Unraveling “Orange Peel” on CNC Aluminum

Is the dreaded “orange peel” texture sabotaging the aesthetics and performance of your CNC machined aluminum parts? You’re not alone. This common defect plagues countless manufacturers, leading to costly rework, delayed production, and compromised product integrity. But what if you could understand its true origins and, more importantly, eliminate it for good?

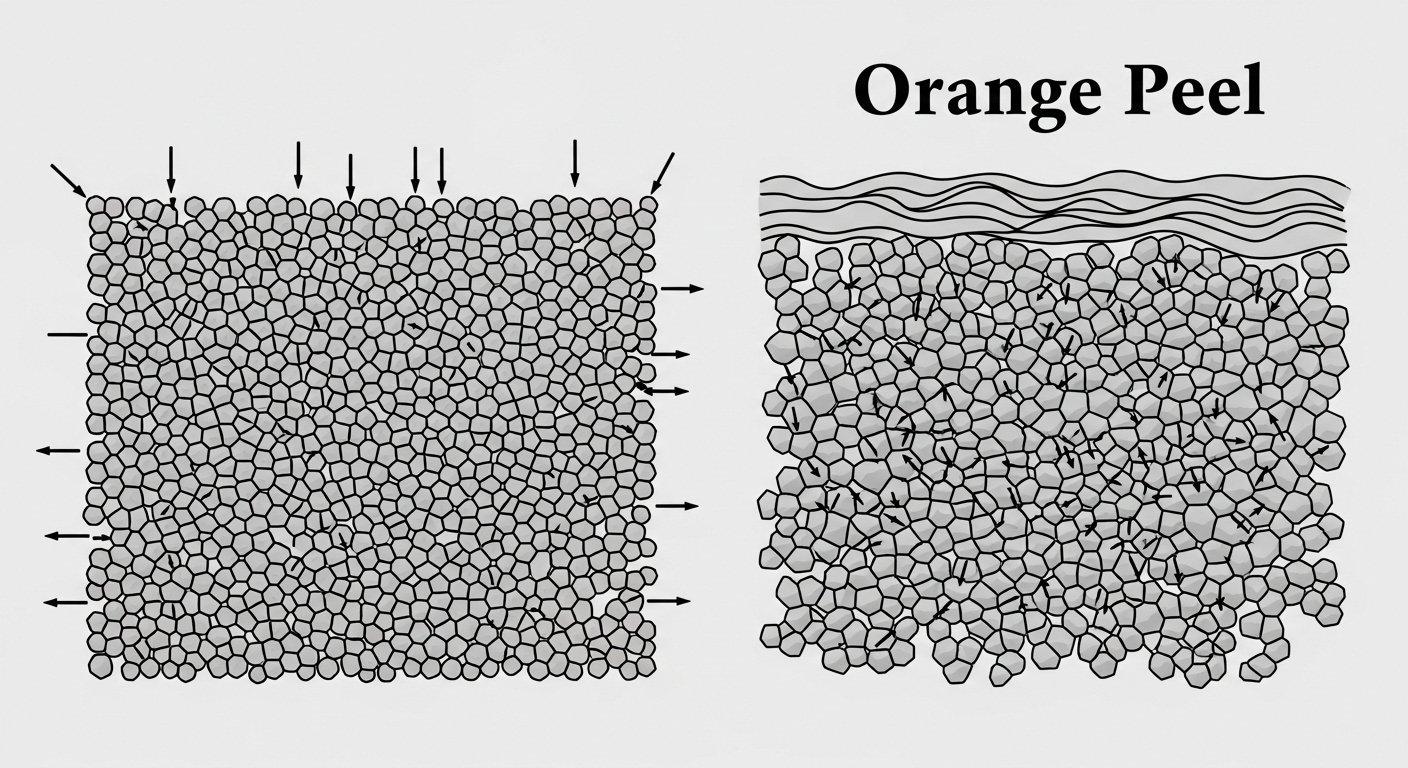

Orange peel” texture on CNC machined aluminum is a surface defect characterized by a dimpled, uneven appearance resembling the skin of an orange. It typically arises from issues related to material properties, machining parameters, tool selection, or machine dynamics. Addressing this defect is crucial for parts requiring high aesthetic quality or precise dimensional accuracy, such as those used in aerospace, medical devices, and robotics.

