Many engineering and procurement professionals face a critical dilemma when selecting a manufacturing process for camera enclosures: how to balance technical specifications with cost and time-to-market constraints. This decision is rarely straightforward, as each method presents distinct trade-offs.

Making the wrong manufacturing choice can lead to significant repercussions, including protracted development cycles, budget overruns, and ultimately, a product that fails to meet performance or aesthetic expectations. The anxiety of committing to a process that might not deliver the required precision, durability, or scalability is a constant concern. This often results in costly redesigns or delayed product launches.

This guide provides a definitive comparison of CNC machining and die casting, empowering you to make an informed, confident decision for your specific camera enclosure needs. We will meticulously break down each process, ensuring your product’s success from concept to completion.

For optimal camera enclosure performance and cost-efficiency, choosing between CNC machining and die casting hinges on a precise evaluation of design complexity, material requirements, production volume, and budget.

Understanding Camera Enclosure CNC Machining

CNC machining offers a highly precise and versatile method for crafting camera enclosures, particularly for prototypes and low-to-medium volume production. It involves subtractive manufacturing, where material is removed from a solid block using computer-controlled tools. This allows for intricate geometries and tight tolerances.

Advantages of CNC Machining for Enclosures

The inherent precision of CNC machining allows for the creation of camera enclosures with exceptionally tight tolerances and complex internal features. This process is ideal when intricate details or critical assembly interfaces are paramount, ensuring superior fit and finish for custom camera enclosure projects. Material waste is higher than die casting.

Key Considerations for CNC Camera Enclosures

CNC machining excels in rapid prototyping and iterative design, enabling swift adjustments without the significant upfront tooling costs associated with die casting. It supports a wide array of materials, from various aluminum alloys to plastics, making it highly adaptable to diverse environmental and functional requirements. It also offers flexibility for custom camera enclosure designs.

| Feature | CNC Machining Advantages |

|---|---|

| Precision & Tolerance | Exceptional, down to ±0.005 mm |

| Design Complexity | Very high, complex geometries, thin walls |

| Material Versatility | Broad range (Al, Mg, Ti, Steel, Plastics) |

| Prototyping Speed | Fast iteration, no dedicated tooling |

| Surface Finish | High quality, can achieve very smooth surfaces |

Limitations of CNC Machining for Enclosures

While highly precise, CNC machining can be less economically viable for very high-volume production due to longer cycle times per unit and higher material costs. The subtractive nature of the process generates material waste, which can add to the overall cost, especially for large production runs. This impacts camera enclosure production costs at scale.

