Choosing Your Ideal Aluminum Shell CNC Partner

To select the optimal Aluminum shell CNC machining manufacturer, prioritize deep technical expertise, robust ISO-certified quality control, transparent communication, and a proven track record in Custom Aluminum Enclosure Machining. This ensures reliable and Precision Aluminum CNC Manufacturing.

Navigating the landscape of CNC machined aluminum parts suppliers can be a complex endeavor, fraught with potential pitfalls that can impact project timelines, budgets, and product quality. The seemingly small decision of selecting your Aluminum shell CNC machining manufacturer can, in fact, have massive repercussions on your product’s success.

This definitive guide will cut through the noise, providing critical criteria and expert insights. It will empower you to identify a partner you can truly trust to deliver precision, transparency, and timely delivery for every custom aluminum enclosure you require.

Understanding Aluminum Shell CNC Needs

The journey to successful product development often hinges on the quality of its components, especially when it comes to custom aluminum enclosures. Clearly defining your needs from the outset is paramount for selecting the right Custom Aluminum Enclosure Machining partner.

This foundational step ensures alignment between your project requirements and a manufacturer’s capabilities. It helps in avoiding costly rework and delays down the line, setting the stage for efficient Precision Aluminum CNC Manufacturing.

Defining your Custom Aluminum Enclosure Machining goals

Before engaging any Aluminum shell CNC machining manufacturer, articulate your project’s specific objectives. This includes understanding the required functionality, the environment the enclosure will operate in, and its aesthetic demands.

Consider target costs, desired lead times, and the production volume, whether for rapid prototyping or high-volume production. These parameters guide ly-machining in tailoring an optimal manufacturing strategy for your CNC machined aluminum parts.

Common pain points with CNC Machined Aluminum Parts

Many companies face challenges with inconsistent part quality, dimensional inaccuracies, or poor surface finishes from their Aluminum shell CNC machining manufacturer. Delayed deliveries and opaque pricing are also frequent frustrations.

These issues directly impact product launch schedules and overall project profitability. ly-machining addresses these by prioritizing clear communication and meticulous process control.

Setting quality standards for Precision Aluminum CNC

Establishing clear quality benchmarks is crucial for any CNC machining project. This includes defining critical tolerances, required surface finishes (e.g., Ra values, anodizing type), and any specific material certifications needed.

Ensure your chosen Aluminum shell CNC machining manufacturer can meet or exceed these standards consistently. ly-machining routinely works with tolerances down to 0.005mm and offers comprehensive surface treatment options.

Technical Expertise in CNC Machining

The bedrock of high-quality Aluminum shell CNC machining is profound technical expertise. It distinguishes a capable manufacturer from a merely adequate one, especially for complex Custom Aluminum Enclosure Machining projects.

A partner with deep technical knowledge can offer invaluable insights. This leads to Design for Manufacturability (DFM) improvements and optimal material utilization, ensuring superior CNC machined aluminum parts.

Assessing a manufacturer’s CNC machining capabilities

Evaluate the range and sophistication of a manufacturer’s equipment. Do they possess multi-axis CNC machines (e.g., 5-axis) capable of handling complex geometries? What is their experience with tight tolerances and intricate feature creation?

In ly-machining’s experience, advanced machinery translates directly into higher precision and efficiency. Our fleet of over 80 machines, including high-precision 5-axis centers, ensures we meet diverse project demands.

Material specialization for Aluminum shell machining

Expertise in various aluminum alloys is critical for selecting the right material for your application. Different alloys offer unique properties, from strength and corrosion resistance to machinability and aesthetic appeal.

A skilled Aluminum CNC Manufacturing partner will guide you in choosing the optimal alloy. ly-machining regularly works with 6061, 7075, 2024, and other specialized aluminum grades.

