Brass Surface Treatments: Electroplating vs. Polishing

The precision of CNC machining brings brass components to life, but their true potential in terms of durability, function, and aesthetic appeal is often unlocked through expert surface treatment. For engineers and product designers, the choice between techniques like brass electroplating, brass polishing, and brass passivation is critical, impacting performance, longevity, and cost. This article, drawing from our extensive experience as a source manufacturer, will guide you through a detailed comparison of these essential CNC brass surface treatments, helping you make an informed decision for your next project.

Quick Comparison: Electroplating vs. Polishing vs. Passivation

| Feature | Brass Electroplating | Brass Polishing | Brass Passivation |

|---|---|---|---|

| **Core Function** | Enhance functional properties (wear, corrosion, conductivity) & aesthetics | Improve aesthetic appearance (luster, smoothness) & surface quality | Increase corrosion resistance by forming a passive layer |

| **Main Advantage** | Superior functional enhancements & diverse finishes | High-end aesthetic finish & smooth tactile feel | Cost-effective, invisible corrosion protection |

| **Aesthetic Outcome** | Wide range of colors/finishes (e.g., bright, matte, antique) | Bright, reflective, mirror-like finish or satin brushed | No significant change in appearance |

| **Corrosion Resistance** | Excellent (dependent on plating material and thickness) | Limited inherent resistance, can accelerate tarnishing | Good to excellent, prevents tarnishing |

| **Surface Hardness** | Significantly increased (dependent on plating material) | Unchanged (base material) | Unchanged (base material) |

| **Typical Cost** | Moderate to High (variable by plating type & thickness) | Low to Moderate (variable by finish requirement & labor) | Low |

What is Brass Electroplating?

Definition

Brass electroplating is an electrochemical process where a thin layer of another metal (e.g., nickel, chrome, gold, silver) is deposited onto the surface of a CNC brass component. This process uses an electric current to reduce dissolved metal cations in an electrolyte solution, causing them to coat the electrically conductive brass part.

Core Features

In our experience, electroplating offers unparalleled versatility. Key features include the ability to significantly alter the component’s surface properties, such as increasing wear resistance, enhancing electrical conductivity, or providing superior corrosion protection. Different plating materials yield distinct aesthetic and functional characteristics, from bright chrome finishes to durable nickel undercoats.

Typical Use Cases

Brass electroplating is indispensable in applications requiring specific functional enhancements or high-end aesthetics. Common uses include electrical connectors (for improved conductivity and corrosion resistance), automotive parts (for wear resistance and decorative appeal), plumbing fixtures, and decorative hardware where specific color, luster, or durability are paramount.

What is Brass Polishing?

Definition

Brass polishing is a mechanical or chemical process designed to smooth and brighten the surface of CNC brass components. It involves removing a microscopic layer of material to eliminate scratches, tool marks, and surface irregularities, resulting in a highly reflective or satin finish.

Core Features

Polishing primarily focuses on the aesthetic improvement and surface quality of brass. It enhances the natural luster of the brass, providing a smooth, tactile feel. Common methods include mechanical buffing with abrasive compounds, vibratory finishing, or chemical polishing solutions. The degree of polish can range from a brushed satin look to a mirror-like sheen.

Typical Use Cases

Brass polishing is predominantly chosen for decorative or architectural applications where visual appeal is critical. This includes high-end consumer goods, musical instruments, luxury interior fittings, and decorative architectural elements. It can also be used as a pre-treatment before electroplating to ensure a flawless underlying surface.

Electroplating vs. Polishing: Detailed Head-to-Head Comparison

Functional Properties (Corrosion, Wear, Conductivity)

When it comes to enhancing functional properties, brass electroplating generally outperforms polishing. A properly selected and applied plating, such as nickel or chrome, offers excellent corrosion resistance and significantly increases surface hardness and wear resistance. In contrast, while polishing creates a smoother surface that might be less prone to dirt accumulation, it does not inherently improve the brass’s corrosion resistance or hardness. In fact, by removing the stable oxide layer, it can sometimes make the brass more susceptible to tarnishing without further protection. For electrical applications, certain electroplating types, like gold or silver, provide superior conductivity and contact resistance compared to raw or polished brass.

