Precision CNC for Camera Housings

Manufacturers frequently face significant hurdles when bringing advanced camera designs to fruition, often struggling with inconsistent part quality and unforeseen design-for-manufacturing issues. These challenges can lead to costly redesigns and critical delays in product development cycles. The intricacies of modern camera housings demand precision that generic manufacturing processes simply cannot deliver.

The consequences of these manufacturing missteps are substantial. Without stringent quality control and DFM expertise, companies risk releasing products with suboptimal performance, compromised durability, or even complete functional failures. This impacts brand reputation, inflates production costs, and delays market entry, placing innovative products at a distinct competitive disadvantage.

We offer an integrated solution, leveraging advanced CNC machining and comprehensive DFM analysis, to transform your complex camera housing designs into high-quality, precision-engineered components. This approach ensures unparalleled efficiency and robust technical support from concept to market.

High-precision CNC machining is essential for transforming intricate camera housing designs into durable, market-ready components, ensuring optimal performance and aesthetic integrity.

Initial Design & DFM for Camera Housing

Creating a superior camera housing begins long before machining, with a thorough understanding of its operational context. We meticulously analyze every requirement to ensure the final product meets exacting performance standards. This foundational step is crucial for overall project success.

Understanding Camera Housing Requirements

The functional and environmental demands placed upon a camera housing dictate its design and material choices. We consider every aspect to optimize both performance and longevity. Our team ensures the housing can withstand its intended operational environment.

Functional and Environmental Factors

Critical functional aspects include heat dissipation for internal electronics, electromagnetic interference (EMI) shielding, and secure mounting points for optical components. The housing must also protect sensitive internal components from physical shock and vibration.

Environmental factors like moisture, dust, temperature extremes, and chemical exposure significantly influence material selection and surface finishes. We analyze these conditions to specify appropriate protective measures, ensuring reliability in diverse settings.

| Environmental Factor | Design Consideration |

|---|---|

| Moisture & Dust | Sealing features, IP ratings |

| Temperature Extremes | Thermal expansion, material stability |

| Chemical Exposure | Corrosion-resistant coatings, material inertness |

Aesthetic and Ergonomic Considerations

Beyond pure functionality, the housing’s aesthetic appeal and ergonomic qualities are paramount, especially for consumer electronics. We focus on smooth lines, comfortable grips, and visually appealing finishes that align with brand identity.

The tactile experience, button placement, and overall form factor contribute significantly to user satisfaction. Our engineers collaborate closely with designers to balance technical requirements with optimal user interaction and visual coherence.

