Precision CNC with Copper Alloys

Introduction: The Right Alloy, Optimized Machining

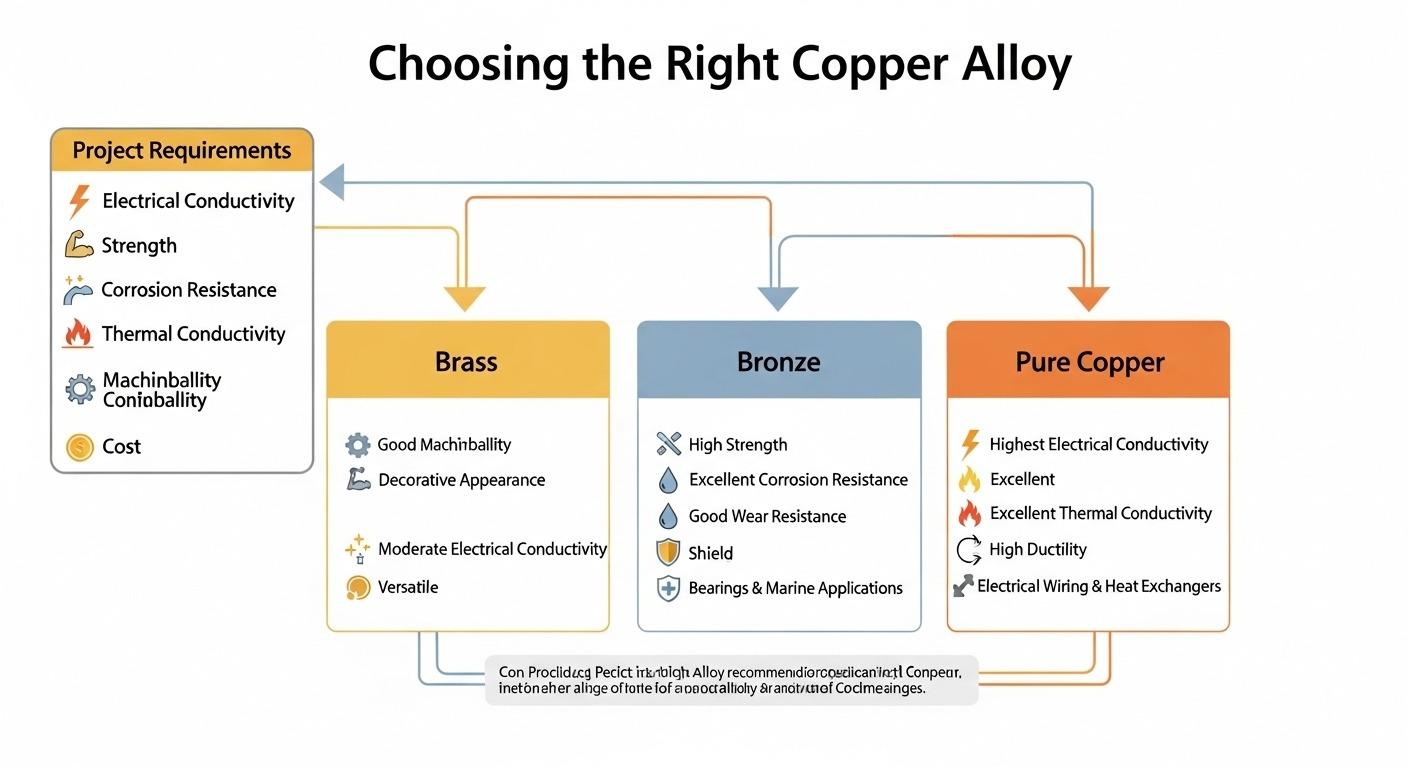

Choosing between Brass, Bronze, and Pure Copper for your CNC project isn’t just a material decision—it’s a critical engineering choice that directly impacts part performance, production cost, and lead time. Are you confident you’re selecting the *right* alloy to unlock optimal results? This uncertainty, often leading to suboptimal part function or budget overruns, truly agitates the entire development cycle, doesn’t it?

At ly-machining, we solve this by providing profound technical expertise, ensuring precisely engineered components optimized for both performance and cost. Our specific angle throughout this rigorous analysis centers on optimizing component performance and manufacturing efficiency through expert material selection and precise machining strategies, transforming your material challenges into precision solutions.

Copper alloys, including Brass, Bronze, and Pure Copper, are fundamental to numerous industrial applications due to their diverse properties. Understanding their distinct CNC machining characteristics is paramount for achieving optimal part performance and manufacturing efficiency. This guide meticulously compares these properties, offering insights from an engineer’s perspective.

Brass CNC Machining Characteristics

Brass, an alloy of copper and zinc, offers a unique blend of machinability and aesthetic appeal, making it a cornerstone in many industries. Its inherent characteristics provide both distinct advantages and specific challenges during CNC processing. Indeed, this material can be an absolute miracle in the right application.