What Causes Aluminum “Orange Peel” Texture?

Understanding the root causes of “orange peel” is the first step toward prevention. This texture is not merely a cosmetic flaw; it signifies underlying material deformation or improper chip formation during the machining process. At ly-machining, our expert engineers analyze various contributing factors to identify and mitigate this issue.

Material properties and alloy composition

Aluminum alloys, particularly those with specific compositions or heat treatments, can be inherently prone to “orange peel.” The microstructure, including grain size and uniformity, plays a significant role. Large, uneven grain structures in certain alloys can deform inconsistently under tool pressure, leading to surface irregularities.

The work-hardening characteristics of an alloy also contribute. If the material hardens too rapidly ahead of the cutting edge, it can cause uneven material flow and subsequent surface roughness. Alloys chosen without consideration for machining characteristics are frequently implicated.

Table: Common Aluminum Alloys and Machinability for Surface Finish

| Alloy Type | Typical Microstructure | Machinability for Smooth Finish |

|---|---|---|

| 6061-T6 | Fine, uniform grains | Good |

| 7075-T6 | Slightly coarser grains | Good, but demands precise tools |

| 2024-T3/T4 | Fine, strong precipitates | Moderate, chip control critical |

| 5052-H32 | Recrystallized, uniform | Good, less prone to build-up |

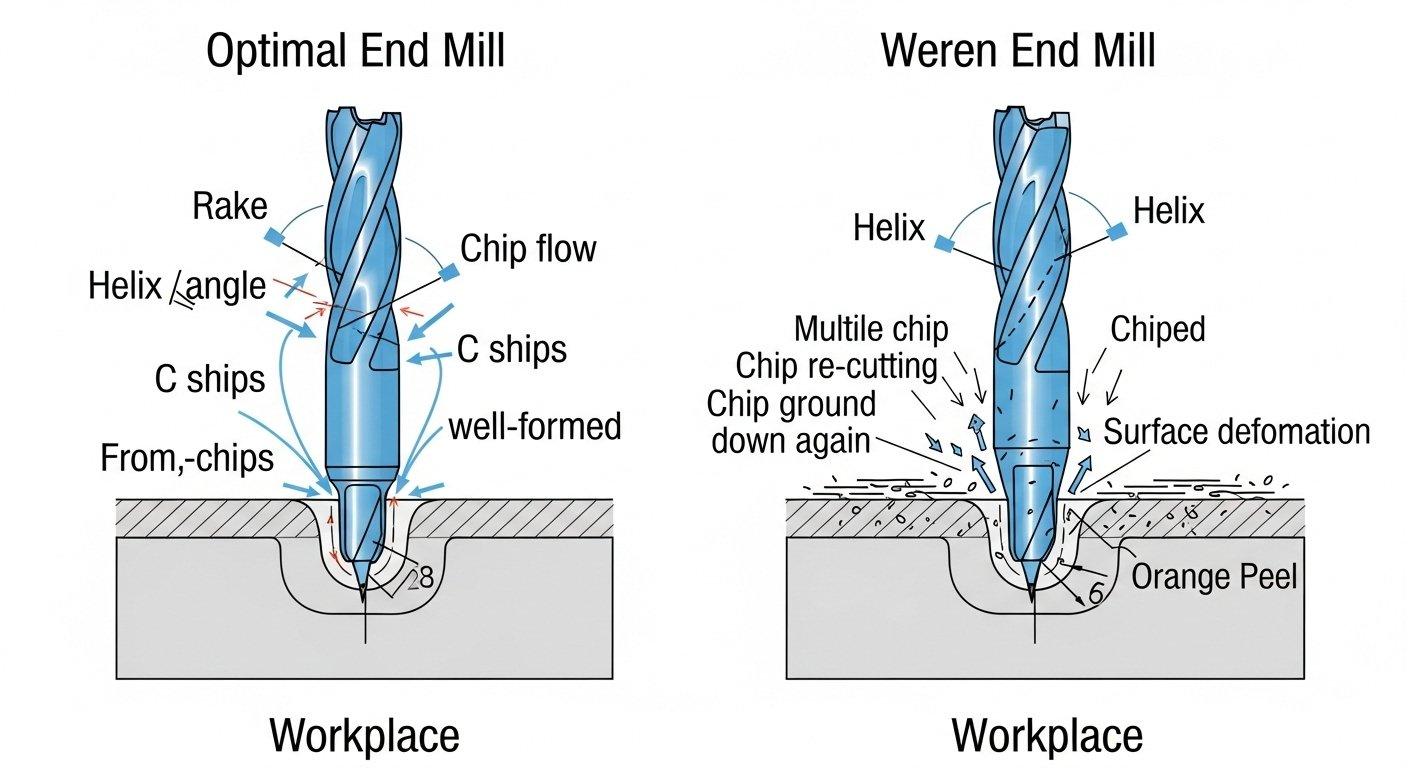

Incorrect tool geometry and wear

The cutting tool is the direct interface with the material, making its geometry and condition paramount. Tools with incorrect rake angles, helix angles, or nose radii can create excessive cutting forces or poor chip evacuation. This leads to material smearing, push-off, or re-cutting of chips, all of which contribute to “orange peel.”

Tool wear, even slight, drastically affects surface finish. A dull or chipped cutting edge requires more force to remove material, increasing friction and heat. This can cause plastic deformation of the aluminum surface rather than clean shearing, resulting in the undesirable texture.

Suboptimal machining parameters

Machining parameters like spindle speed, feed rate, and depth of cut must be meticulously optimized for each material and tool combination. An excessively high feed rate can overwhelm the cutting edge, leading to deeper scallop marks that resemble “orange peel.” Conversely, a very low feed rate might cause excessive friction and heat, leading to material dragging.

