You have a design that benefits from the unique shape of an aluminum extrusion, but standard extrusion tolerances are not precise enough for your application. Critical features like mounting holes, pockets, and interfaces demand higher accuracy.

This reliance on imprecise extrusions can lead to assembly problems, subpar performance, and a product that lacks a professional finish. Conversely, starting the entire component from a solid block of aluminum is incredibly wasteful and drives up costs through excessive material and CNC machining time.

The superior solution is the secondary CNC machining of aluminum extrusions. Ly-machining masterfully combines the cost-effectiveness of near-net shape extrusions with the accuracy of CNC milling. This hybrid approach transforms standard profiles into high-quality, complex, and affordable precision parts.

From Profile to Precision Part via CNC Machining

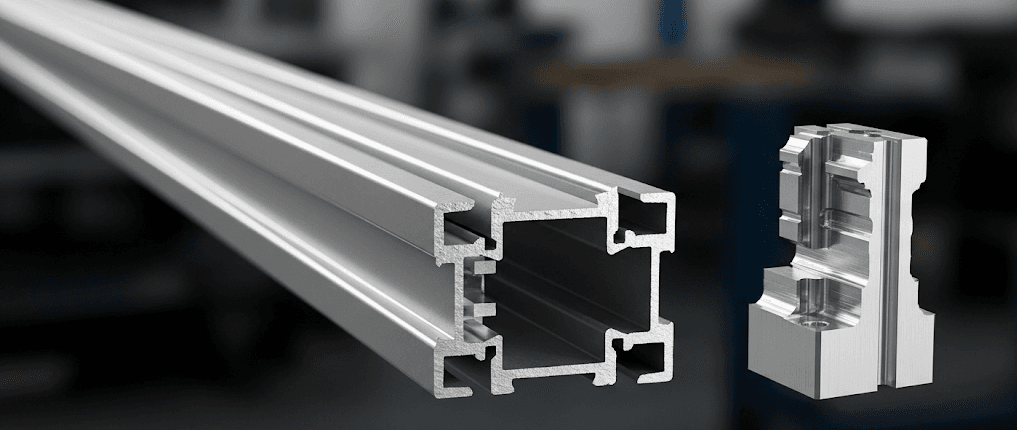

CNC machining of an aluminum extrusion is an advanced, hybrid manufacturing process. It begins with a custom-shaped aluminum profile—the extrusion—which is already close to the final desired shape. From there, we utilize precision CNC milling or turning to add fine details, achieve tight tolerances, and create complex features that the extrusion process alone cannot form. This powerful method allows for the creation of intricate precision parts while dramatically reducing material waste and overall CNC machining time.

Therefore, leveraging this two-step approach is a formidable strategy for optimizing both project cost and final quality. Furthermore, understanding the workflow, from the raw aluminum extrusion to the finished component, is essential for any engineer looking to implement design for manufacturing (DFM) principles. Consequently, this guide will detail the journey of an aluminum extrusion as it is expertly transformed into a precision part through state-of-the-art CNC machining.

Why Start with an Aluminum Extrusion for CNC Machining?

Choosing to begin with an aluminum extrusion before CNC machining offers significant advantages over machining from a solid billet. The primary benefit is starting with a near-net shape, a profile that is already very close to the final part’s geometry.

This immediately reduces the amount of material that must be removed. Less material removal means less waste, which is both environmentally responsible and cost-effective. It also substantially cuts down on the required CNC machining time, leading to faster production cycles and lower costs for your precision parts.

Moreover, the extrusion process itself aligns the grain structure of the aluminum alloy, which can enhance the strength-to-weight ratio of the final component. This makes an aluminum extrusion the ideal starting point for structural and high-performance precision parts.

