Mastering CNC Tolerance & Geometric Accuracy

In the unforgiving world of high-performance product development, the difference between groundbreaking innovation and costly failure often hinges on one critical factor: the absolute mastery of tolerance and geometric accuracy in CNC machined parts. Are your current suppliers truly delivering the precision your designs demand? This often leads to costly reworks, extended lead times, and product performance issues.

At ly-machining, we specialize in overcoming these challenges, ensuring every component we produce meets the most stringent specifications. Our deep technical expertise in CNC machining tolerances and geometric accuracy control guarantees your complex designs translate into high-performing parts, delivered with predictable precision and cost efficiency.

Decoding Tolerance & Geometric Accuracy Concepts

Achieving functional excellence in manufactured parts begins with a clear understanding and rigorous control of their dimensional and geometric characteristics. Precision part manufacturing requires more than just holding a size; it demands control over form, orientation, and location.

This foundational knowledge underpins our approach to every project, ensuring that your parts perform exactly as intended. We bridge the gap between design intent and physical reality through meticulous process control.

Understanding Dimensional Tolerances in Machining

Dimensional tolerances define the permissible variations in the size of a part feature. These are critical for ensuring components fit together correctly and function as a cohesive assembly.

Tight dimensional tolerances minimize clearance or interference, directly impacting assembly performance and product lifespan. Excessive variation leads to assembly failures, increased friction, or compromised structural integrity.

Here is a brief overview of common dimensional tolerance types:

| Tolerance Type | Description | Impact on Part |

|---|---|---|

| Limit Dimensions | Direct specification of upper and lower size limits. | Simple to apply, common for basic features. |

| Plus/Minus (Bilateral) | A nominal size with equal deviation above and below. | Easy to interpret, widely used in general machining. |

| Unilateral Tolerance | Deviation permitted in only one direction from the nominal size. | Useful for clearance/interference fits or specific datum features. |

| Basic Size | The theoretical exact size from which deviations are specified. | Foundation for defining tolerance zones, especially with GD&T. |

Fundamentals of Geometric Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T) is a standardized language used to specify engineering tolerances in a precise and unambiguous way. It controls the form, orientation, location, and runout of features, going beyond simple dimensional size.

GD&T is essential for defining the true functional requirements of a part, ensuring interchangeability and proper assembly. It allows for optimized manufacturing processes by providing maximum permissible variation while still guaranteeing part function.

We leverage GD&T to clearly communicate design intent and ensure our CNC machining processes meet these critical specifications.

Why Geometric Accuracy is Crucial for Performance

Geometric accuracy is paramount for the reliable function and longevity of any mechanical assembly. It directly impacts mating, alignment, and load distribution.

Consider components in a high-speed rotating assembly or parts requiring fluid sealing. Imprecise flatness, perpendicularity, or concentricity can lead to premature wear, leakage, vibration, and catastrophic failure.

Mastering geometric accuracy in CNC machining is not just about aesthetics; it is about ensuring the structural integrity and operational reliability of your product. This is especially true for precision part manufacturing where performance margins are narrow.

Key Factors Influencing CNC Machining Precision Control

Achieving high-quality CNC parts with tight tolerances is a multi-faceted challenge. It requires a holistic approach that considers every element of the manufacturing process, from machine selection to material properties.

At ly-machining, our comprehensive understanding of these factors allows us to precisely control the outcome of every machining operation. This proactive management minimizes errors and ensures consistent results.

Machine Tool Capability & Environmental Stability

The foundation of precision CNC machining lies in the machine tool itself. High-rigidity machines with advanced control systems and precise linear scales are indispensable.

Environmental factors like temperature fluctuations, vibration, and humidity can significantly affect machine accuracy and part stability. We maintain a controlled environment to mitigate these external influences.

Regular maintenance and calibration of our CNC machines are critical to sustain their inherent precision over time.

