CNC Machining Cost Optimization: The Material Selection Impact on Part Costs

Quick Solution: Optimizing CNC machining cost profoundly relies on smart material selection, directly impacting raw material price, machinability, tool life, and post-processing needs for enhanced CNC parts optimization.

Introduction:

Did you know the greatest opportunity to cut your CNC machining costs lies not in the machine shop, but in your initial material choice? It is a critical decision that can swing project budgets by 30% or more, long before the first chip is cut.

A common issue we see is overlooking the total lifecycle cost, focusing solely on raw material price. This often leads to unexpected expenses and delays down the line.

Discover how smart material selection, guided by true engineering expertise, transforms your bottom line. We will detail the direct and indirect impacts, providing a roadmap for superior CNC parts optimization.

Why Material Selection Impacts CNC Machining Cost

In our experience, the decision of which material to specify for a CNC machined part is often underestimated in its financial consequences. It extends far beyond the initial purchase price of the raw stock. We find that ignoring this early stage consideration can inflate overall project expenditures significantly.

This section delves into the fundamental reasons why careful material selection is paramount for effective CNC machining cost optimization. It highlights the complex interplay between material characteristics and manufacturing realities.

Raw Material Price vs. Total Cost?

The initial raw material price is an obvious factor, yet it represents only a fraction of the total cost of a finished CNC part. Many procurement managers mistakenly prioritize low raw material costs above all else. This can be a costly error.

A material that appears inexpensive on paper might be difficult to machine, leading to higher labor, tool, and machine time expenses. Conversely, a premium material could offer superior machinability, ultimately lowering overall production costs.

Consider the holistic view: raw material cost plus all subsequent processing costs.

How Material Properties Affect Machinability?

Material properties fundamentally dictate how easily a material can be cut, formed, or finished by CNC machinery. These characteristics directly influence machining speed, tool wear, and achievable surface finish. Different materials react uniquely to cutting forces and heat.

For instance, materials with high hardness or tensile strength often require slower cutting speeds and more robust tooling. This translates directly into longer cycle times and increased tooling expenditure.

Understanding these inherent properties is key to predicting machining difficulty and selecting optimal materials for CNC parts optimization.

Direct Cost Factors of CNC Machining Materials

The direct costs associated with CNC machining are tangible and quantifiable, making them critical targets for optimization through material selection. These factors include everything from the tools used to the power consumed. Our engineers meticulously analyze these elements.

By understanding these direct influences, we can guide clients toward choices that reduce per-part expenditure. This leads to more efficient machining material cost management.

Material Hardness & Tool Life?

Material hardness is a primary determinant of tool life, which directly impacts tooling costs. Harder materials, such as hardened steels or exotic alloys, cause accelerated wear on cutting tools. This necessitates more frequent tool changes and replacements.

Soft materials, like some plastics or aluminum, generally extend tool life significantly. We often see that a slight increase in material cost can be offset by a substantial reduction in tool expenditure and downtime.

Balancing material hardness with application requirements is crucial for CNC machining cost optimization.

| Material Type | Typical Hardness (Rockwell C Scale) | Impact on Tool Life |

|---|---|---|

| Soft Aluminum Alloys | ~20-40 | Excellent |

| Mild Steel (1018) | ~55-65 | Good |

| Stainless Steel (304) | ~80-90 | Moderate |

| Hardened Tool Steel | ~45-60 | Low |

| Titanium Alloys | ~30-40 | Very Low |

Machinability Index & Cycle Time?

The machinability index provides a quantitative measure of a material’s ease of machining compared to a baseline material (usually 1212 free-machining steel, rated at 100%). A higher index indicates easier machining. Materials with a lower machinability index require slower cutting speeds, lighter depths of cut, and more passes.