The CNC Milling Process for Aluminum Extrusions

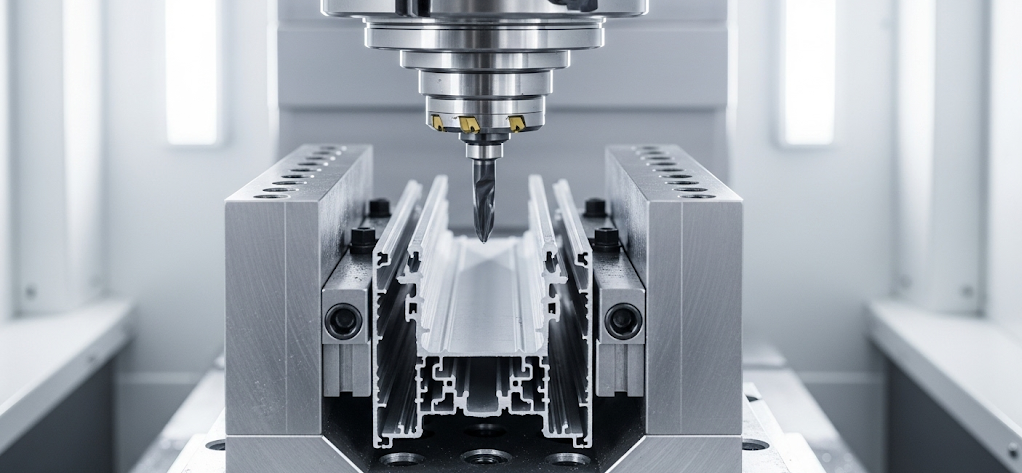

Once the raw aluminum extrusion is sourced, the transformation into a precision part begins with CNC milling. The first and most critical step is creating custom fixturing. Due to their often complex and irregular shapes, standard vises are not suitable for holding extrusions securely.

We design and produce custom jigs and fixtures that grip the aluminum extrusion firmly without warping or damaging it. This robust workholding is the foundation for all subsequent CNC machining operations, ensuring stability and repeatability.

With the extrusion securely in place, the CNC milling machine executes the programmed toolpaths. It precisely cuts features such as holes, threads, slots, pockets, and complex contoured surfaces. Our multi-axis machines can access the part from various angles, allowing us to create intricate geometries on multiple faces of the aluminum extrusion in a single setup.

Achieving High-Tolerance Precision Parts

The ultimate goal of this process is to produce high-tolerance precision parts that meet exacting specifications. While the aluminum extrusion process can hold tolerances of around +/- 0.5mm, CNC machining elevates this to a much higher standard.

Using advanced CNC milling techniques, we can achieve tolerances as tight as +/- 0.025mm on critical features. This level of accuracy is essential for precision parts used in aerospace, medical devices, and high-end electronics, where fit and function are paramount.

Beyond dimensional accuracy, CNC machining defines the surface finish. We can deliver a range of finishes, from a standard machine finish to brushed or bead-blasted textures, ensuring your precision parts meet both functional and aesthetic requirements. This meticulous attention to detail turns a simple aluminum extrusion into a refined, high-value component.

| Manufacturing Method | Material Waste | Machining Time | Cost-Effectiveness | Design Suitability |

| CNC Machining from Billet | High | High | Low (for complex shapes) | Good for any geometry, but wasteful. |

| CNC Machining from Extrusion | Low | Low | High | Ideal for parts with a constant cross-section. |

Common Applications for Machined Aluminum Extrusions

The combination of extrusion and CNC machining is incredibly versatile, making it suitable for a wide array of industries and products. The ability to create lightweight, strong, and complex precision parts is highly valuable.

One of the most common applications is the manufacturing of custom heat sinks. The extrusion process forms the fins, and CNC milling adds precise mounting holes and surfaces for mating with electronic components. This is a perfect example of a cost-effective precision part.

Other widespread uses include electronic enclosures, where an aluminum extrusion forms the body and CNC machining creates openings for connectors, buttons, and displays. It is also used for architectural components, custom guide rails, robotics frames, and structural brackets where both a specific profile and high precision are required.

Your Partner for Precision Parts: Ly-machining

Choosing the right manufacturing partner is key to successfully realizing your design. Ly-machining is your one-stop solution for transforming an aluminum extrusion into a finished precision part. We manage the entire supply chain, from sourcing the custom extrusion die to final inspection.

Our expertise in both extrusion technology and advanced CNC machining allows us to provide valuable design for manufacturing (DFM) feedback. We help you optimize your design to ensure it is both functional and cost-effective to produce.