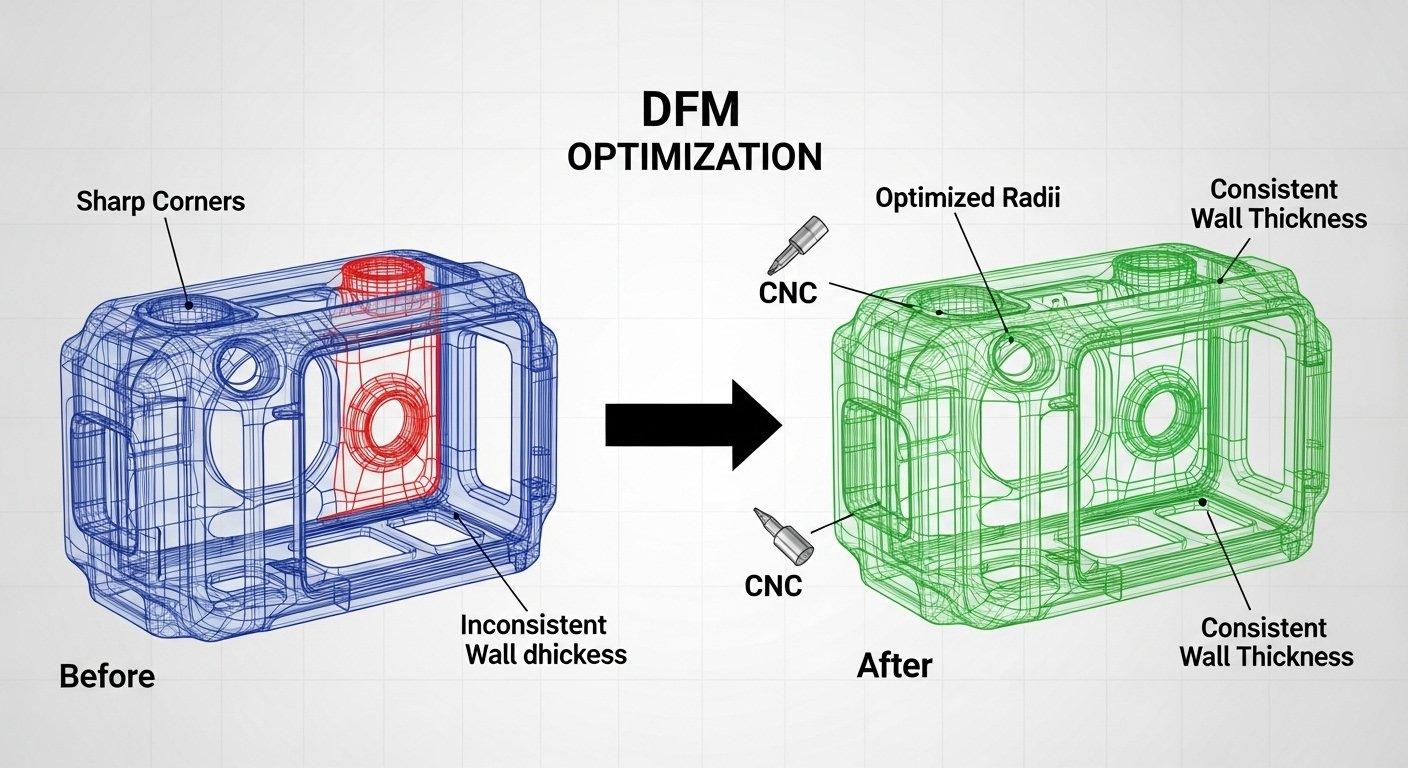

Design for Manufacturability (DFM) Review

Our DFM review process is proactive, identifying potential manufacturing challenges early in the design phase. This rigorous analysis prevents costly rework and accelerates production timelines. It is a cornerstone of our service.

Optimizing Geometry for CNC Machining

We scrutinize design geometries to ensure they are fully optimized for CNC machining. This involves simplifying complex features where possible, ensuring adequate corner radii for tool access, and maintaining consistent wall thicknesses.

Optimizing geometry minimizes machining time and reduces material waste, translating directly into cost savings and improved part quality. Our expertise in DFM ensures efficient and precise production.

Tolerance Analysis and Specification

Accurate tolerance specification is critical for the seamless assembly and reliable performance of camera components. We conduct detailed tolerance analysis, ensuring that critical dimensions meet the tightest possible specifications without over-engineering.

This analytical approach balances performance requirements with manufacturing feasibility, preventing issues during assembly. We use advanced software to simulate tolerance stacks and predict potential fitment problems.

| Component Feature | Typical Tolerance Range (mm) |

|---|---|

| Lens Mount Bore | ±0.015 – ±0.005 |

| Internal Ribs | ±0.05 – ±0.02 |

| Mating Surfaces | ±0.02 – ±0.01 |

Material Suitability Assessment

We assess proposed materials against the camera housing’s functional, environmental, and aesthetic requirements. This includes evaluating mechanical properties, thermal conductivity, and machinability characteristics.

Our material suitability assessment ensures the chosen material performs optimally throughout the product’s lifespan. We guide clients through selection, considering both performance and cost-effectiveness for their custom camera shell manufacturing.

Material Selection for CNC Camera Housings

Selecting the correct material is fundamental to the performance and durability of any custom camera shell manufacturing project. Our deep understanding of material science guides clients to optimal choices.