This directly increases the machine’s cycle time per part. Longer cycle times translate to higher labor costs, increased machine overheads, and reduced throughput. Optimizing for machinability is a direct path to lower CNC machining costs.

| Material | Machinability Index (%) | Typical Cycle Time Impact |

|---|---|---|

| 1212 Free-Machining Steel | 100 | Baseline |

| 6061 Aluminum | 90 | Shorter |

| 303 Stainless Steel | 78 | Moderate |

| 304 Stainless Steel | 45 | Longer |

| Titanium Grade 5 | 40 | Significantly Longer |

Waste & Material Utilization Rates?

Some materials, particularly high-value alloys or composites, produce significant waste during machining. The geometry of the part and the chosen manufacturing process also influence material utilization. More intricate parts often require more material removal.

Additionally, certain materials may be challenging to recycle or have lower scrap value, further increasing net material costs. Strategic material selection, paired with optimized cutting paths, can significantly improve utilization rates. This directly impacts machining material cost.

Minimizing waste means maximizing the return on your raw material investment.

Post-Processing Needs & Material Choice?

The material chosen often dictates the necessity and complexity of post-processing steps, such as heat treatment, surface finishing, or plating. These processes add substantial cost and lead time to part production. For example, specific alloys require heat treatment for desired mechanical properties.

Certain materials are inherently resistant to corrosion or possess excellent surface finishes directly from machining, reducing the need for expensive secondary operations. Considering post-processing during material selection is vital for overall CNC machining cost optimization.

| Material | Common Post-Processing Needs | Cost Impact |

|---|---|---|

| 6061 Aluminum | Anodizing, Passivation | Low |

| 1018 Steel | Heat Treat, Plating, Black Oxide | Moderate |

| 304 Stainless Steel | Passivation, Electropolishing | Low |

| Titanium Grade 5 | None often, Heat Treat (special cases) | Low/Moderate |

| Delrin (Acetal) | None often | Very Low |

Indirect Cost Impacts in CNC Parts Production

Beyond the direct costs, material selection casts a long shadow over indirect expenditures in CNC parts production. These often-overlooked factors can accumulate into significant financial burdens if not managed proactively. In our role as engineers, we constantly assess these hidden costs.

Understanding these indirect impacts is crucial for truly comprehensive CNC machining cost optimization. It helps avoid unforeseen problems and ensures long-term project success.

Lead Time & Supply Chain Risks?

The availability and lead time of specific materials can significantly impact project schedules and costs. Exotic or specialized alloys may have limited suppliers, leading to extended lead times and higher prices. Geopolitical factors or natural disasters can also disrupt supply chains.

Choosing readily available materials with a stable supply chain can mitigate these risks, ensuring timely delivery and predictable costs. In our experience, diversified sourcing for common materials is also key.

This strategic consideration is essential for maintaining project momentum and controlling overall CNC machining cost.

| Material Type | Supply Chain Risk | Typical Lead Time Impact |

|---|---|---|

| Commodity Aluminum | Low | Short |

| Standard Steels | Low | Short |

| Common Plastics | Low | Short |

| Aerospace-Grade Alloys | Moderate | Medium |

| Rare Earth Metals | High | Long |

Part Performance & Warranty Claims?