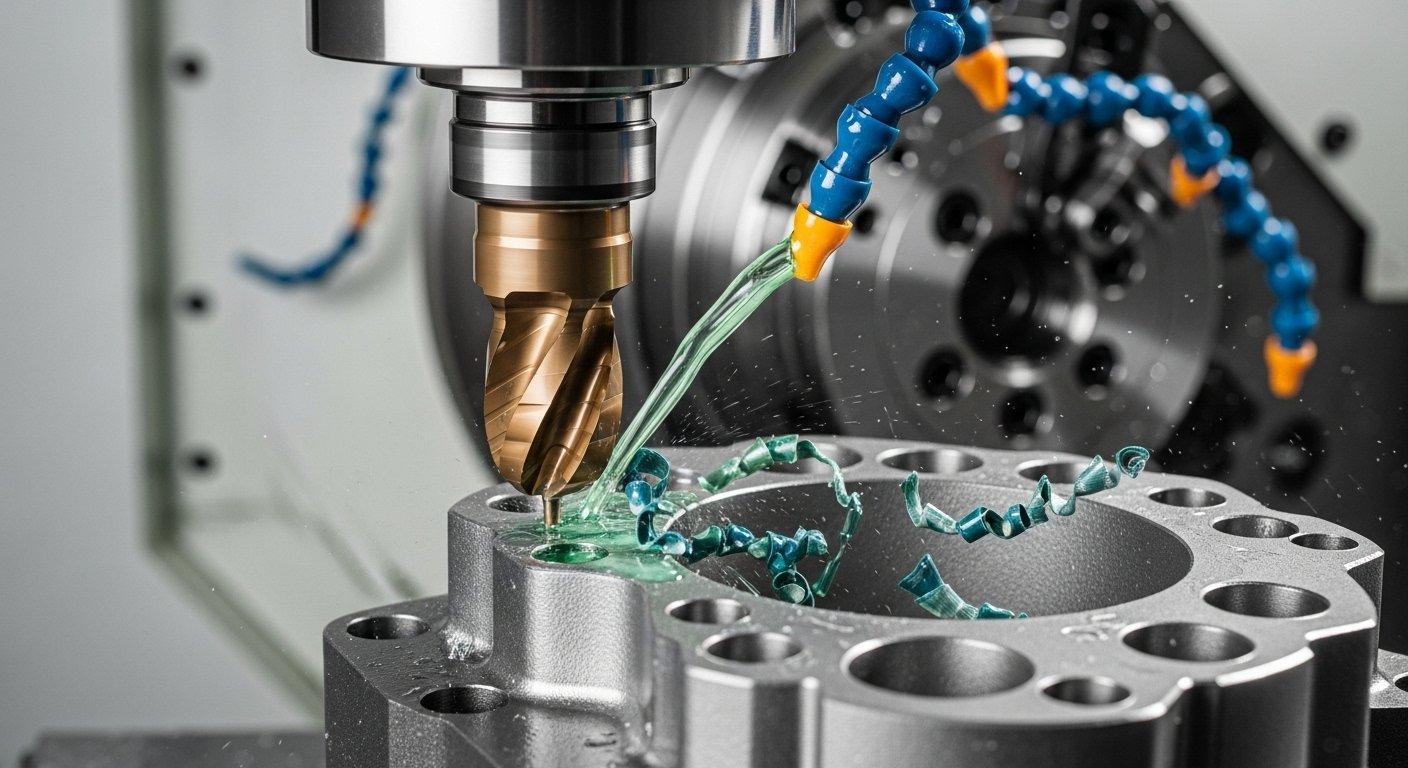

Tooling Selection, Wear, and Path Optimization

The choice of cutting tool profoundly influences surface finish, material removal rates, and ultimately, part accuracy. Optimal tool materials, coatings, and geometries are selected for each specific material and feature.

Tool wear is an unavoidable aspect of machining. We employ strategies such as real-time tool wear compensation and scheduled tool changes to maintain consistent cutting performance and prevent out-of-tolerance conditions.

Tool path optimization, including climb vs. conventional milling, appropriate feed rates, and depth of cut, minimizes cutting forces and deflection, contributing to superior geometric accuracy control.