Common Alloys for Camera Housing

Various alloys are commonly utilized for camera housings, each offering a distinct balance of properties. Our selection process is tailored to specific application demands. We consider every detail.

Aluminum Alloys (e.g., 6061, 7075)

Aluminum alloys are a primary choice due to their excellent strength-to-weight ratio, machinability, and corrosion resistance. 6061 is highly versatile, offering good strength and weldability.

For applications demanding higher strength, 7075 aluminum is preferred, often used in aerospace. Both alloys can be easily anodized for enhanced durability and aesthetic finish, crucial for precision camera enclosures.

Magnesium Alloys (e.g., AZ91D)

Magnesium alloys, such as AZ91D, offer an even lighter alternative to aluminum, providing superior weight reduction. This is particularly advantageous for portable or drone-mounted camera systems.

While lighter, magnesium requires specific handling during machining and often needs protective coatings due to lower corrosion resistance. Its thermal dissipation properties are also excellent.

| Material Type | Key Advantage | Common Application |

|---|---|---|

| Aluminum 6061 | Versatility, cost | Consumer cameras, general enclosures |

| Aluminum 7075 | High strength | Professional cameras, drone components |

| Magnesium AZ91D | Lightweight | Action cameras, portable devices |

Other Specialized Materials

For niche applications, we explore specialized materials like titanium for extreme durability or certain engineering plastics for radio-transparent sections. The choice depends entirely on specific project requirements.

Our material expertise extends to advising on composites or hybrid structures where multiple material properties are needed. This ensures custom camera shell manufacturing meets every unique challenge.

Material Properties and Performance

Understanding the intrinsic properties of each material is crucial for predicting its behavior under various stresses. We match material properties to the expected performance demands of the camera housing.

Strength-to-Weight Ratio

A high strength-to-weight ratio is vital for portable cameras or those used in dynamic environments, optimizing both durability and ease of use. This ratio influences overall system design.

Thermal Dissipation & EMI Shielding

Effective thermal management is paramount for camera electronics, preventing overheating and ensuring stable operation. Many metal alloys naturally provide excellent thermal conductivity and EMI shielding.

EMI shielding protects sensitive internal components from external electromagnetic interference, maintaining signal integrity. We engineer our camera housing CNC machining processes to maximize these inherent benefits.

Corrosion Resistance and Durability

The chosen material and its finish must provide adequate corrosion resistance, especially in harsh environments like marine or industrial settings. Durability against impacts and abrasion is also a key factor.

We carefully select materials and apply appropriate surface treatments to extend the lifespan of the precision camera enclosure, even under rigorous use. This guarantees long-term product reliability.

Precision CNC Machining of Camera Housing

Our state-of-the-art facility is equipped for the most demanding camera housing CNC machining operations. We transform raw material into complex, high-precision camera enclosures with unmatched accuracy.

CAD/CAM Programming and Tool Path

The machining process begins with meticulous CAD/CAM programming, where design data is translated into precise machine instructions. This step is critical for accurate and efficient manufacturing.

Software Integration and Simulation

We utilize advanced CAD/CAM software to generate optimal tool paths, integrating directly with our CNC machines. Complex simulations are performed to verify machining strategies and prevent collisions.

This virtual prototyping ensures manufacturing efficiency and reduces potential errors before physical production begins. It is a key factor in our reliable prototype camera housing capabilities.

Fixturing and Workholding Strategies

Effective fixturing is essential for holding the workpiece securely and accurately throughout the machining process. We design custom fixtures that minimize vibration and ensure dimensional stability.

Our workholding strategies enable multi-sided machining in fewer setups, enhancing precision and reducing cycle times. This approach is fundamental to high-precision camera enclosure production.

High-Precision Machining Operations

Our advanced CNC machinery allows for a wide range of high-precision operations, catering to the intricate details required for camera housings. We are capable of executing complex geometries with exceptional accuracy.

