Optimize Fascia Gun Shell CNC Costs

Strategic DFM, material selection, and transparent CNC manufacturing optimize CNC fascia gun shell cost. Partnering with experts yields significant machining cost control strategy savings.

The booming demand for fascia guns presents a unique challenge for manufacturers. Balancing premium quality, ergonomic design, and a competitive price point for your CNC fascia gun shell is paramount. High production expenses can silently erode profit margins, making proactive cost control strategies essential.

At ly-machining, we understand these pressures intimately. Our deep technical expertise as a source manufacturer offers actionable insights and transparent CNC manufacturing processes. We provide proven methods to achieve optimal cost-efficiency without compromising the precision and performance your product demands.

Unpacking Fascia Gun Shell CNC Costs

Understanding where costs originate is the first step in effective management. For CNC fascia gun shells, several key factors contribute significantly to the overall production expense. Identifying these allows for targeted optimization.

Key Cost Drivers in Fascia Gun Shell Production

In our experience, material selection, machining time, and post-processing are primary cost drivers. Complex geometries and stringent tolerance requirements also add to manufacturing complexity and cost. Each decision, from design to delivery, has a financial implication.

Why Cost Control is Crucial for Product Margins

Aggressive market competition and consumer expectations for high-quality, affordable products demand stringent cost management. Effective machining cost control strategy directly impacts your bottom line, securing healthier profit margins and market competitiveness. It allows for reinvestment in innovation and product development.

Strategic Material Selection & Cost

Material choice profoundly affects both product performance and manufacturing costs. For fascia gun shells, striking the right balance is critical. Our team provides expert guidance on material properties and machinability.

Balancing Performance and Price: Alloys vs. Plastics

Aluminum alloys (e.g., 6061, 7075) offer excellent strength, heat dissipation, and a premium feel but come at a higher material and machining cost. Engineering plastics (e.g., ABS, PC, POM) are lighter, often more cost-effective, and provide good impact resistance, but may require different tooling and finishing.

Here’s a comparison for common choices:

| Material Type | Advantages | Disadvantages | Typical Application |

|---|---|---|---|

| Aluminum 6061 | High strength, good machinability, corrosion resistance | Higher cost, heavier | Premium, durable shells |

| PC (Polycarbonate) | High impact strength, good aesthetics, lightweight | Machining can be challenging, less heat dissipation | Lightweight, consumer models |

| ABS | Cost-effective, good processability, impact resistance | Lower strength, limited aesthetics | Budget-friendly shells |

Impact of Material Form on CNC Costs

Starting material form—such as extruded bar stock, plate, or custom-cast blanks—significantly influences machining time and material waste. Using a near-net-shape blank can drastically reduce material removal, lowering both cycle time and scrap. We often recommend this for high-volume parts.

Leveraging Source Manufacturer Raw Material Advantages

As a source manufacturer, we procure raw materials in bulk directly from mills. This gives us a distinct cost advantage, which we pass on to our clients. Our long-standing relationships with suppliers ensure consistent material quality and supply chain stability.

DFM for Lower CNC Machining Costs

Design for Manufacturability (DFM) is perhaps the most powerful tool for machining cost control strategy. By integrating manufacturing considerations early in the design phase, significant savings can be realized. This approach is central to our transparent CNC manufacturing ethos.

Simplifying Geometry for Efficient Tool Paths

Complex features like deep pockets, thin walls, and intricate curves demand more machining time and specialized tooling. Simplifying the design by reducing feature count, standardizing radii, and ensuring adequate wall thicknesses can dramatically improve machinability and cut costs. Our engineers collaborate closely on DFM.

Optimizing Tolerances and Surface Finishes

Overly tight tolerances and extremely smooth surface finishes (e.g., Ra 0.4) drive up machining time, require specialized tools, and increase inspection costs. We work with clients to define the minimum necessary tolerances and finishes, ensuring functionality without incurring unnecessary expenses.

Standardizing Features for Tooling Efficiency

Using common hole sizes, thread types, and chamfer dimensions across a design or product line allows for the reuse of standard tooling. This reduces setup times, minimizes tool changes, and decreases overall tooling inventory costs. It streamlines the entire production process.

Case Study: DFM Savings on a Fascia Gun Shell

A client approached us with a fascia gun shell design featuring numerous deep, narrow internal pockets and non-standard radii. Our DFM analysis identified these as major cost drivers due to extended machining time and custom tool requirements.

Our Solution: We proposed design modifications, simplifying the internal geometry by combining pockets and standardizing radii. We also suggested a slightly less stringent, yet still functional, surface finish for non-critical internal areas.

