CNC Machining Factories: Delivery & Efficiency

Quick Solution: Selecting a reliable CNC Machining Factory for precision components hinges on proven Delivery Time CNC and demonstrated Machining Efficiency, ensuring consistent quality and project timelines.

Are unpredictable CNC machining delivery times costing your projects precious time, escalating costs, and creating sleepless nights? We understand the immense pressure to deliver high-quality products on schedule. Discover how partnering with a truly efficient source manufacturer can transform your production schedule and ensure unparalleled quality, giving you crucial peace of mind.

At ly-machining, our engineering team consistently focuses on operational excellence. We aim to mitigate the common pain points of delayed projects and inconsistent part quality. This guide will reveal the critical factors to evaluate when seeking a dependable CNC factory recommendation.

CNC Factory Choice: Delivery Speed

Why is on-time delivery critical?

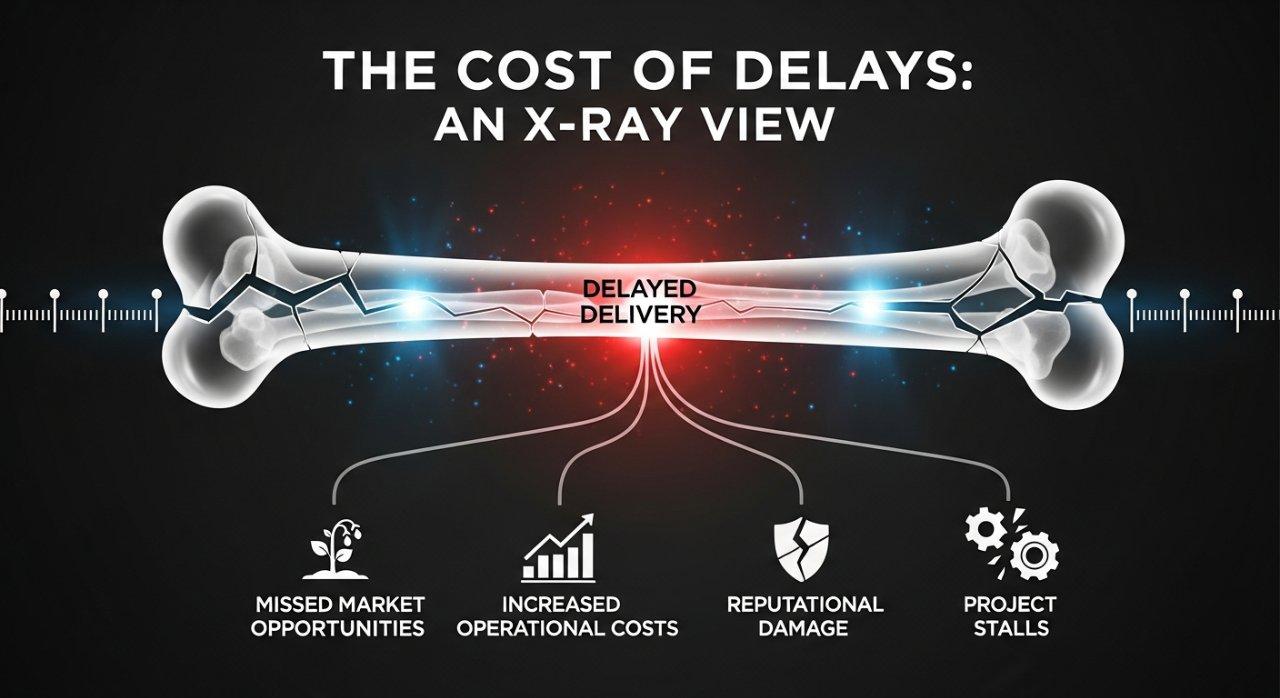

In our experience, missed delivery dates are not just minor inconveniences; they trigger a cascade of negative impacts. Late parts can halt assembly lines, push back product launches, and ultimately damage market reputation.