Milling, Turning, and Drilling Techniques

We employ sophisticated milling techniques for creating complex external shapes and internal pockets, while turning operations achieve perfect rotational symmetry for lens mounts or cylindrical features. Precise drilling forms mounting holes and access ports.

These combined techniques allow us to produce highly integrated and functionally robust camera enclosures from a single block of material. Our expertise ensures optimal material utilization.

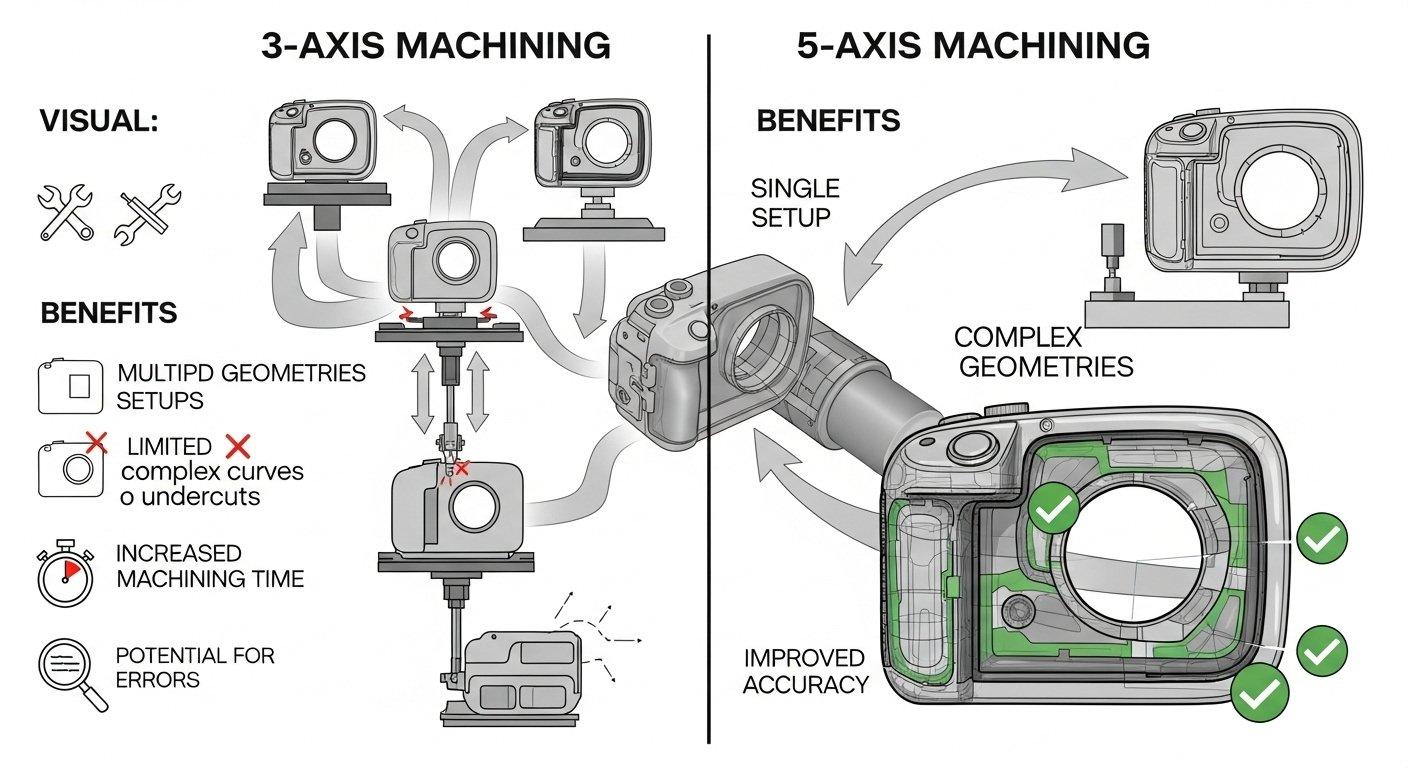

Multi-Axis Machining for Complexity

For the most intricate camera housing designs, our multi-axis CNC machines (e.g., 5-axis) provide unparalleled flexibility. They allow for machining complex curves and undercuts in a single setup.

