CNC Machining Ranking: Strategies to Become a Top Manufacturer & Best Supplier

Are you tired of supply chain headaches, inconsistent part quality, and delayed project launches? Our advanced precision machining services are engineered to eliminate these frustrations, ensuring your critical components are delivered flawlessly and on schedule, every time. Partner with a truly top CNC machining company and accelerate your innovation with complete confidence.

The Problem You Solve

In our experience, sourcing high-precision CNC parts often comes with hidden risks that undermine your project’s success. We understand the challenges you face:

– **Unreliable Suppliers:** Missing critical deadlines and causing costly production halts.

– **Inconsistent Quality:** Receiving substandard parts that require extensive rework or lead to product failures.

– **Lack of Transparency:** Opaque pricing structures and communication breakdowns creating uncertainty.

– **Limited Technical Capability:** Suppliers unable to handle complex geometries, tight tolerances, or specialized materials for your most demanding applications.

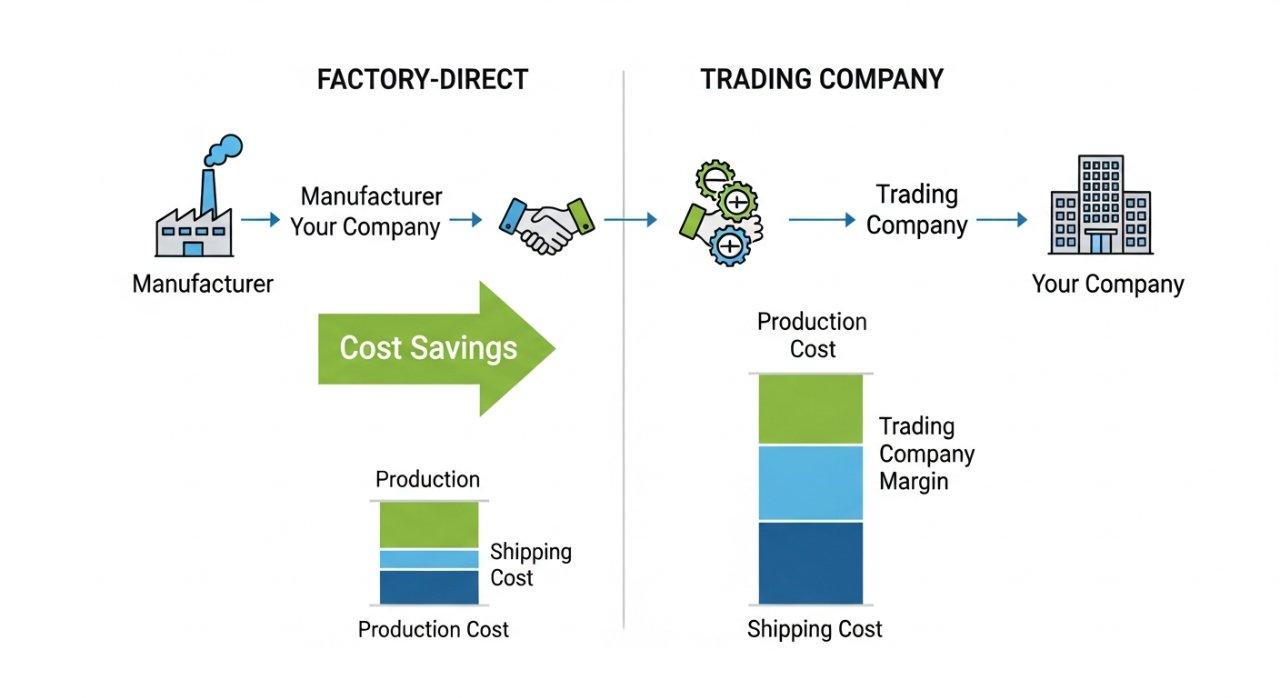

– **Excessive Costs:** Dealing with middlemen and trading companies inflates prices without adding value.