Reliable delivery directly translates to project stability and reduced carrying costs. For our clients, predictable lead times mean better planning and the ability to meet their own customer commitments without fail. This is fundamental to supply chain integrity.

What impacts CNC delivery times?

Several factors directly influence a CNC machining factory’s ability to deliver on time. Material availability, machine capacity, and the complexity of the part design are primary considerations.

Effective production scheduling and robust supply chain management are also paramount. A manufacturer’s internal processes, from quoting to quality control, significantly dictate the final lead time for any given project.

Table 1: Key Factors Influencing Delivery Time

| Factor | Impact on Delivery Time |

|---|---|

| Material Sourcing | Delays from suppliers directly affect production start. |

| Machine Availability | Insufficient capacity or frequent breakdowns cause lags. |

| Part Complexity | Intricate designs require longer machining cycles. |

| Process Efficiency | Streamlined workflow reduces bottlenecks. |

| Quality Control | Rigorous, but efficient, checks prevent rework delays. |

Red flags for unreliable suppliers?

Identifying potential issues early can save significant headaches. Vague communication regarding lead times is a major red flag, often indicating a lack of internal control or transparency.

Consistently missing previous project deadlines or offering unrealistically low quotes without clear justification should raise concerns. These often signal underlying operational inefficiencies or a compromised quality approach.

Optimizing CNC Efficiency: Core Factors

How does technology improve efficiency?

Advanced CNC machinery, such as 5-axis milling centers and automated loading systems, significantly boosts machining efficiency. These technologies reduce setup times and allow for more complex operations in a single setup.

Integrated CAD/CAM software solutions streamline programming and minimize human error. Real-time monitoring systems provide crucial data for optimizing machine utilization and predictive maintenance.

What role does process control play?

Strict process control, often guided by lean manufacturing principles, is vital for achieving high Machining Efficiency. Standardized operating procedures (SOPs) ensure consistency and reduce variability in production.

Implementing rigorous in-process inspections and statistical process control (SPC) helps identify and correct deviations early. This prevents the costly production of scrap parts and minimizes rework.

Table 2: Aspects of Effective Process Control

| Aspect | Benefit to Efficiency |

|---|---|

| Standardized Procedures | Ensures consistent quality and reduces errors. |

| Regular Maintenance | Prevents unexpected machine downtime. |

| In-Process Inspection | Catches defects early, avoiding costly rework. |

| Data Analysis | Identifies bottlenecks and areas for improvement. |

| Employee Training | Enhances skill and reduces operational mistakes. |

Why demand transparent pricing?

Transparent pricing is a hallmark of an efficient and trustworthy CNC Machining Factory. It means clear breakdowns of costs for materials, labor, machine time, and finishing processes.

This clarity helps clients understand the value they are receiving and avoids unexpected charges. It also fosters trust, demonstrating that the supplier has confidence in their cost structure and operational efficiency.

Our Factory’s Delivery & Quality Promise

How do we ensure fast turnarounds?

At ly-machining, our commitment to fast turnarounds begins with robust internal planning and capacity management. We leverage advanced production scheduling software to optimize machine allocation and workflow.

Our lean manufacturing principles minimize waste and unnecessary delays at every stage of the process. This proactive approach allows us to provide reliable Delivery Time CNC even for complex projects.

What quality standards do we uphold?

We adhere to stringent international quality standards, including ISO 9001 and AS9100 certifications. This commitment ensures that every part we produce meets the highest benchmarks for precision and performance.

Our comprehensive quality control system incorporates multiple inspection points, from raw material verification to final product validation. This meticulous approach guarantees consistent quality for every component leaving our facility.

Table 3: Our Core Quality Certifications

| Certification | Focus Area |

|---|---|

| ISO 9001 | General quality management systems and customer focus. |

| AS9100 | Quality management for aerospace and defense. |

Our technical expertise for projects?

Our team comprises highly skilled engineers and experienced machinists with deep technical expertise across various materials and complex geometries. We offer Design for Manufacturability (DFM) support.