This capability reduces human error, improves geometric accuracy, and significantly shortens lead times for even the most challenging designs. It is vital for advanced custom camera shell manufacturing.

Minimizing Chatter and Tool Wear

We meticulously control machining parameters, including spindle speed, feed rates, and tool selection, to minimize chatter and optimize tool life. This ensures a superior surface finish and consistent part quality.

Our skilled machinists employ advanced tooling and cutting strategies to maintain peak efficiency and precision throughout the production run. This attention to detail is critical for aluminum camera housing production.

In-Process Quality Checks & Monitoring

Throughout the machining process, we implement rigorous in-process quality checks and real-time monitoring. This proactive approach ensures that any deviations are identified and corrected immediately.

Dimensional Verification during Machining

Operators conduct periodic dimensional verifications using precision instruments directly on the machine. This ensures that the part adheres to tight tolerances at every stage of its transformation.

Surface Finish Control and Consistency

We continuously monitor the surface finish during machining to ensure it meets specified requirements, from smooth cosmetic surfaces to critical functional textures. Consistency across batches is paramount.

Post-Processing & Finishing Camera Housings

After precision CNC machining, camera housings undergo a series of post-processing and finishing steps. These enhance both the functional performance and aesthetic appeal of the final product.

Deburring and Surface Preparation

Meticulous deburring and surface preparation are essential to remove any sharp edges or burrs resulting from machining. This ensures safety and prepares the surface for subsequent treatments.

Manual and Automated Deburring

Depending on the complexity and volume, we employ both manual deburring by skilled technicians and automated methods. Automated processes ensure consistency for high-volume production.

Surface Blasting and Polishing

Surface blasting can create specific texture finishes or prepare the surface for better coating adhesion. Polishing achieves a high-gloss, aesthetically pleasing finish where required.

Anodizing and Protective Coatings

Anodizing is a common and highly effective surface treatment for aluminum camera housing production, providing enhanced durability and a range of aesthetic options.

Aesthetic and Functional Anodization

We offer various anodizing types, including Type II (cosmetic) and Type III (hard coat), in a spectrum of colors. Hard anodizing significantly increases surface hardness and corrosion resistance.

Powder Coating and Chemical Finishes

For certain applications, powder coating offers excellent chip resistance and durability in a wide array of colors. Chemical finishes provide specialized properties like enhanced corrosion protection or electrical conductivity.

Laser Engraving and Branding (Optional)

Laser engraving provides a permanent and precise method for adding identification, serial numbers, or branding elements directly onto the camera housing.

Permanent Marking for Identification

We offer permanent laser marking for critical information such as serial numbers, part numbers, and regulatory compliance. This ensures traceability and compliance.

Logo and Text Application

Company logos, product names, and custom text can be precisely engraved, enhancing brand visibility and product aesthetics. This is executed with exceptional clarity and detail.

Quality Control for Finished Camera Housings

Our commitment to quality extends through every stage, culminating in a rigorous quality control process for all finished camera housings. We guarantee adherence to the highest standards.