Material Properties and Residual Stress Management

Different materials react uniquely to machining forces and temperature changes. Understanding their machinability, thermal expansion coefficients, and inherent stress characteristics is vital.

Internal residual stresses, introduced during material processing or machining, can lead to part distortion once material is removed. This is a common challenge in precision part manufacturing.

We employ strategies such as multi-stage machining, annealing, or specific stress-relieving heat treatments to minimize and manage these stresses, ensuring the final part maintains its designed shape and tight tolerances.

Fixturing Design & Part Clamping Strategies

Effective fixturing is fundamental to securing the workpiece rigidly and preventing movement or distortion during machining. Poor fixturing is a frequent cause of geometric inaccuracies.

The design of the fixture must consider accessibility for tooling, chip evacuation, and the distribution of clamping forces. Uneven clamping can induce stresses and lead to distortion.

Our engineers design bespoke fixtures that precisely locate and support the part, ensuring repeatable setup and minimal workpiece deformation throughout the machining process.

Advanced Strategies for CNC Part Accuracy Control

Achieving extreme precision goes beyond standard practices. It involves integrating advanced methodologies throughout the entire production lifecycle.

Our factory implements these sophisticated strategies to tackle the most demanding precision requirements, ensuring that every high-quality CNC part meets its exact specifications. This proactive approach minimizes risks for our clients.

Design for Manufacturability (DFM) for Precision Parts

Early engagement in Design for Manufacturability (DFM) is crucial for precision parts. Our engineers collaborate with clients to review designs, identifying potential manufacturability issues related to tolerance stack-up, material choice, and machining access.

This proactive feedback loop helps optimize designs for consistent geometric accuracy and cost-effective production. It prevents costly re-design iterations down the line.

Through DFM, we ensure that the design intent is not compromised by manufacturing limitations.

In-Process Monitoring & Real-time Compensation Techniques

Advanced CNC machines are equipped with in-process measurement probes and sensors that monitor key dimensions during machining. This allows for real-time feedback and adjustment.

Temperature compensation systems actively track thermal expansion of the machine components and workpiece, applying automatic offsets to maintain accuracy. This is critical for long machining cycles.

These real-time adjustments significantly reduce the risk of producing out-of-spec parts, ensuring consistent geometric accuracy control across batches.

Post-Machining Stress Relief for Shape Stability

For parts with very tight flatness or straightness tolerances, or those prone to distortion after material removal, post-machining stress relief is often necessary.

Techniques such as vibration stress relief or thermal annealing can stabilize the material, preventing creep or long-term distortion. This is particularly important for aerospace and optical components.

This extra step ensures the final part dimensions remain stable over its service life, safeguarding its performance.

Error Budgeting and Tolerance Stack-up Analysis

Error budgeting meticulously accounts for all potential sources of error within the machining process, from machine repeatability to tool deflection. This helps predict and manage overall part accuracy.

Tolerance stack-up analysis rigorously evaluates how individual component tolerances accumulate within an assembly. This is vital for ensuring overall fit and function.

By performing these analyses early, we can identify critical dimensions and features that require tighter control, optimizing the process for reliable geometric accuracy.

Quality Assurance & Measurement in Precision CNC Machining

Rigorous quality assurance is the cornerstone of delivering high-quality CNC parts with guaranteed precision. Our comprehensive QC system is designed to verify and certify the accuracy of every component.

This commitment to verification provides our clients with complete confidence in our products and processes. Transparency in our quality control procedures builds trust.