Result: These DFM changes reduced machining time by 28% and tooling costs by 15%, leading to an overall unit cost reduction of 18% for the CNC fascia gun shell, without compromising performance or aesthetics. This demonstrates the power of collaborative engineering.

Optimize CNC Machining for Savings

Beyond design, the actual machining process offers numerous avenues for cost optimization. Our expertise in advanced CNC techniques directly translates into efficiency and savings. We are always seeking ways to refine our processes.

Tool Path Optimization and Multi-Axis Machining

Advanced CAM software and our experienced programmers optimize tool paths to minimize air cuts and maximize material removal rates. Utilizing multi-axis (e.g., 5-axis) machining reduces the need for multiple setups, cutting both cycle time and fixture costs. This is crucial for complex CNC fascia gun shells.

Fixture Design for Reduced Setup Times

Efficient fixture design is paramount for streamlining production. We engineer robust, quick-change fixtures that minimize setup and changeover times between parts or batches. This directly translates to lower labor costs and increased machine utilization, a core aspect of our machining cost control strategy.

Effective Chip Management and Coolant Use

Proper chip evacuation prevents tool wear and ensures a consistent cut, while optimized coolant delivery extends tool life and improves surface finish. These seemingly minor details significantly impact tool consumption and machining stability, contributing to overall cost reduction.

Post-Processing Techniques and Cost Implications

Surface finishing, deburring, and anodizing are common post-processing steps for CNC fascia gun shells. Each method carries different costs and aesthetics. We help clients select the most appropriate and cost-effective finishing process that meets their product’s functional and cosmetic requirements.

Here are common post-processing options and their cost impact:

| Process Type | Cost Impact | Benefits | Considerations |

|---|---|---|---|

| Deburring | Low | Removes sharp edges | Manual or automated |

| Bead Blasting | Medium | Matte finish, improves paint adhesion | Can alter dimensions slightly |

| Anodizing | Medium | Corrosion resistance, color, hard layer | Adds lead time, material specific |

| Polishing | High | Mirror-like finish | Labor intensive, precise control needed |

Partner for Transparent CNC Costs

Transparency in pricing is a cornerstone of our service as a source manufacturer. We believe in clear communication regarding all aspects of your CNC fascia gun shell project costs. Hidden fees are not part of our business model.

The Advantage of a Source Manufacturer Partnership

Partnering directly with a source manufacturer like ly-machining eliminates middleman markups. This direct relationship also provides unparalleled access to our engineering expertise, quality control systems, and production capabilities, ensuring better communication and accountability. We offer a truly transparent CNC manufacturing experience.