Here’s a comparison of common aluminum alloys used in CNC machining:

| Alloy Type | Key Properties | Common Applications |

|---|---|---|

| 6061 | Good strength, weldability, corrosion resistance | General purpose, structural components, frames |

| 7075 | High strength, good fatigue resistance | Aerospace, high-stress parts, sporting goods |

| 2024 | High strength-to-weight ratio, good fatigue | Aircraft structures, automotive racing parts |

| 5052 | Excellent corrosion resistance, formability | Marine applications, fuel tanks, electronic chassis |

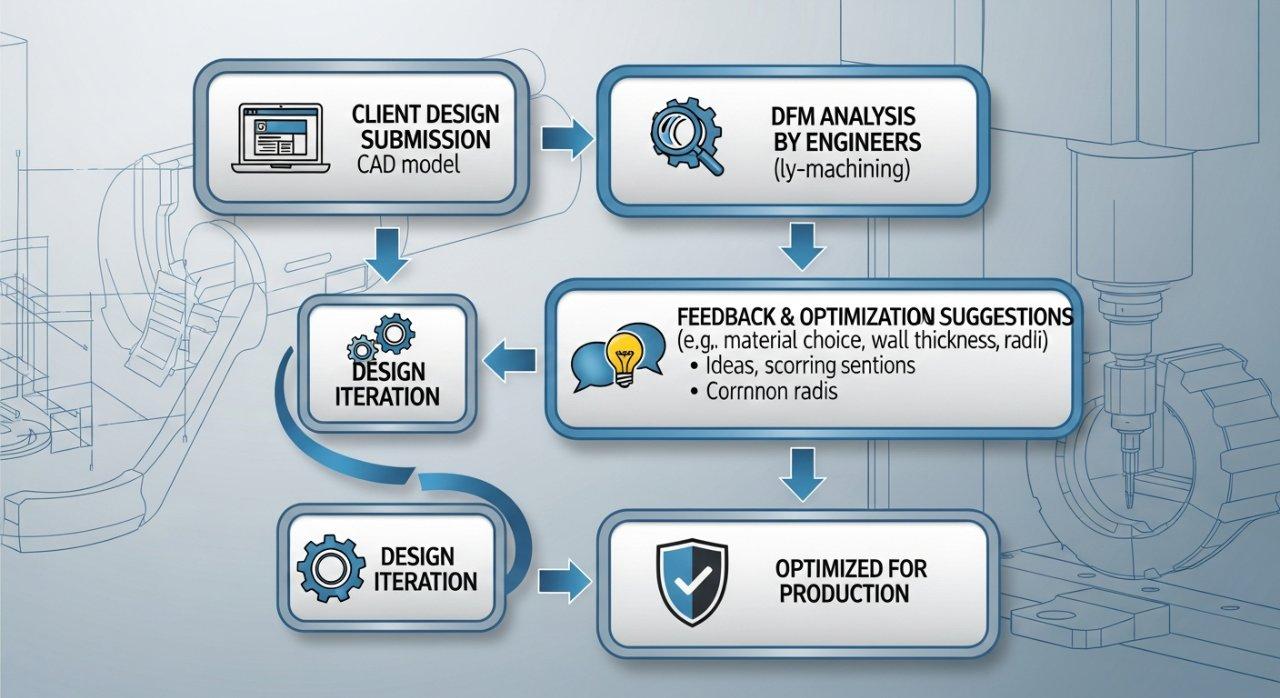

DFM support from your Aluminum CNC Manufacturing

Design for Manufacturability (DFM) support is a hallmark of a truly expert Aluminum shell CNC machining manufacturer. This involves reviewing your designs for potential manufacturing challenges and suggesting improvements.

DFM reports can significantly reduce production costs and lead times while improving part quality. ly-machining provides comprehensive DFM analysis, proactively identifying optimal solutions for Precision Aluminum CNC.

Advanced technologies in Precision Aluminum CNC

Beyond basic CNC milling, consider manufacturers leveraging advanced technologies. These can include high-speed machining, lights-out manufacturing, or robotic automation, which enhance efficiency and consistency.

Such technologies indicate a commitment to innovation and capability in handling large volumes with unwavering quality. ly-machining continuously invests in cutting-edge equipment to maintain its competitive edge.

Quality Assurance & Control Processes

Uncompromising quality is non-negotiable for CNC machined aluminum parts, particularly for applications demanding high reliability. A robust Quality Assurance (QA) and Quality Control (QC) system is the backbone of a trustworthy Aluminum shell CNC machining manufacturer.

This systematic approach ensures that every component meets the strictest specifications. It provides peace of mind regarding the integrity and performance of your Custom Aluminum Enclosure Machining.

