Choosing China’s Best CNC Parts Makers

Quick Solution: Selecting top Chinese CNC machining partners demands vetting source manufacturers for verifiable expertise, rigorous quality, and transparent processes, ensuring delivery of precision CNC parts China.

Navigating the vast landscape of Chinese CNC machining manufacturers can feel like finding a needle in a haystack – especially when ‘top 10’ lists often miss the crucial elements of true quality, technical expertise, and transparency. How do you cut through the noise to find a partner that guarantees precision and reliability?

As a seasoned source manufacturer in Shenzhen, ly-machining understands the complexities involved in sourcing high-quality CNC parts. This guide will equip you with the insights needed to identify truly top-tier CNC parts manufacturers in China, moving beyond superficial rankings to verifiable excellence. We aim to help you secure a trusted partnership for your most demanding projects.

Understanding China’s CNC Landscape

The Global Role of Chinese CNC Parts

China has firmly established itself as a global powerhouse in manufacturing, and its CNC machining sector is no exception. Companies worldwide increasingly rely on CNC parts manufacturers China for their capacity, efficiency, and growing technical capabilities. This reliance spans critical industries.

In our experience, clients from aerospace, medical devices, and robotics frequently seek partners who can consistently deliver high-precision components. The scale of manufacturing in China allows for competitive pricing without necessarily compromising on quality, provided the right partner is chosen.

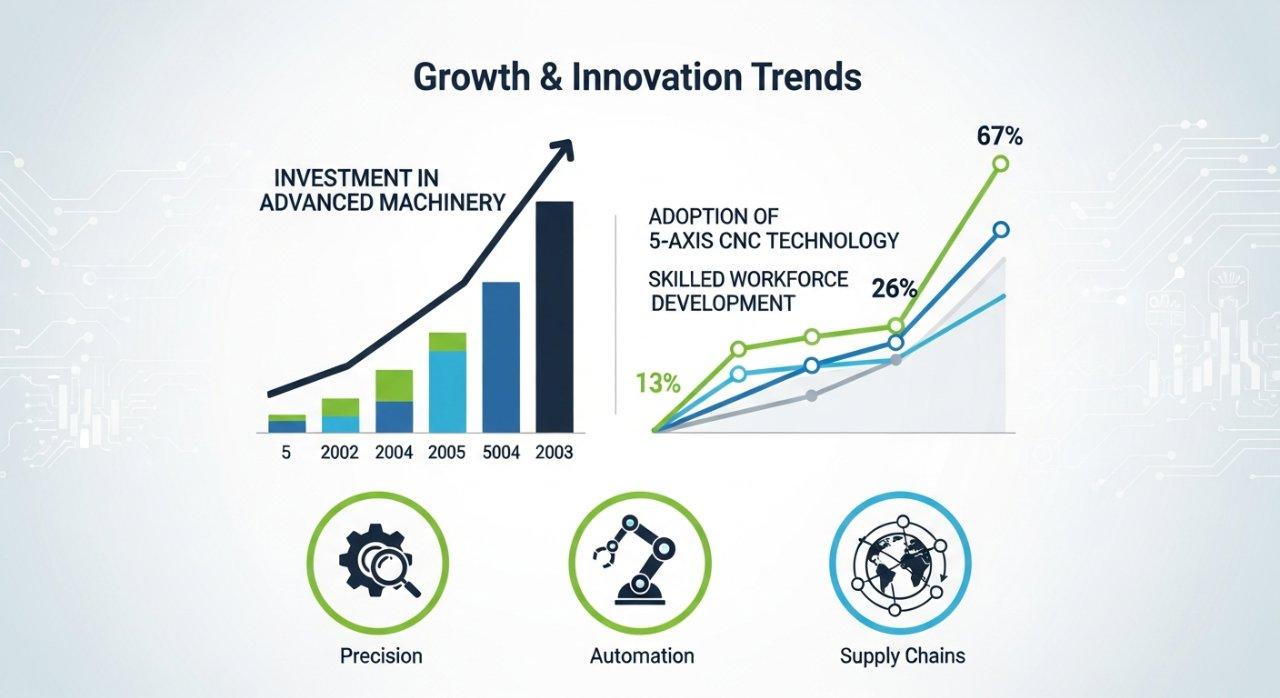

Growth & Innovation in Chinese Machining

The Chinese CNC machining industry is characterized by continuous investment in advanced technology and skilled labor. We observe rapid adoption of sophisticated machinery, including multi-axis CNC centers and automated systems. This commitment to innovation is crucial.

This growth has transformed the landscape, enabling Chinese manufacturers to tackle increasingly complex geometries and tighter tolerances. The drive for technical excellence ensures that China remains at the forefront of precision CNC parts production globally.