Machinability and Chip Formation of Brass

Brass is renowned for its exceptional machinability, often considered the gold standard for free-machining operations. The presence of lead, or alternative bismuth and selenium additions in lead-free variants, significantly contributes to this ease of processing. Chips formed are typically short, brittle segments, which is incredibly advantageous for chip evacuation and preventing tangling—a truly desirable trait, believe me.

Tooling Considerations for Brass CNC

For brass, carbide tooling, or even high-speed steel (HSS) in some cases, performs admirably, boasting impressive tool life. We often find that specific coatings aren’t always necessary for straightforward operations. However, maintaining sharp cutting edges is perpetually important; dull tools, well, they just generate excessive heat, don’t they, leading to dimensional inaccuracies.

Surface Finish and Post-Processing for Brass

Achieving superior surface finishes on brass is remarkably straightforward, requiring minimal post-machining operations. A mirror-like finish is frequently attainable directly from the machine, a truly wondrous outcome. Sometimes, however, a light polishing step can further enhance its already brilliant luster.

Bronze Machining Properties Deep Dive

Bronze, an alloy primarily of copper with tin, aluminum, manganese, or silicon, presents a significantly more complex machining landscape than brass. Its diverse compositions dictate vastly different approaches to CNC processing. We understand these nuances implicitly.

Diverse Bronze Alloys and Machining

The term “bronze” encompasses a vast array of alloys, each possessing distinct metallurgical properties. Phosphor bronze, for instance, known for its strength and fatigue resistance, machines differently than aluminum bronze, which is celebrated for its corrosion resistance. Each variant demands a tailored approach to cutting parameters and tool selection; a one-size-fits-all methodology here would be an unbelievably foolish mistake.

Tool Wear and Heat Management for Bronze

Bronze alloys, especially those with high hardness or abrasive inclusions, inflict considerable tool wear—a perpetual nemesis for efficient production. Managing the generated heat is paramount; effective coolant application, often flood coolants, is not merely recommended, but absolutely essential to preserve tool integrity and prevent material distortion. Wait, I need to clarify this: without proper cooling, the material can warp, compromising critical tolerances.

Achieving Precision in Bronze CNC Parts

Despite the challenges, achieving exceptional precision with bronze is entirely feasible, albeit demanding rigorous parameter optimization. We meticulously adjust spindle speeds, feed rates, and depth of cut, often employing specific carbide grades with appropriate geometries. This careful orchestration yields parts with critical dimensional accuracy and robust mechanical properties.

Pure Copper CNC Processing Specifics

Pure copper, with its extraordinary electrical and thermal conductivity, is indispensable in applications requiring superior heat dissipation or current transfer. However, its unalloyed nature introduces unique, rather vexing, machining characteristics that demand specialized strategies.

Toughness and Thermal Conductivity of Copper

Pure copper is notoriously tough and ductile, leading to challenges like built-up edge (BUE) formation on cutting tools. Furthermore, its exceptionally high thermal conductivity means heat rapidly dissipates into the workpiece and the tool, requiring incredibly efficient cooling to prevent thermal expansion issues and maintain dimensional stability. It’s a double-edged sword, truly.

Strategies for Copper Chip Control in CNC

Controlling the long, stringy, and incredibly tenacious chips generated by pure copper is arguably the most formidable task. We employ specialized chip-breaker geometries on our cutting tools and often utilize high-pressure coolant to mechanically break and evacuate these problematic chips. Otherwise, entanglement—a truly disastrous scenario—becomes inevitable.

Preventing Defects in Copper CNC Machining

Preventing common defects like burrs, poor surface finish, and dimensional inaccuracies in copper machining hinges on precise tool selection, aggressive cooling, and optimized cutting parameters. Low cutting speeds and high feed rates, carefully balanced, often yield the best results, minimizing the material’s tendency to deform rather than cut cleanly. This is not a task for the uninitiated, let me assure you.

Copper Alloy Machinability Comparison

Understanding the comparative machinability indices of these copper alloys is not merely academic; it is an absolutely irreplaceable truth for engineers designing components and for manufacturers optimizing production. Our factory relentlessly validates these characteristics.

Machinability Index: Brass vs. Bronze vs. Copper

For those keeping score, the machinability index, often benchmarked against free-cutting brass (100%), provides a quantifiable metric. Brass generally enjoys the highest rating, followed by certain bronze alloys, with pure copper consistently ranking significantly lower. This index is not just a number; it dictates machine time, tool cost, and ultimately, project viability.

| Material Type | Typical Machinability Index (Free-Cutting Brass = 100%) | Chip Characteristics |

|---|---|---|

| Brass | 70-100% | Short, brittle |

| Bronze | 20-70% (Varies greatly by alloy) | Segmented, curly |

| Pure Copper | 20-30% | Long, stringy, tough |

Tool Life and Cost Implications for Alloys

Tool life directly correlates with material hardness and abrasiveness. Machining brass typically results in excellent tool life, whereas bronze, particularly those containing harder elements, will degrade tooling much faster. Pure copper, despite its softness, is incredibly tough and sticky, also reducing tool life and escalating consumable costs. Such a distinction is paramount for budget allocation, isn’t it.