Verifying certifications for Aluminum shell CNC

Look for industry-recognized certifications like ISO 9001 and IATF 16949. These demonstrate a commitment to quality management systems and continuous improvement.

These certifications provide objective evidence of a manufacturer’s adherence to stringent quality standards. ly-machining proudly holds both ISO 9001 and IATF 16949, reflecting our dedication to world-class quality in Precision Aluminum CNC.

Inspection protocols for CNC Machined Aluminum Parts

Inquire about the manufacturer’s inspection processes at every stage of production. This includes incoming material inspection, in-process checks, and final quality control before shipment.

Utilize Coordinate Measuring Machines (CMMs), optical comparators, and other precision measurement tools for dimensional accuracy. ly-machining employs rigorous multi-stage inspection using advanced CMMs and skilled technicians.

Here are common inspection methods for CNC machined parts:

| Inspection Method | Purpose | Equipment Used |

|---|---|---|

| First Article Inspection | Verify initial setup and part accuracy | CMM, Calipers, Micrometers |

| In-Process Inspection | Monitor consistency during production | Go/No-go gauges, Height gauges |

| Final Inspection | Full dimensional check before shipment | CMM, Optical comparator, Bore gauges |

| Material Verification | Confirm material composition | Spectrometer, Hardness tester |

Traceability and reliability from your CNC supplier

A reliable Aluminum shell CNC machining manufacturer offers complete traceability for all materials and processes. This means you can track a part from its raw material origin through every manufacturing step.

Traceability is vital for accountability and problem-solving, especially in demanding industries like aerospace or medical. ly-machining maintains meticulous records, ensuring full transparency and reliability for every part.

Ensuring consistent quality in Precision Aluminum CNC

Consistency across batches is as important as individual part quality. A superior CNC machined aluminum parts supplier will have processes in place to minimize variation and maintain tight tolerances over high volumes.

This often involves statistical process control (SPC) and regular equipment calibration. ly-machining’s advanced production environment and robust QC procedures ensure consistent, high-quality output for all projects.

Transparency and Communication Factors

Effective communication and transparency are crucial elements of a successful partnership with an Aluminum shell CNC machining manufacturer. They build trust and prevent misunderstandings throughout the Custom Aluminum Enclosure Machining process.

A clear and open dialogue ensures that expectations are managed, potential issues are addressed promptly, and project goals remain aligned for your CNC machined aluminum parts.

Clear communication with Custom Aluminum Enclosure

Look for a manufacturer that offers dedicated project managers and provides regular updates on production status. Responsiveness to inquiries and clear explanations of technical details are indicators of good communication.

In ly-machining’s experience, proactive communication is key to minimizing delays and ensuring client satisfaction. We believe in keeping our partners informed every step of the way.

Understanding pricing structures for CNC machining

Transparent pricing avoids hidden costs and unexpected budget overruns. Request detailed quotes that itemize costs for materials, machining, surface treatments, tooling, and shipping.

A reputable Aluminum shell CNC machining manufacturer will be upfront about their pricing model. ly-machining offers clear, factory-direct pricing, ensuring you understand the value proposition for your Precision Aluminum CNC projects.

Supply chain visibility from an Aluminum CNC supplier

Understanding a manufacturer’s supply chain practices is critical for risk management. Inquire about their material sourcing, lead times for raw materials, and any potential geopolitical or logistical vulnerabilities.

A transparent supply chain strengthens reliability and allows for better planning. ly-machining, as a source manufacturer, offers robust supply chain management, ensuring steady delivery of CNC machined aluminum parts.

Addressing issues with your Aluminum shell manufacturer

Even with the best partners, issues can occasionally arise. The key is how quickly and effectively a manufacturer addresses them. Look for clear procedures for handling quality discrepancies or delays.

A committed Aluminum shell CNC machining manufacturer will take responsibility and work collaboratively to find swift resolutions. ly-machining’s dedicated customer service team is always ready to assist.

Evaluating Your Potential CNC Manufacturer

Thorough evaluation is essential before committing to an Aluminum shell CNC machining manufacturer. Beyond certifications and equipment, examining real-world performance provides invaluable insights.