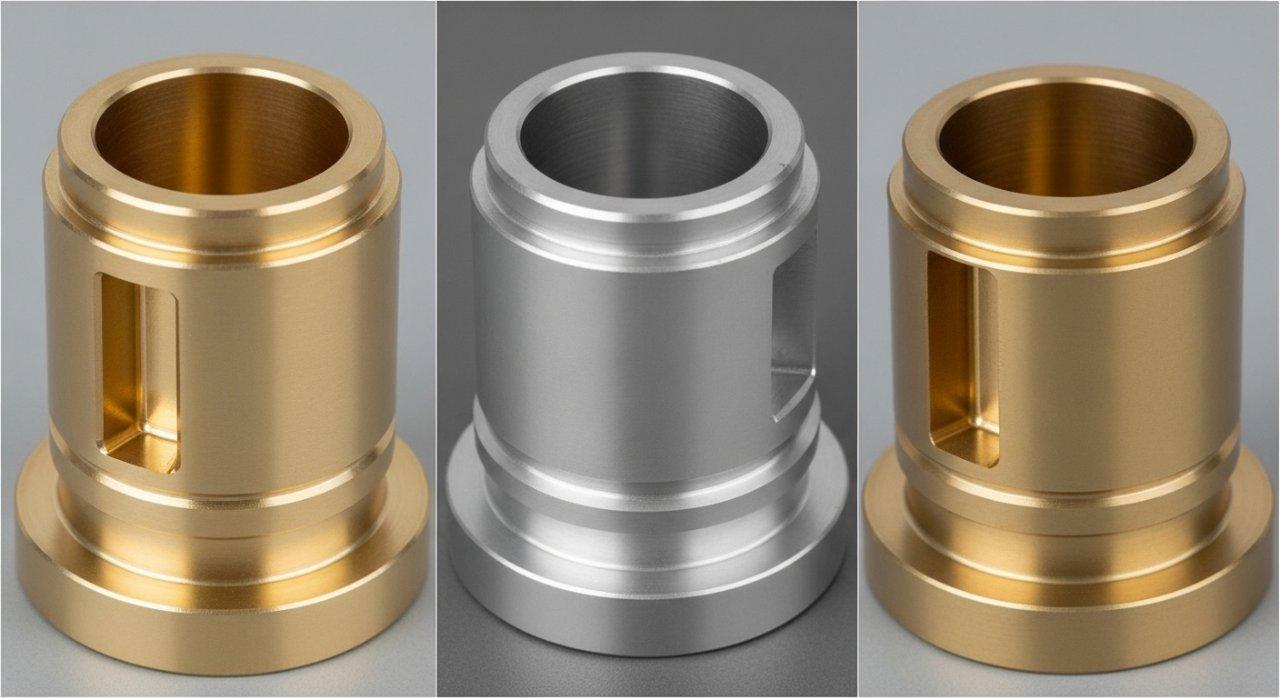

Aesthetic Outcomes & Surface Finish

Both treatments aim to improve aesthetics, but with different results. Brass polishing accentuates the natural golden hue of brass, producing a brilliant, reflective, or satin finish. The look is “pure brass.” Brass electroplating, however, offers a much wider palette of finishes. We can achieve anything from a bright, mirror-like chrome or nickel finish to antique brass, satin gold, or even black nickel, completely transforming the component’s appearance. The choice here depends entirely on the desired visual identity for the final product.

Process Complexity & Control

Electroplating is a more complex multi-stage process involving precise chemical solutions, current control, and post-treatment. Achieving uniform thickness and adhesion requires significant expertise and specialized equipment. Quality control is paramount to prevent issues like blistering, pitting, or uneven deposition.