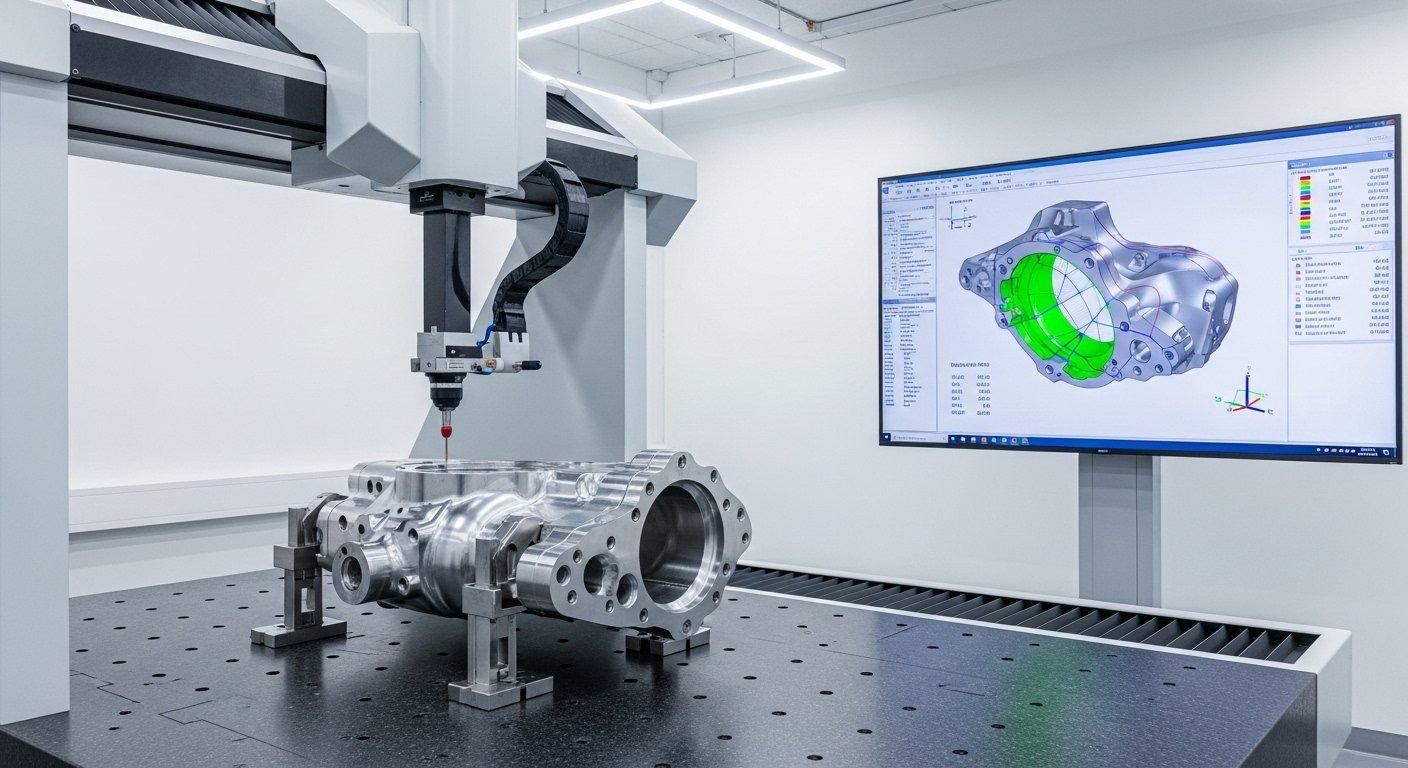

State-of-the-Art Inspection Technologies (CMM, Vision Systems)

We utilize advanced inspection technologies to precisely measure and verify part dimensions and geometric accuracy. Coordinate Measuring Machines (CMMs) provide highly accurate 3D measurements of complex features.

Optical comparators and vision systems offer rapid, non-contact inspection for precise measurement of profiles and critical features. These systems ensure comprehensive evaluation.

These state-of-the-art tools are crucial for validating that every part adheres to the specified CNC machining tolerances and GD&T requirements.

