CNC: Key to Small Batch Cost Reduction

CNC machining is paramount for small batch cost reduction by eliminating tooling, enabling rapid, high-precision custom CNC parts, and delivering core CNC machining benefits.

Introduction: The Small-Batch Production Dilemma

Is your innovative small-batch product stalled by prohibitive production costs and slow lead times? You are certainly not alone in facing this common manufacturing challenge. Many designers and engineers often believe that high-quality, low-volume manufacturing is inherently expensive and fraught with delays.

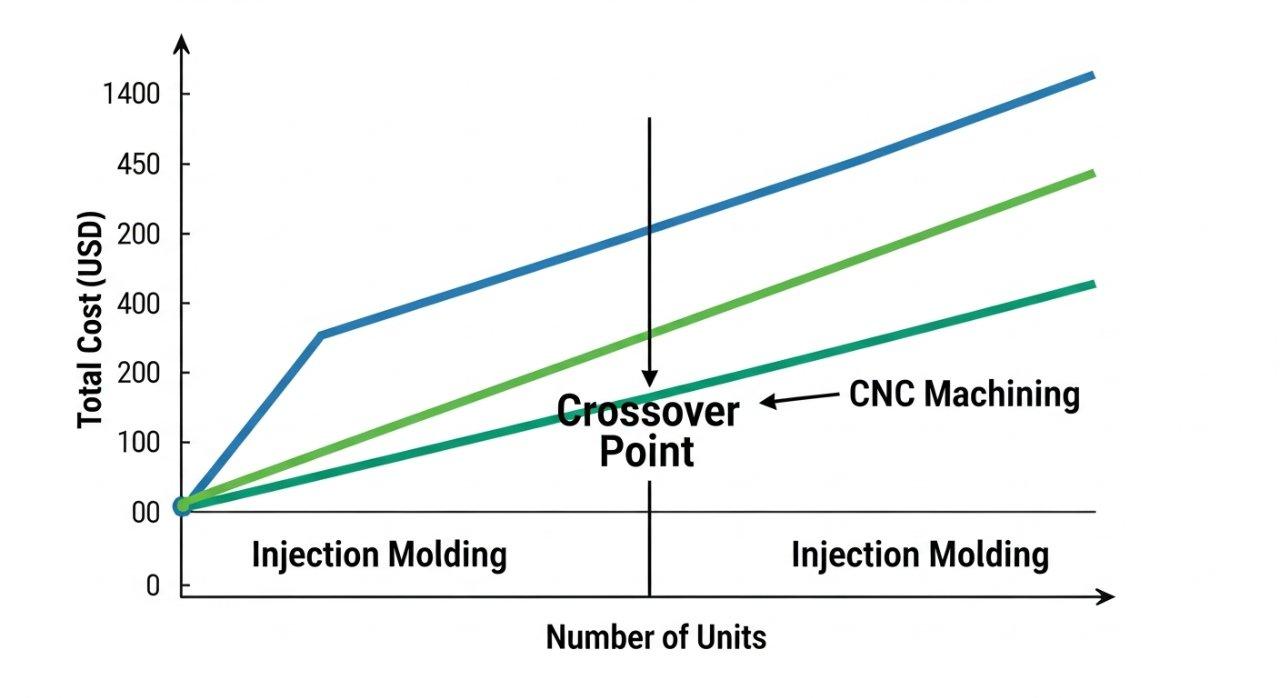

Traditional methods frequently involve significant upfront investments in molds and specialized tooling. These costs quickly become disproportionate when spread across a limited number of units, eroding profit margins and hindering market entry.

However, the landscape of manufacturing is evolving. We at ly-machining have seen firsthand how computer numerical control (CNC) technology fundamentally changes the economics of small-batch production, transforming these challenges into opportunities for growth and innovation.

Introduction: The Small-Batch Production Dilemma

High Tooling Costs & Setup Time

In our experience, one of the biggest deterrents for small-batch projects using conventional methods is the prohibitive cost of tooling. Injection molds, for instance, demand substantial upfront investment, often running into tens of thousands of dollars.

Beyond the financial outlay, the lead times for creating and refining these tools can be extensive. This slows down product development cycles, making rapid prototyping and market responsiveness nearly impossible for custom CNC parts.

Inefficient Production for Low Volumes

Traditional manufacturing processes are typically optimized for mass production, where economies of scale significantly reduce per-unit costs. For small batch production, these same processes become highly inefficient.

The labor required for manual setups, frequent changeovers, and specialized fixtures does not scale down economically. This leads to disproportionately high unit costs, limiting the viability of many innovative projects.

