Yes, material selection plays a significant role in preventing deformation. Choosing the right aluminum alloy can contribute to stability during machining. Alloys that are stiffer or less prone to heat changes may be more effective for certain applications.

Additionally, pre-machining treatments, such as stress relieving, can help eliminate internal stresses that could lead to unwanted deformations.