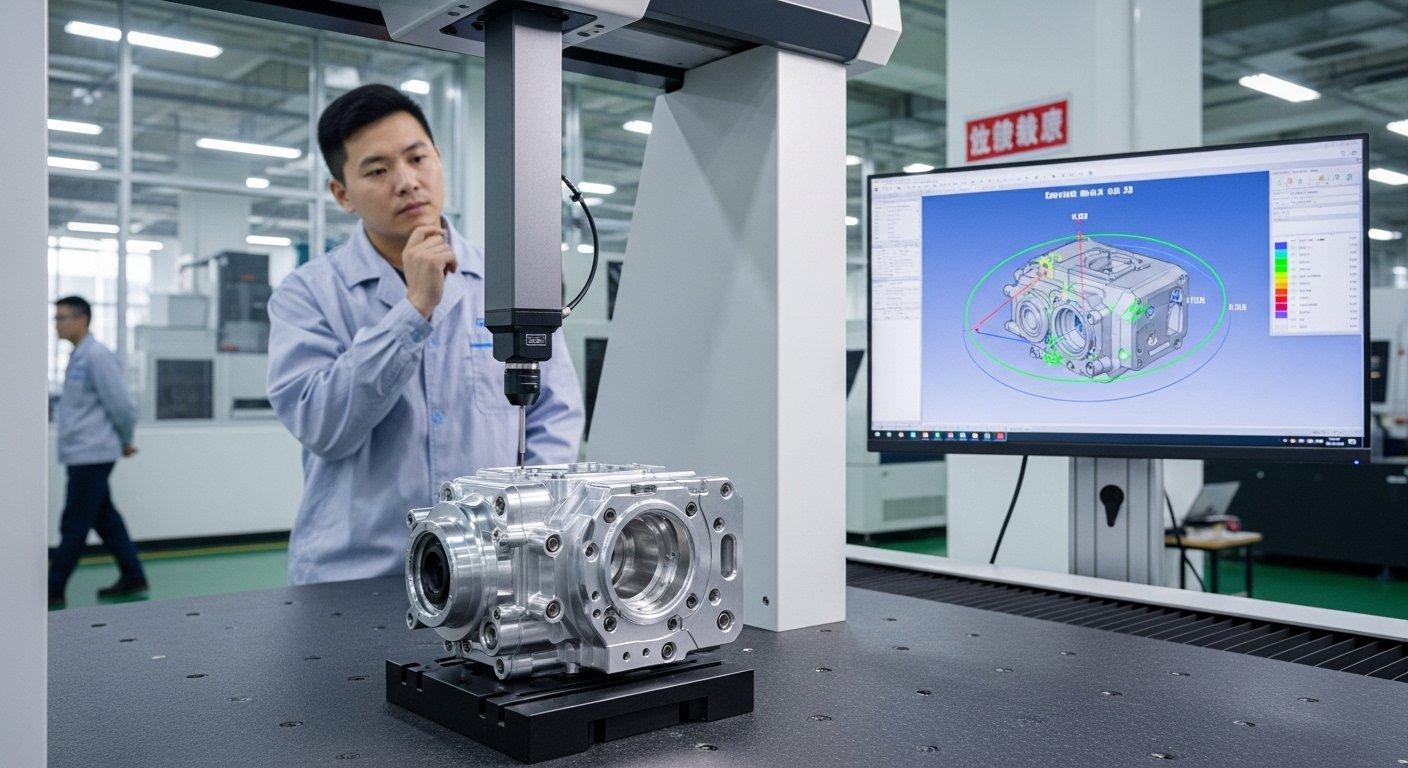

Comprehensive Inspection Protocols

Before dispatch, every camera housing undergoes comprehensive inspection protocols using advanced measurement equipment. This verifies all critical dimensions and features.

CMM (Coordinate Measuring Machine) Checks

We utilize CMMs to perform highly accurate, three-dimensional measurements of complex geometries and tight tolerances. CMM reports provide objective verification of part conformity.

Optical and Vision Inspection Systems

For detailed surface feature verification and small dimensions, our optical and vision inspection systems provide high-resolution imaging and automated anomaly detection.

Go/No-Go Gauging for Critical Features

For high-volume production, we employ custom Go/No-Go gauges for rapid and reliable verification of critical features. This ensures consistency and accelerates throughput.

Adherence to Specifications & Standards

Our quality assurance protocols ensure strict adherence to all client-provided specifications and industry standards. This guarantees that every precision camera enclosure meets its design intent.

Dimensional Accuracy Verification

Every finished part is verified against its engineering drawings to confirm dimensional accuracy, including feature location, hole diameters, and overall part geometry.

Surface Roughness and Aesthetics

We measure and inspect surface roughness to ensure it meets specifications, critical for both functional performance and cosmetic appeal. Aesthetic finishes are checked for uniformity.