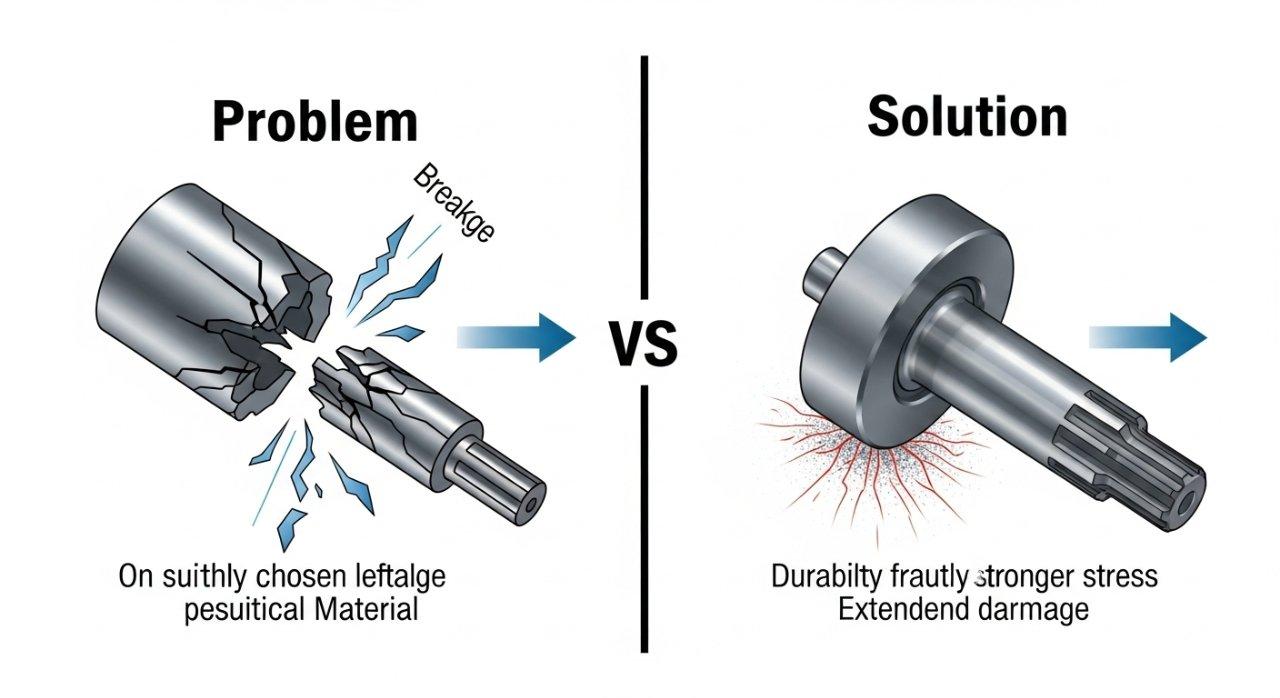

Incorrect material selection can lead to premature part failure, impacting the final product’s performance and reliability. Such failures result in costly warranty claims, product recalls, or reputational damage for our clients. We emphasize selecting materials that meet or exceed application requirements.

Investing in a slightly more robust or appropriate material upfront can prevent exponentially higher costs associated with field failures. This is a critical aspect of long-term CNC parts optimization.

Ensuring optimal part performance through material choice safeguards brand integrity and reduces future liabilities.

Design Flexibility & Material Limits?

Certain materials impose inherent limitations on part design. For example, some materials are difficult to machine into thin walls or complex geometries without introducing stress concentrations or warping. This can restrict design flexibility and necessitate design compromises.

Conversely, highly machinable materials open up possibilities for more intricate and innovative designs. Considering these limitations during the design phase, in conjunction with material selection, can prevent costly redesigns and manufacturing hurdles.

This foresight is a cornerstone of effective CNC parts optimization.

Optimize Your CNC Machining Costs with Smart Selection

At ly-machining, we believe that true CNC machining cost optimization begins at the design and material specification stage. We leverage our deep engineering knowledge and extensive manufacturing experience to guide our clients. Our goal is to ensure every material choice is a strategic investment.

This proactive approach not only reduces immediate machining material cost but also enhances the overall value and performance of the finished component. We partner with you to achieve the best possible outcome.

How Our Expertise Reduces Your Material Costs?

Our team of experienced engineers works closely with clients to analyze application requirements, performance criteria, and budget constraints. We then recommend the most suitable and cost-effective materials. This goes beyond raw material price.

We consider machinability, tool life impact, post-processing needs, and long-term part performance. Our comprehensive approach ensures that you select a material that offers the optimal balance of performance and value, minimizing your overall CNC machining cost.