The Solution We Provide

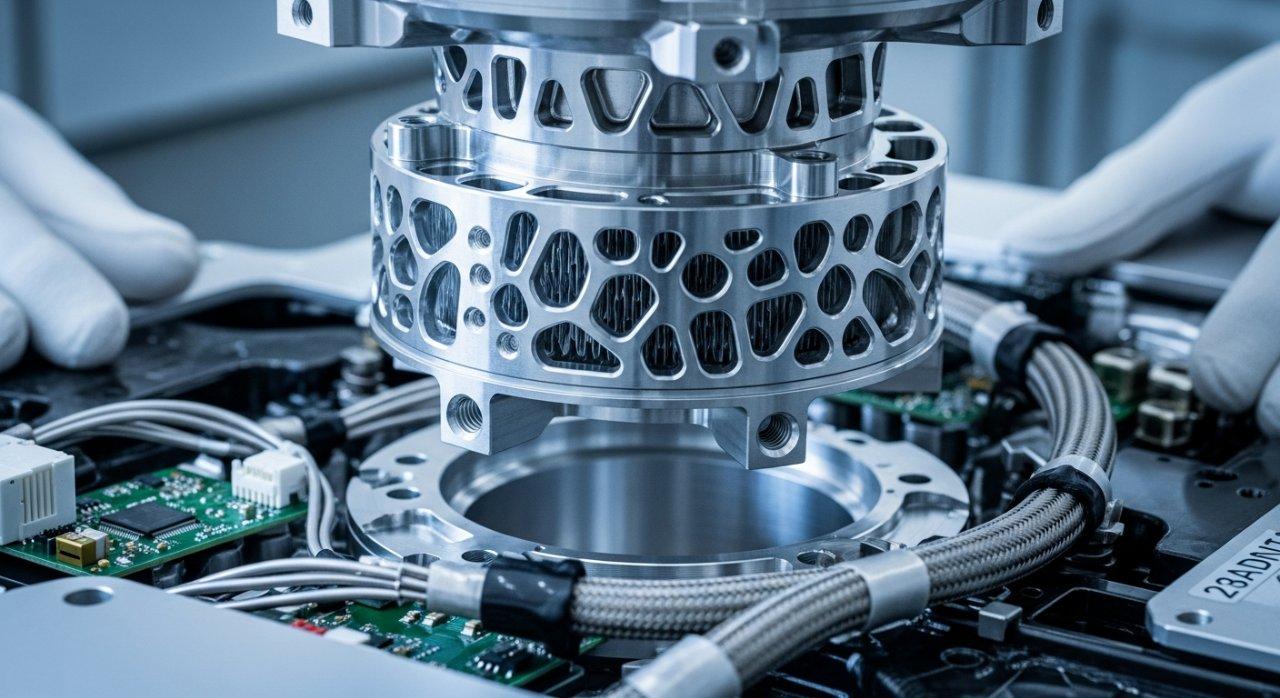

At ly-machining, we are a source manufacturer, not a trading company. We deliver unparalleled quality and efficiency in custom CNC machining. We solve your most pressing manufacturing challenges by providing world-class precision parts, direct from our advanced Shenzhen facility.

As a leading precision machining firm, we combine deep technical expertise with a commitment to transparent partnerships. This ensures you receive superior components that meet your exact specifications, every time. We are dedicated to helping our clients become the best manufacturing suppliers in their respective industries.

How It Works (Simple 3-Step Process)

Getting started with a top CNC machining manufacturer should be effortless. We’ve streamlined our process to ensure speed, clarity, and precision from your initial concept to final delivery.

Step 1: Submit Your CAD File

Easily upload your design files and requirements through our secure portal. Our engineering team is ready to review your project specifications.

Step 2: Get a DFM Report & Quote in 24 Hours

Our experts provide a detailed Design for Manufacturability (DFM) report, identifying potential optimizations. You receive a transparent, competitive quote within one business day.

Step 3: Receive Your Perfect Parts

Once approved, we leverage our advanced CNC manufacturing capabilities for rapid prototyping and production. Your high-quality, precision parts are then delivered to your doorstep.

Core Features & Benefits

Our commitment to being one of the top CNC machining companies is built on a foundation of advanced capabilities and client-focused benefits.