This includes scrutinizing past projects, client feedback, and their overall operational integrity. It solidifies confidence in their ability to deliver high-quality CNC machined aluminum parts.

Case studies of successful Aluminum shell CNC projects

Requesting case studies provides tangible evidence of a manufacturer’s capabilities and problem-solving skills. Look for examples that align with the complexity and requirements of your own project.

These stories illustrate how they tackle challenges and achieve specific client objectives. ly-machining’s portfolio includes diverse, complex Custom Aluminum Enclosure Machining projects across multiple industries.

Client testimonials for CNC Machined Aluminum Parts

Authentic client testimonials offer direct insights into a manufacturer’s reliability, service quality, and ability to meet deadlines. Seek feedback that speaks to their precision, communication, and overall partnership experience.

These endorsements provide social proof and build confidence in a prospective Aluminum shell CNC machining manufacturer. ly-machining proudly shares testimonials highlighting our exceptional service and quality.

Site visits and audits for Precision Aluminum CNC

Whenever feasible, conduct a site visit or a virtual audit of the manufacturing facility. This allows you to observe their operations firsthand, assess cleanliness, organization, and adherence to safety protocols.

Audits are crucial for verifying quality control processes and equipment maintenance. As a source manufacturer, ly-machining welcomes clients to tour our Shenzhen facility to see our capabilities directly.

Comparing lead times for Custom Aluminum Enclosure

Lead time directly impacts your time-to-market. Compare quoted lead times from various manufacturers, ensuring they are realistic and achievable given the project’s complexity and volume.

Inquire about their capacity and ability to handle rush orders or provide rapid prototyping services. ly-machining offers rapid prototyping services, often delivering initial samples within 24 hours.

Partnering with a Source Manufacturer

Choosing a source manufacturer like ly-machining for your Aluminum shell CNC machining needs offers distinct advantages. It streamlines the supply chain and enhances control over quality and cost.

Working directly with the factory eliminates middlemen. This translates to better communication, more transparent pricing, and direct access to technical expertise for your CNC machined aluminum parts.

The benefits of direct Aluminum shell CNC sourcing

Direct sourcing from a factory means you’re dealing with the actual producers, not a trading company. This typically results in faster response times, more accurate technical feedback, and a closer relationship with the manufacturing team.

It reduces the risk of miscommunication and ensures a clearer understanding of your project requirements. ly-machining prides itself on being a direct, factory-to-client Custom Aluminum Enclosure Machining partner.

Achieving cost efficiency in CNC Machined Aluminum Parts

By bypassing intermediaries, source manufacturers offer more competitive and transparent pricing. You’re paying for the manufacturing directly, without added markups.

This direct relationship allows for better negotiation and understanding of cost drivers, leading to significant savings over the project lifecycle. ly-machining’s transparent pricing model ensures cost-effectiveness for Precision Aluminum CNC.

Our commitment to Precision Aluminum CNC quality

ly-machining’s unwavering commitment to quality is embedded in every step of our process, from raw material selection to final inspection. Our ISO 9001 and IATF 16949 certifications are testament to this dedication.

We uphold the highest standards to ensure every Aluminum shell meets stringent specifications. Our rigorous full-chain quality control guarantees exceptional CNC machined aluminum parts.

Deep technical expertise in Aluminum CNC manufacturing

At ly-machining, our team of experienced engineers provides unparalleled technical expertise. We excel in complex structure processing, including advanced 5-axis machining, and specialized material handling.

This deep knowledge allows us to offer valuable DFM reports and innovative solutions. We ensure your Custom Aluminum Enclosure Machining projects are executed with optimal efficiency and precision.

Making Your Final CNC Machining Decision

The decision of which Aluminum shell CNC machining manufacturer to partner with is a critical one, impacting your product’s success and your company’s reputation. It requires careful consideration of all factors discussed.

By consolidating your evaluation criteria and maintaining a long-term perspective, you can confidently select the best Custom Aluminum Enclosure Machining partner.

Consolidating criteria for your ideal Aluminum shell

Review all the criteria: technical expertise, quality assurance, communication transparency, and cost efficiency. Create a weighted checklist to objectively compare potential CNC machined aluminum parts suppliers.

Prioritize the factors most critical to your project’s success. ly-machining’s comprehensive capabilities often position us as an ideal partner for demanding projects.