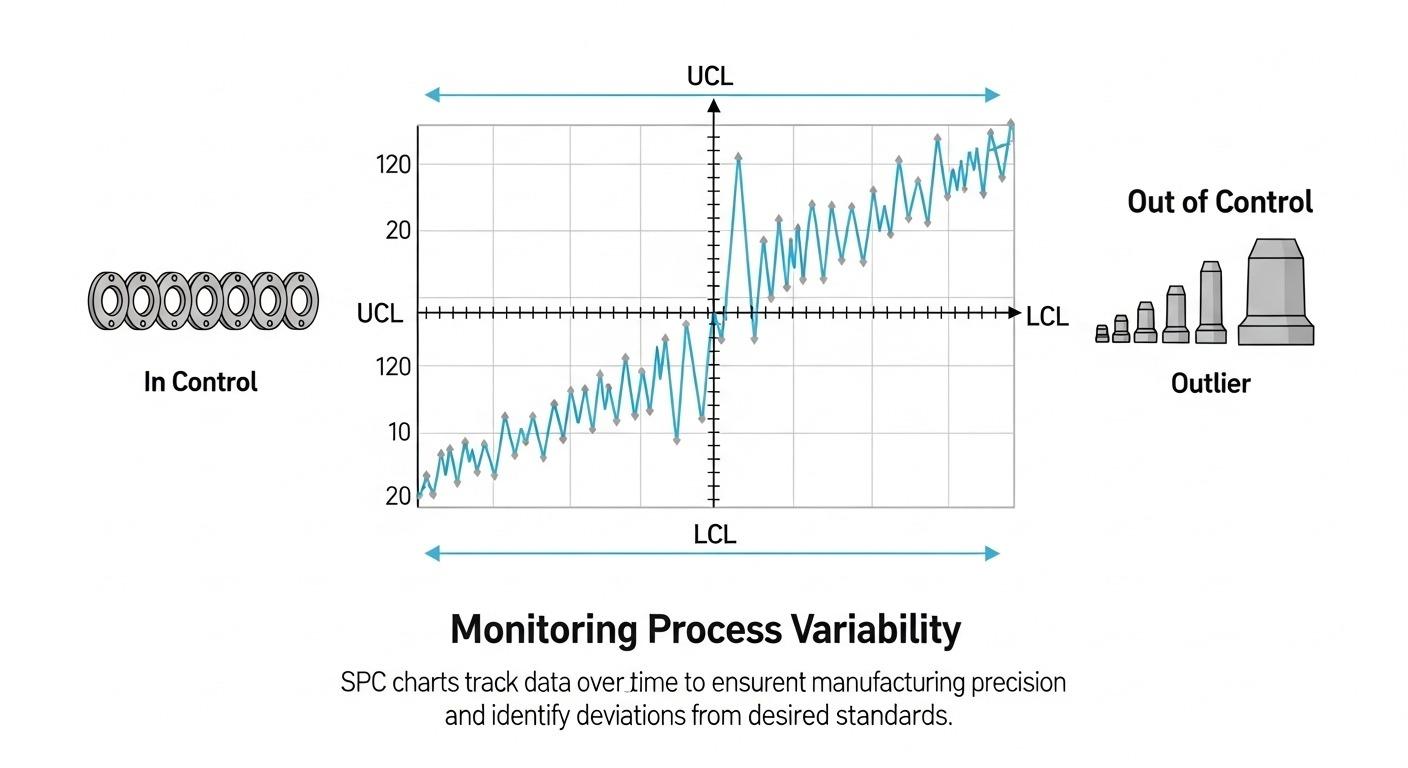

Statistical Process Control (SPC) for Consistency

Statistical Process Control (SPC) is integral to maintaining consistent precision in high-volume production. By continuously monitoring key process parameters and part characteristics, we can detect and correct deviations before they lead to defects.

SPC charts provide visual feedback on process stability and capability, allowing for proactive adjustments. This ensures predictable quality and reduces variability batch-to-batch.

This systematic approach is essential for achieving reliable geometric accuracy and minimizing scrap rates.

Calibration & Traceability of Measurement Equipment

All our measurement equipment, from calipers to CMMs, undergoes regular, scheduled calibration by accredited third-party services. This ensures the accuracy and reliability of our inspection results.

Calibration records are meticulously maintained, providing a traceable chain back to national and international standards. This traceability is critical for compliance and trust.

Our robust calibration program guarantees that every measurement we take is accurate and dependable.