This collaborative approach helps optimize designs for cost-efficiency and performance, often identifying potential issues before production begins. Our technical insights are invaluable in achieving superior project outcomes.

The benefits of a source manufacturer?

As a true source CNC Machining Factory, we maintain complete control over the entire production process, from material procurement to final inspection. This eliminates third-party markups and potential communication gaps.

This vertical integration provides unparalleled transparency and accountability. Clients benefit from direct communication with the manufacturing team, leading to quicker problem resolution and more reliable project execution.

Partnering for Reliable CNC Outcomes

How do case studies demonstrate reliability?

Case studies provide concrete evidence of a CNC factory’s capabilities and reliability. They showcase how a manufacturer has successfully addressed specific client challenges, often highlighting critical delivery and quality metrics.

They offer insight into problem-solving approaches, technical expertise, and overall project management prowess. A strong case study builds confidence and demonstrates real-world performance.

What questions to ask potential partners?

When seeking a CNC Factory Recommendation, probe deeply into their operational practices. Inquire about their typical lead times for similar parts, their capacity utilization, and their contingency plans for unexpected issues.

Ask about their quality control protocols, certifications, and how they handle design changes or rework. Transparent answers to these questions are indicative of a reliable and professional partner.

Table 4: Essential Questions for CNC Suppliers

| Question | Why it Matters |

|---|---|

| What are your standard lead times? | Direct measure of Delivery Time CNC capability. |

| How do you ensure quality control? | Reveals their commitment to part integrity. |

| Can you provide DFM support? | Indicates technical expertise and cost-saving potential. |

| What are your communication protocols? | Crucial for project transparency and issue resolution. |

| How do you handle rush orders? | Shows flexibility and capacity for urgent needs. |

Ready for a streamlined CNC project?

Choosing the right CNC Machining Factory is a critical decision that impacts your project’s success. Prioritizing partners who can demonstrate consistent Delivery Time CNC and superior Machining Efficiency is paramount.

We invite you to experience the difference that a dedicated, expert source manufacturer can make. Our commitment to precision, transparency, and timely delivery ensures your components meet specifications every time.

Case Study: Accelerating Medical Device Prototype to Production

Problem: A medical device startup required ultra-precise, complex titanium components for a new diagnostic device. Their previous supplier struggled with inconsistent quality and extended lead times, jeopardizing their product launch timeline and crucial funding rounds. The designs demanded micron-level tolerances and a flawless surface finish.

Our Solution: ly-machining collaborated closely with the client’s R&D engineers. Our DFM specialists identified optimizations in the design that reduced machining time without compromising functionality. We utilized our 5-axis CNC machines and stringent in-process CMM inspection to guarantee the required tolerances and surface finish. Our expedited process flow ensured material was sourced, machined, and validated efficiently.

Result: We delivered the first batch of prototypes ahead of the revised schedule, enabling the client to complete their testing phase on time. This prompt delivery and the superior quality of the components secured their next round of investment, moving their innovative device closer to market. The client gained a reliable, long-term partner for their subsequent production needs.

Call to Action: Ready to eliminate project delays and secure consistently high-quality CNC parts? Contact us today for a free consultation or request a transparent quote. Let our technical experts demonstrate the difference of partnering with a true source manufacturer.

How do you guarantee delivery times?

We guarantee delivery times through rigorous production planning, real-time capacity monitoring, and a robust supply chain. Our lean manufacturing processes also minimize potential bottlenecks and delays. This integrated approach ensures we meet our commitments consistently.

What materials do you specialize in?

We specialize in machining a wide range of materials, including various grades of aluminum, stainless steel, titanium, and engineering plastics. Our expertise extends to superalloys and exotic materials for specialized applications. Our team can advise on optimal material selection.

Can you handle complex part geometries?

Yes, our advanced multi-axis CNC machines and experienced engineering team are adept at handling highly complex part geometries. We leverage sophisticated CAD/CAM software for precision programming. We excel in intricate designs requiring tight tolerances.