An improper depth of cut can also be problematic. If too shallow, it may not effectively engage the cutting edge, causing rubbing rather than cutting. If too deep for a finishing pass, it can induce tool deflection and vibration, impacting surface quality.

Table: Impact of Machining Parameters on Surface Finish

| Parameter | Too Low | Optimal | Too High |

|---|---|---|---|

| **Spindle Speed** | Poor chip evacuation, rubbing | Clean cut, reduced heat | Excessive heat, tool wear |

| **Feed Rate** | Excessive friction, dragging | Consistent chip load, good finish | Coarse scallops, poor surface |

| **Depth of Cut** | Rubbing, inefficient | Stable cut, minimal deflection | Tool deflection, vibration |

Machine rigidity and vibration issues

The stability of the CNC machine itself is fundamental to achieving superior surface finishes. Any instability, such as loose components, worn bearings, or insufficient machine mass, can introduce vibrations during machining. These vibrations cause the tool to oscillate relative to the workpiece, creating an uneven cutting action and leaving behind the characteristic “orange peel” pattern.

Even the fixturing and workpiece clamping can contribute to vibration. If the part is not securely held, it can chatter under cutting forces, directly translating into surface defects. ly-machining’s state-of-the-art 5-axis machines are designed with high rigidity to minimize these issues.

Thermal effects during cutting

Heat generated during machining significantly influences aluminum’s behavior. Aluminum’s high thermal expansion coefficient means localized heating can cause the material to expand and contract unevenly. This thermal cycling, especially without adequate cooling, can lead to residual stresses and surface irregularities.

Insufficient coolant application or an ineffective coolant type can exacerbate these thermal effects. Poor chip evacuation, allowing chips to linger in the cutting zone, also increases heat accumulation, contributing to both tool wear and surface degradation.

Preventing “Orange Peel” in Aluminum Machining

Preventing “orange peel” requires a holistic approach, considering every aspect of the machining process. At ly-machining, our DFM (Design for Manufacturability) reports and rigorous process controls are designed to eliminate these defects from the outset.

Selecting the right aluminum alloy

Choosing an aluminum alloy with a fine, uniform grain structure and good machinability is crucial for achieving high-quality surface finishes. For critical applications, we often recommend alloys like 6061-T6 or 7075-T6, which offer excellent balance of strength and machinability when processed correctly. Our technical team can advise on the best material for specific surface finish requirements.