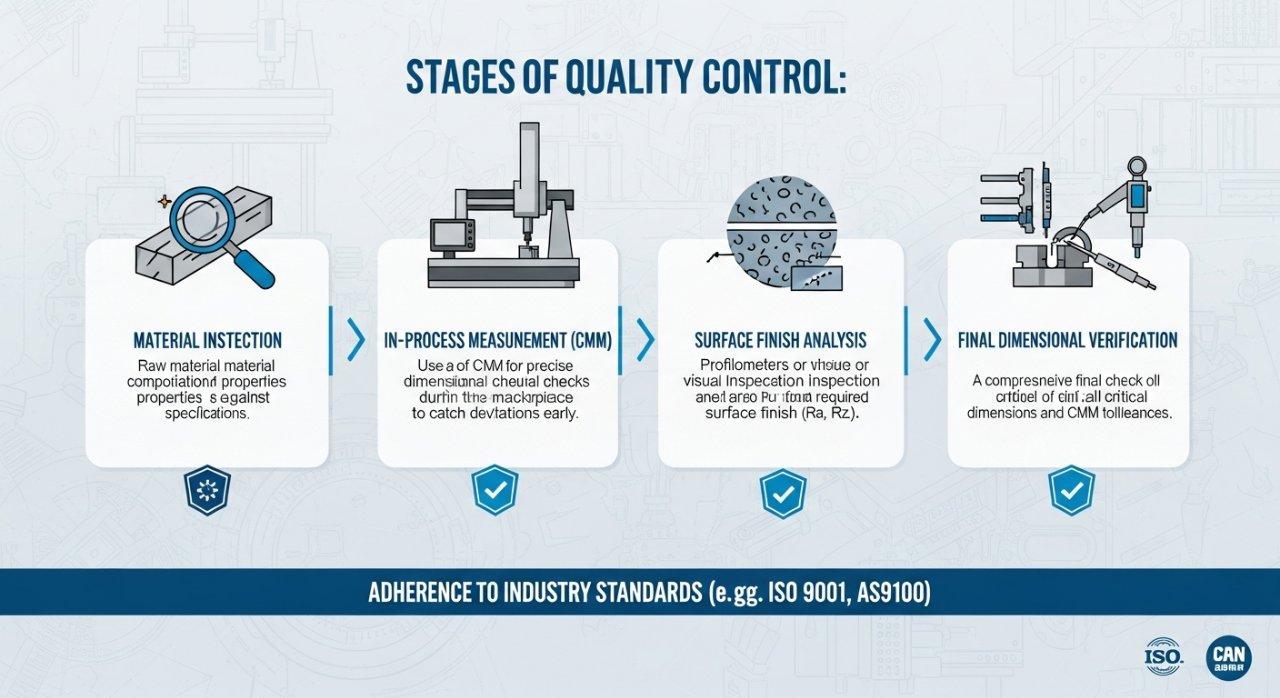

Quality Control & Consistency Issues

Maintaining consistent quality across small batches using manual or semi-manual processes presents a significant challenge. Human intervention introduces variability, making it difficult to achieve tight tolerances and uniform finishes.

Ensuring every custom component meets exacting specifications can become a laborious and expensive process, increasing scrap rates and rework. This directly impacts both cost and delivery schedules.

Why CNC Transforms Small Batch Production

Why CNC Machining Eliminates Tooling Costs

The fundamental advantage of CNC machining lies in its ability to operate directly from digital design files. This eliminates the need for expensive, dedicated molds and fixtures for each new part design.

Instead, the machine uses versatile cutting tools to subtract material, guided by precise G-code instructions. This direct digital-to-physical process dramatically reduces initial investment and setup costs, making small batches economically feasible.

CNC Machining Benefits for Rapid Prototyping

Rapid prototyping is a core strength of CNC machining, offering significant CNC machining benefits. Engineers can move from a CAD model to a physical custom CNC part in a matter of days, sometimes even hours.

This speed allows for quick design iterations and functional testing, accelerating product development cycles. The ability to quickly test and refine designs reduces the risk of costly errors later in the production process.

Custom CNC Parts: Material & Geometry Freedom

CNC machining offers unparalleled versatility in material choice, handling everything from common plastics and aluminum to exotic alloys and composites. This flexibility ensures that custom CNC parts can be made from the optimal material for their application.

Furthermore, the precision and multi-axis capabilities of modern CNC machines allow for the creation of incredibly complex geometries. Designs that would be impossible or prohibitively expensive with traditional methods become achievable.

Precision CNC Machining & Cost Savings

Precision CNC Machining Minimizes Waste

Our precision CNC machining processes are designed to optimize material utilization. By starting with a digital model, tool paths are meticulously calculated to remove only the necessary material.

This highly efficient material removal, coupled with tight tolerance control, significantly reduces scrap rates. Minimizing waste directly translates into lower material costs, a crucial factor in small-batch budgets.

Consistent Quality for Custom CNC Parts

The automated nature of CNC machining ensures repeatable precision, a key attribute for high-quality custom CNC parts. Once programmed, the machine performs each operation identically, part after part.

This consistent quality is essential for applications requiring strict adherence to specifications, such as those governed by ISO 9001 or AS9100 standards. Reduced variability means fewer defects and less need for costly rework or quality control interventions.

Optimized Material Use in CNC Machining

Beyond minimizing waste, CNC machining allows for strategic material choices. We can often use less expensive raw stock and achieve complex features through machining, rather than relying on expensive pre-formed or molded components.

Our engineers carefully select the right raw material and machining strategy to balance performance and cost. This optimization is a direct CNC machining benefit, ensuring cost-effectiveness without compromising integrity.