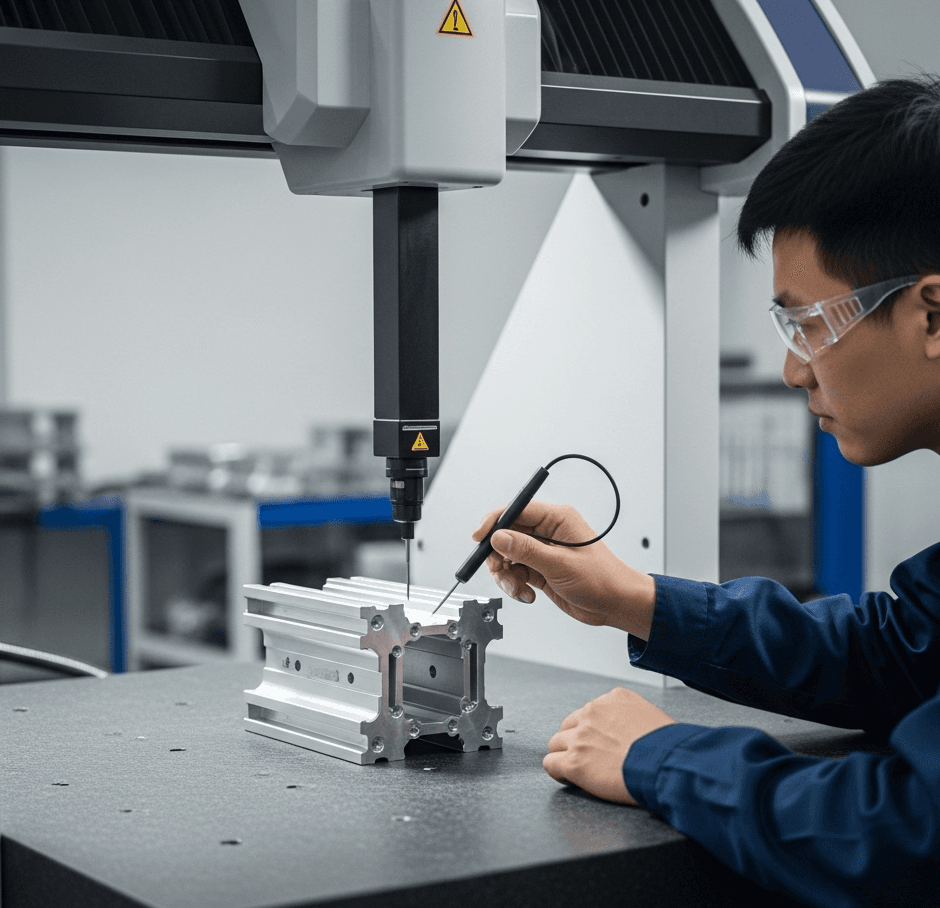

Every precision part that leaves our facility undergoes a rigorous quality control process. Using CMMs, digital calipers, and other metrology tools, we verify that every dimension and feature on your machined aluminum extrusion meets your exact specifications. Trust ly-machining to deliver quality you can count on.

Related Questions

What aluminum alloys are best for extrusion and CNC machining?

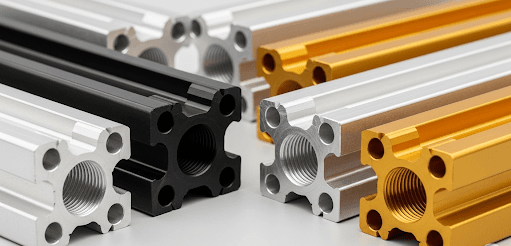

The most common and versatile alloys for this dual process are from the 6000 series. 6061 aluminum is a popular choice, offering an excellent combination of strength, corrosion resistance, and machinability. 6063 aluminum is another frequent option, prized for its superior surface finish and its suitability for creating very complex extruded shapes. Both alloys are highly receptive to CNC machining, allowing for the creation of high-quality precision parts.

How does fixturing work for complex aluminum extrusion profiles?

Fixturing is a critical, custom step in the CNC machining of any aluminum extrusion. We design custom jigs, often milled from steel or aluminum, that precisely match the negative profile of the extrusion. This creates a secure “nest” for the part to sit in. Clamps are then strategically applied to hold the part down without causing any deflection, ensuring the CNC milling operations are stable and highly accurate.

Frequently Asked Questions

1. What tolerances can be achieved when CNC machining an aluminum extrusion?

While the base aluminum extrusion has relatively loose tolerances, the secondary CNC machining operations are extremely precise. For critical features like hole diameters, positions, and milled pockets, we can consistently hold tolerances of ±0.025 mm to ±0.1 mm, depending on the part’s geometry and requirements.

2. Can you machine all surfaces of an aluminum extrusion?

Yes, with modern multi-axis CNC machining centers, we can access and machine features on virtually every surface of an aluminum extrusion. Our 4-axis and 5-axis CNC milling capabilities allow the cutting tool to approach the part from multiple angles, enabling the creation of complex features on the front, back, top, bottom, and sides of the profile in a single setup.

3. What is the typical lead time for creating precision parts from extrusions? The lead time involves two main stages. First is the creation of the extrusion die and the production of the raw profiles, which can take several weeks. Once the aluminum extrusion is available, the CNC machining stage is much faster, often taking 1-3 weeks depending on the complexity of the precision part and the quantity required. We work to streamline this entire process for you.