| Material Type | Expected Tool Life (Relative) | Typical Coolant Requirement |

|---|---|---|

| Brass | Excellent | Moderate (Emulsion) |

| Bronze | Moderate to Low | High (Flood, specialized) |

| Pure Copper | Low | Very High (Flood, high-pressure) |

Achieving Desired Finishes Across Materials

Surface finish quality varies considerably. Brass, with its free-cutting nature, readily produces smooth, bright finishes. Bronze often achieves good finishes but may require more effort depending on the specific alloy. Pure copper, due to its ductility and propensity for BUE, is the most challenging, often yielding a rougher, smeared appearance unless meticulously managed.

Optimizing Material Choice for CNC Success

The strategic selection of the optimal copper alloy—this is where true engineering prowess shines. It is an intersection of application demands, manufacturing feasibility, and economic reality. Such a decision cannot be trivialized, not by any stretch of the imagination.

Application-Specific Alloy Selection Guide

For high electrical conductivity or thermal transfer, pure copper is the obvious, almost inevitable choice. But really, if machinability and aesthetic finish are paramount, brass often wins the day. When superior strength, wear resistance, or corrosion resistance is needed, certain bronze alloys become indispensable. Each application dictates its unique, non-negotiable requirements.

Balancing Cost, Performance, and Machining

The ultimate material selection, therefore, is a delicate balancing act. One must weigh the raw material cost, the anticipated machining time, tool wear expenses, and the ultimate required performance characteristics. A cheaper raw material that doubles machining time is not, in fact, cheaper at all. It’s a false economy, a truly deceptive illusion.

Expert Consultation for Your CNC Project

This entire complex equation, this multifactorial challenge, is precisely where our expertise becomes invaluable. Our engineers at ly-machining don’t merely machine parts; they consult, they analyze, they optimize. We assist clients in making informed decisions, preventing costly missteps before they even occur. This level of partnership is, frankly, what sets us apart.

Case Study: Revolutionizing Thermal Management with Copper

A client approached us, initially specifying a standard brass for a heatsink component due to its relative ease of machining. However, their primary concern was ultimately superior thermal dissipation in a compact electronic assembly. The brass, we quickly ascertained, simply would not suffice for the demanding thermal load, it was an absolutely fundamental miscalculation on their part.

Our solution involved a comprehensive re-evaluation. We recommended switching to a C11000 (pure copper) alloy, despite its known machining difficulties. Through meticulous optimization of tool geometries, implementing high-pressure internal coolant delivery, and applying specific cutting strategies, we not only successfully machined the complex heatsink geometry but also achieved the critical thermal conductivity required. This truly showcases our deep understanding of CNC machining copper alloys.

The result was a 25% improvement in the component’s thermal dissipation efficiency, directly impacting the electronic assembly’s reliability and lifespan, something brass could not have delivered. The client, moreover, significantly reduced warranty claims related to overheating, validating our initial, albeit challenging, recommendation. We turned a machining headache into a genuine competitive advantage.

Your CNC Copper Alloy Partner

Recap of Key CNC Machining Insights

We’ve traversed the intricate landscape of brass, bronze, and pure copper CNC machining, highlighting their distinct characteristics. From brass’s forgiving machinability to copper’s thermal prowess and bronze’s structural integrity, each alloy presents a unique set of engineering considerations for precision manufacturing.

Partnering with a Source Manufacturer

Ultimately, navigating these complexities demands more than just capable machinery; it requires profound, almost instinctual, technical expertise. As a source manufacturer, ly-machining provides not merely parts but solutions, grounded in transparent processes and an unwavering commitment to quality. This is our solemn pledge.

Article Summary:

This article meticulously compares the CNC machining characteristics of Brass, Bronze, and Pure Copper, emphasizing the critical role of material selection for optimal component performance and manufacturing efficiency. We detail each alloy’s machinability, tooling requirements, and surface finish potential, offering an expert guide for engineers and project managers. The piece underscores ly-machining’s deep technical expertise in navigating these complexities to deliver precision solutions.

What drives copper alloy selection?

The primary driver for selecting a copper alloy is the specific functional requirement of the part. This includes electrical or thermal conductivity, mechanical strength, wear resistance, or corrosion properties. Machinability and cost are critical secondary considerations, perpetually influencing the final choice.

Why is chip control crucial for copper?

Chip control is absolutely crucial for pure copper due to its ductility and tendency to form long, stringy chips. Poor chip control leads to entanglement, tool damage, and poor surface finish. Specialized tool geometries and high-pressure coolant are indispensable for effective evacuation.

How do you optimize tool life in bronze?

Optimizing tool life in bronze machining involves a multifaceted approach, truly. It requires selecting appropriate carbide grades with specific coatings, meticulously managing heat through flood coolants, and carefully calibrating cutting parameters. This strategy mitigates the abrasive wear inherent in many bronze alloys.