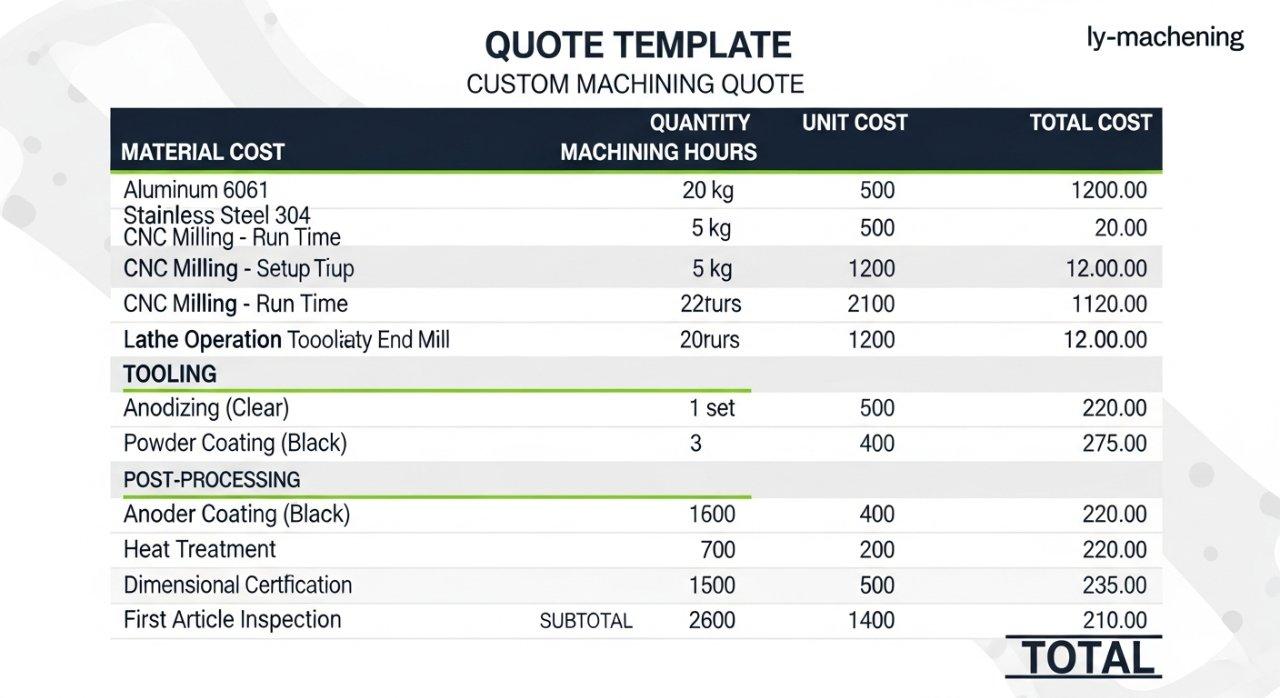

Understanding Transparent CNC Machining Quotes

Our quotes are detailed, breaking down costs by material, machining time, tooling, post-processing, and quality control. We explain each line item, allowing you to understand exactly what you’re paying for and where potential savings might exist. This fosters trust and enables informed decision-making.

Collaborative Engineering for Long-Term Savings

Our engineers collaborate with your team from the outset, offering DFM advice, material recommendations, and process optimization suggestions. This proactive approach ensures that cost-saving strategies are baked into the design and manufacturing plan, leading to sustainable, long-term savings on your CNC fascia gun shell.

Quality Control: Prevent Rework Costs

Quality is not an afterthought; it’s integrated into every stage of our process. Preventing defects is far more cost-effective than fixing them. This is a critical aspect of our machining cost control strategy.

Implementing Robust In-Process Quality Checks

From raw material inspection to in-process measurements and final dimensional verification, our rigorous AS9100-certified quality control system minimizes errors. Each part undergoes strict checks, ensuring consistent adherence to specifications and preventing costly rework.

Ensuring Consistent Part Accuracy and Aesthetics

Consistent part accuracy is vital for assembly and product functionality. We use advanced metrology equipment and statistical process control (SPC) to maintain tight tolerances and achieve the desired surface finishes. This ensures every CNC fascia gun shell meets your exact aesthetic and functional requirements.

The Cost of Poor Quality: Avoiding Recalls

Poor quality leads to increased scrap, rework, warranty claims, and potentially damaging product recalls. By investing in robust quality control and transparent CNC manufacturing, we help you avoid these significant financial and reputational costs. Our focus is on getting it right the first time.

Future Trends in Fascia Gun Shells

Staying ahead of manufacturing trends is key to long-term cost control. We continually invest in new technologies to enhance our capabilities and offer more efficient solutions.

Automation and Robotics for Cost Reduction

Integrating automation and robotics into our CNC machining processes reduces labor costs, increases throughput, and improves consistency. Automated material handling and machine tending are becoming standard, offering significant efficiencies for high-volume CNC fascia gun shell production.

Sustainable Practices in CNC Machining

Adopting sustainable manufacturing practices, such as optimizing energy consumption, recycling coolants and metal chips, and reducing waste, not only benefits the environment but also leads to operational cost savings. We are committed to eco-friendly production methods.

Expert Partnership for Cost Control

Effective CNC fascia gun shell cost control is a multifaceted endeavor, requiring deep expertise and a collaborative approach. It’s about smart choices at every stage of the product lifecycle.

Your Path to High-Quality, Cost-Effective Production

At ly-machining, we are more than just a vendor; we are your strategic partner. Our commitment to transparent CNC manufacturing, DFM for CNC parts, and continuous process optimization ensures you achieve high-quality, cost-effective production for your fascia gun shells. Let’s build your next success story together, leveraging our proven machining cost control strategy.

Ready to transform your fascia gun shell manufacturing with optimal quality and controlled costs? Contact our expert engineering team today for a free DFM consultation and a transparent, no-obligation quote tailored to your specific project needs. Let’s build your next success story together.

What is DFM in CNC machining?

DFM, or Design for Manufacturability, is an engineering methodology. It involves designing products to optimize all facets of the manufacturing process. The goal is to reduce production costs, improve quality, and shorten time-to-market.

How does material choice impact CNC fascia gun shell cost?

Material choice significantly impacts the CNC fascia gun shell cost through raw material price, machinability, and tool wear. Harder materials increase machining time and tooling expenses. Softer materials may require specific finishes or structural considerations.

Why is transparent CNC manufacturing important for cost control?

Transparent CNC manufacturing ensures that all cost components, from materials to labor and post-processing, are clearly itemized and understood. This transparency helps clients identify areas for optimization. It also builds trust, and fosters a collaborative relationship for long-term machining cost control strategy.