Avoiding common pitfalls in CNC Machined Aluminum

Beware of overly low pricing that might signal compromised quality or hidden costs. Also, be wary of manufacturers with poor communication or a lack of verifiable certifications.

These are red flags that can lead to significant problems down the line. A thorough vetting process helps you avoid these common pitfalls in Precision Aluminum CNC Manufacturing.

A long-term vision for your Custom Aluminum Enclosure

Look beyond the immediate project to a partner who can support your evolving needs. Consider their scalability, ability to handle future design iterations, and commitment to continuous improvement.

A long-term partnership with a trusted Aluminum shell CNC machining manufacturer can be a significant asset. ly-machining aims to be a strategic partner, growing with your business.

Your Next Step for CNC Machined Aluminum

Having thoroughly explored how to choose the best Aluminum shell CNC machining manufacturer, it’s time to take action. ly-machining is poised to be your trusted partner.

We combine deep technical expertise with transparent processes to deliver superior Precision Aluminum CNC solutions.

Request a consultation for Aluminum shell CNC needs

Are you ready to discuss your specific Custom Aluminum Enclosure Machining requirements with an expert? ly-machining’s engineers are available to provide in-depth technical consultations.

We can assist with design optimization and material selection. Our team ensures your project starts on the right foot, offering insights that only a seasoned Aluminum CNC Manufacturing partner can provide.

Get a transparent quote for Precision Aluminum CNC

Experience the ly-machining difference with a detailed, no-obligation quote. Our transparent pricing structure ensures you understand every aspect of your investment.

We are committed to delivering exceptional value for high-quality CNC machined aluminum parts. Contact ly-machining today to receive a comprehensive proposal tailored to your project.

Case Study: Optimizing Robotics Enclosures for Extreme Environments

Problem: A robotics company approached ly-machining with a challenge. Their existing aluminum enclosures for outdoor robotics were failing due to insufficient heat dissipation and susceptibility to harsh weather.

The enclosures, critical for protecting sensitive electronics, also required extremely tight tolerances for sealed components. Their current supplier struggled with both the thermal design and maintaining the required precision for reliable sealing.

Our Solution: ly-machining’s DFM engineers collaborated closely with the client’s team. We recommended a specialized 6061-T6 aluminum alloy for its excellent thermal conductivity and machinability.

Utilizing our 5-axis CNC machining capabilities, ly-machining integrated intricate internal fin structures into the enclosure design, significantly increasing surface area for passive cooling. We also suggested a hard anodized finish for enhanced corrosion resistance and durability.

The Result: The new Custom Aluminum Enclosure Machining solution provided by ly-machining dramatically improved the robot’s performance in extreme temperatures. The precision machining ensured an IP67-rated seal, protecting internal electronics from dust and water.

The client experienced a 30% reduction in thermal management failures and extended product lifespan in the field. This success reinforced ly-machining’s reputation as a trusted Precision Aluminum CNC Manufacturing partner.

Your Partner for Precision: ly-machining

Ready to secure a partner that delivers unparalleled quality and technical expertise for your aluminum enclosure projects?

Invite readers to get a free quote or technical consultation.

What is DFM and why is it important for CNC?

DFM, or Design for Manufacturability, is the process of optimizing a product’s design for easier, more efficient, and cost-effective manufacturing.

For CNC machining, it helps prevent errors, reduces material waste, and ensures the part can be produced to exact specifications without issues.

ly-machining provides comprehensive DFM reports, saving clients time and money.

How does ly-machining ensure quality control?

ly-machining adheres to stringent ISO 9001 and IATF 16949 certified quality management systems.

Our multi-stage inspection process includes incoming material verification, in-process checks using advanced CMMs, and final quality control before shipment.

This full-chain approach ensures every CNC machined aluminum part meets the highest standards.

Can ly-machining handle complex aluminum parts?

Yes, ly-machining specializes in complex structure processing.

With our advanced fleet of over 80 machines, including high-precision 5-axis CNC centers, we are fully equipped to handle intricate geometries and tight tolerance requirements for any Custom Aluminum Enclosure Machining project.

Our deep technical expertise allows us to tackle even the most challenging designs effectively.