In our experience, this collaborative engineering review often uncovers significant savings.

Transparent Pricing: Material-to-Part Breakdown?

We pride ourselves on transparent pricing. Our quotes provide a detailed breakdown of costs, illustrating how material choice directly influences each aspect of production. This includes material acquisition, machining time, tooling, and any necessary post-processing.

This clear insight empowers our clients to make informed decisions and understand the true value behind their material selection. You see exactly where your investment goes, enabling better CNC parts optimization.

We offer an honest assessment, ensuring no hidden costs or surprises.

Case Study: Cost Savings Through Material Choice?

**Problem:** A client, a manufacturer of industrial automation equipment, needed a critical sensor housing. Their initial design specified 304 Stainless Steel for its corrosion resistance. However, machining costs were excessively high due to the material’s poor machinability, delaying their product launch.

**Our Solution:** Our engineers reviewed the application and identified that while corrosion resistance was vital, the specific environmental exposure did not require the full extent of 304 Stainless Steel’s properties. We proposed switching to 303 Stainless Steel, which offers similar corrosion resistance in less aggressive environments but has significantly superior machinability due to added sulfur.

**Result:** By guiding the client to 303 Stainless Steel, ly-machining reduced machining time by 35% and extended tool life by 50%. This led to an overall 20% reduction in per-part CNC machining cost, enabling the client to meet their budget and accelerate their product launch without compromising performance. This was a clear win for CNC parts optimization.

Partner for Quality CNC Parts & Cost Efficiency

Choosing the right CNC machining partner is as crucial as selecting the right material. At ly-machining, we combine our technical prowess with a client-centric approach to deliver exceptional value. We are dedicated to delivering not just parts, but solutions.

Our commitment to quality, precision, and cost-efficiency makes us your ideal manufacturing ally. We are more than a supplier; we are an extension of your engineering team, dedicated to your project’s success and CNC parts optimization.

Your Go-To Source for Premium Materials?

As a trusted source manufacturer, we have established robust relationships with reputable material suppliers worldwide. This ensures consistent access to a wide range of premium-grade materials, from standard alloys to specialized composites. We guarantee material authenticity and quality.

Our stringent incoming material inspection processes conform to industry standards, safeguarding against defects and ensuring traceability. You can trust that the materials we use meet the highest specifications for your CNC parts.

This meticulous sourcing further enhances our ability to provide superior machining material cost value.

Ensuring Performance & Value in Every Part?

Our engineering-led approach means that every part we produce is optimized for both performance and value. We leverage advanced CAM software and our extensive machining expertise to maximize efficiency and minimize waste. Our stringent quality control processes ensure compliance with critical specifications.

From initial material selection through final inspection, we maintain an unwavering focus on precision and reliability. We ensure that your CNC parts not only meet but exceed expectations, embodying the best in CNC parts optimization.

Your project’s success is our highest priority, reflecting our commitment to superior CNC machining cost solutions.

Ready to Optimize Your Project? Contact Us Today

Ready to optimize your CNC parts’ cost and performance through expert material selection? Contact our technical team today for a free consultation and a transparent, detailed quote tailored to your project. Leverage our source manufacturing advantage for superior quality and value.

FAQ Section:

How does material choice affect lead time?

The availability and sourcing complexity of a material directly impact lead times. Exotic materials may have longer procurement periods, whereas common alloys are readily available, affecting project schedules. Our supply chain expertise helps mitigate these risks for CNC parts.

Can material selection reduce post-processing?

Yes, absolutely. Materials with inherent properties like corrosion resistance or a naturally smooth finish can reduce or even eliminate the need for costly secondary operations. This directly contributes to lower overall CNC machining cost.

What is machinability index?

The machinability index is a numerical rating indicating how easily a material can be machined. It compares a material’s cutting speed, tool wear, and surface finish to a baseline steel. A higher index suggests easier and more cost-effective machining.