Beyond ‘Top 10’ CNC Manufacturer Lists

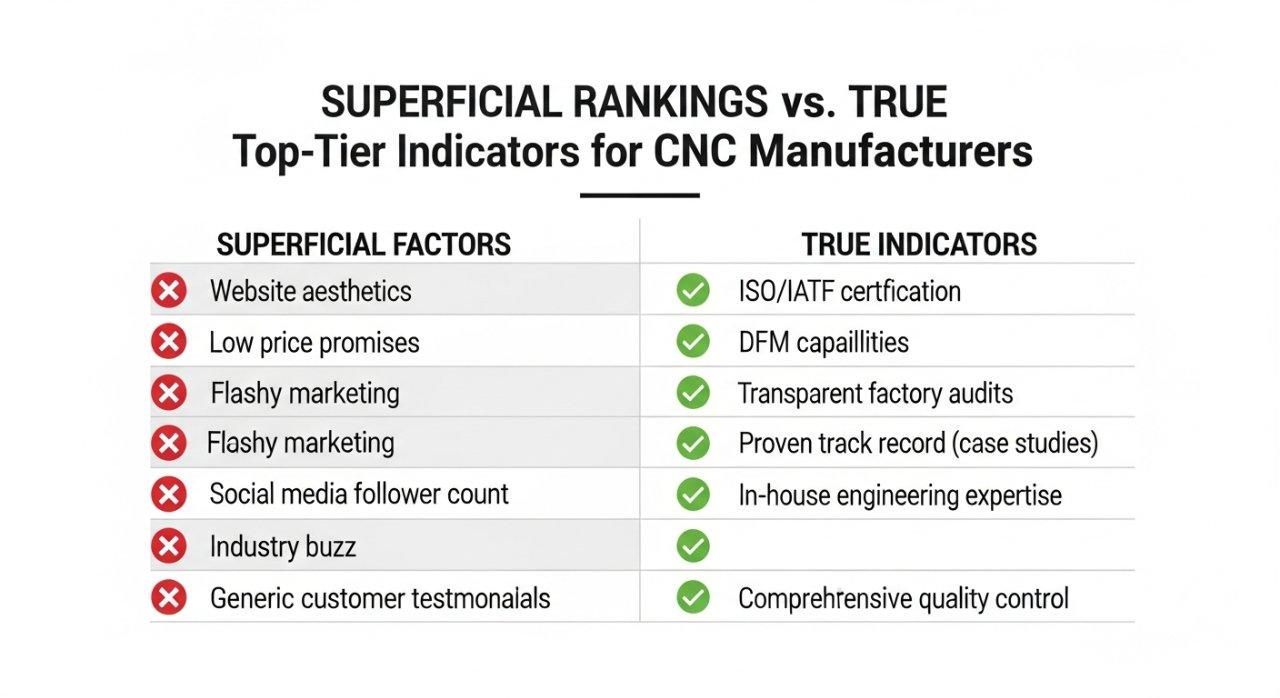

Why Generic Lists Fall Short

Many online “Top CNC Manufacturers China” lists are often superficial, based on limited data or commercial interests. They frequently overlook the critical factors that truly define a reliable and high-quality manufacturing partner. Such lists can be misleading.

These rankings rarely delve into a manufacturer’s core capabilities, quality control systems, or their commitment to technical support like Design for Manufacturability (DFM). For sourcing precision CNC parts, a deeper evaluation is essential.

What Truly Defines a Top Chinese CNC Maker

A truly top-tier Chinese CNC manufacturer excels in several key areas beyond mere size or revenue. They prioritize technical expertise, consistent quality, and transparent processes. These are the hallmarks of a trusted partner.

They are source manufacturers with full control over their production chain, offering robust quality assurance and engineering support. This holistic approach ensures project success and mitigates risks associated with outsourcing.

Key Traits of Top Chinese CNC Parts Firms

Source Manufacturer Advantage & Expertise

As a source manufacturer, ly-machining directly manages every step of the production process, from raw material procurement to final inspection. This eliminates intermediaries, enhancing communication and accountability. It’s a critical differentiator.

This direct control allows for unparalleled quality assurance and responsiveness to technical challenges. When you partner with us, you engage directly with the experts who will be fabricating your precision CNC parts China.