Polishing, while appearing simpler, still demands skilled labor and specific abrasive selections to achieve a consistent finish without distorting part geometry. For intricate parts, manual polishing can be highly labor-intensive and challenging to standardize across batches. Both processes require stringent adherence to specifications to ensure consistent quality, a cornerstone of our manufacturing philosophy.

Environmental and Safety Considerations

Both processes have environmental footprints. Electroplating involves various chemicals, and responsible management of wastewater and byproducts is crucial. At ly-machining, we adhere to strict environmental regulations and employ advanced wastewater treatment systems to minimize impact. Polishing, particularly mechanical polishing, generates fine metallic dust and requires proper ventilation and dust collection. Chemical polishing, like electroplating, involves chemical handling. The selection of a treatment often considers not just performance but also the lifecycle environmental impact and compliance with industry standards like ISO 14001.

Pros and Cons Analysis

Advantages and Disadvantages of Brass Electroplating

Advantages:

* Significantly enhances functional properties: superior corrosion resistance, increased wear resistance, improved hardness, and specific electrical conductivity.

* Offers a vast array of aesthetic finishes beyond brass’s natural color.

* Provides a durable, uniform coating that can extend the lifespan of the component.

* Suitable for both decorative and highly functional applications.

Disadvantages:

* More complex process, requiring specialized equipment and skilled operators.

* Higher cost compared to polishing, especially for precious metal platings or thick layers.

* Potential for issues like hydrogen embrittlement or uneven deposition if not meticulously controlled.

* Environmental considerations due to chemical usage.

Advantages and Disadvantages of Brass Polishing

Advantages:

* Enhances the natural beauty and luster of brass, providing a classic, high-end aesthetic.

* Removes surface imperfections, tool marks, and minor burrs.

* Can achieve very smooth surfaces, improving tactile feel.

* Generally lower cost than electroplating for standard finishes.

Disadvantages:

* Offers minimal to no improvement in corrosion resistance; polished brass can tarnish more easily without a protective coating.

* Does not enhance surface hardness or wear resistance.

* Can be labor-intensive, especially for complex geometries, leading to higher labor costs.

* Material removal might slightly alter critical dimensions if not carefully managed.

Unique Considerations for Brass Passivation

Brass passivation is a chemical treatment designed to enhance the natural corrosion resistance of brass by forming a stable, protective oxide layer on its surface. Unlike electroplating, it doesn’t apply an external coating, and unlike polishing, it doesn’t primarily focus on aesthetics. It’s often chosen for applications where the natural brass look is desired, but protection against tarnishing and corrosion is essential, especially in mild environments. It’s a cost-effective solution for extending the life of brass components without altering their appearance or dimensions. However, it doesn’t offer the same level of wear resistance or functional enhancement as electroplating.