Cost Factors in CNC Camera Enclosure Production

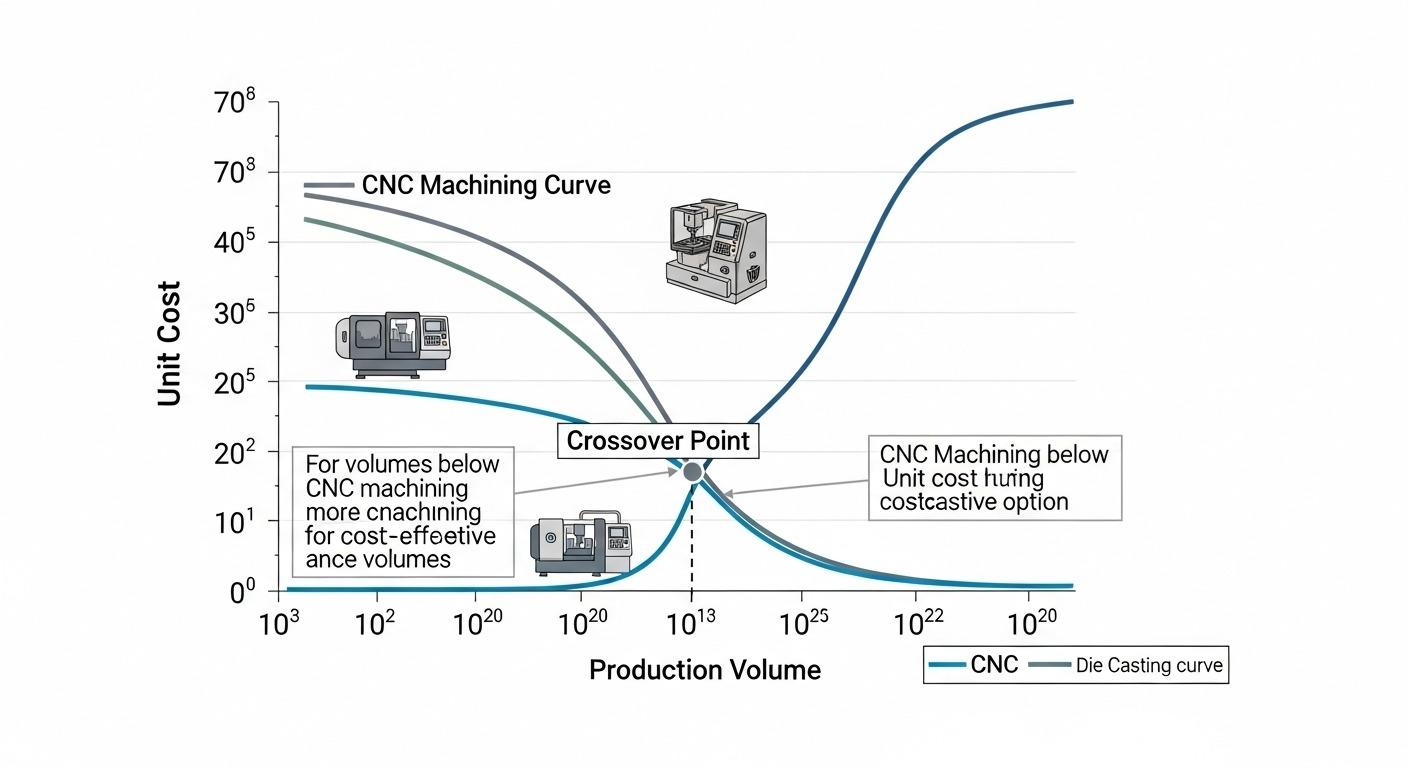

The primary cost drivers in CNC machining include material cost, machine time, and operator expertise. Unit costs remain relatively constant regardless of volume, making it less scalable than die casting for mass production. This contrasts sharply with the economies of scale offered by tooling-intensive processes.

| Cost Factor | Description |

|---|---|

| Unit Cost | Higher per-part cost, less sensitive to volume changes |

| Tooling Cost | Low or non-existent (no dedicated molds) |

| Material Waste | Higher due to subtractive process |

| Production Speed | Slower cycle times per part, limiting throughput |

Exploring Camera Enclosure Die Casting Process

Die casting is a high-pressure metal casting process that forces molten metal into a mold cavity, ideal for producing large volumes of metal camera housing options. This method is renowned for creating parts with excellent surface finish and dimensional accuracy at a rapid production rate.

Advantages of Die Casting for Enclosures

Die casting offers significant advantages for mass production, delivering parts with high dimensional accuracy and superior surface finishes directly from the mold. Its ability to create complex shapes rapidly makes it ideal for camera enclosure manufacturing where uniformity and speed are critical. This process optimizes camera enclosure production costs for large batches.

Production Scale Benefits for Die Cast Enclosures

Once the initial tooling investment is made, the per-unit cost in die casting becomes exceptionally low at high volumes. The rapid cycle times enable efficient production of hundreds of thousands of identical parts, ensuring consistency and cost-effectiveness for metal camera housing options. This is a key benefit for large-scale production.

| Feature | Die Casting Advantages |

|---|---|

| Production Volume | Excellent for high volumes, highly scalable |

| Per-Unit Cost | Very low at high volumes |

| Cycle Time | Very fast per part |

| Surface Finish | Smooth, often requires minimal post-processing |

| Complex Geometries | Good for consistent, intricate designs |

Limitations of Die Casting for Enclosures

The initial investment in custom tooling, known as NRE (Non-Recurring Engineering) costs, is substantial for die casting. This makes it unsuitable for low-volume production or frequent design changes, as retooling is expensive and time-consuming. Material selection is also more restricted.

