How Long Do Copper CNC Machining Deliveries Take?

How Long Do Copper CNC Machining Deliveries Take? Read More »

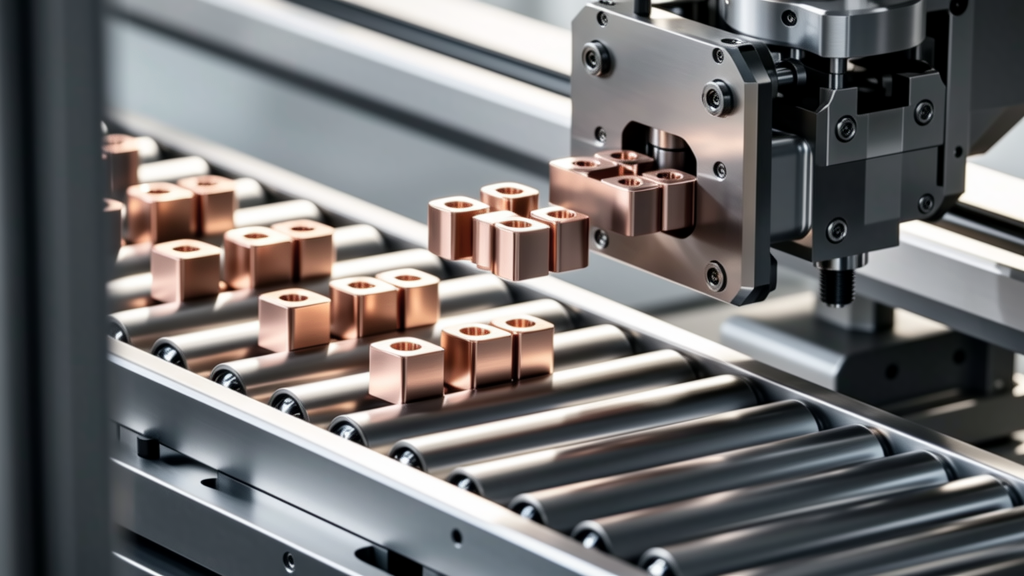

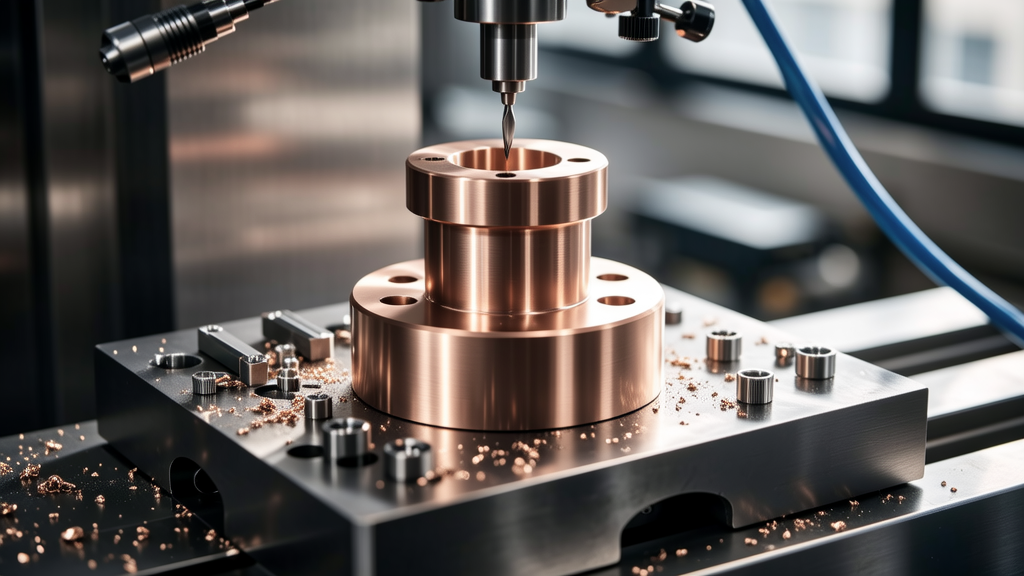

FAQWe’ll explore the standard delivery durations in the industry, key considerations that may affect these timelines—including material availability, complexity of the designs, and manufacturer capabilities. By the end, you’ll have actionable insights to help you […]