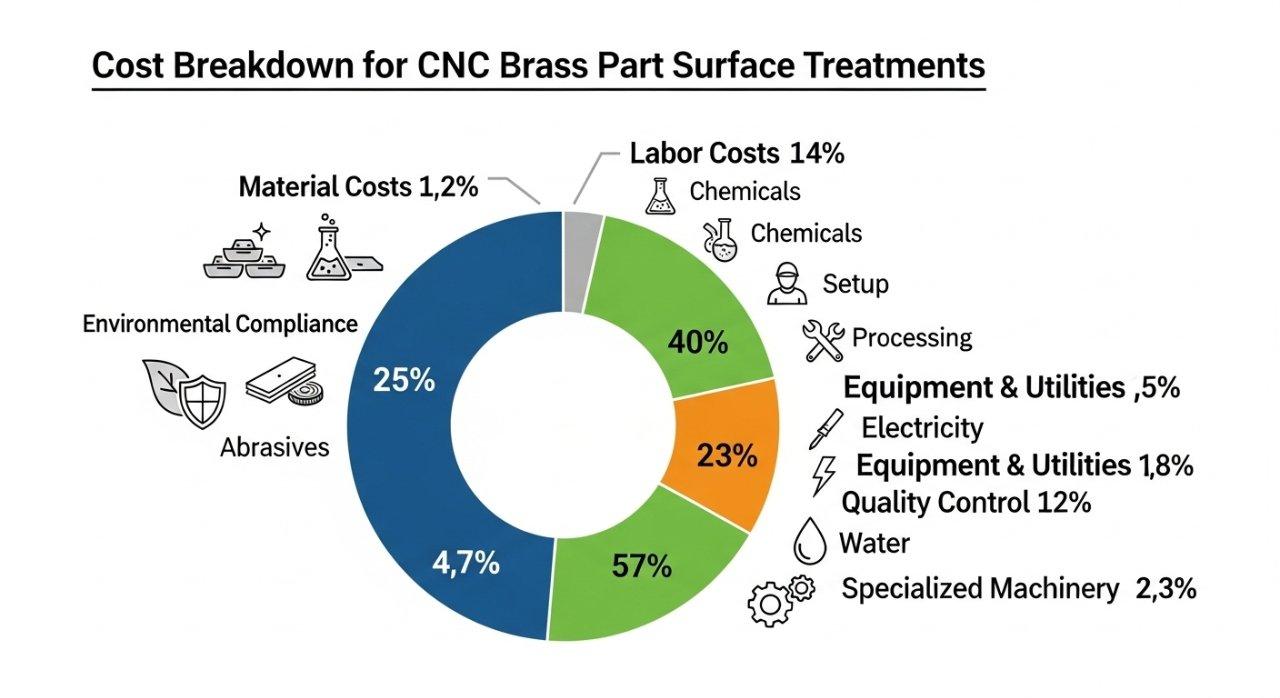

Cost and Pricing Comparison

The cost of surface treatments for CNC brass parts is a significant factor in project planning. In our experience, pricing is not a one-size-fits-all, but rather depends on several variables.

| Treatment Type | Key Cost Drivers | Typical Cost Range (Relative) |

|---|---|---|

| **Brass Electroplating** | Plating material (nickel, chrome, gold), thickness, part geometry complexity, required quality standards, volume | Moderate to High (Gold/Platinum: Very High) |

| **Brass Polishing** | Labor intensity, desired finish (satin vs. mirror), part size & complexity, abrasive media consumed, volume | Low to Moderate |

| **Brass Passivation** | Chemical solution cost, immersion time, volume, minimal labor | Low |

For brass electroplating, precious metals like gold or silver significantly increase costs. Thicker platings for enhanced durability also add to the expense due to longer processing times and material usage. Complex part geometries increase labor for racking and precise coverage.

Brass polishing costs are heavily influenced by the level of finish desired; a mirror polish requires more stages and skilled labor than a satin finish. Large parts or those with intricate features will have higher polishing costs.

Brass passivation is generally the most economical option, involving relatively low material and processing costs, making it attractive for budget-conscious projects requiring basic corrosion protection.

Real-World Use Cases

Use Case 1: Application of Brass Electroplating

Consider high-performance electrical connectors used in demanding aerospace applications. These CNC machined brass connectors require not only precise dimensions but also excellent conductivity, wear resistance for repeated mating cycles, and protection against corrosion in harsh environments. In this scenario, brass components are often gold-plated or nickel-plated. Gold plating ensures superior electrical contact and corrosion resistance, while nickel plating provides a robust, wear-resistant barrier, securing the component’s reliability and longevity under extreme conditions.

Use Case 2: Application of Brass Polishing

Imagine luxury yacht hardware, such as railing components or decorative fittings. These parts are often CNC machined from solid brass. For such applications, the natural elegance of brass is paramount. Polishing transforms the raw brass into a dazzling, mirror-like finish that perfectly complements the opulent aesthetic of the yacht. The goal here is purely visual splendor and a smooth tactile experience, where the inherent beauty of the brass material is brought to the forefront. While not offering corrosion protection, the polished finish creates a stunning visual impact.