Design Constraints in Die Cast Camera Enclosures

Die casting imposes certain design constraints, such as minimum wall thickness requirements and the necessity for draft angles to facilitate part ejection. While capable of complex forms, intricate internal features might require additional machining post-casting, adding to the overall cost and complexity of custom camera enclosure designs.

| Constraint | Description |

|---|---|

| Tooling Cost | Very high initial NRE, not suitable for low volumes |

| Material Options | Limited (Al, Zn, Mg alloys are common) |

| Design Flexibility | Less agile for frequent changes due to tooling |

| Porosity Potential | Can occur, requiring careful process control |

| Wall Thickness | Minimum wall thickness must be maintained |

Direct Comparison: CNC vs. Die Casting for Camera Enclosures

Selecting the optimal camera enclosure manufacturing method requires a direct comparison across several critical parameters. This evaluation should encompass material properties, achievable tolerances, surface finish, and the overarching implications for cost, production volume, and lead time. Understanding these distinctions is fundamental.

Material Suitability for Camera Enclosure Manufacturing

The choice of material significantly influences the performance and durability of the final camera enclosure. Both CNC machining and die casting leverage robust metal alloys, but their compatibility and optimal use cases differ based on specific material properties and manufacturing process requirements. This impacts custom camera enclosure projects.

Alloy Options for CNC and Die Casting

CNC machining can work with a broader spectrum of alloys, including various grades of aluminum (e.g., 6061, 7075), stainless steel, titanium, and specialized plastics. Die casting is primarily restricted to lower melting point alloys like aluminum (A380, A360), zinc, and magnesium. These differences dictate the available mechanical properties for metal camera housing options.

| Material Feature | CNC Machining Compatibility | Die Casting Compatibility |

|---|---|---|

| Alloy Variety | High (Aluminum, Steel, Titanium, Plastics) | Moderate (Aluminum, Zinc, Magnesium Alloys) |

| Material Properties | Retains inherent material strength | Can alter material grain structure |

| Cost (Raw Material) | Varies widely by specific alloy chosen | Generally lower for common casting alloys |

Tolerance and Surface Finish of Camera Enclosures

Achieving the desired level of precision and aesthetic appeal for camera enclosures is critical, directly impacting product functionality and brand perception. Both processes can deliver high quality, yet their inherent capabilities for achieving tight tolerances and specific surface finishes vary.