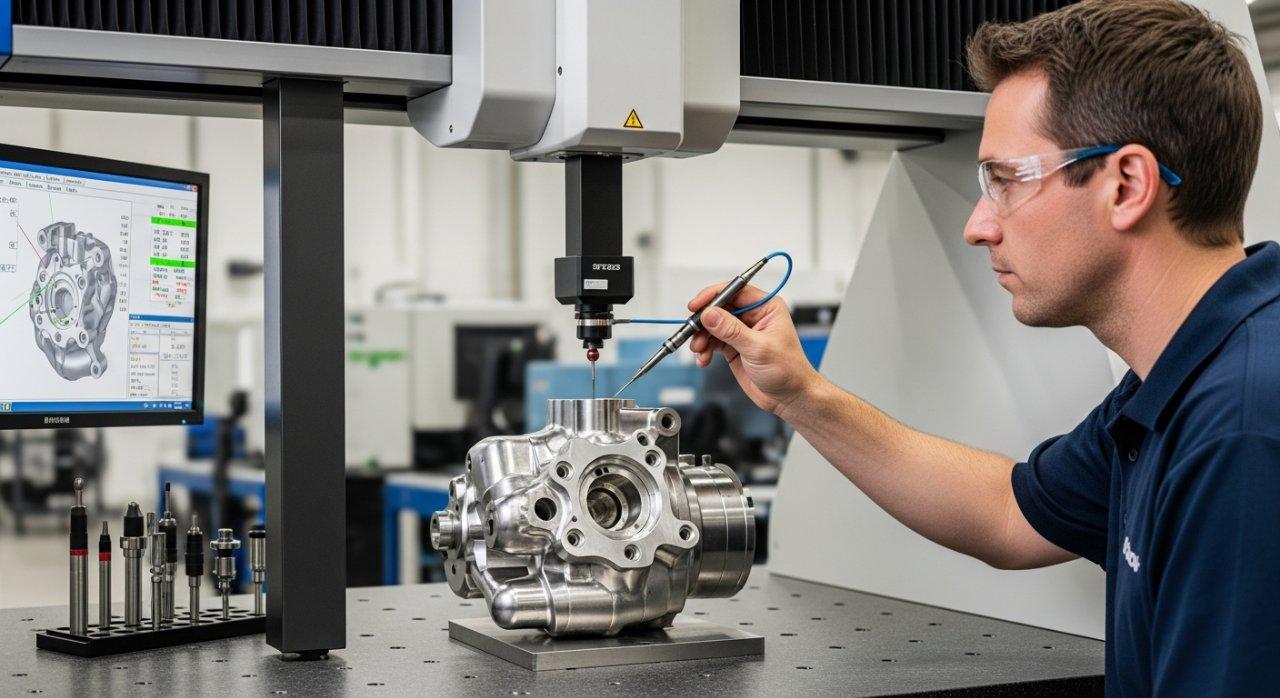

Unwavering Quality & Precision for Parts

Top CNC parts manufacturers in China are defined by their commitment to unwavering quality and precision. This goes beyond simple visual inspection and involves rigorous metrology and adherence to tight tolerances. It is fundamental.

Our factory utilizes advanced measurement equipment, including CMM machines, optical comparators, and surface roughness testers, to ensure every part meets the exact specifications of the engineering drawings. Precision is not optional; it is engineered.

Transparency in Pricing & Process

Transparency builds trust. A leading Chinese CNC machining partner will offer clear, factory-direct pricing without hidden fees and provide visibility into their manufacturing process. This fosters a collaborative relationship.

We believe in open communication regarding lead times, material sourcing, and potential DFM recommendations. This clarity ensures that clients have a full understanding of their investment and the production journey.

Deep Technical Expertise & DFM Support

True expertise lies in the ability to understand complex engineering challenges and provide proactive solutions. This includes offering Design for Manufacturability (DFM) reports before production begins. DFM is invaluable.

Our engineering team works closely with clients, analyzing designs for potential improvements in machinability, cost-efficiency, and performance. This collaborative approach helps optimize designs for precision CNC manufacturing.

How to Evaluate CNC Machining Partners

Due Diligence Checklist for Suppliers

Performing thorough due diligence is paramount when selecting CNC parts manufacturers China. This involves a comprehensive review of their capabilities, certifications, and operational history. A checklist can guide this process.

Consider factors such as equipment inventory, material expertise, maximum part dimensions, and their average lead times for prototyping and production. A detailed understanding of their capacity is key.

Table: Key Supplier Due Diligence Checklist

| Aspect | Description |

|---|---|

| **Certifications** | ISO 9001, IATF 16949, AS9100, Material Certificates |

| **Equipment List** | Types & number of CNC machines, metrology tools |

| **Material Expertise** | Alloys, plastics, exotics handled |

| **DFM Capability** | Engineering support & design review offered |

| **Quality System** | In-process & final inspection protocols |

Asking the Right Questions to China Makers

Engage potential partners with targeted questions to uncover their true capabilities. Inquire about their experience with similar projects, their approach to tight tolerances, and their problem-solving methodologies. Specificity is crucial.

Ask about their communication protocols, project management systems, and how they handle revisions or unexpected challenges. A proactive and transparent response indicates a reliable partner.

Importance of Certifications & Audits

Certifications like ISO 9001 and IATF 16949 are non-negotiable indicators of a manufacturer’s commitment to quality management. For aerospace, AS9100 is often required. These provide a foundational level of trust.