Optimizing Design & Production with CNC

CNC Machining Enables Flexible Design & Iteration

One of the most powerful CNC machining benefits is the unprecedented design flexibility it offers. Engineers are no longer constrained by the limitations of moldability or casting, allowing for more innovative and functional custom CNC parts.

Furthermore, design iterations are simple to implement; a change in the CAD model can be quickly translated into a revised part. This agility is crucial for product development and continuous improvement.

Streamlined Supply Chains: CNC Machining Benefits

By consolidating design, prototyping, and production into one highly efficient process, CNC machining simplifies the supply chain. This reduces reliance on multiple vendors and minimizes logistical complexities.

A streamlined supply chain leads to shorter lead times and improved responsiveness to market demands. This agility is a significant CNC machining benefit, especially for small businesses and startups.

Scalability for Custom CNC Parts Production

While ideal for small batches, CNC machining also offers inherent scalability. As demand for custom CNC parts grows, production can be easily increased by adding more machines or running existing ones for longer periods.

Unlike tooling-dependent methods, there are no new expensive molds to create when scaling up. This flexibility provides a seamless path from low-volume production to moderate volumes, supporting business growth.

Partnering for Custom CNC Parts Success

Why Choosing a Source Manufacturer for CNC is Key

As a source manufacturer, ly-machining provides direct access to our expertise and production capabilities. This eliminates intermediaries, leading to clearer communication, faster problem-solving, and more transparent pricing.

Our direct involvement ensures strict quality control at every stage, from material sourcing to final inspection. This is critical for delivering high-quality custom CNC parts consistently.

High-Quality & Transparent Precision CNC Pricing

At ly-machining, we are committed to transparent pricing for all precision CNC machining projects. Our quotes are detailed and upfront, with no hidden fees, allowing clients to accurately budget and understand their investment.

This transparency, combined with our rigorous quality assurance processes, ensures that clients receive exceptional value. We believe in building trust through clear communication and superior results.

Deep Technical Expertise: CNC Machining Benefits

Our team of experienced engineers and machinists possesses deep technical expertise in every aspect of CNC machining. We leverage this knowledge to optimize designs, select the best materials, and develop efficient machining strategies.

This expertise is a core CNC machining benefit, ensuring even the most complex custom CNC parts are produced to exacting standards. We are problem-solvers, dedicated to achieving the best possible outcome for your project.

Conclusion: Embrace CNC for Cost-Effective Production

For small-batch production, CNC machining stands out as the most cost-effective, flexible, and high-quality solution available today. By addressing the core pain points of tooling costs, lead times, and design limitations, it empowers businesses to innovate without compromise. The unparalleled precision CNC machining delivers also ensures consistent, high-quality custom CNC parts.

Your Next Step: Partnering for Custom CNC Parts

Embracing CNC machining means embracing efficiency, precision, and economic viability for your custom CNC parts. As a source manufacturer, ly-machining is equipped with the advanced technology and deep technical expertise to bring your designs to life.

We offer transparent pricing and a commitment to high-quality output, ensuring your project’s success. Partner with us to unlock the full CNC machining benefits for your small-batch needs.

Case Study: Accelerating Medical Device Development

**Problem:** A medical device startup needed 50 highly precise, custom titanium components for a new surgical instrument. Traditional manufacturing quotes involved a six-figure tooling cost and 12-week lead time, significantly delaying their FDA submission and market entry. The complexity of the parts also required extremely tight tolerances (±0.01mm) and a fine surface finish.

**Our Solution:** ly-machining proposed a multi-axis precision CNC machining solution. Our engineers worked closely with their design team to optimize the part geometry for efficient machining, ensuring manufacturability without compromising functionality. We leveraged our advanced 5-axis machines to mill the complex titanium components directly from medical-grade bar stock, bypassing the need for expensive and time-consuming tooling. Our in-house quality control, including CMM verification, guaranteed every part met the stringent specifications.

**Result:** The startup received all 50 high-quality custom CNC parts in just four weeks, with a total cost reduction of over 70% compared to traditional quotes. This allowed them to accelerate their FDA testing, stay within budget, and bring their innovative device to market ahead of schedule. Our transparent pricing and deep technical expertise proved crucial to their project’s success.

Ready to optimize your small-batch production costs without compromising quality or design? Contact our engineering experts today for a transparent quote on your custom CNC machining project or a technical consultation.

FAQ Section

What are the main CNC machining benefits for startups?

Startups greatly benefit from CNC machining by avoiding high initial tooling costs, enabling rapid prototyping for quick design iteration, and providing access to high-precision custom CNC parts without large minimum order quantities. This reduces financial risk and accelerates market entry.

How does precision CNC machining ensure quality?

Precision CNC machining utilizes automated, computer-controlled processes that ensure repeatable accuracy and tight tolerances. Our strict quality control protocols, including in-process checks and final inspections, guarantee consistent, high-quality custom CNC parts every time.

Can CNC machining handle complex custom CNC parts?

Yes, modern multi-axis CNC machines are exceptionally capable of producing complex custom CNC parts with intricate geometries and fine details. This includes internal features, complex curves, and precise angles that are challenging or impossible with other manufacturing methods.