Optimizing cutting tool design

Precision tool selection is paramount. We utilize high-quality, sharp carbide tools with specific geometries optimized for aluminum, including high rake angles for clean shearing and polished flutes for efficient chip evacuation. Tools with a larger nose radius are often employed for finishing passes to reduce scallop height and improve surface roughness.

Regular inspection and replacement of worn tools are standard practice at ly-machining to maintain consistent cutting performance and surface integrity. Our advanced equipment supports a wide range of specialized tooling.

Precision adjustment of feed and speed

Achieving an optimal balance between spindle speed, feed rate, and depth of cut is critical. For finishing passes on aluminum, higher spindle speeds combined with moderate feed rates and shallow depths of cut are generally preferred. This generates smaller, more manageable chips and minimizes cutting forces, promoting a smoother surface.

Our engineers develop precise machining strategies for each part, often utilizing multi-pass approaches where roughing removes the bulk material and subsequent finishing passes focus solely on achieving the desired surface quality with minimal material removal.

Ensuring machine stability and damping

A stable machining environment is non-negotiable. Our large fleet of over 80 CNC machines, including advanced 5-axis centers, are regularly maintained to ensure optimal rigidity and vibration damping. We also employ robust fixturing solutions to securely hold workpieces, preventing chatter and movement during high-precision operations.

The inherent stability of our heavy-duty machines and our expertise in advanced fixturing techniques significantly reduce the risk of vibration-induced “orange peel.”

Effective coolant and chip management

Proper coolant application is essential for controlling temperature, lubricating the cut, and efficiently evacuating chips. We use high-performance coolants and precise delivery systems to ensure the cutting zone remains cool and clear. This prevents chip re-cutting and minimizes thermal expansion effects on the workpiece.

Effective chip management, including appropriate chip breakers and evacuation strategies, ensures that chips are quickly removed from the cutting zone, preventing heat buildup and potential damage to the finished surface.

Advanced Strategies for Superior Surface Finish

Beyond foundational techniques, ly-machining employs advanced strategies to guarantee a superior surface finish on all aluminum CNC parts, meeting the most demanding specifications.

High-speed machining techniques

High-speed machining (HSM) is particularly effective for aluminum. By utilizing high spindle speeds and light depths of cut with optimized feed rates, HSM can reduce cutting forces, minimize heat generation, and improve surface integrity. This approach results in exceptionally smooth surfaces with minimal “orange peel” defects.

Our advanced CNC centers are equipped for HSM, allowing us to deliver rapid prototyping and high-volume production with consistently superior finishes.

Specialized surface finishing tools

For ultra-smooth finishes, we integrate specialized tools such as diamond-tipped cutters or ceramic tools designed for fine finishing passes. These tools have exceptional hardness and edge retention, allowing for incredibly precise material removal and mirror-like surface qualities on aluminum.

We also utilize burnishing tools or roller-finishing techniques where appropriate, which can mechanically smooth the surface without additional material removal.

Post-machining treatments for perfection

While our primary goal is to achieve the desired surface finish directly from the machine, some applications benefit from post-machining treatments. These can include vibratory finishing, polishing, or anodizing. Anodizing not only adds corrosion resistance and color but can also help mask minor surface imperfections, providing a uniform, high-quality appearance.

Our one-stop service encompasses these finishing capabilities, ensuring a complete solution from raw material to final product.

Rigorous quality control protocols

Quality is non-negotiable at ly-machining. Our full-chain quality control system, certified under ISO9001 and IATF1649, involves meticulous inspection at every stage. For surface finish, we employ advanced metrology tools, including surface roughness testers (profilometers) and optical comparators, to quantitatively assess and verify the surface texture against precise specifications.

Each part undergoes a comprehensive inspection to ensure it meets both dimensional accuracy and surface finish requirements, guaranteeing that no “orange peel” defects escape our facility.