We welcome client audits of our facility in Shenzhen, as this transparency reinforces our trustworthiness and allows you to verify our processes firsthand. Verifiable standards are a cornerstone of our operations.

Our Commitment to CNC Parts Excellence

Source Manufacturer Benefits We Offer

As a dedicated source manufacturer for precision CNC parts China, ly-machining provides direct access to our engineering and production teams. This means streamlined communication and direct accountability. We control the entire process.

Our clients benefit from factory-direct pricing, eliminating the margins of trading companies, and ensuring transparency from quote to delivery. We foster long-term partnerships built on trust and mutual success.

Our Quality Control & Assurance Systems

Quality is not just a department; it’s ingrained in every stage of our operations. Our full-chain quality control adheres strictly to ISO9001 and IATF16949 standards, covering everything from raw material inspection to final packaging. It’s a comprehensive system.

We utilize advanced in-process and post-process inspection techniques, employing skilled quality engineers to meticulously check every batch of custom CNC components. This vigilance guarantees consistent, high-quality output.

Table: ly-machining’s Quality Certifications

| Certification | Focus Area |

|---|---|

| **ISO 9001** | General Quality Management System |

| **IATF 16949** | Automotive Industry Quality Management System (specific) |

| **AS9100** | Aerospace Quality Management System (available for projects) |

Real-World Examples & Case Studies

In our experience, clients often come to us with demanding projects requiring tight tolerances and complex geometries. We’ve successfully machined intricate medical instrument components, robust robotic frames, and critical aerospace fittings. These are challenging assignments we excel at.

Our ability to handle diverse materials, from various aluminum alloys and stainless steels to titanium and specialty plastics, positions us as a versatile partner for precision CNC manufacturing across multiple sectors.

Transparent Engagement & Support

From the initial RFQ to post-delivery support, transparency and clear communication are our guiding principles. We provide detailed DFM feedback, regular project updates, and are always available for technical consultations. This ensures peace of mind.

Our commitment extends to rapid prototyping services, often with 24-hour turnaround capabilities, and flexibility with no minimum order quantity (MOQ) for prototypes, facilitating agile product development for our clients.

Partnering for CNC Parts Success

Get a Custom Quote Today

Moving forward with your next project requires a partner who understands precision and delivers reliability. We invite you to experience the difference that a dedicated, high-end Chinese CNC machining factory can make.

Submit your drawings and specifications for a detailed, transparent, and competitive quote from ly-machining. Our team is ready to provide the insights and pricing clarity you deserve.

Discuss Your Project with Experts

Do you have a complex design or specific technical challenges? Our engineering experts are available for a comprehensive technical consultation. Leverage our deep experience in precision CNC parts China to optimize your project for success.

We are committed to being more than just a supplier; we aim to be an extension of your engineering team, ensuring the highest standards for your custom CNC components.

Case Study: Accelerating Medical Device Prototyping

A leading medical technology company faced significant delays and quality inconsistencies with their previous supplier for critical surgical instrument prototypes. The parts required extremely tight tolerances, complex internal channels, and specific biocompatible material finishes, which their existing partner struggled to achieve consistently. This jeopardized their product launch timeline.

Our engineering team at ly-machining performed a thorough DFM analysis on their complex CAD models, identifying several opportunities for design optimization that would improve machinability without compromising function. We proposed a specific 5-axis machining strategy and a post-machining surface treatment protocol to achieve the required finish and dimensional accuracy. Leveraging our rapid prototyping capabilities, we delivered the initial batch of high-precision CNC parts within 48 hours.

The client received flawlessly machined prototypes, fully compliant with their stringent medical standards and significantly ahead of their previous supplier’s schedule. This accelerated their R&D cycle, validating their design and allowing them to proceed to clinical trials with confidence. They quickly transitioned to us as their primary long-term manufacturing partner for this critical product line.

Get a free quote or technical consultation.

What is Chinese CNC machining?

Chinese CNC machining refers to the process of using computer numerical control machines in China to manufacture precision parts and components from various materials. This industry encompasses a wide range of services, including milling, turning, and multi-axis machining for global markets. It is known for its extensive capacity and competitive advantage.

How to find top CNC manufacturers China?

Finding top CNC manufacturers in China involves looking beyond generic lists and focusing on key criteria such as source manufacturer status, robust quality certifications (e.g., ISO, IATF), deep technical expertise including DFM support, and transparent communication. It also requires conducting thorough due diligence and potentially factory audits. Prioritize partners offering verifiable quality.

Why choose a source manufacturer for CNC parts?

Choosing a source manufacturer like ly-machining for your CNC parts ensures direct control over the entire production process, eliminating intermediaries and reducing risks. This typically leads to better communication, greater accountability, more transparent pricing, and direct access to engineering expertise for design optimization and problem-solving. It guarantees higher quality and efficiency.