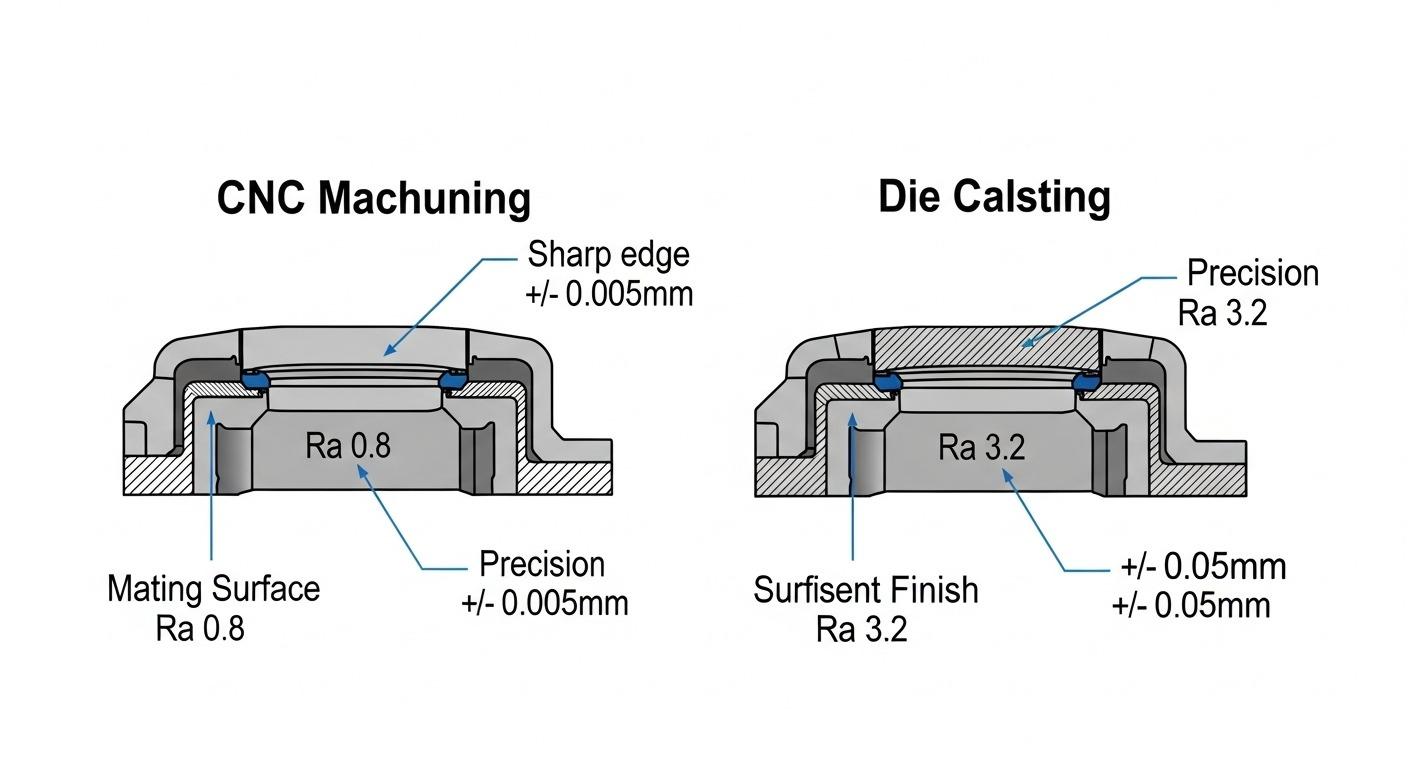

Achieving Precision in Camera Enclosure Parts

CNC machining generally achieves tighter absolute tolerances (e.g., ±0.005 mm) and a finer surface finish (e.g., Ra 0.8 µm) without extensive post-processing, making it superior for critical dimensions. Die casting offers good precision (e.g., ±0.05 to ±0.1 mm) and a smooth surface (e.g., Ra 3.2 µm) directly from the mold, but often requires secondary machining for very tight features.

| Aspect | CNC Machining Performance | Die Casting Performance |

|---|---|---|

| Achievable Tolerance | Very tight (e.g., ±0.005 – ±0.025 mm) | Good (e.g., ±0.05 – ±0.1 mm) |

| Surface Finish | Very smooth (e.g., Ra 0.8 – 1.6 µm) | Smooth (e.g., Ra 1.6 – 3.2 µm) |

| Post-processing | Minimal for surface finish | Often requires for critical features |

Cost, Volume, and Lead Time for Camera Enclosures

The economic viability and project schedule are heavily influenced by the chosen manufacturing process. Evaluating the interplay between initial tooling costs, per-unit costs at various production volumes, and overall lead times is essential for strategic planning of camera enclosure manufacturing.

Impact on Project Budget and Schedule

CNC machining has low to no upfront tooling costs, offering quick turnaround for initial prototypes and low-volume production. However, per-unit costs are higher and do not decrease significantly with volume. Die casting demands a substantial initial investment in tooling, but this cost is quickly amortized across high production volumes, leading to very low per-unit costs and faster overall mass production cycle times for camera enclosure production costs.

| Metric | CNC Machining | Die Casting |

|---|---|---|

| Tooling Cost (NRE) | Low to none | High (Amortized over high volumes) |

| Unit Cost | Higher, consistent across volumes | Low at high volumes, decreases with volume |

| Lead Time | Faster for prototypes and small batches | Slower for initial tooling, very fast for mass production |

| Optimal Volume | Low to Medium (1-1,000s) | High to Very High (1,000s to millions) |

Expert Recommendations for Your Camera Enclosure Product

The decision between CNC machining and die casting is not about superiority, but suitability. It requires a nuanced understanding of your project’s unique demands, from early-stage design validation to full-scale market deployment. Our expertise guides you through this critical selection.

When to Choose CNC for Your Camera Enclosure

CNC machining is the preferred choice when design flexibility, precision, and a broad material selection are paramount. This is especially true for projects with evolving specifications or those that cannot justify high upfront tooling expenses. It ensures rapid iteration for custom camera enclosure projects.