Partnering for Flawless Aluminum Parts

Choosing the right manufacturing partner is paramount for achieving consistent, high-quality aluminum CNC parts free from frustrating defects like “orange peel.” As a source manufacturer based in Shenzhen, China, ly-machining offers unparalleled expertise and reliability.

Our deep technical expertise in aluminum

With years of experience and a team of highly skilled engineers, ly-machining possesses profound technical knowledge in aluminum machining. We provide DFM reports, offering invaluable insights from the design phase to optimize part manufacturability and ensure superior surface finishes. Our expertise extends to complex structures and specialized material handling.

We are adept at identifying potential “orange peel” risks early and implementing preventative measures tailored to your specific alloy, design, and application.

Source manufacturer quality assurance

As a direct source manufacturer, not a trading company, we control every aspect of production. This full control, combined with our ISO9001 and IATF1649 certifications, guarantees consistent, high-quality output. Our stringent quality management system ensures that every aluminum part we produce meets the most exacting standards, free from defects such as “orange peel.”

You benefit from direct communication with our manufacturing experts, ensuring transparent processes and reliable results from our Shenzhen facility.

Transparent pricing for premium results

We believe in providing exceptional value through superior quality and efficiency, backed by transparent, factory-direct pricing. Our commitment is to deliver high-performance, defect-free aluminum parts that reduce your overall project costs by eliminating rework and ensuring faster time-to-market.

Our value proposition focuses on long-term partnerships built on trust and consistent delivery of premium machined components.

Collaborative design for manufacturability

Our one-stop service extends from initial design evaluation to final delivery. We encourage collaborative design for manufacturability (DFM) to refine your part designs, optimize material selection, and develop the most efficient and effective machining strategies. This proactive approach prevents issues like “orange peel” before they even arise.

Whether you need rapid prototyping with our 24-hour service or high-volume production with no minimum order quantity, our team is ready to transform your vision into flawless physical products.

Article Summary:

“Orange peel” texture on CNC aluminum parts is a common defect caused by material properties, tool issues, machining parameters, machine rigidity, and thermal effects. Preventing it requires a comprehensive approach, including careful alloy selection, optimized tooling, precise parameter control, stable machine environments, and effective coolant management.

ly-machining offers advanced strategies, deep technical expertise, and rigorous quality control as a source manufacturer to ensure consistently superior, defect-free aluminum surface finishes for demanding industries.

FAQ Section:

Q1: What are the most critical factors for preventing “orange peel” on aluminum CNC parts?

A1: The most critical factors are a combination of material selection, tool geometry, and optimized machining parameters. Choosing an aluminum alloy with a fine, uniform grain structure, using sharp tools with appropriate rake and helix angles for aluminum, and precisely balancing spindle speed, feed rate, and depth of cut for finishing passes are paramount. Ensuring machine rigidity and effective chip management are also vital.

Q2: How does ly-machining ensure consistently high-quality surface finishes on aluminum, especially for complex parts?

A2: At ly-machining, we employ a multi-faceted approach. This includes providing DFM reports to optimize designs, utilizing a large fleet of high-precision 5-axis CNC machines for stability, and employing specialized tooling and high-speed machining techniques.

Our full-chain quality control, ISO9001 and IATF1649 certifications, and advanced metrology tools guarantee that even complex aluminum parts meet stringent surface finish requirements.

Q3: Can “orange peel” be completely eliminated, or is some level of surface texture inevitable in CNC aluminum machining?

A3: With the right expertise, equipment, and process control, “orange peel” can be virtually eliminated in CNC aluminum machining, especially for critical applications. While no surface is perfectly smooth at a microscopic level, achieving a surface finish where “orange peel” is not visually apparent and meets specified roughness values (e.g., Ra, Rz) is entirely achievable.

Our goal at ly-machining is to provide finishes that meet or exceed your exact aesthetic and functional requirements.

Ready to achieve consistently superior surface finishes for your aluminum CNC parts, free from ‘orange peel’ defects? Leverage our deep technical expertise and advanced manufacturing capabilities.

Contact our engineering team today for a free consultation, or request a precise quote tailored to your project’s unique requirements. Let’s transform your designs into flawless, high-quality components.