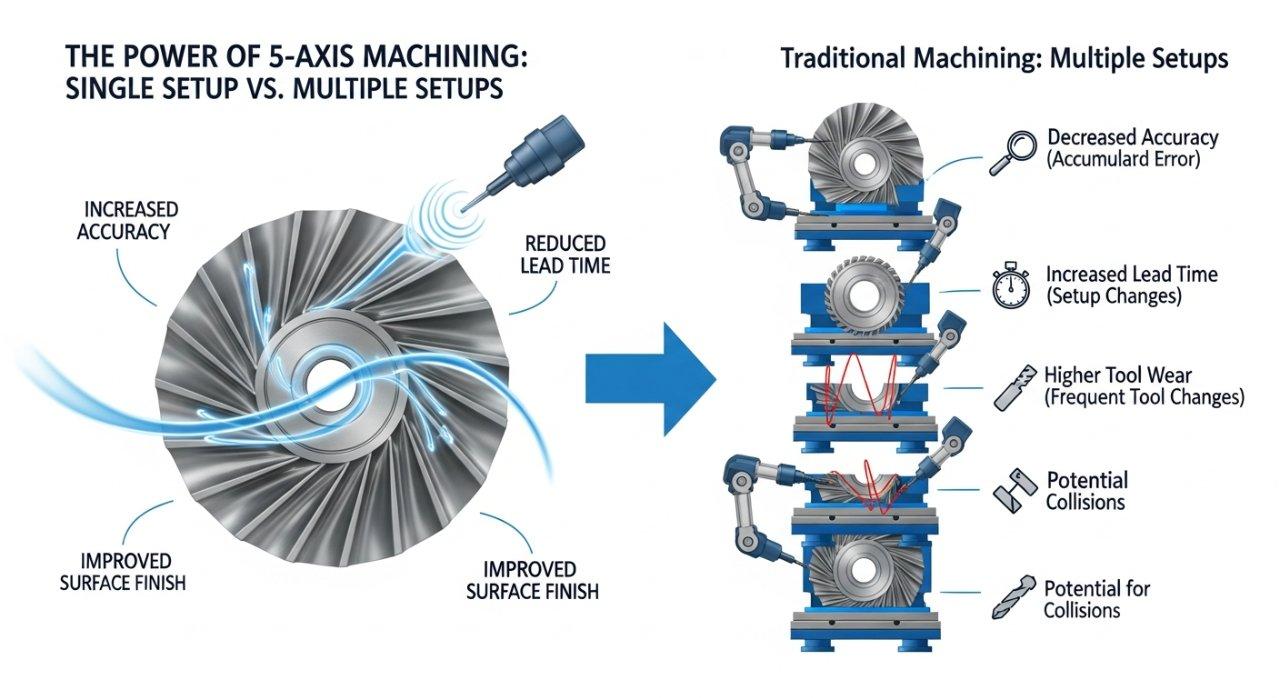

Advanced 5-Axis Machining

Our extensive fleet includes state-of-the-art 5-axis CNC machines. This means we can create highly complex geometries and intricate features in a single setup, drastically reducing cost and improving accuracy for your most demanding parts. This capability is crucial for leading precision machining firms.

Typical Tolerances for Our Precision Machining Services

| Feature | Standard Tolerance | High Precision Tolerance |

|---|---|---|

| Linear Dimensions | +/- 0.05 mm | +/- 0.01 mm |

| Hole Diameter | H7 | H6 |

| Concentricity | 0.02 mm | 0.005 mm |

| Surface Roughness | Ra 1.6 | Ra 0.8 |

ISO9001 & IATF1649 Certified Quality

Our rigorous, full-chain quality control systems are ISO9001 and IATF1649 certified. This gives you complete peace of mind, knowing every part is meticulously inspected and meets the highest industry standards. It eliminates costly rework and ensures consistent reliability, a hallmark of all top CNC machining companies.

Key Quality Assurance Protocols

| Protocol | Description | Benefit to You |

|---|---|---|

| Incoming Material Check | Verification of raw material certifications. | Guarantees material integrity from the start. |

| In-Process Inspection | Real-time checks during machining. | Minimizes defects and ensures process consistency. |

| Final Quality Control (FQC) | Comprehensive inspection of finished parts. | Ensures every part meets specified tolerances. |

| Traceability | Batch and material traceability system. | Full accountability and rapid issue resolution. |

Factory-Direct Pricing & No MOQ

As a source manufacturer, we cut out the middleman, offering you transparent, factory-direct pricing. This allows you to get the best possible price without sacrificing the superior quality expected from a top CNC manufacturer. We also offer rapid prototyping with no minimum order quantity (MOQ), providing maximum flexibility for your projects.

Proof & Trust Builders

Our reputation as a leading precision machining firm is built on consistent delivery and unwavering quality. We are among the top CNC machining companies globally because we earn the trust of our clients every single day.

Trusted by Engineers at Leading Global Innovators

“The quality from ly-machining was outstanding. They delivered on time and on budget, which was critical for our project. Their technical team provided invaluable DFM feedback.” – John Doe, Lead Engineer, Top Aerospace Firm

The Final, Unbeatable Call to Action

Stop settling for subpar parts and unreliable suppliers. It’s time to partner with a top CNC machining manufacturer that prioritizes your success. Experience the difference that deep technical expertise, uncompromising quality, and transparent service make.

Ready to elevate your project with precision CNC manufacturing? Get a free, no-obligation quote for your next high-quality project today and discover why we are recognized among the best CNC manufacturing suppliers in the industry.