Prototype and Low-Volume Camera Enclosure Needs

Opt for CNC machining for initial prototypes, proof-of-concept models, or limited production runs (e.g., 1 to 1,000 units). Its ability to produce highly accurate parts quickly, with minimal setup costs, makes it ideal for testing designs and bringing innovative metal camera housing options to market swiftly without commitment to expensive molds.

When to Opt for Die Casting for Your Camera Enclosure

Die casting becomes the economically compelling choice for projects requiring robust, uniform parts in substantial quantities. When the design is finalized and mass production is imminent, its efficiency and low per-unit costs yield significant savings over the product’s lifecycle.

High-Volume and Cost-Optimized Camera Enclosure

Select die casting for large-scale production (e.g., 10,000+ units) where cost per unit is a critical driver and the design is stable. The high initial tooling investment is offset by rapid cycle times and reduced material waste, making it the most economical solution for consistent camera enclosure manufacturing.

Partnering with a Source Manufacturer for Camera Enclosures

Collaborating with an experienced source manufacturer like ly-machining ensures access to deep technical expertise and integrated manufacturing capabilities. This partnership facilitates optimal process selection, guaranteeing quality and cost-efficiency throughout your camera enclosure project. Our factory in Shenzhen, China provides comprehensive solutions.

Ensuring Quality and Technical Support

A reliable manufacturing partner offers not just production, but expert guidance on Design for Manufacturability (DFM), material science, and quality control. This holistic support minimizes risks, optimizes designs for both CNC and die casting processes, and ensures your camera enclosure meets the highest standards. We are your trusted partner for custom camera enclosure projects.

Case Study: Precision Enclosures for Autonomous Drones

A client, a leader in autonomous drone technology, faced a critical challenge: their existing camera enclosures for aerial navigation units were failing stringent environmental tests, primarily due to inconsistent material properties and insufficient thermal dissipation. They needed a lightweight, durable, and highly precise enclosure capable of withstanding extreme vibration and temperature fluctuations.

Our engineers at ly-machining conducted a thorough technical consultation. Recognizing the demand for both high precision and eventually scalable production, we initially recommended CNC machining using a specific aerospace-grade aluminum alloy (6061-T6). This allowed for rapid prototyping and fine-tuning of thermal management features.

Following successful validation, we transitioned the client to high-pressure die casting using an optimized A380 aluminum alloy, leveraging our in-house expertise to design robust tooling that ensured consistent part quality and excellent heat dissipation. This strategic shift reduced per-unit costs by over 70% at volume, while still achieving critical dimensional tolerances and thermal performance. The client’s drone enclosures now reliably perform in diverse operational environments, reinforcing their market leadership.

Unlock Your Camera Enclosure’s Potential

Stop guessing and start optimizing. For a camera enclosure that truly excels, precision matters from concept to completion. Contact our engineering experts today for a free, no-obligation consultation and receive a transparent, detailed quote tailored to your specific CNC machining or die casting project. Leverage our source manufacturing advantage for unparalleled quality and technical partnership.

Frequently Asked Questions

Which process is cheaper?

The cheaper process depends on your production volume. CNC machining has lower upfront costs but higher per-unit costs, making it ideal for low volumes. Die casting has high tooling costs, but very low per-unit costs for high-volume production.

This cost structure means that for large quantities, die casting is significantly more economical. For prototypes or small batches, CNC machining is the more cost-effective choice.

Can I combine both processes?

Yes, a hybrid approach is often beneficial for complex camera enclosures. This might involve die casting the main body for cost efficiency at high volumes, then performing secondary CNC machining.

Secondary CNC operations can add critical features, achieve tighter tolerances, or refine surfaces that are difficult to achieve in the initial casting process. This ensures optimal precision and cost balance.

What about material options?

CNC machining offers a wider array of material choices, including various aluminum grades, stainless steels, and engineering plastics, allowing for diverse performance characteristics. Die casting is generally limited to specific low-melting-point alloys.

These include common aluminum alloys (like A380), zinc, and magnesium alloys. Your specific material requirements for strength, weight, and thermal properties will guide this selection.