Material Certifications and Traceability

We provide complete material certifications and maintain full traceability for all raw materials used. This ensures transparency and compliance with industry regulations.

Project Management & Delivery of Housings

Effective project management and seamless logistics are integral to our service, ensuring that your camera housing CNC machining project progresses smoothly from start to finish.

Communication and Progress Updates

Transparent communication is a cornerstone of our partnership. We keep clients informed at every stage of the manufacturing process, providing regular updates.

Transparent Project Tracking

Clients receive access to clear project tracking, detailing milestones, production status, and projected delivery dates. This fosters trust and provides peace of mind.

Expert Technical Support and Feedback

Our engineering team provides continuous technical support and proactive feedback, addressing any questions or concerns promptly. We offer solutions throughout the project lifecycle.

Efficient Logistics and Timely Delivery

We manage all aspects of logistics, ensuring efficient and timely delivery of your finished camera housings, regardless of your global location.

Global Shipping and Customs Expertise

With extensive experience in international shipping, we navigate customs procedures efficiently, ensuring smooth and rapid delivery. Our global network facilitates reliable transport.

Secure Packaging for Transit

All finished parts are meticulously packaged to prevent damage during transit. We use custom protective packaging designed to safeguard sensitive components.

After-Sales Support & Partnership

Our relationship with clients extends beyond delivery, with dedicated after-sales support and a commitment to long-term manufacturing partnerships.

Continuous Improvement Feedback

We value client feedback for continuous improvement, refining our processes to better serve future projects. This iterative approach drives excellence.

Long-Term Manufacturing Partnership

We strive to build enduring partnerships, becoming a trusted, reliable source manufacturer for all your future custom camera shell manufacturing needs.

Case Study

A startup developing an advanced compact drone camera faced significant challenges with their initial prototype camera housing. The design required extremely tight tolerances for lens alignment and heat dissipation, alongside a lightweight structure. Their previous manufacturer struggled to consistently meet the ±0.01mm tolerance for critical optical features, leading to assembly failures and compromised image quality.

Our solution began with a comprehensive DFM review, where we identified specific geometric modifications that improved machinability without compromising the original design intent. We recommended switching to a custom-machined magnesium alloy (AZ31B) to achieve the desired weight reduction while maintaining structural integrity.

Our 5-axis CNC machines executed the complex internal and external geometries in a single setup, drastically improving precision. We implemented in-process CMM checks and developed custom fixturing to guarantee lens bore concentricity and precise sensor seating.

The result was a precision camera enclosure that perfectly met all specified tolerances, enabling flawless assembly and superior optical performance. The lightweight magnesium housing provided optimal thermal management, improving drone flight time and camera stability.

The client successfully launched their drone ahead of schedule, attributing their success to our technical expertise and consistent quality.

Get a Free Quote

Invite readers to get a free quote or technical consultation.

Frequently Asked Questions

What materials do you machine?

We machine a diverse range of materials, primarily focusing on aluminum alloys like 6061 and 7075, and magnesium alloys such as AZ91D. We also work with specialized materials based on specific project requirements.

Our engineers provide expert guidance on material selection, ensuring the chosen material optimizes both performance and cost-effectiveness for your camera housing. This ensures ideal mechanical and thermal properties.

What tolerances can you hold?

Our precision CNC machining capabilities enable us to consistently hold exceptionally tight tolerances, typically down to ±0.01mm (0.0004 inches) for critical features. This ensures accurate component fit and functionality.

Specific achievable tolerances depend on the material, part geometry, and feature size, but we are equipped for the most demanding applications. Our advanced equipment and skilled technicians ensure superior accuracy.

How do you ensure quality?

We implement a multi-stage quality control process, starting with DFM analysis and in-process dimensional verification during machining. Every finished camera housing undergoes comprehensive inspection.

Our inspection protocols include CMM checks, optical vision systems, and adherence to ISO standards, providing full traceability and material certifications. This commitment guarantees superior product quality and reliability.