Documenting and Certifying Part Accuracy

Comprehensive documentation is a standard practice for all precision CNC machining projects. This includes material certifications, inspection reports, and conformity certificates.

First Article Inspection (FAI) reports provide detailed verification of the initial production part against all specifications. This ensures the manufacturing process is correctly established.

These certifications provide objective evidence of part quality and compliance, offering peace of mind to our clients.

Partnering for Uncompromised CNC Machining Precision

Choosing the right manufacturing partner is paramount when geometric accuracy and tight tolerances are critical to your product’s success. Your partner should be an extension of your engineering team.

ly-machining is committed to being that reliable, expert partner, delivering the precision and quality your projects demand. We are a source manufacturer, providing direct value.

The Advantage of a Deep Technical Expertise Manufacturer

As a source manufacturer with deep technical expertise, we offer unparalleled control over the entire CNC machining process. Our in-house engineering team possesses extensive knowledge of materials science, machining physics, and GD&T.

This expertise allows us to proactively identify and mitigate risks, optimize manufacturing strategies, and consistently achieve even the most challenging tolerance requirements. We speak your technical language.

We don’t just follow blueprints; we contribute to their successful execution.

Transparent Processes for Reliable Tolerance Control

We believe in transparency throughout the manufacturing journey. Our clients receive clear communication regarding process capabilities, potential challenges, and quality control methodologies.

This open approach fosters stronger partnerships and ensures alignment on critical precision requirements. You understand exactly how we achieve your required geometric accuracy.

Transparent pricing also means no hidden costs, allowing for better budget management.

Case Studies: Achieving Complex Geometric Accuracy

We have a proven track record of successfully delivering complex parts with stringent geometric accuracy for diverse industries, including aerospace, medical, and robotics. Each project presents unique challenges, which our team systematically addresses.

For instance, a recent project involved a critical optical mount requiring flatness within 5 microns and positional accuracy of ±0.005mm. Through careful material selection, multi-axis machining, and post-machining stress relief, we met these demands flawlessly.

These successes demonstrate our capability in precision part manufacturing.

Your Next Step Towards High-Quality Precision Parts

Don’t compromise on precision. Partner with a source manufacturer that guarantees geometric accuracy and transparent pricing.

Contact our engineering team today to discuss your critical CNC machining project and discover how our expertise can bring your designs to life, flawlessly.

Article Summary

This article has thoroughly explored the critical aspects of mastering tolerance and geometric accuracy in CNC machining. We delved into understanding dimensional and geometric tolerances, highlighting their importance for part performance.

Key influencing factors such as machine capability, tooling, material properties, and fixturing were discussed, alongside advanced control strategies like DFM, in-process monitoring, and stress relief.

Finally, we outlined our robust quality assurance processes, including state-of-the-art inspection and SPC, underscoring ly-machining’s expertise as a trusted partner for high-quality, precision parts.

Frequently Asked Questions

What are the most common challenges in achieving tight tolerances in CNC machining?

The most common challenges include managing material properties and residual stresses, compensating for machine tool deflection and thermal expansion, and ensuring proper fixturing. Additionally, tool wear and accurately interpreting complex GD&T callouts can present significant hurdles.

Overcoming these requires a deep understanding of machining physics and advanced process control.

How does ly-machining ensure consistent geometric accuracy across large production batches?

At ly-machining, we ensure consistency through a multi-pronged approach. This includes utilizing Statistical Process Control (SPC) for real-time monitoring and proactive adjustments, implementing rigorous tool wear management strategies, and maintaining a stable manufacturing environment.

Regular calibration of all equipment and thorough in-process inspection protocols are also fundamental to maintaining consistent geometric accuracy across large batches.

What role does Design for Manufacturability (DFM) play in achieving precision parts?

DFM is crucial for achieving precision parts by integrating manufacturing considerations early in the design phase. Our engineers collaborate with clients to optimize designs for machinability, identify potential tolerance stack-up issues, and suggest material or feature modifications that enhance precision while reducing production costs and lead times.

This proactive approach minimizes design iterations and ensures the final part can be manufactured to the required geometric accuracy.