Use Case 3: Application of Brass Passivation

In medical device manufacturing, particularly for internal components that require precise fit and mild corrosion resistance without altering the material’s properties or introducing new coatings, brass passivation is often employed. These parts might be exposed to non-corrosive bodily fluids or cleaning agents where a protective barrier is needed but a metallic coating is undesirable. Passivation provides a subtle yet effective layer of protection against tarnishing and mild corrosion, maintaining the component’s original dimensions and material compatibility, which is critical in sterile environments.

Decision Framework: Which One Should You Choose?

Making the right choice for your CNC brass components requires a careful evaluation of functional requirements, aesthetic goals, and budget. As your trusted source manufacturer, we provide tailored guidance.

Choose Brass Electroplating if you…

* Need significantly enhanced functional properties like superior corrosion resistance, increased wear resistance, or specific electrical conductivity.

* Desire a specific aesthetic finish that cannot be achieved with natural brass, such as chrome, nickel, or gold.

* Require a durable, protective layer to extend the component’s lifespan in harsh or demanding environments.

* Are willing to invest in a more complex process for superior performance and longevity.

Choose Brass Polishing if you…

* Prioritize the natural aesthetic beauty and luster of brass.

* Aim for a smooth, reflective, or satin finish to enhance visual appeal and tactile quality.

* Your application is primarily decorative, or environmental conditions are mild, minimizing corrosion risk.

* Seek a relatively cost-effective way to improve surface finish without altering fundamental material properties.

Consider Brass Passivation if you…

* Require basic protection against tarnishing and mild corrosion without altering the brass’s appearance or dimensions.

* Your budget is highly constrained, making it the most cost-effective solution for corrosion prevention.

* The application does not demand high wear resistance or specific electrical enhancements from a coating.

* You need to maintain the natural brass material properties without an added metallic layer.

Conclusion

The ideal surface treatment for your CNC brass components is a strategic decision that balances functionality, aesthetics, and cost. Whether you opt for the robust protection and diverse finishes of brass electroplating, the timeless elegance of brass polishing, or the subtle corrosion resistance of brass passivation, each process offers unique advantages. At ly-machining, our deep technical expertise and commitment to quality as a source manufacturer ensure that we can deliver high-quality, precisely treated parts tailored to your exact specifications.

Ready to elevate your CNC brass components with the perfect finish? Contact our engineering experts today for a personalized consultation, receive transparent pricing, and secure high-quality solutions tailored precisely to your project’s needs.

FAQ Section

What is the primary difference in protection between brass electroplating and brass passivation?

The primary difference is the mechanism and extent of protection. Brass electroplating applies an entirely new layer of a different metal onto the brass surface, offering robust protection against wear, corrosion, and often enhancing electrical properties. Brass passivation, conversely, is a chemical process that enhances the natural oxide layer of the brass itself, providing a lighter form of corrosion and tarnish resistance without altering the part’s dimensions or adding a new material.

Can I combine brass polishing with either electroplating or passivation?

Yes, brass polishing is often used as a preparatory step. For electroplating, a highly polished surface ensures a smoother, more lustrous final plated finish, as any imperfections on the brass will be magnified by the plating. For passivation, polishing can create a uniform surface for the chemical treatment to act upon, although passivation is typically performed on a cleaned, but not necessarily highly polished, surface.

How does environmental impact factor into choosing between these CNC brass surface treatments?

Environmental impact is an important consideration. Electroplating processes involve various chemicals and generate wastewater that requires sophisticated treatment. Polishing creates airborne particulates and can use chemical compounds. Passivation also uses chemical solutions, though often less aggressive than some plating baths. Our factory prioritizes sustainable practices and adheres to stringent environmental regulations for all surface treatment operations, ensuring responsible manufacturing for our CNC brass components.